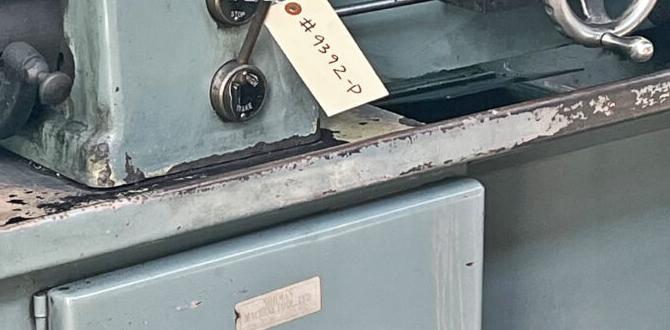

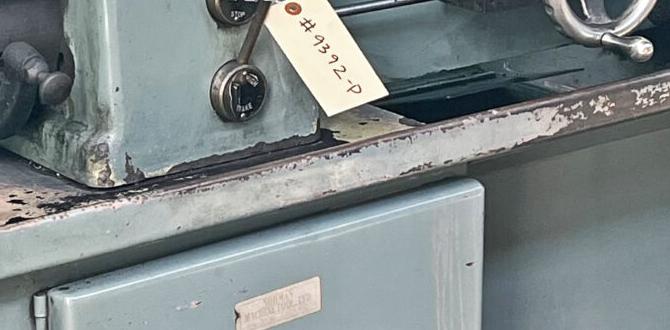

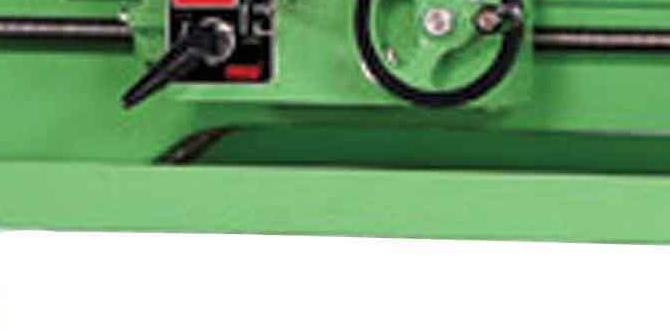

Imagine a big machine that can carve, shape, and create things from metal. It’s called a lathe machine. This brilliant invention has been around for ages, helping makers create everything from simple toys to complex parts in cars. But how does it work? Well, one important part of a lathe is the lead screw. This screw helps move the cutting tool back and forth, making precise cuts.

Now, picture this: What if we used machines and computers to make lathes even better? That’s where machine learning comes in. It can teach lathe machines to cut more accurately and faster. Isn’t it amazing that computers can help us with metalworking tasks?

In this article, we’ll explore how machine learning improves metal lathes. We’ll uncover the magic behind the lead screw and its role in shaping our world. Are you ready to dive into the fascinating world of lathes and technology? Let’s get started!

Lathe Machine Learning: Optimizing Metal Lathe Lead Screw

Lathe Machine Learning and Metal Lathe Lead Screw

Lathe machines are fascinating tools in manufacturing. They shape metal by rotating it against a cutting tool. Learning about the metal lathe’s lead screw reveals how it controls accuracy. Did you know the lead screw allows precision movement? This means you get smoother and more detailed work. With machine learning, manufacturers can improve lathe performance. Machines can even adapt based on past data. Isn’t it exciting to think about the future of metalwork?The Importance of Lead Screws in Lathe Machines

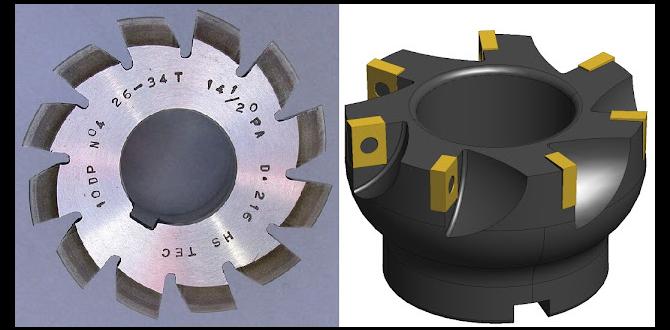

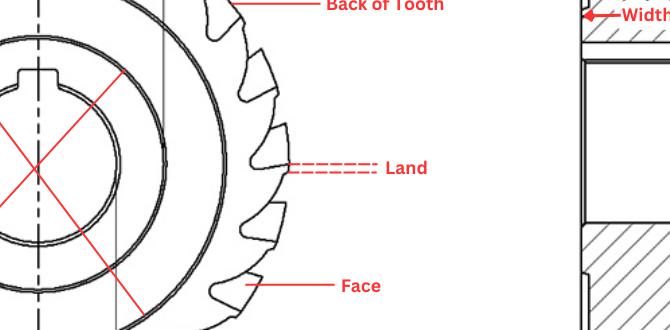

Function and role of lead screws in precision machining. Types of lead screws and their applications.In lathe machines, lead screws play a key role in making precise cuts. They move the tool or the material smoothly, helping to create exact shapes. There are different types of lead screws, each with its own use:

- Acme Lead Screws: Ideal for heavy loads and good for simple designs.

- Ball Lead Screws: Great for high-speed operations; they are efficient and reduce friction.

- Square Lead Screws: Perfect for heavy loads with low friction.

This variety helps machinists choose the right screw for each job. Overall, lead screws make precision machining easier and more effective.

What is the function of a lead screw in a lathe machine?

The lead screw moves the cutting tool or material accurately, which helps in creating detailed designs and shapes.

Integrating Machine Learning with Lathe Operations

How machine learning can optimize lathe operations. Examples of machine learning applications in metalworking.Machine learning can make lathe operations smoother and more efficient. By analyzing data, it finds ways to improve speed and precision. Imagine a robot helping a friendly lathe—working together to create perfect parts! One cool example is using sensors to adjust settings automatically, ensuring everything runs like clockwork. This leads to less waste and better quality. You can even teach the machine what not to do! Below is a summary of some applications:

| Application | Description |

|---|---|

| Predictive Maintenance | Detect problems before they cause breakdowns. |

| Quality Control | Check parts in real-time for defects. |

| Process Optimization | