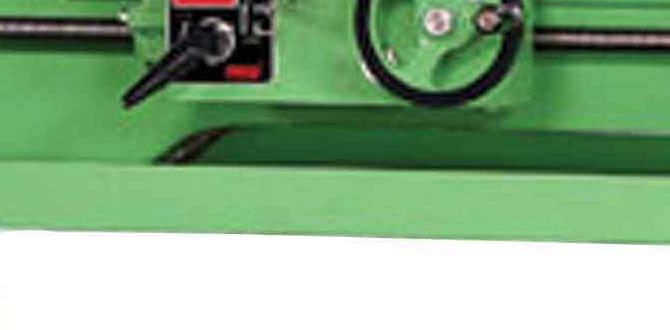

Have you ever wondered how machines shape metal with precision? A lathe machine does just that. It’s an amazing tool that spins metal to create various shapes. But what if we could make this tool even smarter?

Imagine a lathe that learns from its past performances. This idea isn’t just a dream; it’s called lathe machine learning. With advancements in technology, this concept becomes more real every day. The bed of a metal lathe could soon help it improve its efficiency and accuracy.

What if your lathe could adjust itself based on your previous work? Wouldn’t that save time and effort? Learning machines may soon change how we view metalworking forever.

Stay with us as we explore the exciting world of lathe machine learning. You’ll learn how metal lathe beds play a key role in this groundbreaking breakthrough!

Lathe Machine Learning: Enhancing Metal Lathe Bed Efficiency

Understanding Lathe Machines and Their Metal Lathe Beds

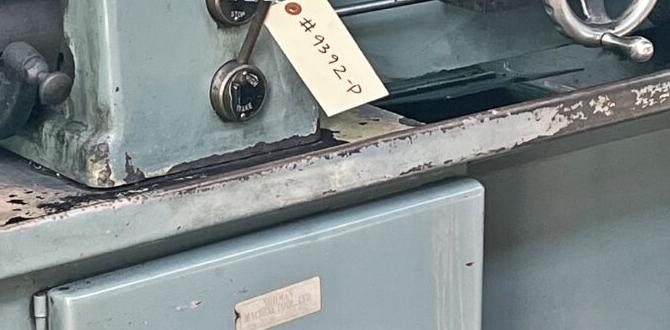

Lathe machines play a crucial role in shaping metal. Did you know that the bed of a lathe machine is key to its stability? A strong metal lathe bed supports precise cuts and movements. When selecting a lathe, consider how its bed affects the overall performance. Machines with solid metal beds last longer and produce better results. Curious about how this impacts your projects? Investing in a quality lathe bed can transform your metalworking skills!The Importance of Metal Lathe Beds

Explanation of metal lathe bed components. Role of lathe beds in machining accuracy and stability.Metal lathe beds are crucial parts of lathe machines. They provide a stable base for the machine. This makes sure that workpieces are cut accurately. A good lathe bed reduces vibrations. This improves the machine’s performance. Key components include:

- Base: Supports the entire machine.

- Bedways: Guides the movement of the cutting tools.

- Headstock: Holds the workpiece in place.

With a sturdy metal lathe bed, the chances of error decrease, ensuring precision in every cut.

What do metal lathe beds do?

Metal lathe beds play a vital role in machining. They ensure accuracy and stability for the machine. Without them, cutting tools may shake and cause mistakes.

Fundamentals of Lathe Machine Learning

Definition of machine learning in manufacturing. Key algorithms used in lathe machine applications.Machine learning helps factories make better products. It means using computers to learn from data and improve processes without human help. In lathe machine applications, some key algorithms work wonders:

- Linear Regression: Predicts outcomes based on input data.

- K-means Clustering: Groups similar data together.

- Decision Trees: Makes choices based on data rules.

These tools help make metal lathe beds more efficient and reliable.

What is machine learning in manufacturing?

Machine learning in manufacturing is using computer programs to analyze data and improve production.

Integrating Machine Learning with Lathe Operations

Benefits of using machine learning for optimizing lathe processes. Realtime data monitoring and its impact on performance.Using machine learning with lathe operations can improve performance significantly. Optimizing lathe processes leads to better efficiency and less waste. Real-time data monitoring helps operators know what is happening instantly. This means quick adjustments can be made, which leads to smoother operations. Here are some benefits:

- Increased accuracy in cutting.

