Have you ever wondered how important oil is for machines? The lathe is a fascinating tool that shapes metal and wood. But just like our cars need oil changes, so do lathes. That’s where the lathe gearbox oil change comes in.

Changing the oil in your lathe’s gearbox is more than just a chore. It helps keep your machine running smoothly and safely. Imagine trying to carve a masterpiece with a tool that’s not working right! Regular oil changes prevent this problem and can save you time and money.

Think of it as a health check-up for your lathe. You wouldn’t skip visits to the doctor, right? By maintaining the gearbox oil, you ensure your lathe can perform its best. Curious about how to do it? Let’s explore the simple steps together and keep your lathe happy!

Lathe Gearbox Oil Change: Essential Maintenance Tips

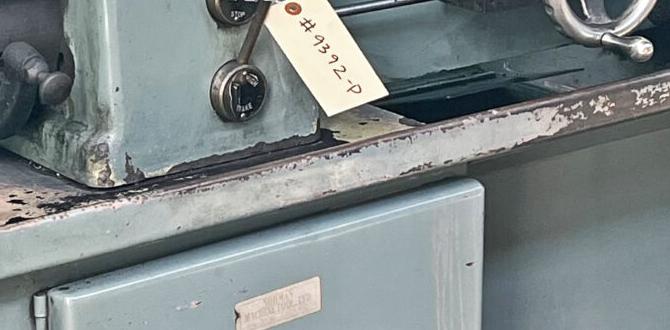

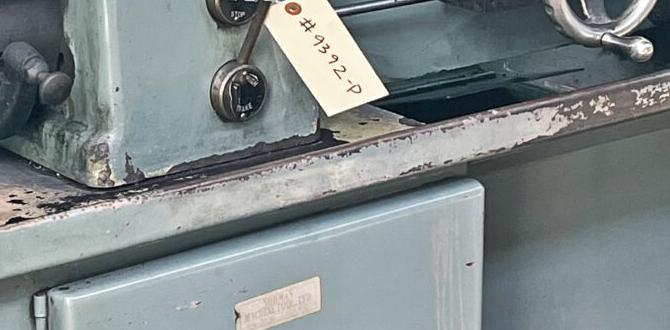

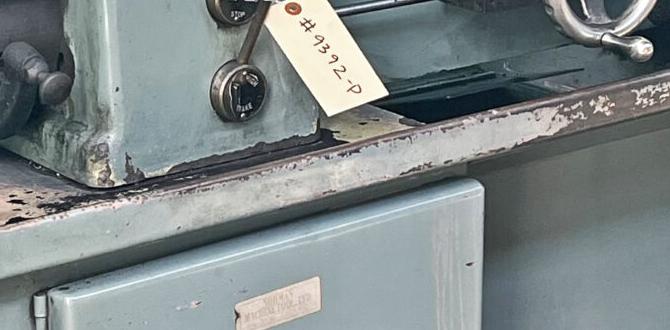

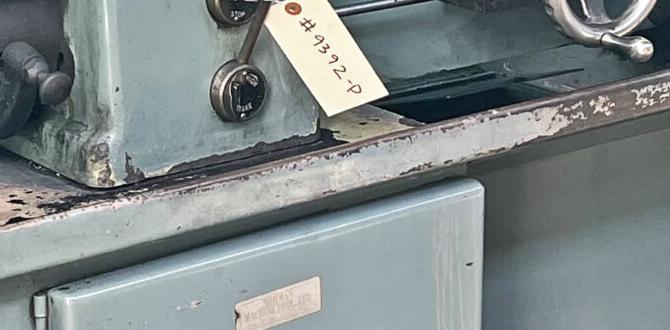

Lathe Gearbox Oil Change

Changing the oil in your lathe’s gearbox is crucial for its health. Clean oil helps the moving parts run smoothly. Did you know that dirty oil can cause wear and tear? It’s important to check oil levels regularly. A simple oil change can extend the life of your machine. Be sure to use the right type of oil, as specified in your lathe’s manual. You’ll keep your lathe happy and working efficiently!Understanding the Importance of Gearbox Oil in Lathes

Explanation of the role of gearbox oil in lathe performance. Consequences of neglecting gearbox oil maintenance.Gearbox oil is like the lifeblood of a lathe. It helps the machine run smoothly and efficiently. The oil keeps parts working well, reducing wear and tear. If you ignore gearbox oil, problems can arise. These issues can lead to costly repairs and longer downtime. Regular maintenance ensures your lathe stays in top shape.

What happens if I don’t change the gearbox oil?

Not changing the gearbox oil can cause serious damage. It can lead to:

- Overheating: This can harm your lathe.

- Worn gears: They won’t work properly.

- Shorter lifespan: Your lathe may break down sooner.

