Have you ever wondered how a lathe keeps spinning smoothly? It’s all about the gear train! Taking care of these gears is crucial for the machine’s performance. Dirty gears can slow down your work and even cause accidents. That’s why lathe gear train cleaning tips are so important!

Imagine trying to ride a bicycle with muddy wheels. It would be hard to pedal, right? Similarly, your lathe needs clean gears to work well. But don’t worry! Cleaning your lathe gear train doesn’t have to be hard. With the right steps, you can keep your gears shiny and ready for work.

Did you know that proper cleaning can extend the life of your lathe? It’s true! Regular maintenance makes your gear train last longer. In this article, we will share easy and effective tips to clean your lathe gear train. Let’s dive in!

Lathe Gear Train Cleaning Tips For Optimal Performance

Lathe Gear Train Cleaning Tips

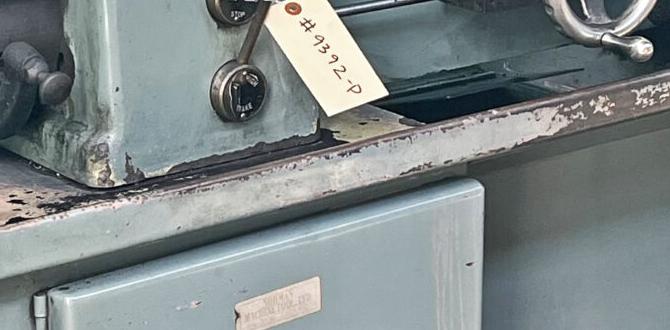

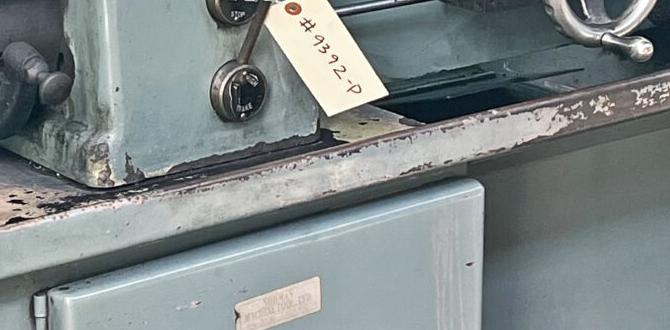

Cleaning the lathe gear train can keep your machine running smoothly. Start by disconnecting power for safety. Use a soft brush to remove dust and debris. A gentle cleaning solution helps remove grease without damaging gears. Did you know that old oil can attract dirt? Regular cleaning prevents this, ensuring longevity. Always check for wear on gears while cleaning. A quick habit to pick up can save you time and money in repairs!Understanding the Importance of Cleaning the Gear Train

Discuss the role of the gear train in lathe operation.. Explain how dirt and debris can affect performance..The gear train plays a key role in how a lathe works. It helps transfer power from the motor to the cutting tool. If dirt and debris build up, they can cause problems. The lathe can run slower or even jam. Regular cleaning keeps everything moving smoothly.

- Improves accuracy: Dirt can change how the lathe cuts.

- Increases lifespan: Clean parts last longer.

- Enhances safety: A clean lathe reduces risks of accidents.

Why is cleaning the gear train important?

Cleaning the gear train is important because it helps the lathe run better and last longer. A clean machine means safer and more precise work.Tools and Materials Needed for Gear Train Cleaning

List essential cleaning tools (brushes, solvents, etc.).. Recommend protective gear and safety measures..Cleaning your lathe gear train can be a fun challenge with the right tools! First, grab some brushes in various sizes to get into those tricky spots. Don’t forget a good solvent to break down the grease—it’s like a magic potion for dirt. And, of course, wear protective gear. Safety goggles and gloves are your best friends here; nobody wants a face full of mystery goo!

| Essential Tools | Purpose |

|---|---|

| Brushes | For scrubbing dirt and grease |

| Solvents | To dissolve grime |

| Gloves | To keep your hands clean |

| Safety Goggles | To protect your eyes |

With these simple tools, you’re ready to tackle that gunky mess! Just think of it as a spa day for your lathe. Happy cleaning!

