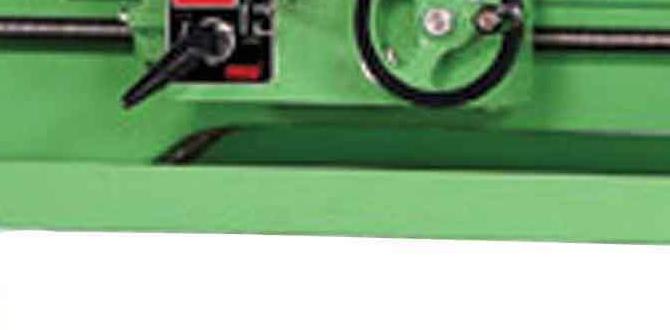

Have you ever stood puzzled in front of your lathe, wondering why it isn’t working properly? You’re not alone. Many people face issues with their floor mount metal lathe. Understanding how to troubleshoot these problems can save time and money.

Imagine you’re getting ready to start a new project. You check your lathe. It looks fine, but something feels off. Maybe the motor hums, but the tool doesn’t spin. Frustrating, isn’t it? This is a common issue that can often be fixed with a few simple steps.

Knowing how to troubleshoot your lathe can turn a frustrating experience into a successful one. Did you know that the root of many lathe problems is often a simple fix? Whether it’s a loose belt or a faulty switch, solutions can be easier than you think.

In this article, we’ll explore common troubleshooting tips for your floor mount metal lathe. You’ll learn how to identify the problem quickly and fix it like a pro. Get ready to get your machine back in action!

Lathe Floor Mount Metal Lathe Troubleshooting Guide

Lathe Floor Mount Metal Lathe Troubleshooting

Troubleshooting a floor mount metal lathe can seem tricky. Common issues include problems with vibrations, poor cuts, and motor failures. Have you ever noticed strange noises while using your lathe? It might be a sign of loose parts or worn bearings. Checking the alignment and ensuring proper lubrication can make a big difference. Understanding these tips helps you maintain your lathe better. Remember, taking a moment to check your machine can save time and create smoother projects!Common Issues with Floor Mount Metal Lathes

Identifying frequent mechanical problems. Symptoms of electrical malfunctions.Floor mount metal lathes can face some common problems. Identifying these issues early helps maintain smooth operation. Mechanical problems often show as strange noises or uneven cuts. Electrical faults may cause sudden stops or unusual vibrations. Check for the following signs of trouble:

- Unusual noises when running.

- Inconsistent cuts that are not smooth.

- Sudden shutdowns during use.

- Vibrations that feel unusual.

What are signs of electrical failures?

Electrical issues may appear as lights flickering or the machine not starting. Always check connections and power sources to find the problem quickly.

Troubleshooting Mechanical Issues

Stepbystep guide to diagnose misalignments. Solutions for wornout components.Got a stubborn lathe acting like a diva? First, check for misalignments! Start by measuring the distance from the spindle to the tailstock on both sides. If it’s off, shim it up! Next up, for those worn-out components, inspect belts and bearings. If they look sad, it’s time to replace them. Remember, a happy lathe makes for smooth machining. Let’s turn those frowns upside down!

| Issue | Diagnosis | Solution |

|---|---|---|

| Misalignment | Measure spindle to tailstock distances | Shim appropriately |

| Worn-Out Belts | Check for cracks or fraying | Replace with new belts |

| Faulty Bearings | Listen for odd noises | Change damaged bearings |

Electrical Troubleshooting Techniques

How to check wiring and connections. Diagnosing motor and control panel issues.Checking wiring and connections is crucial. First, ensure power is off before touching anything. Look for loose wires or broken connections. Tighten any loose ends. Next, check for signs of wear, like frayed wires. If something looks wrong, replace it.

Diagnosing motor and control panel issues can seem tricky. Start by listening for unusual sounds. If the motor does not turn on, inspect the control panel. Look for burned-out fuses or blinking lights, which might indicate problems.

How do you check the wiring and connections on a lathe?

To check the wiring, first, make sure the power is off. Look for loose or frayed wires. Make connections tight and clear of damage. Regularly inspecting these parts helps avoid bigger issues later.

