Have you ever wondered how a metal lathe works? It’s like magic when you see it in action. A lathe can shape metal into many forms, from simple rods to complex parts. One key part of its operation is the lathe gear ratio.

The gear ratio helps the lathe spin at different speeds. This means you can create different shapes and finishes. It gives you control over the cutting process. Do you know what a quick change tool post is? It’s a handy tool that lets you switch between different cutting tools fast. This saves time and makes metalworking easier.

Imagine needing to cut a metal piece for a school project. You want it to be perfect and done quickly. Understanding lathe gear ratios and quick change tool posts can help you see how professionals achieve amazing results.

In this article, we will explore these topics further. You’ll learn why they are important for metalworking. Get ready to dive into the fascinating world of metal lathes!

Understanding Lathe Gear Ratio For Metal Lathe Quick Change Tool Post

Understanding Lathe Gear Ratio and Quick Change Tool Post

Many metal lathe operators may wonder how gear ratios affect their work. Gear ratios determine the speed and torque of the lathe. A higher gear ratio means faster spindle speeds, allowing for smoother cuts. Quick change tool posts enhance efficiency, enabling quick swaps of tooling without losing precision. Did you know that some tool posts can be changed in seconds? This combination of gear ratio and tool post design can greatly improve a lathe’s versatility and ease of use.What is a Lathe Gear Ratio?

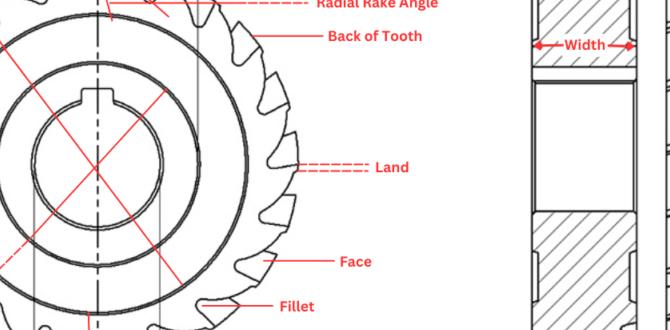

Definition and importance of gear ratio in lathe operations. How gear ratio affects machining speed and torque.A lathe gear ratio tells us how many times the motor’s speed is increased or decreased. It is vital for achieving the right speed during machining. The gear ratio affects both machining speed and torque, which is the twisting force on tools. A higher gear ratio means faster work but less force. A lower gear ratio offers more power but slower speed. Understanding it helps users choose the best settings for their projects.

What is the effect of gear ratio on lathe operations?

The gear ratio directly impacts machining speed and torque.Key Points:

- A higher gear ratio = Faster speed

- A lower gear ratio = More torque

- Choosing the right ratio matters for clean cuts

Calculating Gear Ratio in Metal Lathes

Steps to calculate gear ratio for various metal lathe models. Examples of gear ratio calculations and their implications.To find the gear ratio in metal lathes, follow these steps:

- Identify the motor speed (RPM) and spindle speed.

- Divide the motor speed by the spindle speed.

- This will give you the gear ratio.

For instance, if your motor runs at 1200 RPM and the spindle runs at 300 RPM, the calculation would be:

1200 ÷ 300 = 4

This means the gear ratio is 4:1. A higher ratio offers more torque, while a lower ratio provides higher speed.

What is a gear ratio in metal lathes?

A gear ratio is the relationship between the motor speed and spindle speed of the lathe. It tells you how much torque or speed the machine can produce. Different models may have different ratios. Understanding this helps you pick the right settings for your projects.

Benefits of Using the Correct Gear Ratio

Enhanced precision and quality of finished products. Improved efficiency and productivity in metalworking.Choosing the right gear ratio is like picking the perfect pizza topping—vital for a tasty result! Using the correct ratio enhances precision and boosts the quality of your finished products. With the right setup, your metalworking becomes faster and more efficient. Picture this: you’ll finish projects quicker than a cheetah on roller skates! That means more time for coffee breaks and less stress about deadlines.

| Benefits | Details |

|---|---|

| Precision | Improves accuracy in shaping metal. |

| Efficiency | Reduces time spent on each task. |

| Quality | Delivers smoother and better finishes. |

So remember, finding the right gear ratio keeps your projects on track and your happiness levels high!

How Quick Change Tool Posts Improve Workflow

Timesaving benefits of quick change tool posts. Comparison of quick change tool posts vs traditional tool holders.Switching between tools can feel like a never-ending game of musical chairs. With quick change tool posts, you can save time and avoid that dreaded tool hunt. They allow you to swap out tools in seconds, compared to the old-fashioned tool holders that need a whole production crew to change. Studies show that using quick change posts can boost your efficiency by up to 50%! Here’s a fun comparison:

| Feature | Quick Change Tool Posts | Traditional Tool Holders |

|---|---|---|

| Change Time | Seconds | Minutes |

| Ease of Use | Very Easy | Moderate |

| Efficiency | High | Low |

So, why stick with old-school methods? Embrace the speed of quick change tool posts and watch your productivity soar!

