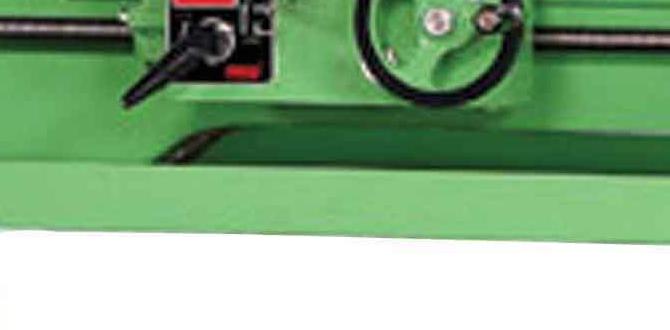

Have you ever wondered how a metal lathe works smoothly? One key to its success is proper lubrication. Without it, the machine can wear out quickly.

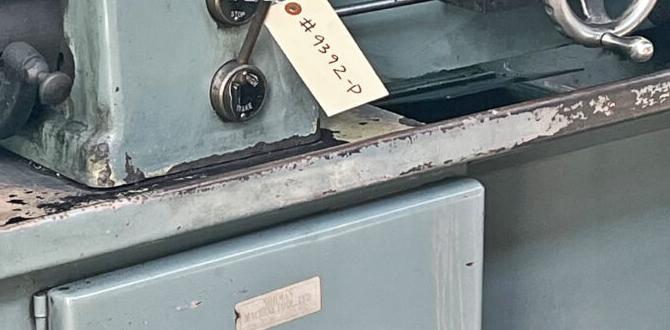

Many use metal lathes in workshops to create amazing things. But did you know that tailstock alignment is just as important? Correctly aligning the tailstock helps make accurate cuts and shapes.

Imagine trying to cut a straight piece of wood, but your tool keeps slipping. Frustrating, right? This often happens because of poor lubrication or misalignment. A well-lubricated lathe operates efficiently and gives great results.

In this article, we’ll explore how to take care of your lathe. We will look at the best ways to lubricate it and how to align the tailstock effectively. Let’s make your metal lathe run like a champ!

Essential Lathe Lubrication And Metal Lathe Tailstock Alignment Techniques

Lathe Lubrication and Tailstock Alignment Insights

Lathe lubrication is crucial for smooth operation. Proper lubrication reduces wear and tear, extending the machine’s life. Tailstock alignment is equally important. Misalignment can cause uneven cuts and poor finish quality. Regular checks can prevent problems and improve accuracy. Imagine working hard on a project, only to find out the tailstock wasn’t aligned! Keeping your lathe well-lubricated and aligned makes a huge difference in results. Small changes lead to big successes in your metalworking projects!Understanding Lathe Lubrication

Importance of lubrication in metal lathe operations. Types of lubricants suitable for lathes.Lubrication is vital for smooth metal lathe operations. It helps reduce friction and wear between moving parts. Without proper lubrication, machines can overheat and break down. Using the right lubricant ensures your lathe runs efficiently.

- Oil: Common for general use, provides good protection.

- Grease: Best for parts that don’t move much. It stays in place.

- Cutting fluid: Helps during cutting tasks. It cools and lubricates.

Pick the right type for your lathe and watch it work better!

What is the best lubricant for a lathe?

The best lubricant for a lathe is machine oil or cutting oil. They help keep parts cool and running smoothly. Always check your machine’s manual for specifics!

Choosing the Right Lubricant for Your Lathe

Factors to consider: viscosity, application, and environmental conditions. Comparing synthetic vs. traditional lubricants.Choosing the right lubricant for your lathe is crucial. Viscosity matters because it affects how well the lubricant flows. You also need to think about where and how you use it. Weather and dust can change your choice too.

Here’s a quick look at synthetic vs. traditional lubricants:

- Synthetic lubricants: Last longer and resist heat better.

- Traditional lubricants: Often cheaper but may break down faster.

Pick the best option for smooth operations and better performance!

What is viscosity in lubrication?

Viscosity is how thick or thin a lubricant is. It helps the lubricant stay in places it needs to be.

How do environmental conditions impact lubrication?

