Have you ever wondered how metal lathe operations create precise parts? It’s fascinating how a lathe can transform solid metal into intricate shapes. At the heart of this process lies an important component: the lathe headstock bearing. This part is crucial for smooth and accurate operations.

The lathe headstock bearing helps reduce friction. This makes everything run smoothly. Imagine trying to ride a bike with a flat tire. It just doesn’t work well, right? In the same way, without a good bearing, a lathe struggles to perform.

Many do not realize that the right bearing can make a huge difference. It can improve the quality of your finished parts. This is why understanding lathe headstock bearings is vital for anyone interested in metalworking.

Whether you’re a beginner or a pro, knowing how to care for your lathe is essential. Are you ready to dive deeper into the world of lathe headstock bearing and discover how it impacts your metal lathe operations?

Lathe Headstock Bearing: Essential For Metal Lathe Operations

Lathe Headstock Bearing: Key to Smooth Metal Lathe Operations

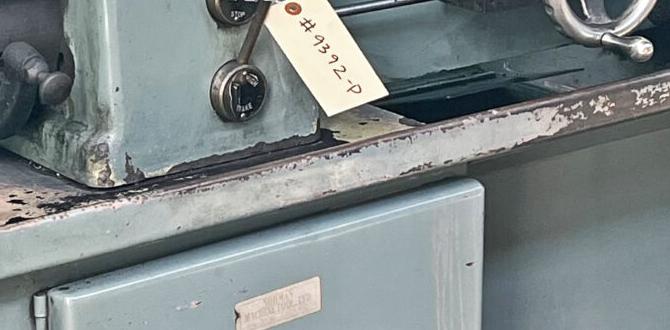

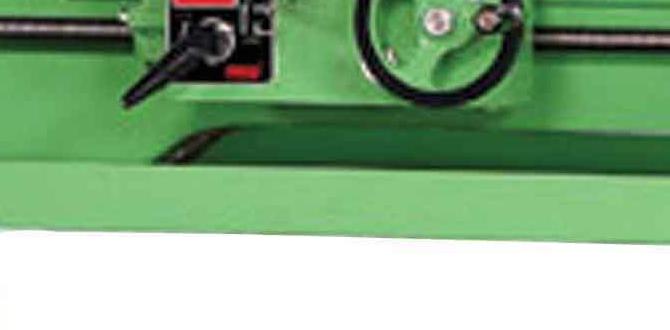

Have you ever wondered how lathes work so smoothly? The secret often lies in the lathe headstock bearing. This special part supports the spindle and allows it to turn effortlessly. With proper maintenance, the bearing ensures precision in metal lathe operations. Using quality bearings can reduce wear and tear on your machine. Did you know that a worn bearing can cause costly repairs? Keeping an eye on this component is vital for any metalworker. Discover the impact of good bearings and improve your projects!What is a Lathe Headstock Bearing?

Definition and purpose of the headstock bearing in a lathe.. Types of bearings used in metal lathes..A lathe headstock bearing is a crucial part of a lathe machine. Its main job is to support the spindle, allowing it to spin smoothly. Think of it as the cozy chair for the spinning top in the playground—it keeps everything steady and happy! There are several types of bearings used in metal lathes, each with its own special traits. Some common ones are ball bearings and roller bearings, which fancy up the spinning without causing a ruckus.

| Type of Bearing | Description |

|---|---|

| Ball Bearing | Great for speed and low friction! |

| Roller Bearing | Best for heavier loads! |

So, whether you’re crafting a masterpiece or just trying to impress your friends, the headstock bearing has your back! Remember, without it, your lathe would be spinning out of control—like a whirling dervish on a caffeine rush!

Importance of Headstock Bearings in Metal Lathe Operations

Role in precision and accuracy during machining.. Impact on the overall performance and longevity of the lathe..Headstock bearings play a big role in the world of metal lathe operations. They help keep everything running smoothly. With good bearings, you get better precision and accuracy when cutting. Imagine trying to slice bread with a wobbly knife—chaos! Right? On top of that, solid bearings can extend the life of your lathe, saving you time and money in repairs.

| Benefits of Good Bearings | Impact |

|---|---|

| Improves Cutting | Enhanced precision |

| Less Vibration | Better performance |

| Longer Lifespan | Cost savings |

So, keep those bearings in check, or your lathe might start doing the cha-cha instead of working!