Choosing the Right Quick Change Tool Post for Your Lathe

Factors to consider when selecting a tool post. Compatibility with different types of lathes and tooling systems.Choosing a quick change tool post is crucial for your lathe work. Several factors matter here. First, think about compatibility. Does the tool post fit your lathe? Check for different models and sizes.

Next, consider the tooling system. What kind of tools do you use? Make sure they match the tool post type. Here are some important factors to keep in mind:

- Size of the lathe

- Type of tools

- Material quality

- Ease of use

Taking the time to analyze these factors will help you select the right quick change tool post for smooth and effective machining.

What should I look for in a quick change tool post?

Look for compatibility, size, and the quality of materials. Ensure it matches your lathe and tools for the best results.

Common Issues and Solutions with Lathe Gear Ratios and Tool Posts

Troubleshooting common problems in gear ratio settings. Solutions for optimizing performance of quick change tool posts.Setting the right gear ratio is important for smooth operation. Common issues include noise and vibration, which can indicate incorrect settings. To fix this, check the gear alignment and adjust as needed. Optimizing performance for your quick change tool post can also help. Issues like difficulty in tool change can be fixed by ensuring parts are free of debris and lubricated properly. Regular maintenance is key to keeping everything working well. Here are quick tips:

- Check gear alignment to reduce noise.

- Lubricate tool post for smoother changes.

- Inspect for debris regularly.

What are common troubles with lathe gear ratios?

Issues often arise from misalignment, improper settings, or worn parts. Regular checks can help spot problems early.How do I improve my quick change tool post?

To optimize your tool post, ensure all parts are clean and well-greased. This makes changing tools easier and faster.Maintenance Tips for Lathe Gear Systems and Tool Posts

Routine maintenance practices to ensure longevity. Signs of wear and necessary interventions.Keeping your lathe gear systems and tool posts in top shape is key to smooth operations. A little care goes a long way! Regular cleaning and lubrication can help parts work happily together. Look for *funny* signs like unusual noises or vibrations. These could mean something isn’t right. If you notice worn-out gears, it’s time to step in with repairs or replacements.

| Signs of Wear | Interventions |

|---|---|

| Unusual Noises | Check lubrication |

| Vibrations | Tighten components |

| Slipping Gears | Replace gears |

By giving your tools some extra love, they’ll thank you with many good years of use. Remember, a little maintenance means fewer worries down the road!

Conclusion

In summary, understanding lathe gear ratios helps you control speed and torque when using a metal lathe. A quick change tool post makes tool swaps easy and efficient. By mastering these concepts, you can enhance your machining skills. So, dive deeper into these topics, practice with your lathe, and watch your projects improve! Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio, Metal Lathe, And Quick Change Tool Post:Sure! A lathe is a machine that helps us shape metal into different forms. The gear ratio tells us how fast the lathe can spin the metal. A metal lathe is useful for making things like screws or parts for machines. A quick change tool post is a special part that lets us switch tools quickly, saving us time. Using these tools makes working with metal easier and more fun!

Sure! Please provide the question you want me to answer.

What Is The Significance Of Gear Ratio In A Metal Lathe, And How Does It Affect The Machine’S Performance?The gear ratio in a metal lathe is really important. It helps control how fast the lathe spins. A higher gear ratio makes the machine spin faster, while a lower ratio slows it down. If you want to cut metal easily, you need the right gear ratio. This way, the lathe can work better and do a good job.

How Do You Calculate The Gear Ratio For A Specific Cutting Application On A Metal Lathe?To find the gear ratio for cutting on a metal lathe, you first look at the gears. Count the teeth on the driving gear, the one that spins. Then, count the teeth on the driven gear, the one that gets spun. You divide the number of teeth on the driving gear by the number on the driven gear. This number is your gear ratio, and it helps you understand how the lathe will cut the metal.

What Are The Advantages Of Using A Quick Change Tool Post Compared To A Standard Tool Holder On A Metal Lathe?A quick change tool post is easier and faster to use than a standard tool holder. You can switch tools quickly without using extra tools. This saves you time when working on projects. It makes your work faster and smoother. You’ll spend less time changing tools and more time making cool things!

How Does The Gear Selection Process Influence The Spindle Speed And Torque When Operating A Metal Lathe?When you change the gears on a metal lathe, it affects how fast the spindle spins and how much power it has. If you choose a lower gear, the spindle will spin slower but have more power (torque) to cut through tough metal. If you pick a higher gear, the spindle spins faster but has less power. So, by selecting the right gear, you can control the speed and strength needed to do different types of work.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of The Quick Change Tool Post On A Lathe?To keep the quick change tool post on a lathe in good shape, we should clean it regularly. Dust and chips can make it work poorly. You should also check the screws and parts for tightness. Lubricate moving parts with oil to keep them smooth. Lastly, store tools safely to avoid bumps and damage.