Have you ever wondered how a lathe turns raw metal into beautiful shapes? It’s like magic when you see it in action! One important part of this magic is the gear ratio. The gear ratio on a metal lathe can make a big difference in how the machine works. It controls the speed and power going into your workpiece.

Now, imagine you have a digital readout (DRO) attached to your lathe. This tool makes it easier to get precise measurements. You can cut metal with accuracy and confidence. But to get the best results, understanding gear ratios is key.

So, why should you care about lathe gear ratios and DRO systems? Knowing this can help you create perfect parts for your projects. Whether you’re a hobbyist or a pro, this knowledge can elevate your metalworking skills. Let’s dive deeper into how these concepts work together in the fascinating world of metal lathe machining!

Understanding Lathe Gear Ratio For Metal Lathe Dro Systems

Understanding Lathe Gear Ratio for Metal Lathes

Lathe gear ratio affects how quickly a metal lathe turns. It helps control the speed and torque, which are important for different materials. A high gear ratio boosts speed, while a low ratio increases torque. Choosing the right ratio can make the difference between a smooth cut and a ruined piece. Did you know that using digital readouts (DRO) can help you monitor these changes? This tech can improve your precision and speed while machining!What is a Lathe Gear Ratio?

Definition of lathe gear ratio. Importance in the operation of a metal lathe.A lathe gear ratio helps control the speed of a metal lathe. It is the relationship between the speed of the spindle and the speed of the cutting tool. A correct gear ratio is essential for smooth operation. It ensures the tool cuts at the right speed, preventing damage. Understanding this ratio can improve work quality and efficiency.

What is the importance of lathe gear ratio?

The lathe gear ratio is important for several reasons:

- Controls Speed: It helps determine how fast the cutting tool spins.

- Accuracy: The right ratio gives precise cuts, leading to better projects.

- Prevents Damage: A proper gear ratio avoids tool wear and tear.

How Gear Ratio Affects Metal Lathe Performance

Influence on spindle speed and torque. Impact on precision and finishing quality.Have you ever noticed how a car zooms faster when it shifts gears? The same idea applies to a metal lathe! The gear ratio affects spindle speed and torque. Higher gear ratios can push the spindle faster, but it may lose some torque, while lower ratios provide more power for tough cuts. This balance is crucial for precision; too high, and your finish might look like a bumpy road. Here’s a look at how different gear ratios affect performance:

| Gear Ratio | Spindle Speed | Torque | Finishing Quality |

|---|---|---|---|

| High (e.g., 4:1) | Fast | Lower | Possible rough edges |

| Medium (e.g., 2:1) | Balanced | Moderate | Smooth finish |

| Low (e.g., 1:1) | Slow | Higher | Very smooth |

In summary, finding the right gear ratio is like trying to find the best pizza topping—everyone has their favorite! It deeply influences how your metal lathe performs, affecting both speed and quality.

Calculating the Gear Ratio in Your Metal Lathe

Formula for determining gear ratio. Practical example of gear ratio calculation.To find the gear ratio in your metal lathe, use this formula: Gear Ratio = Number of Teeth on Driven Gear / Number of Teeth on Driving Gear. For example, if your driven gear has 20 teeth and your driving gear has 5 teeth, the gear ratio is 20/5 = 4. This means the driven gear turns four times for every turn of the driving gear. This calculation helps in determining the speed and torque needed for different tasks.

How is gear ratio helpful?

The gear ratio affects how fast and powerful your lathe works. A higher gear ratio offers more strength but less speed, making it easier to cut tough materials.

Key Points:

- Higher gear ratio = More strength

- Lower gear ratio = More speed

Choosing the Right Gear Ratio for Your Projects

Factors to consider (material, size, complexity). Optimal gear ratios for different types of machining.Choosing the right gear ratio affects your project’s success. First, think about the material you’re using. Hard materials need different settings than soft ones. Next, consider the size of your workpiece. Small pieces often require higher gear ratios, while big ones can use lower ratios. Lastly, remember the complexity of your design. More complex projects may need special adjustments. The right gear ratio enhances precision and efficiency for each task.

What factors should you consider for gear ratios?

Consider three main factors:

- Material: Select a gear ratio based on how tough or soft the material is.

- Size: Smaller items typically use higher gear ratios for better control.

- Complexity: Intricate designs may require careful adjustments for accuracy.

Finding the optimal gear ratio can greatly improve your machining results. Pay attention to these factors for the best outcome!

The Role of DRO (Digital Readout) in Enhancing Gear Ratio Efficiency

Explanation of DRO and its benefits in lathe operations. How DRO can assist in maintaining accurate gear ratios.In the world of metal lathes, a Digital Readout, or DRO, does wonders! It shows precise measurements and makes tricky tasks much easier. Think of it as a GPS for your lathe—never lost and always on track! By using a DRO, you can keep your gear ratios accurate. This means you’ll create smoother, more consistent pieces. Who wouldn’t want that? Here’s a little look at how it helps:

| Benefit | Description |

|---|---|

| Accuracy | DRO provides real-time measurements for perfect cuts every time. |

| Efficiency | It saves time by reducing mistakes and reworks. |

| User-Friendly | Easy to read and use, making it suitable for all skill levels. |

So, a DRO is like a magic wand for lathe operators, waving away errors and bringing in efficiency!

