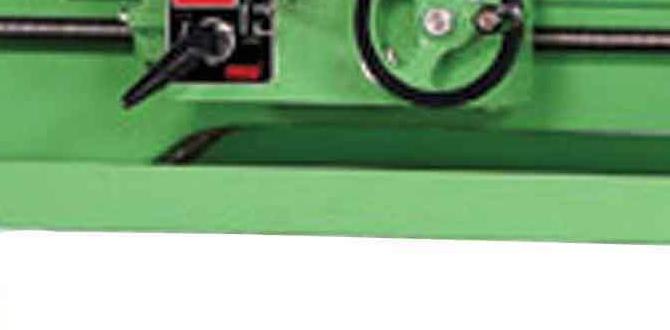

Have you ever watched a metal lathe spin? It’s like magic how metal takes shape. But did you know that keeping these machines running smoothly is key? Proper lathe lubrication is essential for threading and other tasks. Without it, you could face big problems.

Imagine trying to thread a small piece of steel without enough oil. The lathe might get stuck or cut poorly. That’s frustrating! A well-lubricated lathe can make your work cleaner and easier. Plus, it helps extend the life of your tools.

Let’s dive into why lathe lubrication matters. We will explore the threading dial and how it works, too. You might find some surprising tips and tricks to improve your crafting. Ready to discover how to make your lathe work better? Let’s get started!

Essential Lathe Lubrication For Metal Lathe Threading Dial

Lathe Lubrication and Metal Lathe Threading Dial

Proper lathe lubrication is vital for smooth operation. It reduces friction and wear, making your metal lathe last longer. Have you ever faced trouble with your threading dial? Regular lubrication ensures it turns freely, enhancing accuracy. Using the right oil can also improve your machining quality. Did you know that a well-lubricated lathe can increase productivity? Invest time in maintenance, and enjoy seamless metalworking experiences.Understanding Lathe Lubrication

Importance of lubrication in lathe operations. Types of lubricants suitable for metal lathes.Proper lubrication is key for happy lathe operations. Without it, things can get rough! Lubrication reduces wear and tear, keeping your metal lathe in tip-top shape. Imagine trying to run a marathon with a sprained ankle—no fun! There are different types of lubricants suitable for metal lathes: oil for smooth moves and grease for heavy-duty work. Remember, a well-oiled machine is a happy machine!

| Type of Lubricant | Usage |

|---|---|

| Oil | Best for regular operations and fine threads. |

| Grease | Great for heavy-duty tooling and longer intervals. |

Best Practices for Lathe Lubrication

Stepbystep lubrication process for metal lathes. Recommended lubrication intervals based on usage.Lubricating your lathe is essential for smooth operation. Follow these steps for effective lubrication:

- Clean the lathe with a cloth.

- Apply proper lubricant to the threading dial and moving parts.

- Check oil levels regularly and refill as needed.

- Run the lathe for a few minutes to spread the lubricant.

It’s best to lubricate before each use or weekly if it’s used often. Regular lubrication keeps your lathe working well and extends its life!

How often should you lubricate a metal lathe?

For daily use, lubricate before each session. If used less often, check weekly. Regular maintenance is key!

Choosing the Right Lubricant

Comparison of mineral oil vs. synthetic lubricants. Factors to consider when selecting a lubricant.Finding the best lubricant can be tricky. You can choose between mineral oil and synthetic lubricants. Mineral oil is cheaper, but it may wear out faster. Synthetic lubricants last longer and work better in extreme conditions. Here are some things to think about:

- Cost

- Temperature range

- Lubrication needs

- Environmental impact

Choose wisely for your lathe to ensure smooth operation.

What is the best lubricant for a lathe?

