Imagine a world where machines work smarter, not harder. In that world, the lathe machine stands out as a key player. This fascinating tool shapes metal into precise parts. But did you know there’s a twist? Machine learning can make these machines even better!

Think of a metal lathe with a gear train. This gear train helps the lathe turn smoothly and accurately. Now, picture combining this with advanced technology. What if the lathe could learn from each cut? It could improve its skills, just like a person does. Sounds cool, doesn’t it?

In this article, we’ll explore how machine learning and lathe machines team up. Together, they could change the way we create metal parts forever. Are you ready to dive into this exciting journey of innovation?

Lathe Machine Learning: Metal Lathe Gear Train Innovations

Understanding Lathe Machines in Gear Train Operations

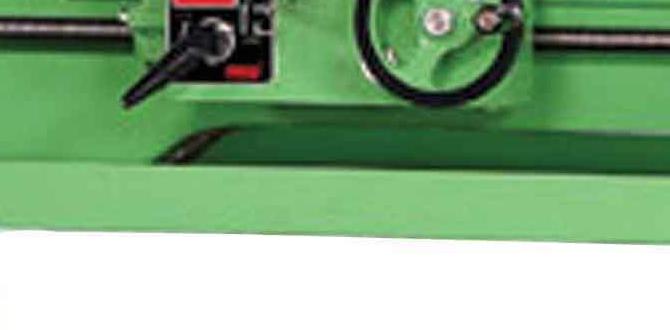

Lathe machines play a crucial role in shaping metal. They work by rotating the material against a cutting tool. You might wonder how this relates to gear trains. Gear trains, found in many machines, can depend on lathe technology for precision. Imagine creating custom gears for a robot or a car! These machines help in achieving accurate shapes and sizes. Learning about lathe machines opens up exciting possibilities in metalworking and engineering.What is a Lathe Machine?

Definition and types of lathe machines. Basic components and their functions.A lathe machine is a tool that shapes metal, wood, or plastic. It spins the material while a cutting tool removes parts to create desired shapes. There are different types, including:

- Engine lathe – Common for general purposes.

- CNC lathe – Uses computer control for precision.

- Turret lathe – Excellent for repetitive tasks.

- Bed – Holds the machine steady.

- Headstock – Drives the rotation.

- Tailstock – Helps support the material.

- Tool post – Holds the cutting tool.

What are the main uses of a lathe machine?

The lathe machine is widely used in various industries. Its main uses include:

Key Applications:

- Creating cylindrical shapes

- Shaping parts for engines

- Making furniture components

From toys to cars, lathes are everywhere!

Importance of Gear Trains in Metal Lathes

Role of gear trains in the functionality of metal lathes. Types of gear trains used in lathe machines and their applications.Gear trains play a vital role in metal lathes. They help control the speed and direction of the machine’s movements. Without gear trains, metal lathes would struggle to perform precise tasks. Common types of gear trains include:

- Simple Gear Trains: Used for basic functions.

- Compound Gear Trains: Offer better speed and torque.

- Bevel Gear Trains: Change direction effectively.

Each type fits different jobs. They make lathes more efficient, allowing workers to create accurate shapes with ease.

What are gear trains in metal lathes?

Gear trains in metal lathes are systems that control movements and speeds. They ensure the machine operates smoothly.

How Machine Learning Enhances Gear Train Performance

Data analysis and predictive maintenance for gear train optimization. Using machine learning algorithms to improve efficiency and reduce wear.Smart machines can make gear trains work better. Machine learning helps by looking closely at data. It finds patterns that can make machines run smoother. Predictive maintenance is key. This means fixing things before they break. It saves time and money. Here are some benefits:

- Improves overall efficiency.

- Reduces wear and tear on parts.

- Increases the lifespan of machines.

Using these tools keeps gear trains running like new!

Why is machine learning important for gear trains?

Machine learning helps predict problems and boosts performance. It keeps gear trains efficient and saves resources.

Case Studies: Successful Implementations of Machine Learning in Metal Lathes

Examples of companies benefiting from machine learning applications. Results and insights gained from these implementations.Many companies have turned to machine learning in their metal lathe operations, and the results are impressive. For instance, a factory that used to struggle with gear train issues now sees fewer crashes and less wasted metal. They achieved a 30% increase in efficiency. Another firm noted that machine learning helped cut production time in half. They joked, “Now our machines work harder, so we can go home earlier!”

| Company | Benefit | Result |

|---|---|---|

| Factory A | Reduced crashes | 30% increase in efficiency |

| Company B | Faster production | 50% less time |

These examples show that using machine learning can truly change the game in manufacturing. With happy workers and less wasted resources, everybody wins—unless machines start taking over the world, then we might have a problem!

