Have you ever wondered how a simple machine can create complex shapes? A metal lathe is one of those amazing tools. It spins metal to shape it into useful objects. But did you know that the lathe gear ratio plays an important role in how these machines operate?

The gear ratio helps control the speed and power of the lathe. This means it influences how smoothly the metal is cut and shaped. Imagine trying to slice a cake with a dull knife. It’s hard and messy! The right gear ratio makes metal cutting easy and clean.

Here’s a fun fact: Many metalworkers tweak their lathe gear ratios to achieve different effects. They create unique designs and finishes that make their projects stand out. Want to learn how these ratios work? Understanding lathe gear ratios opens a whole new world of metal lathe operations.

So, whether you’re a beginner or an experienced machinist, knowing about gear ratios can make you a better craftsman. Get ready to explore the exciting details of lathe gear ratios and how they can transform your metalworking experience!

Understanding Lathe Gear Ratio For Metal Lathe Operations

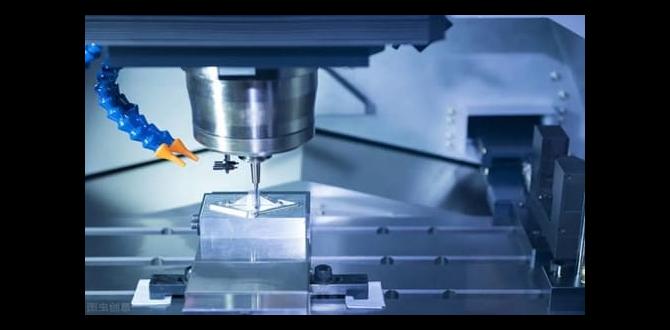

Lathe Gear Ratio in Metal Lathe Operations

Understanding lathe gear ratio is essential for efficient metal lathe operations. Gear ratios determine how fast a lathe spins compared to the motor. This impacts the final results of your work. A higher gear ratio means more speed but less torque, while a lower ratio does the opposite. Choosing the right gear ratio can help you cut metal accurately and smoothly. Have you ever wondered how small changes can make a big difference in your project? Knowing gear ratios can take your skills to the next level!What is a Lathe Gear Ratio?

Definition of gear ratio in the context of metal lathes. Importance of gear ratios for machining precision.A gear ratio tells us how fast a lathe turns with respect to the motor. It’s like the speed limit on a road: it helps control how fast you go! In metal lathe operations, these ratios are super important. A perfect gear ratio ensures precision in machining. If the gear ratio is off, it’s like trying to watch a movie on fast forward – everything gets jumbled! So, choosing the right gear ratio keeps your work sharp and makes you look like a machining superstar.

| Gear Ratio | Effect on Speed | Effect on Torque |

|---|---|---|

| High Ratio | Slower Speed | More Torque |

| Low Ratio | Faster Speed | Less Torque |

Components Influencing Lathe Gear Ratios

Explanation of gears in a lathe system. Role of the motor and drive mechanisms.The gears in a lathe system are like the tiny wizards that make everything spin just right. They help control how fast and smooth the machine cuts metal. The motor is the strong guy that brings power to the gears, while the drive mechanisms act like a friendly road sign, guiding the movement. Together, they create a perfect dance of forces, allowing you to shape metal objects with ease, like magic! Did you know that a lathe can rotate up to 3,000 RPM? That’s faster than a cheetah on roller skates!

| Component | Role |

|---|---|

| Gears | Control speed and direction of cutting |

| Motor | Powers the lathe and gears |

| Drive Mechanisms | Guide movement and operations |

Calculating Lathe Gear Ratios

Stepbystep guide to calculating gear ratios. Examples and formulas for practical understanding.To find lathe gear ratios, follow these easy steps. First, identify the number of teeth on each gear. Next, use the formula: Gear Ratio = Teeth on Driven Gear ÷ Teeth on Driving Gear. This gives you the ratio of how many turns the driving gear makes compared to the driven gear. For example, if the driven gear has 48 teeth and the driving gear has 12, the gear ratio is 4:1. This means the driving gear turns four times for each turn of the driven gear.

Why are gear ratios important?

Gear ratios affect speed and torque in lathe operations. Choosing the right gear ratio helps create smoother, more efficient cuts.

- Higher ratio = more torque

- Lower ratio = more speed

- Balance ratios for better results

Benefits of Optimizing Gear Ratios in Metal Lathe Operations

Improved machining accuracy and surface finish. Increased efficiency and reduced wear on components.Optimizing gear ratios in metal lathe operations brings many benefits. First, it improves machining accuracy and surface finish. This means smoother and better-looking parts. Second, using the right gear ratio increases efficiency. You finish jobs quicker while using less power. Additionally, it reduces wear on machine components. This helps the lathe last longer and saves money on repairs.

What are the advantages of optimized gear ratios?

- Improved accuracy: Better fitting parts.

- Better surface finish: Smoother results every time.

- Greater efficiency: Finish your work faster.

- Less wear: Keeps your machine in good shape.

