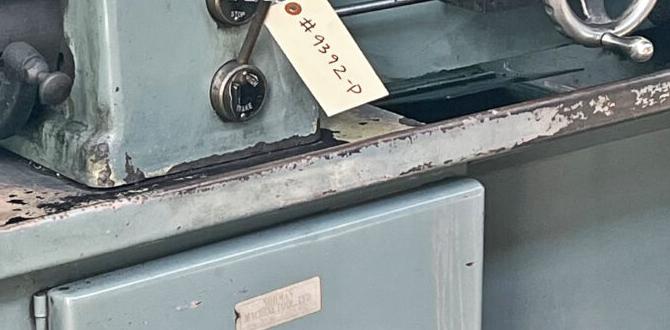

Have you ever watched a metal lathe in action? It’s fascinating to see how it shapes metal. One key part of this machine is the lathe headstock. This piece holds the spindle and makes everything work smoothly. It’s crucial for making accurate cuts, especially when taper turning.

Taper turning is when the lathe makes a part wider or narrower at one end. This technique is used in many projects. Imagine crafting a perfect table leg that fits just right. But did you know the quality of the lathe headstock bearing affects the whole process?

Good bearings ensure the spindle rotates smoothly. This helps in creating precise shapes. Without them, it would be hard to get the right angle. Isn’t it amazing how much of a difference tiny parts make in big machines?

Let’s dive deeper into how lathe headstock bearings work and why they matter in taper turning. You might be surprised at what you discover!

Lathe Headstock Bearing: Metal Lathe Taper Turning Essentials

Understanding Lathe Headstock Bearing in Taper Turning

Lathe headstock bearings play a crucial role in metal lathe taper turning. These bearings support the spindle and help it rotate smoothly. When you work with different materials, knowing how to adjust these parts can improve your work quality. Did you know that the right bearing choice can extend the lathe’s life? By learning about headstock bearings, you’re not just enhancing your skills; you’re also unlocking new possibilities in your projects!What is a Lathe Headstock Bearing?

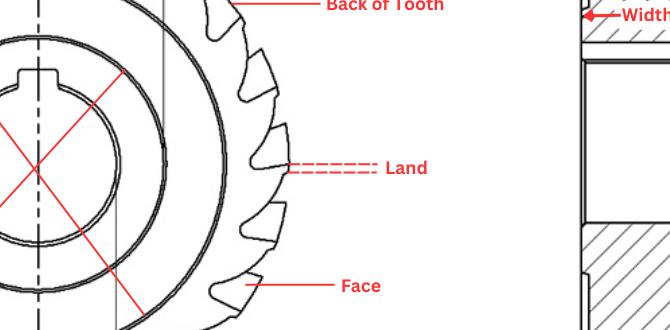

Definition and purpose of headstock bearing in lathes. Types of bearings used in lathe headstocks.A lathe headstock bearing helps machines work well. It supports the lathe’s spindle and lets it turn smoothly. There are two common types of bearings used in headstocks:

- Ball Bearings: These are round and roll, making the spindle spin easily.

- Roller Bearings: These use cylinders to support heavier loads.

These bearings are crucial for precision in metal lathe taper turning. Without them, cutting would be rough and uneven.

What does a lathe headstock bearing do?

A lathe headstock bearing supports the spindle and helps it rotate smoothly during cutting.

Importance of Headstock Bearings in Metal Lathes

Role of bearings in lathe operation and precision. Impact on the overall performance and longevity of the lathe.Bearings are like magic helpers in a metal lathe. They allow smooth rotation, keeping the machine running well. Good bearings means better control when making precise cuts. This helps create parts that fit together perfectly. If bearings wear out, the lathe might shake or make mistakes. Regularly checking and replacing bearings can keep the lathe strong and working longer.

- Ensure smooth movement during operation.

- Help in making precise cuts.

- Extend the life of the lathe.

Why are bearings important in a lathe?

The importance of bearings in a lathe cannot be overstated. They ensure the lathe runs smoothly, making it easier to create precise and high-quality workpieces. Regular care of these components keeps the machine in peak condition.

How to Choose the Right Headstock Bearing

Key features to consider when selecting bearings. Comparison of different types of bearings for various lathe applications.Choosing the right headstock bearing is key for smooth lathe operation. Look for durability, load capacity, and ease of installation. Each bearing type has its strengths. For example, ball bearings are great for high speeds, while roller bearings can handle heavy loads. Check this handy comparison:

| Bearing Type | Best For | Pros | Cons |

|---|---|---|---|

| Ball Bearings | Speed | Fast, low friction | Lower load capacity |

| Roller Bearings | Heavy Loads | Strong, stable | Slower speeds |

A smart choice will lead to precision in your taper turning projects. Remember, it’s all about balancing speed and strength—like a superhero on a skateboard! Choose wisely!