Step-by-Step Cleaning Process

Outline the disassembly process for safe cleaning.. Provide detailed steps for cleaning each component of the gear train..Cleaning your lathe gear requires careful steps. First, turn off and unplug the lathe. Next, take pictures of the setup to help with reassembly. Then, use a small screwdriver to remove screws and gently take apart each gear component. Clean each piece using a soft brush and cloth. Ensure no dirt remains. For oil parts, a cleaning solvent works well. Wipe them down with a clean cloth to avoid rust.

- Disconnect power supply

- Document assembly with photos

- Remove screws carefully

- Use soft brush for cleaning

- Apply cleaning solvent on oily parts

What is the best way to clean a lathe gear train?

Use a soft brush and cloth. For oily parts, a cleaning solvent is effective. Ensure everything is dry before reassembly.

Common Mistakes to Avoid While Cleaning

Highlight improper cleaning techniques that can cause damage.. Discuss how neglecting certain areas can lead to issues..Cleaning a lathe gear train seems simple, but mistakes can lead to big problems. For example, using harsh chemicals can harm the gears. Skipping spots where grime loves to hide can cause future issues. Here are some common cleaning blunders:

| Common Mistakes | Why to Avoid Them |

|---|---|

| Using Strong Chemicals | They can damage gears. |

| Neglecting Tight Spaces | It leads to dirt build-up. |

| Incorrect Tools | They can scratch surfaces. |

Remember, cleaning is like a party. Don’t let dirt crash it!

Frequency of Gear Train Maintenance and Cleaning

Suggest a maintenance schedule based on usage.. Explain signs that indicate it’s time for a thorough cleaning..Regular maintenance keeps your gear train working well. If you use your lathe every day, clean it every week. If you use it less, clean it once a month. Watch for signs that cleaning is needed:

- Noise: Unusual sounds can signal dirt build-up.

- Sluggishness: If it runs slow, it might need cleaning.

- Visible grime: Dust or oil visible on parts means cleaning is due.

Keeping your lathe clean will help it last longer and work better!

How often should I clean my lathe gear train?

If you use your lathe daily, clean it weekly. For occasional use, monthly cleaning works well.

Additional Tips for Gear Train Maintenance

Offer lubrication tips for optimal performance.. Discuss environmental factors that can affect gear train cleanliness..Keeping your gear train clean and well-lubricated is key to its performance. Here are some simple tips:

- Oil Regularly: Apply lubricant every few weeks to prevent rust.

- Check the Environment: Dust and moisture can harm your gear train.

- Seal Areas: Use covers to keep dirt out, especially in humid places.

Maintaining the right conditions ensures your equipment runs smoothly. A clean gear train lasts longer and works better.

Why is lubrication important for gear trains?

The right lubrication reduces friction and wear. Without it, gears can break down quickly. Well-lubricated gears run quietly, which is nice!

What environmental factors harm gear trains?

Humidity and dust are the main culprits. They sneak in and cause trouble. Keeping gear trains clean helps avoid these issues.

Benefits of Regular Gear Train Cleaning

Explain how cleaning improves precision and efficiency.. Discuss the longterm cost savings from proper maintenance..Cleaning the gear train makes your lathe work better and last longer. Dust and grime can mess up the precision. Keeping it clean helps everything run smoothly. This means fewer mistakes and better results.

Taking care of your gear train saves money in the long run. Regular cleaning helps avoid major repairs. By spending a little time now, you can save a lot later. It’s a smart way to protect your tools.

What are the key benefits of regular gear train cleaning?

Regular cleaning improves precision, boosts efficiency, and saves money on repairs.Key Benefits:

- Improves Machine Performance

- Increases Longevity of Tools

- Reduces Repair Costs

Conclusion

In conclusion, keeping your lathe gear train clean is important for smooth operation. Regularly check for dust and debris. Use soft brushes and cleaning cloths. Lubricate the gears to prevent rust. Remember, a clean lathe runs better and lasts longer. Start these cleaning habits today! For more tips, explore resources on lathe maintenance. Happy machining!FAQs

Sure! Here Are Five Questions Related To Lathe Gear Train Cleaning Tips:Sure! Here are some tips for cleaning a lathe gear train. First, always unplug the lathe before you start cleaning. Use a cloth to wipe off any dirt and grease. You can use a small brush to reach tight spots. Finally, make sure everything is dry before plugging the lathe back in.