Signs that Indicate the Need for an Oil Change

Common symptoms of worn or contaminated oil. Recommended frequency for oil changes based on usage.Oil is vital for smooth lathe operation. Worn or contaminated oil can lead to problems. Look for these signs:

- Unusual noises from the machine

- Oil appears dark or muddy

- Increased vibrations during use

- Frequent overheating

Check oil often if you use your lathe daily. A change is needed every 50 hours of heavy use or every 100 hours for lighter work. Keep your lathe running well!

How often should oil be changed in a lathe?

The common rule for oil changes is every 50-100 hours of use. Daily users should change oil more frequently. This keeps the lathe healthy and efficient.

Preparation for the Oil Change Process

List of necessary tools and materials required. Safety precautions to take before starting the oil change.Before diving into the oil change, gather your tools like a treasure hunt! You’ll need a wrench set, a clean oil catch pan, and some fresh gearbox oil. Don’t forget a funnel; otherwise, you’ll have an oil fountain. Next, safety is key—wear eye protection and gloves. It’s better to keep your eyes and hands safe than to end up with an oily Picasso on your workbench!

| Tools & Materials |

|---|

| Wrench Set |

| Oil Catch Pan |

| New Gearbox Oil |

| Funnel |

| Gloves |

| Safety Glasses |

Step-by-Step Guide to Changing Gearbox Oil

Detailed instructions for draining old oil. How to clean and inspect the gearbox before refilling.Start by gathering your tools. You need a drain pan, a wrench, and fresh oil. Follow these steps to change the oil:

- Turn off the machine and unplug it for safety.

- Locate the drain plug and remove it carefully.

- Let the old oil drain completely into the pan.

Next, clean the gearbox. Wipe away dirt and grime. Check for any damage or wear. This helps ensure the new oil works well.

Once clean, replace the drain plug and fill with fresh oil. Check the level to make sure it’s just right.

How do I safely drain the oil?

To safely drain oil, always turn off and unplug your machine first. This protects you from any accidents and keeps your workspace safe.

Changing the gearbox oil is important. It keeps your lathe running smoothly. Regular checks can prevent big problems down the line.

Refilling and Maintaining Gearbox Oil Levels

Guidelines for choosing the correct amount of oil. Tips for monitoring oil levels after a change.Choosing the right amount of oil for your gearbox is key. Too little oil can cause damage. Too much can create pressure. Always check your equipment’s manual for the correct amount. After changing the oil, keep an eye on its level. Here’s how:

- Inspect the level weekly.

- Look for leaks around the gearbox.

- Change the oil at recommended intervals.

Regular checks help ensure everything runs smoothly!

How Do You Monitor Gearbox Oil Levels?

After a change, check levels weekly to avoid issues.Common Mistakes to Avoid During Oil Change

List of errors that can affect lathe operation. Best practices to ensure a successful oil change.Changing lathe gearbox oil can be tricky. Avoid these common mistakes to keep your lathe working well:

- Ignoring the manual: Always refer to your manual for oil type and procedure.

- Skipping cleanup: Dirt can spoil new oil. Clean the area before changing.

- Overfilling: Too much oil can cause leaks. Fill to the correct level.

- Using the wrong oil: Not all oils are the same. Choose one made for lathes.

Follow these best practices to succeed:

- Wear gloves for safety.

- Dispose of old oil properly.

- Check for leaks after the change.

By avoiding these pitfalls and following best practices, your lathe will work better and last longer.

What should I do before changing lathe oil?

Before changing lathe oil, ensure the machine is off and cool. Prepare your tools and have the right oil ready. Clean the area to avoid contamination.

Long-term Maintenance Tips for Lathe Gearbox Health

Routine checks and maintenance schedules. Importance of oil analysis for extended equipment life.Keeping your lathe gearbox happy is easier than pie—well, maybe easier than baking one! Regular checks are key. Set a maintenance schedule and stick to it. Think of it as a gym routine for your lathe; it needs that workout to stay in shape. Don’t skip oil changes—this is like giving your lathe some much-needed hydration. Also, oil analysis can help spot issues early. A small sample can tell you how your gearbox is feeling. Remember, a healthy lathe is a happy lathe!

| Routine Check | Frequency |

|---|---|

| Oil Level Check | Weekly |

| Oil Change | Every 100 hours of use |

| Visual Inspection | Monthly |

So, keep that lathe running smooth. It’ll thank you with perfect cuts and no funny noises—unless it’s cracking jokes!

