Have you ever wondered how machines create precise shapes from metal? It’s fascinating! One essential part of this process is the lathe. The lathe headstock holds everything in place, making sure it works smoothly. But what if I told you that the lathe headstock can’t do its job without proper bearings?

Bearings allow movement while keeping things steady. Without them, your metal lathe chuck might wobble or misalign. Imagine trying to build a toy car from metal, only to have the wheels not align. Frustrating, right?

Using a quality lathe headstock bearing can change everything. It ensures your projects turn out just right. When you understand how these parts work together, you can make amazing things!

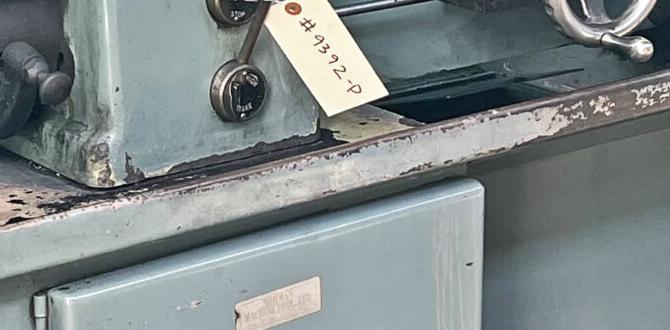

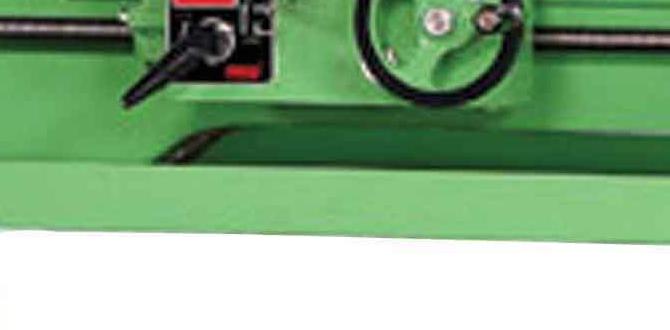

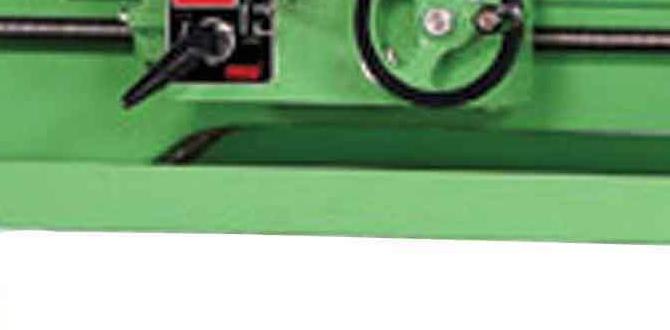

Lathe Headstock Bearing: Essential For Metal Lathe Chuck

Lathe Headstock Bearing Metal Lathe Chuck

Lathe headstock bearings are crucial for smooth operation. They hold the spindle, allowing it to rotate freely. A well-maintained bearing can enhance precision and extend your lathe’s life. Choosing the right metal lathe chuck is just as important. It secures your workpiece tightly, preventing slips during cutting. Imagine trying to craft a masterpiece, only to have your material shift unexpectedly! Understanding these components can greatly improve your lathe experience.Understanding Lathe Headstock Bearings

Definition and function of headstock bearings in a lathe.. Types of bearings commonly used in lathe headstocks..Headstock bearings are key parts of a lathe. They help the spindle turn smoothly. This allows for precise cutting and shaping of materials. There are several types of bearings used in headstocks. Ball bearings are common because they reduce friction. Roller bearings are also popular for heavy loads.

- Ball Bearings: Great for speed and reduced friction.

- Roller Bearings: Handle heavy loads well.

- Plain Bearings: Simple and cost-effective.

What are the functions of headstock bearings?

Headstock bearings keep the spindle stable and reduce wobbling. This helps make precise cuts in materials like wood and metal. By ensuring smooth movement, they improve the lathe’s performance.

