Have you ever wondered how a simple foot brake can make using a lathe safer? Installing a lathe foot brake is easier than you might think. It’s a small change that can bring big benefits.

Imagine working on a project and suddenly needing to stop the machine quickly. A foot brake can help you do just that. It allows you to stop the lathe with a gentle press of your foot, keeping your hands free for better control.

In this article, we will explore the steps for lathe foot brake installation. You’ll learn everything you need to make your workspace safer and more efficient. Ready to discover how a simple upgrade can change your woodworking experience? Let’s dive in!

Lathe Foot Brake Installation: A Step-By-Step Guide

Lathe Foot Brake Installation

Installing a lathe foot brake can greatly improve safety and control. First, ensure you have the right brake for your lathe model. Start by locating the installation points on the lathe. Did you know that a foot brake can reduce stopping time significantly? Secure the brake and test its operation. Proper installation helps prevent accidents. With a functional foot brake, you can focus more on your work and less on safety worries. More control leads to better craftsmanship!Understanding the Importance of a Foot Brake

Explanation of safety features provided by a foot brake.. Benefits of enhanced control during operations..A foot brake acts like a superhero for your lathe. First, it brings safety to the operation, helping to prevent mishaps. Imagine a world where accidents can be avoided with just a tap of your foot! Plus, it gives you better control during tasks. You can stop the machine quickly, making it easier to focus on your work without fear. Having a foot brake is like having a safety net while you juggle! It’s a small addition that packs a big punch.

| Feature | Benefit |

|---|---|

| Safety | Prevents accidents |

| Control | Enhances precision |

Choosing the Right Foot Brake for Your Lathe

Criteria for selecting the appropriate foot brake model.. Comparison of different types of foot brakes available on the market..Finding the perfect foot brake for your lathe can feel like searching for a needle in a haystack. It’s important to think about size, style, and safety features. Not all brakes work the same, so check how easily they can be installed and used. Some types include hydraulic, pneumatic, and mechanical options. Each has its quirks—like that one uncle at family gatherings! To make it easier, here’s a quick comparison:

| Type | Pros | Cons |

|---|---|---|

| Hydraulic | Smooth operation, strong stopping power | Can be tricky to install |

| Pneumatic | Easy to use, quick response | Requires air compressor |

| Mechanical | Simpler design, low maintenance | May lack force for heavy loads |

Choose wisely, and always prioritize safety. After all, a good brake is your best friend when you’re working with powerful machinery!

Preparing Your Lathe for Installation

Steps to safely disconnect power and prepare the workspace.. Tips for inspecting the lathe before installing the foot brake..Start by ensuring your lathe is turned off and unplugged. This keeps you safe during work. Next, clean your workspace to avoid accidents. A tidy area helps you focus and find tools easily.

Before you install the foot brake, check your lathe carefully. Look for wear and tear, loose parts, and rust. This can save you trouble later.

- Check power connections.

- Inspect the bed for damage.

- Ensure the spindle turns smoothly.

What is the first step in preparing for installation?

Always disconnect power to the lathe before starting any work. This is crucial for your safety.