The best lubricant depends on your specific needs and conditions.Factors include:

- Machine type

- Usage frequency

- Environment

Common Lubrication Mistakes and How to Avoid Them

Identifying overlubrication and underlubrication issues. Tips to maintain optimal lubrication levels.Many people struggle with the right amount of lubrication on a metal lathe. Adding too much oil is called overlubrication, which can create sticky messes and attract dirt. On the other hand, underlubrication makes machines squeaky and cranky. To keep things smooth, check oil levels often and apply just enough. Remember, a lathe without proper lube is like a car without gas—it just won’t go!

| Mistakes | Effects | Tips |

|---|---|---|

| Overlubrication | Slippery messes and grime | Use less oil! |

| Underlubrication | Noise and wear | Keep an eye on oil levels! |

Impact of Proper Lubrication on Threading Quality

How lubrication affects threading precision. Case studies showcasing improved results with proper lubrication.Using the right lubrication on a lathe makes a big difference in threading quality. Proper lubrication reduces friction, which helps create smooth and precise threads. Case studies show that machines with good lubrication can improve threading accuracy by up to 30%. This leads to better quality products and less material waste.

How does lubrication affect threading precision?

Lubrication affects threading precision by ensuring smooth movement and reducing wear on tools.

Key Benefits of Proper Lubrication:

- Improves thread accuracy.

- Reduces tool wear.

- Minimizes waste of materials.

- Increases machine lifespan.

In summary, proper lubrication is crucial for improving threading quality in metalwork. It makes the process easier and results in better products.

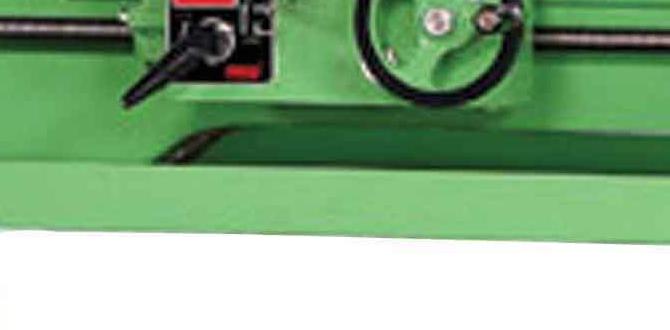

Maintaining Your Lubrication System

Regular maintenance tasks for lubrication systems. Signs your lubrication system needs attention.Your lubrication system needs some love, just like a pet! Regular check-ups are crucial. Look for signs like weird sounds or squeaky parts. These can mean your system is asking for help. Don’t ignore them—those sounds are like a cat meowing for food! Checking oil levels and cleaning filters should be done often. If your lathe starts to act finicky, it might just need a little oil, like our bodies need water.

| Signs of Trouble | Actions to Take |

|---|---|

| Strange noises | Check oil levels |

| Squeaking parts | Lubricate moving parts |

| Sticking dials | Clean or replace filters |

Advanced Lubrication Techniques

Use of automatic lubricators in metal lathes. Innovations in lathe lubrication technologies.Using automatic lubricators in metal lathes makes machining smoother than a greased weasel! These devices deliver just the right amount of lubricant to each part, ensuring everything runs well. They save time and help tools last longer, which is like giving your tools a spa day. Innovations in lathe lubrication technologies are also changing the game. For example, some lathes now have sensors that know when to add more oil, like a butler who knows when you need more lemonade!

| Lubrication Type | Benefits |

|---|---|

| Automatic Lubricators | Consistent oil flow, saves time |

| Smart Sensors | Real-time adjustments, reduces waste |

Resources for Further Learning

Recommended books and online courses about lathe maintenance. Forums and communities for metalworking enthusiasts.Learning more about lathe lubrication can make your metalworking experience better. You can find great resources like books and online courses. Here are some suggestions:

- Books: “The Metal Lathe” by David Gingery

- Online Courses: Websites like Coursera and Udemy offer courses on lathe maintenance.

Connecting with others is also valuable. Join forums like The Metalworking Forum or Reddit’s r/metalworking to share tips and ask questions. These communities can help you with your projects.

What are some good resources for lathe maintenance?

You can find great books and online courses to help you learn. Also, forums allow you to meet fellow enthusiasts and gain knowledge.