Challenges in Integrating Machine Learning with Lathe Gear Trains

Common obstacles faced during integration. Strategies to overcome these challenges.Integrating machine learning with lathe gear trains can be tricky. Common obstacles include the lack of clear data and complex machinery. Also, workers may resist new technology. To overcome these challenges, training staff is essential. It’s important to simplify the technology as well. Here are some strategies:

- Provide hands-on training for workers.

- Use simple language to explain machine learning concepts.

- Start with small projects before larger implementations.

By taking these steps, companies can smoothly blend machine learning into their lathe processes.

What are the key obstacles in using machine learning with lathe machinery?

Challenges include data shortages, worker resistance, and the complexity of machines. Efficient solutions involve training and gradual implementation.

Future Trends in Lathe Machine Learning and Gear Train Technology

Emerging technologies and innovations in the field. Predictions for the future of machine learning in metalworking.Exciting changes are coming in lathe machine learning and gear train technology! New tools and smarter machines are popping up everywhere. These advancements help us create precise parts faster and with less effort. In the future, expect machines that can think and adapt on their own. Imagine a lathe that knows when it needs a break or can suggest the best settings! It’s like having a robot buddy in the workshop—just without the funky dance moves.

| Innovation | Impact |

|---|---|

| AI Integration | Improves efficiency and accuracy |

| Smart Sensors | Monitors machine health in real-time |

| Automated Adjustments | Reduces human error |

In summary, the future looks bright! These innovations will make metalworking easier and more fun. Who knew gears could bring so much joy?

Conclusion

In summary, lathe machines help us shape metal with precision. Learning about gear trains can enhance your understanding of how these machines work. You can explore more about lathe operations and gear mechanics through hands-on projects. Remember, practice will make you better. Dive into books or online resources to keep discovering exciting possibilities with lathe machines!FAQs

Sure! Here Are Five Questions Related To Lathe Machine Learning, Metal Lathe, And Gear Train:Sure! A lathe machine is a tool that helps us shape metal. We can make things like parts for machines. A metal lathe spins the metal while we cut it to make it the right shape. Gear trains are groups of gears that help machines move and work better together. They can make things go faster or slower, depending on how we arrange them.

Sure! Please provide the question you’d like me to answer.

How Can Machine Learning Algorithms Be Utilized To Optimize The Operation And Efficiency Of A Metal Lathe?We can use machine learning to make a metal lathe work better. It can help us find the best cutting speeds and angles. By learning from past work, it suggests changes to save time and materials. This means we can make parts faster and with less waste. Overall, it helps us do a great job every time we use the lathe!

What Role Does The Gear Train Configuration Play In The Performance And Precision Of Metal Lathes When Monitored By Machine Learning Systems?The gear train configuration is like a series of connected gears that help a metal lathe turn smoothly. This setup makes sure the lathe moves at the right speed and power. Machine learning systems can track how well the gears work together. If they find any problems, they can help fix them quickly. This way, the lathe can make precise shapes and cuts in metal.

How Can Predictive Maintenance Models Using Machine Learning Be Implemented For Detecting Wear And Abnormalities In Lathe Gear Trains?You can use machine learning to watch and learn from lathe gear trains. First, we collect data about how the gears run, like sounds and vibrations. Then, we teach the computer to find patterns that show when the gears are wearing out or misbehaving. Finally, the machine can give warnings before problems happen, so we can fix it in time! This way, we keep everything running smoothly.

What Types Of Data Should Be Collected From A Metal Lathe To Effectively Train Machine Learning Models For Enhancing Machining Processes?To train machine learning models for a metal lathe, we should collect different types of data. First, we need information about the machine’s speed and temperature. Next, we can gather details about the materials we are using. We should also track what we are making, like different shapes and sizes. Finally, it helps to note how well the machine is working and if there are any problems.

In What Ways Can Machine Learning Help In Automating The Setup And Calibration Of Metal Lathes For Various Gear Train Configurations?Machine learning can make it easier to set up metal lathes for different tasks. It learns from past setups to find the best ways to calibrate machines. This means you spend less time figuring things out and more time making cool stuff. It can even suggest changes if something isn’t working right. So, machine learning can help make your work faster and more accurate!