Common Issues with Lathe Headstock Bearings

Signs of wear and failure in headstock bearings. Solutions and preventive maintenance for bearing issues.Lathe headstock bearings are vital for smooth operation. However, they can wear out over time. Common signs of wear include strange noises, rough turning, or vibrations. If you notice these issues, it’s time to act.

To prevent problems, maintain your bearings regularly. Here are some tips:

- Keep bearings clean and lubricated.

- Check for signs of damage often.

- Replace bearings at the first sign of wear.

By staying on top of maintenance, you can extend the life of your lathe and improve its performance.

What are signs of headstock bearing failure?

The signs include loud noises, vibrations, and rough movement. These signals indicate that the bearings need inspection or replacement.

How can I prevent bearing issues?

Prevent issues by regularly checking the machine and keeping it clean. Routine lubrication also helps maintain performance.

Installation and Replacement of Lathe Headstock Bearings

Stepbystep guide to installing new headstock bearings. Tips for ensuring proper fit and alignment.Installing new headstock bearings can be straightforward. Follow these steps to make it easier:

- Gather tools like a wrench, screwdriver, and new bearings.

- Remove the old bearings carefully. Clean the area well.

- Position the new bearings where the old ones were.

- Tighten them securely but avoid over-tightening.

Check the alignment. This helps the lathe work smoothly. Make sure there are no gaps. If everything fits well, you’re ready to start using your lathe!

What are the signs that lathe bearings need replacement?

Common signs include unusual noises, vibrations, or difficulty in turning. If you see these issues, it might be time for new bearings.

Upgrading Your Lathe for Enhanced Taper Turning

Benefits of modern bearings and components for taper turning. Recommended upgrades for improved accuracy and operation.Modern bearings can greatly improve taper turning on your lathe. These upgrades offer better support and reduced friction. This means your projects will be more precise and smoother. Imagine creating parts with less effort and more accuracy!

- Increased Stability: Modern bearings provide stronger support.

- Reduced Wear: Fewer moving parts mean less friction and longer life.

- Improved Accuracy: Tight tolerance results in better finishes.

Important upgrades may include high-quality bearings and smoother drive components. Together, these changes will help you achieve amazing results. You will notice the difference in your taper turning!

What upgrades help with taper turning?

High-quality bearings and upgraded drive components are essential for taper turning. They improve accuracy and smooth operation.

Maintenance Best Practices for Lathe Headstock Bearings

Routine maintenance tasks to extend bearing life. Recommended lubricants and their application techniques.Maintaining lathe headstock bearings is crucial for their long life. Regular care keeps them running smoothly. Here are some key tasks:

- Check for wear and damage monthly.

- Clean the bearings to remove dirt and debris.

- Apply proper lubricants every few months.

Choose lubricants like high-quality grease or oil. Apply them using a clean cloth or grease gun. Proper application means less friction and longer-lasting bearings. Don’t forget to inspect the bearings regularly!

What are the best practices for bearing lubrication?

Use oil or grease designed for metal lathe bearings. Apply it evenly and avoid over-lubricating to prevent buildup.FAQs about Lathe Headstock Bearings

Common questions and expert answers regarding bearings. Clarifications on myths and misconceptions related to lathe bearings.Have questions about lathe headstock bearings? You’re not alone! Many people wonder about their maintenance and function. A common myth is that all bearings are the same. Actually, each type serves a unique purpose. Some may ask, “How often do I need to replace them?” Typically, **it’s good to check them every few months** for wear and tear. Remember, ignoring your bearings could be like ignoring a squeaky hamster wheel—nobody likes that! Below is a fun table summarizing common queries:

| Question | Answer |

|---|---|

| How do I know if my bearing needs replacing? | Listen for unusual noises! Sound can be a clear sign. |

| Can I use any grease? | No! Make sure to use the right type for your lathe. |

Conclusion

In summary, the lathe headstock bearing is crucial for smooth taper turning. It supports the spindle and helps accurately shape materials. Understanding this part improves your metal lathe skills. You can practice taper turning and explore more resources online. Keep experimenting, and soon you’ll master your lathe!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Taper Turning:Sure! Here are five questions related to lathes. 1. What is a lathe? A lathe is a tool that helps us shape wood or metal. It spins the material around so we can cut it easily. 2. What is taper turning? Taper turning is when we make one end of a piece thinner than the other. This makes pointed shapes. 3. What does the headstock do on a lathe? The headstock holds the spinning part of the lathe. It helps keep everything steady while we work. 4. What are bearings in a lathe? Bearings help the parts move smoothly. They reduce friction, making it easier to turn the material. 5. Why do we use a metal lathe? We use a metal lathe to create precise shapes for metal objects. It helps us make parts for machines and tools.