Common Types of Headstock Bearings

Comparison between plain bearings and ball bearings.. Advantages and disadvantages of each type..Headstock bearings play a key role in metal lathe operations. Two common types are plain bearings and ball bearings. Plain bearings are simple and easy to maintain. They provide smooth motion but can wear out faster. On the flip side, ball bearings are like the cool kids of bearings. They handle heavy loads and reduce friction well, but they can be pricier. Here’s a quick comparison:

| Type | Advantages | Disadvantages |

|---|---|---|

| Plain Bearings | Easy to maintain, cost-effective | Wear out faster, limited speed |

| Ball Bearings | High load capacity, less friction | More complex, higher cost |

Choosing the right bearing depends on your lathe’s needs. Remember, in the world of metalworking, it’s not just about spinning; it’s about spinning smart!

Factors to Consider When Choosing Headstock Bearings

Load capacity and operating speed considerations.. Material choice and its effect on durability..Choosing the right headstock bearings is like picking the right shoes: you need comfort and durability! First, think about load capacity. Your bearings must handle the weight without giving up and falling flat. Next, consider the operating speed. If they spin too slowly, it’s like a snail race—boring! Also, the material matters. Stronger materials mean a longer lifespan. Think of it as choosing between a plastic toy and a sturdy action figure. Stronger is usually better!

| Factor | Importance |

|---|---|

| Load Capacity | Handles weight without failure |

| Operating Speed | Ensures smooth operation |

| Material | Affects durability and wear |

Maintenance Tips for Lathe Headstock Bearings

Regular inspection methods to detect wear.. Lubrication practices and recommended products..Keeping your lathe headstock bearings in tip-top shape is like giving your favorite pet a good scratch behind the ears. Regular checks are key! Look for any strange noises or rough movements; they’re like the canary in a coal mine for wear and tear. Use the right grease, too! A quality lubricant will keep your bearings happy and your lathe spinning smoothly. Check out the table below for some recommended products:

| Lubricant | Type | Best For |

|---|---|---|

| Mobil DTE 24 | Oil | General lubrication |

| ISO VG 46 | Oil | High-speed operations |

| Grease XL 2000 | Grease | Heavy loads |

Remember to keep your eyes peeled and your bearings well-greased! It’ll make your lathe feel as good as new.

Signs of Failing Headstock Bearings

Common symptoms and noises indicating bearing issues.. Consequences of neglecting headstock bearing maintenance..Many signs can show that your headstock bearings are not working well. You might hear strange noises, like grinding or squeaking. You could also feel vibrations during use. If ignored, these problems can lead to bigger issues. Broken bearings can cause damage to the lathe and may lead to costly repairs.

- Unusual sounds: Grinding or rattling noises.

- Increased vibrations: Tension when operating the lathe.

- Lubrication issues: Signs of oil leaks.

Keep your bearings well-maintained to avoid these problems. Regular checks can save time and money!

What are the symptoms of bad headstock bearings?

Bad headstock bearings show signs like noisy operation or excessive vibration. Addressing these signs early helps prevent major damage.

Replacing Headstock Bearings: A Step-by-Step Guide

Tools and materials required for replacement.. Detailed procedure for safely replacing bearings..To replace headstock bearings, you need some specific tools and materials. Gather a wrench set, hammer, bearing puller, and lubricant. It’s important to have the right replacement bearings ready too. Safety gear like gloves and goggles will keep you protected.

Here’s how you can safely replace bearings:

- First, unplug the lathe.

- Remove the old bearings carefully.

- Clean the area and install the new bearings.

- Make sure everything is secure.

Always check twice to ensure everything is in its place. A safe workspace helps prevent accidents. Happy machining!

What tools do I need for replacing lathe headstock bearings?

You will need a wrench set, hammer, bearing puller, lubricant, and safety gear like gloves and goggles.

Upgrading Headstock Bearings for Enhanced Performance

Benefits of upgrading to highperformance bearings.. Popular upgrades and their impacts on lathe operations..Upgrading to high-performance bearings offers many benefits. These bearings can make your lathe run smoother and faster. Less friction means better precision. This upgrade often leads to longer machine life and less maintenance. Popular options include ceramic and sealed bearings. They improve efficiency and hold up under heavy use.

- Higher accuracy in cuts

- Greater durability

- Quieter operation

What makes high-performance bearings better?

High-performance bearings reduce friction and heat. They help the lathe work more efficiently.

Conclusion

In summary, lathe headstock bearings are crucial for smooth metal lathe operations. They support the spindle and help with precise movements. Keeping bearings clean and well-lubricated extends their life. You can improve your lathe skills by practicing regularly. For more tips, check out books or videos on metalworking. Let’s keep learning and get better at using our lathes!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing And Metal Lathe Operations:Sure! A lathe is a machine that helps shape metal or wood. The headstock is a part that holds the tools to cut. Bearings are like wheels that help parts move smoothly. When we use a lathe, we must keep it clean and oiled. This makes our work easier and helps the lathe last longer.