Importance of Quality Bearings in Metal Lathes

How bearing quality affects performance and accuracy.. The impact of worn bearings on metal lathe operations..Quality bearings are like the secret sauce for metal lathes. They keep things running smoothly and accurately. Without good bearings, your lathe could wobble and produce wonky shapes. Worn bearings? They can turn your perfect project into a comedy show of mistakes! A small drop in performance can lead to big problems, including less precise cuts and bad finishes. Remember, a happy lathe makes a happy machinist!

| Bearing Condition | Effects on Performance |

|---|---|

| New | High accuracy and smooth operation |

| Worn | Decreased precision and potential damage |

Choosing the Right Lathe Headstock Bearing

Factors to consider when selecting bearings for different lathe models.. Comparison of popular bearing brands and their specifications..Choosing the right lathe headstock bearing is essential for smooth operations. Consider the type of lathe and its requirements. Each model may need a different bearing size or material for optimal performance. Popular brands vary in specifications. Here is a quick comparison:

- Brand A: Known for durability and quiet operation.

- Brand B: Offers high speed and precision.

- Brand C: Best for heavy-duty tasks.

Each brand has its strengths. Match the bearing with your lathe model for the best results.

What factors should I consider for lathe headstock bearings?

Look for compatibility, durability, and precision. These features ensure smoother operations and longer-lasting performance.

Popular Bearing Brands and Specifications:

- Brand A: Excellent durability

- Brand B: High performance

- Brand C: Heavy-duty reliability

Installation Process for Lathe Headstock Bearings

Stepbystep guide for installing bearings properly.. Tools and equipment needed for a successful installation..To install lathe headstock bearings, follow these simple steps for success. First, gather the right tools. You will need a wrench, screwdriver, and bearing grease. Next, remove the old bearings. Clean the area well to avoid dirt. Place the new bearings in the correct position and secure them tightly. Finally, apply grease for smooth movement.

- Wrench

- Screwdriver

- Bearing grease

This process makes it easy to keep your lathe running well!

What tools do I need for installing lathe headstock bearings?

You need a wrench, screwdriver, and bearing grease for the installation. Make sure you have these tools ready!

Maintenance Tips for Lathe Headstock Bearings

Recommended maintenance routines to extend bearing life.. Signs of bearing failure and when to replace them..Taking care of your lathe headstock bearings is essential. Regular maintenance can help them last longer. Here are some simple tips:

- Keep the bearings clean and lubricated.

- Check for unusual noises or vibrations.

- Look for signs of wear, like rust or discoloration.

If you notice poor performance, it may be time to replace them. Regular checks can save you time and money. Remember, early action helps avoid bigger problems!

How do I know when to replace my lathe bearings?

Watch for excessive noise or irregular movement. If the bearings feel hot, it’s a sign to look closer. Don’t wait too long; replace them as needed!

Upgrading Your Lathe Headstock Bearings

Benefits of upgrading to highperformance bearings.. How upgrades can enhance chuck performance and overall machining efficiency..Upgrading the bearings in your lathe can make a big difference. New, high-performance bearings improve how the chuck works. This means cleaner cuts and smoother operations. You can finish projects faster and with better quality. Here are some good reasons to upgrade:

- Improved precision in your work.

- Less wear and tear on the lathe parts.

- Longer lifespan for your machine.

With upgrades, your machining efficiency grows. You can take on more complex tasks easily. Your lathe becomes a better tool for all your projects.

What does upgrading bearings do?

Upgrading to high-performance bearings boosts speed and accuracy. This helps ensure your chuck runs smoothly, leading to high-quality work.

Conclusion

In summary, the lathe headstock, bearing, and metal lathe chuck are vital parts of a lathe. They help hold and turn materials smoothly. Understanding these components can improve your lathe skills. If you want to learn more, consider checking out tutorials or videos online. Start experimenting with your lathe and see the difference!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Chuck:Sure! A lathe headstock bearing helps the lathe spin smoothly. When we use a metal lathe, it shapes metal pieces. The chuck is the part that holds the metal tightly. This way, the metal doesn’t move while we work on it. A good bearing makes everything work better!

Sure! Please provide the question you’d like me to answer.