Installation Process

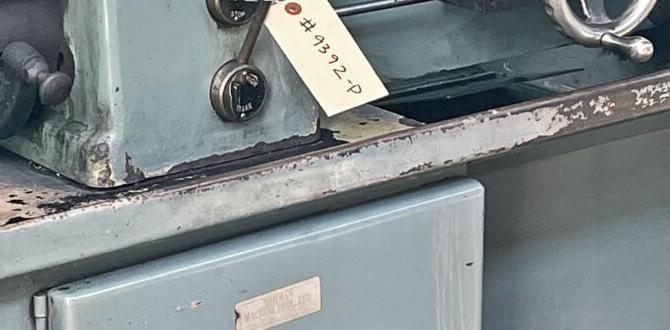

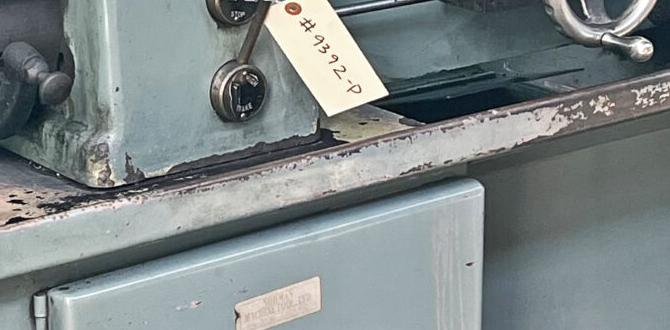

Detailed stepbystep instruction on how to install the foot brake.. Visual aids (diagrams or images) to assist in the installation..First, gather your tools: a wrench, screwdriver, and of course, the foot brake kit. Make sure you’re all set before dive in! Start by removing the old brake. It’s like taking off a shoe that’s two sizes too small—much needed relief!

Next, attach the foot brake to the lathe base, lining it up with the pre-drilled holes. Tighten the bolts until they’re secure, but don’t turn them into Hulk’s grip! You’ll need it to pivot smoothly.

To make it easier, refer to the diagrams. They’re like treasure maps, guiding you to the X that marks the spot. After everything is tight, test it out! If it doesn’t feel right, double-check your work.

| Step | Description |

|---|---|

| 1 | Gather tools and materials. |

| 2 | Remove the old brake. |

| 3 | Install new brake and secure it. |

| 4 | Check diagrams for assistance. |

| 5 | Test for smooth operation. |

By following this guide, you’ll be stopping that lathe faster than a cat when it sees a cucumber! 🐱

Testing Your Foot Brake After Installation

Procedures for checking the functionality of the foot brake.. Safety checks to ensure proper installation and operation..After installing your foot brake, it’s time to ensure everything works perfectly. Start by checking the brake action. Press down on the brake pedal. It should feel firm and responsive. Here are a few key steps:

- Ensure the brake pedal returns to its original position.

- Look for any unusual noises when you press the pedal.

- Check the brake mounting. It should be tight and secure.

Finally, test the lathe in a safe area. Make sure your foot brake quickly stops the machine. This will keep you safe while working. Regular testing helps catch problems early.

How do I know if my foot brake is working correctly?

Your foot brake is working correctly if the brake pedal feels firm and returns to its position quickly. Pay attention to any unusual sounds during use. Regular testing will help maintain safety and functionality.

Common Issues and Troubleshooting

List of potential problems that may arise during use.. Solutions and preventative measures for maintenance..Using your lathe’s foot brake can be a breeze, but sometimes you might encounter a few hiccups. Common problems include the brake not engaging or unusual noises during operation. If your brake feels loose, it might just need a good tightening, like your shoelaces after a sprint! Regular maintenance helps too—check for wear and tear. Here’s a handy table to spot issues and solutions:

| Problem | Solution |

|---|---|

| Brake not engaging | Check connections; tighten screws. |

| Strange noises | Lubricate parts; check for loose items. |

| Brake feels loose | Adjust the tension; replace worn parts. |

Keeping your lathe in shape is like munching on veggies—it’s not always fun, but it’s definitely good for you!

Maintaining Your Foot Brake for Longevity

Recommended maintenance practices to ensure optimal performance.. Signs that indicate the foot brake may need repair or replacement..Taking care of your foot brake keeps it working well. Regular checks can spot issues before they become big problems. Clean it often and look for wear. If you hear strange sounds or notice it feels different, those might be signs something is off. Don’t wait too long; repairing early saves money!

| Signs of Trouble | Action Needed |

|---|---|

| Grinding noise | Check for damage |

| Poor response | Inspect or replace |

| Visible wear | Time for maintenance |

Think of it like a pet—it needs love and care! If you treat it right, your foot brake will be happy and last longer.

Conclusion

In conclusion, installing a lathe foot brake enhances safety and control. You need to gather the right tools first. Follow instructions carefully for a successful installation. Remember to test the brake to ensure it works properly. For more tips and detailed guidance, check out our additional resources. Let’s make your lathe experience safer and more efficient together!FAQs

Here Are Five Related Questions Regarding Lathe Foot Brake Installation:Sure! Please share the five related questions you have about lathe foot brake installation, and I’ll help you with the answers.