Sure! Just give me the question you’d like me to answer, and I’ll respond in the way you described.

What Are The Most Effective Methods For Cleaning Grease And Oil From Lathe Gear Trains?To clean grease and oil from lathe gear trains, we can use warm soapy water. Mix dish soap with warm water and scrub the parts with a brush. You can also use rags to wipe away the gunk. For tough spots, try using a little vinegar. Make sure everything is dry before putting it back together!

How Often Should The Gear Train Of A Lathe Be Cleaned To Ensure Optimal Performance?You should clean the gear train of a lathe every month or so. This keeps it running smoothly. If you use the lathe a lot, clean it more often. Always check for dirt and dust after heavy use. Keeping it clean helps your lathe last longer!

Are There Specific Cleaning Solutions Or Solvents That Are Recommended For Cleaning Lathe Gear Trains?Yes, there are good cleaning solutions for lathe gear trains. You can use mineral spirits or kerosene. These fluids help remove grease and dirt. Always be careful and wear gloves! After cleaning, make sure to wipe everything dry.

What Tools Are Necessary For Disassembling And Cleaning The Gears In A Lathe’S Gear Train?To disassemble and clean the gears in a lathe’s gear train, you need a few tools. First, use a wrench to remove any bolts. A screwdriver helps to take off covers or smaller parts. You’ll also want a brush to clean the gears. Finally, have some cloths handy to wipe everything down.

What Precautions Should Be Taken To Avoid Damaging Gears While Cleaning The Lathe’S Gear Train?To clean the gears on a lathe, you should be gentle. Use a soft cloth or brush to avoid scratches. Make sure to turn off the machine before you start. Don’t use water or strong cleaners, as they can harm the gears. Always check for loose parts after cleaning to keep everything safe and working well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Gear Train Cleaning Tips:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some tips for cleaning a lathe gear train. First, always unplug the lathe before you start cleaning. Use a cloth to wipe off any dirt and grease. You can use a small brush to reach tight spots. Finally, make sure everything is dry before plugging the lathe back in.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you’d like me to answer, and I’ll respond in the way you described.”}},{“@type”: “Question”,”name”: “What Are The Most Effective Methods For Cleaning Grease And Oil From Lathe Gear Trains?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean grease and oil from lathe gear trains, we can use warm soapy water. Mix dish soap with warm water and scrub the parts with a brush. You can also use rags to wipe away the gunk. For tough spots, try using a little vinegar. Make sure everything is dry before putting it back together!”}},{“@type”: “Question”,”name”: “How Often Should The Gear Train Of A Lathe Be Cleaned To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should clean the gear train of a lathe every month or so. This keeps it running smoothly. If you use the lathe a lot, clean it more often. Always check for dirt and dust after heavy use. Keeping it clean helps your lathe last longer!”}},{“@type”: “Question”,”name”: “Are There Specific Cleaning Solutions Or Solvents That Are Recommended For Cleaning Lathe Gear Trains?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are good cleaning solutions for lathe gear trains. You can use mineral spirits or kerosene. These fluids help remove grease and dirt. Always be careful and wear gloves! After cleaning, make sure to wipe everything dry.”}},{“@type”: “Question”,”name”: “What Tools Are Necessary For Disassembling And Cleaning The Gears In A Lathe’S Gear Train?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To disassemble and clean the gears in a lathe’s gear train, you need a few tools. First, use a wrench to remove any bolts. A screwdriver helps to take off covers or smaller parts. You’ll also want a brush to clean the gears. Finally, have some cloths handy to wipe everything down.”}},{“@type”: “Question”,”name”: “What Precautions Should Be Taken To Avoid Damaging Gears While Cleaning The Lathe’S Gear Train?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean the gears on a lathe, you should be gentle. Use a soft cloth or brush to avoid scratches. Make sure to turn off the machine before you start. Don’t use water or strong cleaners, as they can harm the gears. Always check for loose parts after cleaning to keep everything safe and working well.”}}]}