- Temperature changes can affect how well a lubricant works.

- Dust can thicken lubricants and cause problems.

Always consider these factors to keep your lathe running smoothly!

Step-by-Step Guide to Lubricating Your Metal Lathe

Essential tools and materials needed for lubrication. Detailed process of lubricating various components of the lathe.Lubricating your metal lathe is key for its smooth operation. You will need some essential tools. Start with a good quality lubricant, a clean cloth, and a brush. Remember, these tools help reach every part of the lathe. Follow these steps to keep your lathe in top shape:

- Clean all surfaces first.

- Apply lubricant to the bed and ways.

- Don’t forget the tailstock and carriage.

- Wipe off any excess with a cloth.

This process helps prevent wear and tear. A well-lubricated lathe performs better and lasts longer!

What tools do I need for lathe lubrication?

You will need lubricant, a clean cloth, and a brush.

Signs of Improper Lubrication

Common indicators of insufficient lubrication. Potential consequences on machining quality and lathe lifespan.Have your machines been making odd noises? Maybe they’ve turned into an orchestra, but not the kind you want! Lack of lubrication can lead to signs like strange sounds and stiff movements. When oil levels drop, machines can wear out faster than your favorite sneakers. This poor handling can cause rough cuts and affect quality, making your projects look like a toddler’s art. Over time, this could shorten your lathe’s life. Keep the oil flowing for smoother sailing!

| Signs of Insufficient Lubrication | Potential Consequences |

|---|---|

| Odd noises from the lathe | Shortened lifespan |

| Stiff movement | Poor machining quality |

| Rough cuts | Higher repair costs |

Steps to Align the Tailstock Correctly

Tools required for tailstock alignment. Detailed instructions for accurately aligning the tailstock.Aligning the tailstock is key for smooth machining. First, gather essential tools: a level, a dial gauge, and a wrench. Start by placing the level on the lathe bed and adjust the tailstock until it’s perfectly level. Use the dial gauge to check for alignment with the spindle. If it’s off, use the wrench to make small adjustments. Remember, a happy lathe means happy projects—no one likes a wobbly cut! Keep at it, and soon you’ll be the tailstock whisperer!

| Tool | Purpose |

|---|---|

| Level | Check horizontal alignment |

| Dial Gauge | Measure spindle alignment |

| Wrench | Tighten and adjust tailstock |

Common Tailstock Alignment Issues and Solutions

Identifying common problems with tailstock alignment. Troubleshooting tips and corrective measures.Tailstock alignment problems can lead to wobbly workpieces, which is a big no-no! Some common issues include misalignment that can ruin your perfect cylinder. If your tailstock isn’t sliding smoothly, check for dirt and lubricant. It’s like giving your lathe a spa day! Here’s a handy table to help you diagnose problems and solutions:

| Problem | Solution |

|---|---|

| Wobbling workpieces | Check if the tailstock is aligned correctly. Adjust it. |

| Stuck tailstock | Clean and lubricate the rails. It loves a little pampering! |

| Uneven cutting | Verify tailstock and bed alignment. A ruler can be your best friend here! |

By keeping these tips in mind, your lathe will work like a charm. Remember, a happy tailstock makes for a happy lathe!

Routine Maintenance Practices for Lathe Longevity

Importance of regular maintenance and checks. Best practices for ensuring optimal lathe performance.Keeping your lathe in good shape is very important. Regular maintenance helps it last longer and work better. Here are some simple practices you can follow:

- Check for dirt and clean the lathe often.

- Lubricate parts like the tailstock to keep it moving smoothly.

- Inspect belts and gears for wear and tear.

- Align the tailstock correctly for accurate cuts.

With these steps, you can enjoy a reliable lathe that helps you create amazing work!

What are the benefits of regular lathe maintenance?

Regular lathe maintenance improves overall performance, reduces downtime, and extends the machine’s life.Conclusion

In summary, keeping your lathe lubricated helps it run smoothly. Proper tailstock alignment ensures accuracy in your work. Regularly check and maintain these elements to improve your projects. You can find more tips online or in manuals for better techniques. Start applying this knowledge today, and watch your skills grow!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Tailstock Alignment For A Metal Lathe:Sure! Lubricating a lathe helps it work smoothly. You can use oil to keep it running well. Check the tailstock often. If it’s not lined up, the pieces might not fit correctly. Make small adjustments to get it just right!