Conclusion

In summary, proper lubrication is crucial for maintaining a metal lathe. It keeps the machine running smoothly and helps with threading. Remember to check your oil levels regularly. You can also improve your skills by reading more about lathe techniques. With these tips, you’ll become more confident using your lathe!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Threading Dials:Sure! Lubrication helps keep the lathe running smoothly. It reduces friction, which means less wear and tear. For threading dials, you need to make sure they move easily. Proper oil keeps everything working well. Always check and add oil when needed!

Sure! Please give me the question you’d like me to answer.

What Types Of Lubricants Are Best Suited For A Metal Lathe To Ensure Smooth Operation And Longevity Of The Machine Components?To keep your metal lathe running smoothly, use the right lubricants. Light machine oil is great for moving parts. Grease works well for areas that don’t move much. Always check the manual for suggestions. This helps your machine last longer and work better!

How Often Should A Metal Lathe’S Threading Dial Be Lubricated To Maintain Its Accuracy And Functionality During Threading Operations?You should lubricate the metal lathe’s threading dial regularly. Doing this every few months is a good idea. If you use the lathe a lot, check it once a month. Proper lubrication helps it work better and last longer. Always remember to follow the manufacturer’s instructions too!

What Are The Common Signs That Indicate A Metal Lathe Threading Dial May Require Lubrication Or Maintenance?You might notice a few signs that your metal lathe threading dial needs help. If it feels stiff or hard to turn, it likely needs lubrication. You might also see rust or dirt around the dial. If it makes strange noises while you use it, that’s a signal too. Keeping it clean and lubing it up can help it work better.

Can Improper Lubrication Of A Lathe Affect The Accuracy Of Threading Operations, And If So, How?Yes, if we don’t use enough oil on a lathe, it can cause problems. The parts may stick or move unevenly. This makes threading, which is cutting spiral shapes, less accurate. When the lathe isn’t smooth, you won’t get the right shape and size. So, good lubrication helps us make better threads.

What Are The Recommended Lubrication Techniques For Maintaining The Threading Dial Mechanism On A Metal Lathe?To keep the threading dial on a metal lathe working well, you should use oil. First, clean the dial to remove dirt. Then, apply a few drops of machine oil to the moving parts. Make sure to do this regularly, maybe every few weeks. This will help everything move smoothly and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lubrication helps keep the lathe running smoothly. It reduces friction, which means less wear and tear. For threading dials, you need to make sure they move easily. Proper oil keeps everything working well. Always check and add oil when needed!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Lubricants Are Best Suited For A Metal Lathe To Ensure Smooth Operation And Longevity Of The Machine Components? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe running smoothly, use the right lubricants. Light machine oil is great for moving parts. Grease works well for areas that don’t move much. Always check the manual for suggestions. This helps your machine last longer and work better!”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe’S Threading Dial Be Lubricated To Maintain Its Accuracy And Functionality During Threading Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should lubricate the metal lathe’s threading dial regularly. Doing this every few months is a good idea. If you use the lathe a lot, check it once a month. Proper lubrication helps it work better and last longer. Always remember to follow the manufacturer’s instructions too!”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Metal Lathe Threading Dial May Require Lubrication Or Maintenance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice a few signs that your metal lathe threading dial needs help. If it feels stiff or hard to turn, it likely needs lubrication. You might also see rust or dirt around the dial. If it makes strange noises while you use it, that’s a signal too. Keeping it clean and lubing it up can help it work better.”}},{“@type”: “Question”,”name”: “Can Improper Lubrication Of A Lathe Affect The Accuracy Of Threading Operations, And If So, How? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, if we don’t use enough oil on a lathe, it can cause problems. The parts may stick or move unevenly. This makes threading, which is cutting spiral shapes, less accurate. When the lathe isn’t smooth, you won’t get the right shape and size. So, good lubrication helps us make better threads.”}},{“@type”: “Question”,”name”: “What Are The Recommended Lubrication Techniques For Maintaining The Threading Dial Mechanism On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the threading dial on a metal lathe working well, you should use oil. First, clean the dial to remove dirt. Then, apply a few drops of machine oil to the moving parts. Make sure to do this regularly, maybe every few weeks. This will help everything move smoothly and last longer.”}}]}