- Reduced machine downtime.

- Enhanced quality of finished products.

With these tools, machines work smarter, not harder!

What are some advantages of machine learning in lathe operations?

Machine learning helps machines think and learn. It makes lathe operations faster, more accurate, and less wasteful.

Applications of Machine Learning in Metal Lathe Operations

Case studies showcasing successful applications. Predictive maintenance and its advantages.Machine learning is changing how metal lathes work. Many companies have seen great results. For example, some use machine learning to predict when the machines will need maintenance. This results in fewer breakdowns and saves money. Here are some benefits:

- Fewer unplanned repairs.

- Longer machine life.

- Better production quality.

In one case, a company increased production by 20% using these methods. Machine learning helps workers make smarter choices every day.

What are the benefits of machine learning in lathe machine operations?

Machine learning offers better accuracy, less downtime, and increased production rates. It helps companies not only save money but also enhance the quality of their products.

Challenges in Implementing Machine Learning in Lathes

Common obstacles faced by manufacturers. Strategies to overcome these challenges.Manufacturers face several bumps while trying to add machine learning to lathes. First, data is often messy or missing. It’s like trying to bake a cake without the right ingredients! To tackle this, companies can start by collecting quality data early in production. Next, staff may lack training. A few funny “oops” moments could happen without proper guidance. Investing in education can ease fears and build skills for workers. Sometimes, having the right tools is a challenge. Upgrading machines for compatibility can help, making them less grumpy. Overall, a mix of good data, training, and the right gear can smooth out the process.

| Obstacle | Strategy to Overcome |

|---|---|

| Messy or missing data | Collect quality data early |

| Lack of training | Invest in education |

| Incompatible machines | Upgrade equipment |

The Future of Lathe Machines and Machine Learning

Emerging trends in lathe technology. Predictions for the evolution of machine learning in manufacturing.New trends in lathe machines show exciting possibilities. Automation is becoming more common, making machines work faster and better. We can also expect more machine learning. This helps machines learn from their mistakes. Engineers will use smart technology to improve designs. The future looks bright for lathe machines, blending technology with skill. Just imagine the creations on these machines!

What are some emerging trends in lathe technology?

Emerging trends include smart automation, increased precision, and enhanced safety features. These changes are pushing lathe machines to new heights, making manufacturing easier and more efficient.

Key Predictions for Machine Learning Evolution:

- Increased efficiency through predictive maintenance.

- Better design capabilities with AI integration.

- Higher customization options for various industries.

As machines evolve, they will help workers create incredible things while keeping them safe and effective. Keep an eye on this exciting field!

Getting Started with Machine Learning for Your Lathe

Steps to integrate machine learning into existing lathe systems. Resources and tools for training and implementation.Ready to spruce up your lathe with a sprinkle of machine learning? First, check your lathe’s brain—err, software. You want to ensure it’s ready for some smart upgrades. Then, gather resources! Books, online courses, and software are great starts. Don’t forget to grab a few snacks because learning can work up an appetite!

| Resource | Type |

|---|---|

| Online Courses | Learning |

| Books on Machine Learning | Reference |

| Software Tools | Implementation |

As you work, try small projects first. This way, you get to know how your lathe dances with machine learning. Remember, practice makes perfect… or at least less awkward! Happy turning!

Conclusion

In summary, understanding the lathe machine and its bed helps you shape metal accurately. Learning how these tools work can boost your skills. You can explore more about machine learning applications to improve efficiency. Remember, practice is key. Try hands-on projects to see your progress. Keep reading and experimenting to become an expert in metalworking!FAQs

Sure! Here Are Five Related Questions About Lathe Machine Learning, Specifically Focusing On Metal Lathe Beds:Lathe machine learning helps us understand and improve metal lathe beds. These beds hold the metal while it spins. By learning from data, we can make them better and safer. This way, we create smoother and stronger parts. It’s like using smart lessons to make machines work well!

Sure! Please let me know what question you would like me to answer.