What Are The Common Types Of Bearings Used In The Headstock Of A Metal Lathe, And How Do They Affect Machining Precision?In a metal lathe, we often find three types of bearings: plain bearings, ball bearings, and roller bearings. Plain bearings are simple and let the spindle slide smoothly. Ball bearings use small balls to reduce friction, helping parts move easily. Roller bearings add more support and stability. All these bearings help keep the lathe parts in the right place, which makes our cuts precise and accurate.

How Do You Properly Maintain And Lubricate The Bearings In A Lathe Headstock To Ensure Optimal Performance?To keep the bearings in a lathe headstock working well, you need to clean them regularly. First, turn off the lathe and unplug it. Then, wipe away any dirt with a soft cloth. Next, use a good oil or grease made for machines and put it on the bearings. Be careful not to use too much! Finally, check them often to make sure they stay in good shape. This helps your lathe work better and last longer.

What Are The Key Factors To Consider When Selecting A Chuck For A Metal Lathe, And How Do They Influence Workpiece Stability?When picking a chuck for a metal lathe, you want to think about size, type, and grip. The size needs to match your lathe and workpiece. Different types, like three-jaw or four-jaw chucks, hold things in different ways. Good grip helps keep your workpiece steady while you work. A strong grip means fewer mistakes and safer projects.

How Does The Design Of The Lathe Headstock Impact The Overall Rigidity And Accuracy Of The Lathe During Operation?The lathe headstock is the strong part that holds the motor and the workpiece. A well-designed headstock makes the lathe more sturdy. This means it doesn’t shake much when it’s working. When it’s steady, the lathe can make more precise cuts. So, a good headstock design helps us create better and more accurate pieces.

What Troubleshooting Steps Can Be Taken If A Metal Lathe’S Headstock Bearings Are Causing Abnormal Noises Or Vibrations?If your metal lathe is making strange noises or shaking, we can check a few things. First, make sure the lathe is turned off and unplugged. Then, look for any loose parts and tighten them. Next, check the bearings for dirt or damage. If they look dirty, clean them gently. If they seem worn out, you might need to replace them with new ones.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Chuck:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe headstock bearing helps the lathe spin smoothly. When we use a metal lathe, it shapes metal pieces. The chuck is the part that holds the metal tightly. This way, the metal doesn’t move while we work on it. A good bearing makes everything work better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Bearings Used In The Headstock Of A Metal Lathe, And How Do They Affect Machining Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe, we often find three types of bearings: plain bearings, ball bearings, and roller bearings. Plain bearings are simple and let the spindle slide smoothly. Ball bearings use small balls to reduce friction, helping parts move easily. Roller bearings add more support and stability. All these bearings help keep the lathe parts in the right place, which makes our cuts precise and accurate.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Lubricate The Bearings In A Lathe Headstock To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the bearings in a lathe headstock working well, you need to clean them regularly. First, turn off the lathe and unplug it. Then, wipe away any dirt with a soft cloth. Next, use a good oil or grease made for machines and put it on the bearings. Be careful not to use too much! Finally, check them often to make sure they stay in good shape. This helps your lathe work better and last longer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Chuck For A Metal Lathe, And How Do They Influence Workpiece Stability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a chuck for a metal lathe, you want to think about size, type, and grip. The size needs to match your lathe and workpiece. Different types, like three-jaw or four-jaw chucks, hold things in different ways. Good grip helps keep your workpiece steady while you work. A strong grip means fewer mistakes and safer projects.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Lathe Headstock Impact The Overall Rigidity And Accuracy Of The Lathe During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe headstock is the strong part that holds the motor and the workpiece. A well-designed headstock makes the lathe more sturdy. This means it doesn’t shake much when it’s working. When it’s steady, the lathe can make more precise cuts. So, a good headstock design helps us create better and more accurate pieces.”}},{“@type”: “Question”,”name”: “What Troubleshooting Steps Can Be Taken If A Metal Lathe’S Headstock Bearings Are Causing Abnormal Noises Or Vibrations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe is making strange noises or shaking, we can check a few things. First, make sure the lathe is turned off and unplugged. Then, look for any loose parts and tighten them. Next, check the bearings for dirt or damage. If they look dirty, clean them gently. If they seem worn out, you might need to replace them with new ones.”}}]}