Sure! Please provide me with the question you would like me to answer.

What Are The Key Factors To Consider When Selecting Headstock Bearings For A Metal Lathe Intended For Taper Turning Operations?When choosing headstock bearings for a metal lathe, think about a few things. First, pick bearings that can handle heavy loads. This helps the lathe work better when cutting. Second, choose bearings that can turn smoothly to make nice shapes. Lastly, check if the bearings are easy to replace if they wear out.

How Does Spindle Bearing Preload Affect The Precision And Finish Of Taper Turned Parts On A Metal Lathe?When you use a metal lathe to shape parts, spindle bearing preload is important. Preload keeps the spindle, which holds the cutting tool, steady. If it’s too loose or too tight, it can make the part wobbly or uneven. This can hurt the precision and finish of your work. With the right preload, you get smoother, more accurate parts.

What Are The Common Signs Of Wear Or Failure In Headstock Bearings Of A Metal Lathe, Especially During Taper Turning?When headstock bearings in a metal lathe wear out, you might notice a few signs. First, the lathe may make strange noises like grinding or whining. Second, you could see uneven cuts on the metal, meaning the work isn’t smooth. Finally, if the headstock feels loose or wobbly, that’s a big hint something is wrong. Always check these signs to keep your lathe working well!

What Techniques Can Be Employed To Achieve Accurate Taper Angles When Using A Metal Lathe, And How Do Bearings Play A Role In This Process?To get the right taper angles on a metal lathe, you can use special tools and set the machine correctly. You can also measure angles with a protractor to help you. Bearings are important because they keep the metal piece steady while you work. When the piece is steady, it’s easier to make accurate cuts. That way, you get the perfect angle every time!

How Can Lubrication And Maintenance Of Headstock Bearings Impact The Performance And Lifespan Of A Metal Lathe Used For Taper Turning?Keeping the headstock bearings of a metal lathe well-lubricated is really important. Good lubrication helps the lathe run smoothly while taper turning. It reduces wear and tear on the machine, which can make it last longer. If we maintain the bearings properly, we will have better cutting and more precise results. This means your projects will turn out great!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Taper Turning:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions related to lathes. 1. What is a lathe? A lathe is a tool that helps us shape wood or metal. It spins the material around so we can cut it easily. 2. What is taper turning? Taper turning is when we make one end of a piece thinner than the other. This makes pointed shapes. 3. What does the headstock do on a lathe? The headstock holds the spinning part of the lathe. It helps keep everything steady while we work. 4. What are bearings in a lathe? Bearings help the parts move smoothly. They reduce friction, making it easier to turn the material. 5. Why do we use a metal lathe? We use a metal lathe to create precise shapes for metal objects. It helps us make parts for machines and tools.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting Headstock Bearings For A Metal Lathe Intended For Taper Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing headstock bearings for a metal lathe, think about a few things. First, pick bearings that can handle heavy loads. This helps the lathe work better when cutting. Second, choose bearings that can turn smoothly to make nice shapes. Lastly, check if the bearings are easy to replace if they wear out.”}},{“@type”: “Question”,”name”: “How Does Spindle Bearing Preload Affect The Precision And Finish Of Taper Turned Parts On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe to shape parts, spindle bearing preload is important. Preload keeps the spindle, which holds the cutting tool, steady. If it’s too loose or too tight, it can make the part wobbly or uneven. This can hurt the precision and finish of your work. With the right preload, you get smoother, more accurate parts.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Failure In Headstock Bearings Of A Metal Lathe, Especially During Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When headstock bearings in a metal lathe wear out, you might notice a few signs. First, the lathe may make strange noises like grinding or whining. Second, you could see uneven cuts on the metal, meaning the work isn’t smooth. Finally, if the headstock feels loose or wobbly, that’s a big hint something is wrong. Always check these signs to keep your lathe working well!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Achieve Accurate Taper Angles When Using A Metal Lathe, And How Do Bearings Play A Role In This Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get the right taper angles on a metal lathe, you can use special tools and set the machine correctly. You can also measure angles with a protractor to help you. Bearings are important because they keep the metal piece steady while you work. When the piece is steady, it’s easier to make accurate cuts. That way, you get the perfect angle every time!”}},{“@type”: “Question”,”name”: “How Can Lubrication And Maintenance Of Headstock Bearings Impact The Performance And Lifespan Of A Metal Lathe Used For Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Keeping the headstock bearings of a metal lathe well-lubricated is really important. Good lubrication helps the lathe run smoothly while taper turning. It reduces wear and tear on the machine, which can make it last longer. If we maintain the bearings properly, we will have better cutting and more precise results. This means your projects will turn out great!”}}]}