Sure, I can help with that! Please provide the question you want me to answer.

What Are The Essential Tools And Materials Needed For Installing A Foot Brake On A Lathe?To install a foot brake on a lathe, you need a few important tools and materials. First, you’ll need a foot pedal brake. Next, have some screws and bolts ready to hold everything in place. You’ll also want a wrench to tighten the screws. A drill can help make holes if needed. Finally, don’t forget some safety goggles to protect your eyes!

How Do You Determine The Appropriate Position For The Foot Brake Pedal On A Lathe?To find the right spot for the foot brake pedal on a lathe, you need to sit in front of it. Place your foot comfortably on the pedal. It should be easy to reach without stretching. Test it by pressing the pedal and making sure it stops the lathe quickly. Adjust it if needed, so it feels just right for you.

What Safety Precautions Should Be Taken Before Installing A Foot Brake On A Lathe?Before we install a foot brake on a lathe, we should follow some safety steps. First, turn off the lathe and unplug it. This keeps us safe from accidents. Next, wear safety goggles to protect our eyes. Finally, keep the workspace clean and organized to avoid tripping.

Are There Specific Types Of Foot Brakes Recommended For Different Types Of Lathes, And How Do They Vary?Yes, different lathes may need different foot brakes. For example, a small lathe might use a simple brake. Bigger lathes usually need more powerful brakes to stop quickly. These brakes help keep you safe while you work. Always choose a brake that matches your lathe’s size.

What Are The Step-By-Step Instructions For Properly Wiring And Connecting A Foot Brake To A Lathe’S Power Supply?To wire a foot brake to a lathe, first, make sure the lathe is turned off and unplugged. Next, find the two wires for the power supply. You will connect one wire from the lathe to one terminal on the foot brake. Then, connect the other terminal of the foot brake to the other wire of the power supply. Finally, double-check all your connections and plug in the lathe to test the foot brake. Always ask an adult for help if you’re unsure!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions Regarding Lathe Foot Brake Installation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the five related questions you have about lathe foot brake installation, and I’ll help you with the answers.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure, I can help with that! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Materials Needed For Installing A Foot Brake On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a foot brake on a lathe, you need a few important tools and materials. First, you’ll need a foot pedal brake. Next, have some screws and bolts ready to hold everything in place. You’ll also want a wrench to tighten the screws. A drill can help make holes if needed. Finally, don’t forget some safety goggles to protect your eyes!”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Position For The Foot Brake Pedal On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right spot for the foot brake pedal on a lathe, you need to sit in front of it. Place your foot comfortably on the pedal. It should be easy to reach without stretching. Test it by pressing the pedal and making sure it stops the lathe quickly. Adjust it if needed, so it feels just right for you.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken Before Installing A Foot Brake On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before we install a foot brake on a lathe, we should follow some safety steps. First, turn off the lathe and unplug it. This keeps us safe from accidents. Next, wear safety goggles to protect our eyes. Finally, keep the workspace clean and organized to avoid tripping.”}},{“@type”: “Question”,”name”: “Are There Specific Types Of Foot Brakes Recommended For Different Types Of Lathes, And How Do They Vary?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, different lathes may need different foot brakes. For example, a small lathe might use a simple brake. Bigger lathes usually need more powerful brakes to stop quickly. These brakes help keep you safe while you work. Always choose a brake that matches your lathe’s size.”}},{“@type”: “Question”,”name”: “What Are The Step-By-Step Instructions For Properly Wiring And Connecting A Foot Brake To A Lathe’S Power Supply?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a foot brake to a lathe, first, make sure the lathe is turned off and unplugged. Next, find the two wires for the power supply. You will connect one wire from the lathe to one terminal on the foot brake. Then, connect the other terminal of the foot brake to the other wire of the power supply. Finally, double-check all your connections and plug in the lathe to test the foot brake. Always ask an adult for help if you’re unsure!”}}]}