Sure, I’m ready to help! Just ask your question, and I’ll give you a short and simple answer.

What Type Of Lubricant Is Recommended For Different Components Of A Metal Lathe, Including The Tailstock?For a metal lathe, you can use different lubricants for different parts. For the tailstock, a light oil works well. For the ways (the long sliding parts), use a thicker oil or grease. For gears, a special gear oil is best. Always check the machine’s manual for specific recommendations!

How Can Improper Tailstock Alignment Affect The Accuracy Of Machining Operations On A Metal Lathe?If the tailstock on a metal lathe is not lined up properly, it can cause problems. This might make the piece you are working on come out uneven or wobbly. When you try to cut metal, the tool may not hit the right spot. This makes it hard to get an accurate shape or size. So, good alignment is very important for making things that fit well!

What Are The Common Signs That Indicate The Tailstock Needs Realignment On A Metal Lathe?If the tailstock needs realignment on a metal lathe, you might notice a few signs. First, your cuts may be uneven or crooked. Second, the tool could break or get dull quickly. You might also see a gap between the tailstock and the workpiece. Lastly, if you hear strange noises while working, it could mean something is off.

How Often Should Lubrication Be Performed On The Various Parts Of A Metal Lathe, And What Maintenance Schedule Is Best?You should lubricate your metal lathe often to keep it working well. It’s best to oil it every time you use it. Check the oil levels regularly. You can also do a deeper clean and check every month. This way, your lathe stays in good shape for a long time!

What Are The Steps Involved In Adjusting The Tailstock Alignment For Optimal Performance On A Metal Lathe?To adjust the tailstock on a metal lathe, first, make sure the lathe is off. Next, use a tool called a dial indicator to check if the tailstock is straight. If it isn’t, loosen the screws on the tailstock. Then, gently move it until it’s aligned correctly. Finally, tighten the screws and check again to make sure it’s perfect.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Tailstock Alignment For A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lubricating a lathe helps it work smoothly. You can use oil to keep it running well. Check the tailstock often. If it’s not lined up, the pieces might not fit correctly. Make small adjustments to get it just right!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure, I’m ready to help! Just ask your question, and I’ll give you a short and simple answer.”}},{“@type”: “Question”,”name”: “What Type Of Lubricant Is Recommended For Different Components Of A Metal Lathe, Including The Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you can use different lubricants for different parts. For the tailstock, a light oil works well. For the ways (the long sliding parts), use a thicker oil or grease. For gears, a special gear oil is best. Always check the machine’s manual for specific recommendations!”}},{“@type”: “Question”,”name”: “How Can Improper Tailstock Alignment Affect The Accuracy Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock on a metal lathe is not lined up properly, it can cause problems. This might make the piece you are working on come out uneven or wobbly. When you try to cut metal, the tool may not hit the right spot. This makes it hard to get an accurate shape or size. So, good alignment is very important for making things that fit well!”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate The Tailstock Needs Realignment On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock needs realignment on a metal lathe, you might notice a few signs. First, your cuts may be uneven or crooked. Second, the tool could break or get dull quickly. You might also see a gap between the tailstock and the workpiece. Lastly, if you hear strange noises while working, it could mean something is off.”}},{“@type”: “Question”,”name”: “How Often Should Lubrication Be Performed On The Various Parts Of A Metal Lathe, And What Maintenance Schedule Is Best?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should lubricate your metal lathe often to keep it working well. It’s best to oil it every time you use it. Check the oil levels regularly. You can also do a deeper clean and check every month. This way, your lathe stays in good shape for a long time!”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Adjusting The Tailstock Alignment For Optimal Performance On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock on a metal lathe, first, make sure the lathe is off. Next, use a tool called a dial indicator to check if the tailstock is straight. If it isn’t, loosen the screws on the tailstock. Then, gently move it until it’s aligned correctly. Finally, tighten the screws and check again to make sure it’s perfect.”}}]}