Key Steps:

- Turn off power.

- Inspect wires for damage.

- Tighten any loose connections.

What do you need to check on the motor and control panel?

Listen for strange sounds from the motor. If it doesn’t start, check the control panel. Look for burned-out fuses or warning lights. Regular checks help keep things running smoothly.

Preventive Maintenance Tips

Best practices for regular inspections. Importance of lubrication and cleaning.To keep your lathe in top shape, regular inspections are key. Check for wear and tear each month. Make sure everything looks shiny and new—well, kind of! Don’t forget lubrication; it’s like giving your machine a nice spa day. Clean it regularly to prevent gunk buildup. Remember, a clean lathe is a happy lathe!

| Maintenance Task | Frequency |

|---|---|

| Inspect for wear | Monthly |

| Lubricate moving parts | Weekly |

| Clean machine | After every use |

Keeping up with these tips can save you from bigger problems later. Just think, a little upkeep today means your lathe will still be spinning tomorrow!

Adjustments for Precision and Performance

Techniques for tightening and aligning components. Optimizing speed and feed settings.To tighten and align your lathe components, check the bolts and screws regularly. A loose part can cause trouble and make your projects look wobbly. Think of it as giving your lathe a good hug – not too tight, just right! For speed and feed settings, follow guidelines from your lathe manual. Adjusting these can make a big difference in how smooth your cuts are. You want your lathe to glide like a marshmallow on ice!

| Adjustment Type | Technique |

|---|---|

| Tightening | Check bolts and screws regularly |

| Aligning | Ensure components are properly aligned |

| Speed Optimization | Refer to your lathe’s manual for the best settings |

| Feed Settings | Adjust according to material being worked on |

When to Seek Professional Help

Indicators that require expert intervention. Finding a qualified technician or service provider.Sometimes, tinkering with your lathe feels like playing with a stubborn cat. You might need help when things get really hairy. If your lathe is making odd noises or not running smoothly, it might be time to call in an expert. Strange vibrations or smoke are not good signs! Finding a qualified technician can save you time and avoid further damage. Here’s an easy table to follow:

| Indicator | Action |

|---|---|

| Unusual Sounds | Call a technician! |

| Frequent Breakdowns | Seek professional help! |

| Visible Damage | Get it checked! |

Don’t wait until your lathe turns into a paperweight! An expert can help get it back to its happy spinning self.

Resources for Further Learning

Recommended manuals and guides. Online communities and forums for troubleshooting advice.To dive deeper into troubleshooting your lathe, you can explore helpful manuals and guides. These resources offer step-by-step methods for fixing issues. Online communities and forums also provide great advice. Here, you can ask questions and hear from others who faced similar problems. Connecting with experienced users can speed up your learning. Try these resources to boost your skills:

- Manufacturer’s manuals for specific lathe models.

- Online forums like Reddit and dedicated machining sites.

- YouTube tutorials for visual guides and demonstrations.

- Facebook groups focused on metalworking and lathes.

What are good resources for lathe troubleshooting?

Useful resources include manuals, online forums, and helpful videos. These platforms give clear guidance and community support for your projects.

Conclusion

In summary, troubleshooting your lathe floor mount metal lathe involves checking for common issues like alignment and power supply. Regular maintenance helps prevent problems. If you face challenges, don’t hesitate to consult your manual or seek online resources. By staying proactive, you can enjoy smoother operation and better results. Keep learning and happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Troubleshooting A Floor-Mounted Metal Lathe:Sure! Here are five simple questions about fixing a floor-mounted metal lathe: 1. What do you do if the lathe doesn’t turn on? 2. How can you fix strange noises coming from the lathe? 3. What should you check if the cutting tool isn’t working well? 4. How do you know if the lathe is not spinning correctly? 5. What steps can you take if the machine is shaking while it runs?

Sure! Please tell me the question you’d like me to answer.

What Are The Common Symptoms Of A Misaligned Spindle On A Floor-Mounted Metal Lathe, And How Can They Be Corrected?If the spindle on a lathe is misaligned, you might notice some issues. The metal might not cut smoothly, or it could vibrate a lot. You may also see uneven surfaces on the workpiece. To fix this, you need to adjust the spindle’s position carefully. This can involve loosening screws and moving the spindle until it’s straight again.

