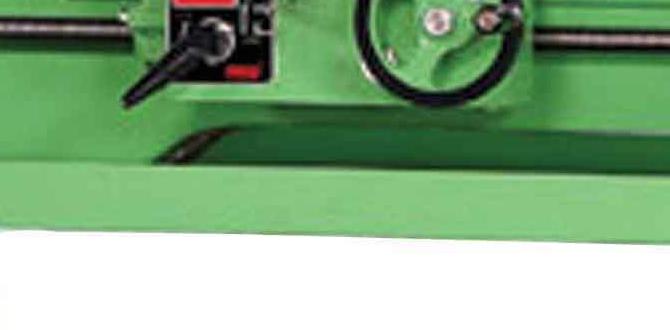

Have you ever wondered how a metal lathe works? It’s fascinating! At the heart of this amazing machine lies the lathe headstock. The headstock rotates and holds the workpiece. But do you know what makes it run smoothly? It’s the headstock bearing. This small component plays a big role in keeping everything on track.

Now, imagine trying to control a metal lathe without a controller. It would be like steering a car without a steering wheel! A lathe controller is what helps you make precise adjustments. Together, the lathe headstock bearing and the controller create magic in the workshop.

In this article, we will explore the importance of these components. Let’s dive in and discover how they work together to create beautiful shapes from raw metal. You might find it more exciting than you think!

Understanding Lathe Headstock Bearing: The Metal Lathe Controller

Understanding Lathe Headstock Bearing and Metal Lathe Controller

Lathe headstock bearings play a crucial role in the smooth operation of a metal lathe. These bearings support the spindle, allowing for accurate cutting and shaping. Without proper support, the lathe might produce uneven workpieces. Did you know that a malfunctioning bearing can lead to costly repairs or accidents? A metal lathe controller helps adjust the speed and feed rate, ensuring precise settings for various materials. Learning about these components can improve your machining skills and results!Understanding Lathe Headstock Bearings

Definition and function of headstock bearings. Importance of bearing quality in metal lathe performance.Headstock bearings play a crucial role in metal lathes. They help hold the spindle in place and allow it to rotate smoothly. A good bearing allows for precise cuts and helps improve the lathe’s overall performance. Without quality bearings, lathes can wobble, leading to errors. This can ruin projects and waste time. Choosing the right bearings is key for any lathe user.

Why are headstock bearings important?

Quality bearings ensure better machine performance. They allow the lathe to operate smoothly and accurately. This makes a difference in the final product and boosts the lathe’s lifespan.

Key points about headstock bearings:

- They support the spindle.

- They help avoid vibrations.

- They affect cutting accuracy.

- Good quality enhances durability.

Identifying Signs of Headstock Bearing Wear

Common symptoms of failing headstock bearings. How to assess bearing condition through visual inspection.Watch for signs that your headstock bearings may be wearing out. Common symptoms include strange noises, like grinding or chirping, during operation. The lathe might vibrate more than usual, too. Inspecting the bearings visually is important. Look for wear marks, rust, or dirt buildup. Here’s a quick checklist to help you assess their condition:

- Odd noises when the lathe runs

- Excessive vibration

- Visible wear or damage

- Rust or dirt accumulation

Addressing these issues early can prevent bigger problems later.

What are the signs of failing headstock bearings?

Common signs include strange noises and excessive vibration. Look for visible wear or rust during inspection. Fixing these problems quickly is key to keeping your lathe running smoothly.

How to Replace Lathe Headstock Bearings

Stepbystep process for bearing replacement. Tools required for a successful replacement.Replacing lathe headstock bearings can seem tricky, but it’s easier than baking a cake without a recipe! First, gather your tools: a wrench, a screwdriver, and new bearings. Now, follow these steps. First, switch off your lathe to avoid any sneaky injuries. Then, remove the headstock cover. Next, take out the old bearings carefully. Finally, fit the new ones in place and reassemble everything. Voilà! You’re ready to make some sparks fly again!