Common Issues with Gear Ratios in Metal Lathes

Signs of incorrect gear ratio settings. Troubleshooting tips for gear ratiorelated problems.Gear ratios can be tricky business! A wrong setting might cause your lathe to act like a confused puppy. Watch for signs like strange sounds, uneven cuts, or the tool moving too slow or too fast. To fix these issues, check your gear settings. Don’t forget to ask yourself, “Is my ratio right or am I just winging it?” Below is a table with common signs and easy fixes:

| Issue | Possible Cause | Solution |

|---|---|---|

| Strange noises | Wrong gear ratio | Check settings |

| Uneven cuts | Incorrect feed rate | Adjust feed settings |

| Slow tool movement | High gear ratio | Lower the ratio |

| Fast tool movement | Low gear ratio | Increase the ratio |

With these tips, you’ll have your lathe purring like a happy kitten in no time!

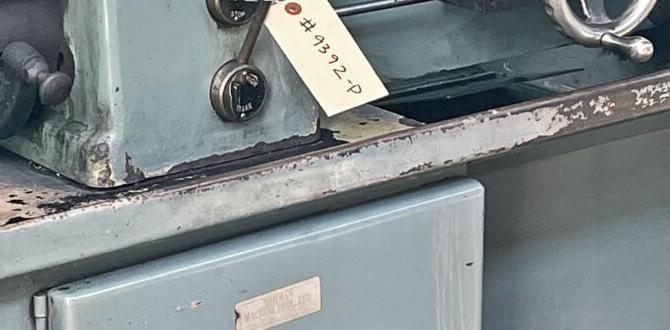

Upgrading Your Metal Lathe Gear Ratio

Advantages of upgrading gear mechanism. Recommended upgrades and modifications.Upgrading your metal lathe gear ratio can bring many benefits. It improves precision and speeds up your work. Better ratios help create cleaner cuts, making projects easier. Recommended upgrades include:

- Changing gears for different speeds.

- Installing a DRO for better measurement.

- Using high-quality belts to reduce slippage.

These changes can boost your lathe’s performance, saving time and effort.

What are the benefits of upgrading a lathe gear ratio?

Upgrading a lathe gear ratio enhances speed, improves accuracy, and increases the overall efficiency of your projects.

Best Practices for Maintaining Lathe Gear Ratios

Regular maintenance routines. Importance of calibration and adjustments.To keep your lathe working smoothly, regular maintenance is key. Check the gear ratios and clean parts often to avoid any surprises. No one likes a grumpy machine! Calibration is just as important. It’s like getting your eyes tested; a little tweak can make a big difference. A well-calibrated lathe makes jobs easier and safer. Plus, it saves time and materials. Remember, a happy lathe equals happy machining!

| Maintenance Task | Frequency |

|---|---|

| Check oil levels | Every week |

| Inspect belts and gears | Monthly |

| Calibrate settings | Every 6 months |

Conclusion

In conclusion, understanding lathe gear ratio, metal lathes, and digital readouts (DRO) helps you become a better machinist. Gear ratios affect speed and precision, while DROs enhance accuracy. We encourage you to explore different lathes and gear setups. Practicing with these tools will improve your skills. Keep learning and experimenting to master your metalworking projects!FAQs

What Factors Should Be Considered When Determining The Ideal Gear Ratio For A Metal Lathe?When choosing the right gear ratio for a metal lathe, think about what you want to make. The gear ratio affects how fast and strong your lathe will work. You should also consider the size of the metal you’re using and how smooth you want the cuts to be. Lastly, make sure the lathe can handle the settings you pick.

How Does Gear Ratio Affect The Torque And Speed Of A Metal Lathe During Operation?Gear ratio helps control how fast and how strong a metal lathe works. A higher gear ratio means the lathe spins slower but has more power, or torque. This is good for cutting hard materials. A lower gear ratio makes the lathe spin faster but with less power. You choose the right ratio based on what you want to do.

What Are The Advantages Of Using A Digital Readout (Dro) System In Conjunction With Lathe Gear Ratios?Using a digital readout (DRO) system with lathe gear ratios helps you make precise cuts. You can see exact measurements right away. This makes it easier to follow your plans and get the right size. It also saves time because you don’t have to keep checking old measurements. Overall, it helps you work better and with less mistakes.

How Can One Calculate The Gear Ratio Needed For Specific Turning Operations On A Metal Lathe?To calculate the gear ratio for a metal lathe, you need to know two things: the spindle speed and the desired cutting speed. First, find out how fast the lathe spins the tool. Then, decide how fast you want it to cut the metal. Divide the spindle speed by the cutting speed to get the gear ratio. This tells you how to set up the gears on the lathe for the job.

What Maintenance Practices Are Recommended To Ensure Precise Gear Engagement And Longevity In Gear-Driven Metal Lathes?To keep your gear-driven metal lathe working well, you should regularly clean it. Dust and oil can build up, so wipe it down. You should also check the gears for any damage and fix any problems you find. Lubricate the gears with the right oil to keep them running smoothly. Finally, always follow the instructions in the manual for best care.