Adjusting Gear Ratios for Different Operations

Situations where gear ratio adjustments are necessary. Tips for adjusting gear ratios effectively.Sometimes, you need to change your lathe’s gear ratios. This happens for tasks like cutting different materials or changing speeds. Each job has its own needs, kind of like choosing what to wear for a season. When you shift gears, it can make your work easier and funnier—just like when you find out your favorite jeans fit! Here are some tips:

| Task | Suggested Gear Ratio |

|---|---|

| Fine Cutting | Low Ratio |

| Heavy Material | High Ratio |

Experiment with different settings. Knowing when to switch can save time and effort. Think of it as giving your lathe a little dance break; it helps everyone groove better!

Troubleshooting Gear Ratio Issues in Lathe Operations

Common problems related to gear ratios. Solutions and maintenance tips to avoid ratiorelated complications.Lathe operations can run into several gear ratio problems. Common issues include strange noises, uneven cuts, and the machine not moving correctly. These annoyances can happen when gear teeth wear out or if the wrong ratio is set. Solution? Regularly check and clean gears, and always refer to the manual for correct settings. It’s like giving your lathe a spa day! A little TLC goes a long way in keeping everything smooth.

| Problem | Solution |

|---|---|

| Strange Noises | Check for wear on gears and tighten any loose parts. |

| Uneven Cuts | Verify the gear ratio settings and maintain even pressure. |

| Machine Not Moving | Inspect gears for damage and ensure correct lubrication. |

Future Trends in Lathe Gear Ratios and Technologies

Innovations in gear mechanisms and controls. Predictions on the evolution of gear ratios in lathe operations.New technology is changing lathe operations fast. Innovations are making gear mechanisms smarter and easier to use. For example, automatic gear controls can adjust ratios on the go. This means better precision and speed for metalworkers. Predictions say that gear ratios will become more efficient over time. Machines will use less power while doing more work. Exciting changes are on the horizon!

What are some future innovations in gear ratios for lathes?

Future innovations include smart gear mechanisms that adjust automatically. These changes promise greater efficiency and ease of use.

Key Innovations

- Automatic controls for quick adjustments

- Smart sensors to track performance

- Energy-efficient designs for reduced power use

Conclusion

In summary, understanding lathe gear ratios is essential for effective metal lathe operations. They help you control speed and torque for better results. Knowing how to adjust these ratios can make your projects easier and more precise. We encourage you to practice with different gear settings. For more tips, check out beginner guides to metal lathe operations!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios In Metal Lathe Operations:Sure! When using a lathe, we can change the gear ratios to control how fast the machine turns. A higher gear ratio makes the lathe turn slower, which is good for careful work. A lower gear ratio lets it spin faster, which can be useful for rough cutting. You can think of gear ratios like bicycle gears—they help you go faster or slower depending on what you need to do. It’s all about making the work easier and better!

Sure! Just ask me a question, and I will give you a short answer.

How Do You Calculate The Gear Ratio For A Metal Lathe, And What Factors Should Be Considered In This Calculation?To calculate the gear ratio for a metal lathe, you divide the number of teeth on the driven gear by the number of teeth on the driver gear. For example, if the driver gear has 10 teeth and the driven gear has 20 teeth, the gear ratio is 20 divided by 10, which equals 2. You should also think about how fast you want the lathe to spin and the power needed to cut the metal. Always check if the gears fit well together!

What Is The Significance Of Gear Ratios In Determining The Spindle Speed And Torque Of A Metal Lathe During Machining Operations?Gear ratios help us control how fast the metal lathe spins and how much power it has. When we change the gears, we can make the spindle speed faster or slower. This helps us choose the right speed for different jobs. More torque means more strength, so we can cut tougher materials. In short, gear ratios let us make the lathe work best for each task.

How Does Adjusting The Gear Ratio Impact The Surface Finish And Accuracy Of A Machined Part On A Lathe?Adjusting the gear ratio on a lathe changes how fast the cutting tool spins. If we make the tool go slower with a higher gear ratio, it can create a smoother surface. This means the part looks nicer and feels better to the touch. A good gear ratio also helps the tool cut more accurately, which means it fits better where it needs to go. So, the right gear ratio makes our work cleaner and more precise!

What Are The Common Gear Configurations Used In Metal Lathes, And How Do They Affect The Versatility Of The Machine?Metal lathes use different gear setups to work with various materials. Common setups include straight gears, spur gears, and change gears. These gears let you easily change the speed and power of the lathe. This means you can make different shapes and sizes more easily. So, more gear options make the lathe more versatile and fun to use!

In What Situations Might A Machinist Need To Modify The Lathe’S Gear Ratio, And What Are The Steps Involved In Making Such Adjustments?A machinist might change the lathe’s gear ratio to make it spin faster or slower. This helps when we need to cut different materials. To adjust the gear ratio, first, turn off the lathe. Then, find the gear settings and change them. Finally, check that everything is tight and turn the lathe back on to try it out.