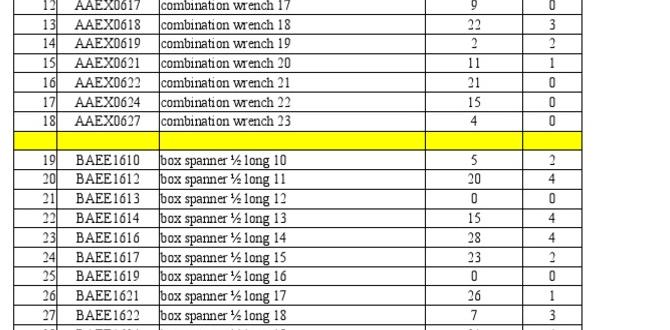

| Tools Required | Description |

|---|---|

| Wrench | To loosen and tighten bolts with ease. |

| Screwdriver | For removing screws from the headstock cover. |

| New Bearings | Ensure smooth operation and no squeaking! |

Choosing the Right Metal Lathe Controller

Features to consider when selecting a controller. Comparison of top metal lathe controllers in the market.Picking the right metal lathe controller is crucial for your projects. First, think about the essential features, like speed control and user-friendliness. A controller should help, not confuse! Compare popular options to find the best fit for you. Some folks say a good controller can make your lathe feel like a superhero. Here’s a quick comparison of top controllers on the market:

| Controller Model | Speed Control | User-Friendly | Price |

|---|---|---|---|

| Model A | Yes | Very Easy | $150 |

| Model B | Yes | Moderate | $200 |

| Model C | No | Easy | $100 |

Choose wisely to craft your masterpieces without a hitch! Remember, a great metal lathe controller can save you time and headaches, making your projects more enjoyable.

Integration of Controllers with Lathe Headstock Bearings

How controller settings can affect bearing life. Importance of calibrating controllers for optimal performance.Controllers play a big role in how long lathe headstock bearings last. Correct settings can prevent wear and tear. When a controller is properly calibrated, it helps the bearings work better. This means less friction and longer life. If a controller is off, it can wear the bearings quickly. Here are some key points:

- Calibration: It should match the lathe’s needs.

- Performance: Better settings lead to smoother operation.

- Longevity: Proper adjustments extend bearing life.

How does controller setting affect bearing life?

Controller settings can extend bearing life by reducing friction and ensuring smooth performance. Proper calibration is key for optimal operation. This prevents excessive wear and keeps the lathe running smoothly.

Maintenance Tips for Longevity of Headstock Bearings and Controllers

Recommended maintenance practices. Schedule for routine checks and lubrication.To keep your lathe headstock bearings and controllers running smoothly, regular care is essential. Following these simple maintenance practices can increase their lifespan:

- Check for any dirt or debris monthly.

- Clean the bearings regularly to prevent wear.

- Lubricate the bearings every three months.

- Inspect for unusual noises during operation.

By staying on top of these tasks, you’ll ensure that your equipment stays in top shape. Remember, a little effort goes a long way!

How often should I check and lubricate my lathe headstock bearings?

It’s a good idea to inspect and lubricate your lathe headstock bearings every three months. Checking monthly for dirt is also helpful.

Common Issues and Troubleshooting for Lathe Headstock Bearings and Controllers

Troubleshooting common problems with bearings. Solutions for controllerrelated malfunctions.Common problems with lathe headstock bearings can lead to frustrating delays. Sometimes, your bearings may produce noise or feel rough. This often means they need lubrication or replacement. Controllers may also fail, causing issues like erratic movements. Always check the connections and restart the unit to see if that helps. Here are some simple fixes:

- Check for dirt or dust around the bearings.

- Lubricate bearings regularly.

- Inspect controller wires for damage.

- Calibrate the controller settings.

What should I do if my lathe doesn’t run?

If your lathe doesn’t run, check the power supply first. Ensure everything is plugged in. If it still doesn’t work, reset the controller and inspect the circuit for issues.

FAQs About Lathe Headstock Bearings and Controllers

Answers to frequently asked questions. Clarifications on misconceptions about lathe components.Many people wonder about lathes and their parts. Here are some common questions answered:

What are headstock bearings?

Headstock bearings support the spindle. They help it spin smoothly. This is important for making precise cuts.

Do controllers affect performance?

Yes, controllers help manage speed and power. A good controller ensures your lathe works effectively.

- Can I replace headstock bearings myself? Yes, but you need proper tools and knowledge.

- What happens if bearings wear out? The lathe may vibrate and produce poor-quality work.

Understanding these parts helps people use lathes better!

Conclusion

In summary, the lathe headstock bearing is vital for smooth operation. A good metal lathe controller helps regulate speed and power. Understanding these parts improves your skills and projects. You can enhance your lathe experience by maintaining these components regularly. For more tips, consider checking guides or videos on lathe maintenance. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Controller:A lathe is a machine that helps us shape metal. The headstock is the part that holds and spins the piece of metal. Bearings in the headstock help the metal turn smoothly. If we use a controller, it helps us decide how fast the metal spins. This makes it easier to create shapes we want.