Conclusion

In summary, changing the lathe gearbox oil is vital for smooth machine operation. Regular oil changes prevent wear and tear. Always check your manual for specific guidelines. Using the right oil keeps your lathe working well. We encourage you to plan your oil change and follow up with more research on lathe maintenance. Let’s keep your tools in great shape!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gearbox Oil Change:1. **How often should you change the oil in a lathe gearbox?** You should change the oil every six months or when it looks dirty. 2. **What type of oil should you use for a lathe gearbox?** Use the oil recommended by the lathe’s manual. It helps the machine run smoothly. 3. **How do you know when it’s time to change the oil?** You can tell by looking at the oil. If it’s dark or has debris, it’s time to change it. 4. **What tools do you need to change the oil?** You will need a wrench, a container for old oil, and a funnel for new oil. 5. **Can you change the oil by yourself?** Yes! With a little care, you can change the oil by yourself and help your lathe work better.

Sure! Please provide the question you would like me to answer.

What Type Of Oil Is Recommended For Use In A Lathe Gearbox, And How Do I Determine The Correct Viscosity?For a lathe gearbox, you should use machine oil or gear oil. Look for oil with a viscosity rating like ISO VG 68. To find the right thickness, check your lathe’s manual. It often tells you what type of oil to use. If you’re unsure, you can ask an adult for help.

How Often Should I Change The Oil In My Lathe Gearbox To Ensure Optimal Performance?You should change the oil in your lathe gearbox every six months or after a lot of use. If you see dirt or the oil looks dark, change it sooner. Fresh oil helps your lathe work better and last longer. Always check your machine’s manual for more tips on oil changes.

What Are The Steps Involved In Draining And Replacing The Oil In A Lathe Gearbox?First, you turn off the lathe and let it cool down. Next, find the oil drain plug and use a wrench to open it. Allow the old oil to pour out into a container. After draining, close the plug and add new oil through the fill hole until it’s full. Finally, check for leaks and make sure everything is tight.

Are There Specific Precautions I Should Take When Changing The Gearbox Oil In My Lathe To Avoid Damage?Yes, there are some important things to do when you change the gearbox oil in your lathe. First, make sure the machine is turned off and unplugged. Then, let the old oil cool down before you remove it. Use the right type of oil for your lathe, as listed in the manual. Finally, check for leaks after you’ve put in the new oil. This will help keep your lathe safe and working well!

How Can I Tell If The Gearbox Oil In My Lathe Needs To Be Changed, And What Signs Should I Look For?You can tell if the gearbox oil in your lathe needs changing by checking its color. If the oil looks dark or dirty, it’s time to change it. Also, if you hear strange noises while using the lathe, that might be a sign. Finally, if the lathe runs less smoothly than before, you should check the oil.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gearbox Oil Change:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “1. **How often should you change the oil in a lathe gearbox?** You should change the oil every six months or when it looks dirty. 2. **What type of oil should you use for a lathe gearbox?** Use the oil recommended by the lathe’s manual. It helps the machine run smoothly. 3. **How do you know when it’s time to change the oil?** You can tell by looking at the oil. If it’s dark or has debris, it’s time to change it. 4. **What tools do you need to change the oil?** You will need a wrench, a container for old oil, and a funnel for new oil. 5. **Can you change the oil by yourself?** Yes! With a little care, you can change the oil by yourself and help your lathe work better.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Use In A Lathe Gearbox, And How Do I Determine The Correct Viscosity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a lathe gearbox, you should use machine oil or gear oil. Look for oil with a viscosity rating like ISO VG 68. To find the right thickness, check your lathe’s manual. It often tells you what type of oil to use. If you’re unsure, you can ask an adult for help.”}},{“@type”: “Question”,”name”: “How Often Should I Change The Oil In My Lathe Gearbox To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in your lathe gearbox every six months or after a lot of use. If you see dirt or the oil looks dark, change it sooner. Fresh oil helps your lathe work better and last longer. Always check your machine’s manual for more tips on oil changes.”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Draining And Replacing The Oil In A Lathe Gearbox?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, you turn off the lathe and let it cool down. Next, find the oil drain plug and use a wrench to open it. Allow the old oil to pour out into a container. After draining, close the plug and add new oil through the fill hole until it’s full. Finally, check for leaks and make sure everything is tight.”}},{“@type”: “Question”,”name”: “Are There Specific Precautions I Should Take When Changing The Gearbox Oil In My Lathe To Avoid Damage?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some important things to do when you change the gearbox oil in your lathe. First, make sure the machine is turned off and unplugged. Then, let the old oil cool down before you remove it. Use the right type of oil for your lathe, as listed in the manual. Finally, check for leaks after you’ve put in the new oil. This will help keep your lathe safe and working well!”}},{“@type”: “Question”,”name”: “How Can I Tell If The Gearbox Oil In My Lathe Needs To Be Changed, And What Signs Should I Look For?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell if the gearbox oil in your lathe needs changing by checking its color. If the oil looks dark or dirty, it’s time to change it. Also, if you hear strange noises while using the lathe, that might be a sign. Finally, if the lathe runs less smoothly than before, you should check the oil.”}}]}