How Can I Diagnose And Fix Excessive Vibration In My Lathe During Operation?To diagnose excessive vibration in your lathe, first, check if it’s on a flat surface. Uneven surfaces can make it shake. Next, look for loose parts; tighten any bolts or screws that aren’t secure. Make sure your tools are sharp and properly attached. If it still vibrates, you might need to ask an adult or a repair expert for help.

What Procedures Should I Follow To Troubleshoot A Lathe That Isn’T Maintaining Accurate Speed Settings?To troubleshoot a lathe that isn’t keeping the right speed, first check the power source. Make sure it’s plugged in and working. Next, look at the speed control knobs. Ensure they are set correctly. If the lathe is still off, check for any loose parts or connections. Lastly, read the owner’s manual for help or ask an adult for assistance.

What Steps Can Be Taken To Resolve Issues With The Lathe’S Feed Mechanism, Such As Skipping Or Jamming?To fix problems with the lathe’s feed mechanism, start by cleaning it. Dust and dirt can make it jam. Next, check the parts for wear and tear. If something is broken, replace it. Finally, make sure everything is lubricated so it runs smoothly. Always remember to follow safety rules when you work!

How Do I Identify And Fix Problems Related To The Lathe’S Electrical Components, Such As The Motor Or Control Panel?To identify problems with the lathe’s electrical parts, start by checking the power supply. Make sure the machine is plugged in and the switch is on. Then, look for loose wires or burnt-out fuses. If you find anything wrong, tighten the connections or replace the parts. If you’re not sure, ask an adult for help.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Troubleshooting A Floor-Mounted Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five simple questions about fixing a floor-mounted metal lathe: 1. What do you do if the lathe doesn’t turn on? 2. How can you fix strange noises coming from the lathe? 3. What should you check if the cutting tool isn’t working well? 4. How do you know if the lathe is not spinning correctly? 5. What steps can you take if the machine is shaking while it runs?”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Symptoms Of A Misaligned Spindle On A Floor-Mounted Metal Lathe, And How Can They Be Corrected?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the spindle on a lathe is misaligned, you might notice some issues. The metal might not cut smoothly, or it could vibrate a lot. You may also see uneven surfaces on the workpiece. To fix this, you need to adjust the spindle’s position carefully. This can involve loosening screws and moving the spindle until it’s straight again.”}},{“@type”: “Question”,”name”: “How Can I Diagnose And Fix Excessive Vibration In My Lathe During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To diagnose excessive vibration in your lathe, first, check if it’s on a flat surface. Uneven surfaces can make it shake. Next, look for loose parts; tighten any bolts or screws that aren’t secure. Make sure your tools are sharp and properly attached. If it still vibrates, you might need to ask an adult or a repair expert for help.”}},{“@type”: “Question”,”name”: “What Procedures Should I Follow To Troubleshoot A Lathe That Isn’T Maintaining Accurate Speed Settings?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot a lathe that isn’t keeping the right speed, first check the power source. Make sure it’s plugged in and working. Next, look at the speed control knobs. Ensure they are set correctly. If the lathe is still off, check for any loose parts or connections. Lastly, read the owner’s manual for help or ask an adult for assistance.”}},{“@type”: “Question”,”name”: “What Steps Can Be Taken To Resolve Issues With The Lathe’S Feed Mechanism, Such As Skipping Or Jamming?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with the lathe’s feed mechanism, start by cleaning it. Dust and dirt can make it jam. Next, check the parts for wear and tear. If something is broken, replace it. Finally, make sure everything is lubricated so it runs smoothly. Always remember to follow safety rules when you work!”}},{“@type”: “Question”,”name”: “How Do I Identify And Fix Problems Related To The Lathe’S Electrical Components, Such As The Motor Or Control Panel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To identify problems with the lathe’s electrical parts, start by checking the power supply. Make sure the machine is plugged in and the switch is on. Then, look for loose wires or burnt-out fuses. If you find anything wrong, tighten the connections or replace the parts. If you’re not sure, ask an adult for help.”}}]}