Sure! Just ask your question, and I’ll provide a short answer for you.

What Types Of Bearings Are Commonly Used In The Headstock Of Metal Lathes, And How Do They Affect Machining Accuracy?Metal lathes often use plain bearings or ball bearings in their headstocks. Plain bearings are simple and keep everything steady. Ball bearings allow for smooth spinning and reduce friction. When the bearings work well, they help make our cuts more precise. This means our finished pieces look and fit better!

How Can The Alignment Of A Lathe Headstock Bearing Impact The Performance And Lifespan Of The Metal Lathe?The alignment of a lathe headstock bearing is very important. If it’s not lined up correctly, the lathe can shake or make bad cuts. This can wear out parts faster and break things. When everything is aligned well, the lathe runs smoothly and lasts longer. So, keeping it aligned helps make better things and saves money!

What Role Does The Lathe Controller Play In Managing The Speed And Torque Of The Headstock During Machining Operations?The lathe controller acts like a boss for the machine. It controls how fast the headstock turns and how much power it uses. When we change the speed, the controller makes sure everything runs smoothly. This helps us make better shapes and cuts from the materials we are using. So, it makes our work easier and safer!

What Are The Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can They Be Diagnosed And Addressed By Operators?You can notice signs of wear in lathe headstock bearings by hearing strange noises or feeling vibrations. If the lathe gets harder to turn or if it shakes, that’s a problem too. To check for issues, we can look for oil leaks and feel the bearings for rough spots. If we find any trouble, we can clean the bearings, add new oil, or even replace them if needed. Taking care of these parts helps keep the lathe running smooth!

How Do Modern Cnc Lathe Controllers Differ From Traditional Manual Systems In Terms Of Headstock Operation And Bearing Management?Modern CNC (Computer Numerical Control) lathes use computers to control the headstock. This means they can move parts very precisely, unlike manual lathes that require you to move everything by hand. The bearings in CNC lathes are often better at reducing friction, helping the machine run smoothly. We get less wear and tear on the parts over time. This makes CNC lathes faster and more accurate than traditional ones.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Controller:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe is a machine that helps us shape metal. The headstock is the part that holds and spins the piece of metal. Bearings in the headstock help the metal turn smoothly. If we use a controller, it helps us decide how fast the metal spins. This makes it easier to create shapes we want.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll provide a short answer for you.”}},{“@type”: “Question”,”name”: “What Types Of Bearings Are Commonly Used In The Headstock Of Metal Lathes, And How Do They Affect Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes often use plain bearings or ball bearings in their headstocks. Plain bearings are simple and keep everything steady. Ball bearings allow for smooth spinning and reduce friction. When the bearings work well, they help make our cuts more precise. This means our finished pieces look and fit better!”}},{“@type”: “Question”,”name”: “How Can The Alignment Of A Lathe Headstock Bearing Impact The Performance And Lifespan Of The Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The alignment of a lathe headstock bearing is very important. If it’s not lined up correctly, the lathe can shake or make bad cuts. This can wear out parts faster and break things. When everything is aligned well, the lathe runs smoothly and lasts longer. So, keeping it aligned helps make better things and saves money!”}},{“@type”: “Question”,”name”: “What Role Does The Lathe Controller Play In Managing The Speed And Torque Of The Headstock During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe controller acts like a boss for the machine. It controls how fast the headstock turns and how much power it uses. When we change the speed, the controller makes sure everything runs smoothly. This helps us make better shapes and cuts from the materials we are using. So, it makes our work easier and safer!”}},{“@type”: “Question”,”name”: “What Are The Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can They Be Diagnosed And Addressed By Operators?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can notice signs of wear in lathe headstock bearings by hearing strange noises or feeling vibrations. If the lathe gets harder to turn or if it shakes, that’s a problem too. To check for issues, we can look for oil leaks and feel the bearings for rough spots. If we find any trouble, we can clean the bearings, add new oil, or even replace them if needed. Taking care of these parts helps keep the lathe running smooth!”}},{“@type”: “Question”,”name”: “How Do Modern Cnc Lathe Controllers Differ From Traditional Manual Systems In Terms Of Headstock Operation And Bearing Management?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern CNC (Computer Numerical Control) lathes use computers to control the headstock. This means they can move parts very precisely, unlike manual lathes that require you to move everything by hand. The bearings in CNC lathes are often better at reducing friction, helping the machine run smoothly. We get less wear and tear on the parts over time. This makes CNC lathes faster and more accurate than traditional ones.”}}]}