What Are The Key Parameters To Monitor On A Metal Lathe Bed To Optimize Machining Performance Using Machine Learning?To optimize machining performance on a metal lathe bed, we need to check a few key things. First, we should look for the bed’s straightness. This means making sure it is level and smooth. Next, we monitor the temperature, so it doesn’t get too hot. Finally, we check for wear and tear, which can affect how well the machine works. By keeping an eye on these things, we can help the lathe do its job better.

How Can Machine Learning Algorithms Be Applied To Predict Wear And Tear On Metal Lathe Beds?We can use machine learning to predict when metal lathe beds might get worn out. First, we collect data about how often they are used and what tools are used. Then, we feed this data into a machine learning program. It learns patterns and helps us see when a lathe bed might need repairs. This way, we can fix things before they break!

What Sensor Technologies Are Most Effective For Collecting Data From Metal Lathe Beds For Machine Learning Applications?To collect data from metal lathe beds, we can use sensors like vibration sensors, temperature sensors, and cameras. Vibration sensors help us see how the machine moves. Temperature sensors check if the lathe gets too hot, which can cause problems. Cameras can take pictures of the work being done. Together, these sensors give us important information to help machines learn and work better.

How Can Machine Learning Improve The Accuracy And Efficiency Of Machining Processes On A Metal Lathe Bed?Machine learning can help us make better parts on a metal lathe. It learns from past mistakes, so we can avoid them in the future. This means we can make parts faster and with fewer errors. By using smart tools, we can save time and make our work easier!

What Challenges Are Faced When Implementing Machine Learning Solutions On Traditional Vs. Cnc Metal Lathes With Respect To Their Beds?When we use machine learning with traditional lathes, they have old parts that can be tricky. The beds might not be strong enough or not very smooth. CNC (Computer Numerical Control) lathes have better technology, but their beds are more complicated. Their parts need to be very precise, which can be hard to manage. You need to think carefully about these differences to make everything work well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Lathe Machine Learning, Specifically Focusing On Metal Lathe Beds:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe machine learning helps us understand and improve metal lathe beds. These beds hold the metal while it spins. By learning from data, we can make them better and safer. This way, we create smoother and stronger parts. It’s like using smart lessons to make machines work well!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please let me know what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Parameters To Monitor On A Metal Lathe Bed To Optimize Machining Performance Using Machine Learning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To optimize machining performance on a metal lathe bed, we need to check a few key things. First, we should look for the bed’s straightness. This means making sure it is level and smooth. Next, we monitor the temperature, so it doesn’t get too hot. Finally, we check for wear and tear, which can affect how well the machine works. By keeping an eye on these things, we can help the lathe do its job better.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Be Applied To Predict Wear And Tear On Metal Lathe Beds?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to predict when metal lathe beds might get worn out. First, we collect data about how often they are used and what tools are used. Then, we feed this data into a machine learning program. It learns patterns and helps us see when a lathe bed might need repairs. This way, we can fix things before they break!”}},{“@type”: “Question”,”name”: “What Sensor Technologies Are Most Effective For Collecting Data From Metal Lathe Beds For Machine Learning Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To collect data from metal lathe beds, we can use sensors like vibration sensors, temperature sensors, and cameras. Vibration sensors help us see how the machine moves. Temperature sensors check if the lathe gets too hot, which can cause problems. Cameras can take pictures of the work being done. Together, these sensors give us important information to help machines learn and work better.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Improve The Accuracy And Efficiency Of Machining Processes On A Metal Lathe Bed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can help us make better parts on a metal lathe. It learns from past mistakes, so we can avoid them in the future. This means we can make parts faster and with fewer errors. By using smart tools, we can save time and make our work easier!”}},{“@type”: “Question”,”name”: “What Challenges Are Faced When Implementing Machine Learning Solutions On Traditional Vs. Cnc Metal Lathes With Respect To Their Beds?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use machine learning with traditional lathes, they have old parts that can be tricky. The beds might not be strong enough or not very smooth. CNC (Computer Numerical Control) lathes have better technology, but their beds are more complicated. Their parts need to be very precise, which can be hard to manage. You need to think carefully about these differences to make everything work well.”}}]}