Sure! Please provide the question you’d like me to answer, and I’ll keep it simple and clear for you.

What Are The Different Types Of Bearings Used In The Headstock Of A Metal Lathe, And How Do They Impact The Lathe’S Performance?In a metal lathe’s headstock, we can find different types of bearings. There are plain bearings, ball bearings, and roller bearings. Plain bearings are simple and good for slow speeds. Ball bearings let the lathe spin quickly and smoothly. Roller bearings help handle heavy loads well. The choice of bearing affects how fast and accurately the lathe can work.

How Can Excessive Wear In The Headstock Bearings Affect The Accuracy And Finish Of Machined Parts On A Lathe?Excessive wear in the headstock bearings can cause the lathe to wobble. When this happens, the pieces you are making may not be shaped correctly. This wobbling can also make the surface of the parts look rough instead of smooth. Overall, it makes your work less accurate and less pretty.

What Are The Common Signs That Indicate The Headstock Bearings On A Metal Lathe Need Maintenance Or Replacement?If the headstock bearings on your metal lathe are worn out, you might notice some signs. First, you could hear strange noises, like grinding or squeaking sounds. Next, the lathe may shake or vibrate more than usual when it’s running. Lastly, the spindle might not turn smoothly and can feel tight or stuck. These signs mean it’s time to check or replace the bearings.

How Does Lubrication Play A Role In The Longevity And Functionality Of Lathe Headstock Bearings?Lubrication helps keep the lathe headstock bearings moving smoothly. It reduces friction, which means less heat and wear. When we add oil or grease, we help the bearings last longer. This way, they work better and don’t break down as fast. Taking care of lubrication is like keeping the machines happy!

What Procedures Should Be Followed To Properly Align And Adjust Headstock Bearings For Optimal Operation In A Metal Lathe?To align and adjust headstock bearings on a metal lathe, first, turn off the machine and unplug it for safety. Next, look for the adjustment screws on the bearings. You can turn these screws slowly to make the bearings snug but not too tight. After adjusting, check to see if the lathe spindle turns smoothly. Finally, plug in the lathe, turn it on, and test it to make sure everything works well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing And Metal Lathe Operations:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal or wood. The headstock is a part that holds the tools to cut. Bearings are like wheels that help parts move smoothly. When we use a lathe, we must keep it clean and oiled. This makes our work easier and helps the lathe last longer.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll keep it simple and clear for you.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Bearings Used In The Headstock Of A Metal Lathe, And How Do They Impact The Lathe’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe’s headstock, we can find different types of bearings. There are plain bearings, ball bearings, and roller bearings. Plain bearings are simple and good for slow speeds. Ball bearings let the lathe spin quickly and smoothly. Roller bearings help handle heavy loads well. The choice of bearing affects how fast and accurately the lathe can work.”}},{“@type”: “Question”,”name”: “How Can Excessive Wear In The Headstock Bearings Affect The Accuracy And Finish Of Machined Parts On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Excessive wear in the headstock bearings can cause the lathe to wobble. When this happens, the pieces you are making may not be shaped correctly. This wobbling can also make the surface of the parts look rough instead of smooth. Overall, it makes your work less accurate and less pretty.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate The Headstock Bearings On A Metal Lathe Need Maintenance Or Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the headstock bearings on your metal lathe are worn out, you might notice some signs. First, you could hear strange noises, like grinding or squeaking sounds. Next, the lathe may shake or vibrate more than usual when it’s running. Lastly, the spindle might not turn smoothly and can feel tight or stuck. These signs mean it’s time to check or replace the bearings.”}},{“@type”: “Question”,”name”: “How Does Lubrication Play A Role In The Longevity And Functionality Of Lathe Headstock Bearings?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lubrication helps keep the lathe headstock bearings moving smoothly. It reduces friction, which means less heat and wear. When we add oil or grease, we help the bearings last longer. This way, they work better and don’t break down as fast. Taking care of lubrication is like keeping the machines happy!”}},{“@type”: “Question”,”name”: “What Procedures Should Be Followed To Properly Align And Adjust Headstock Bearings For Optimal Operation In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and adjust headstock bearings on a metal lathe, first, turn off the machine and unplug it for safety. Next, look for the adjustment screws on the bearings. You can turn these screws slowly to make the bearings snug but not too tight. After adjusting, check to see if the lathe spindle turns smoothly. Finally, plug in the lathe, turn it on, and test it to make sure everything works well.”}}]}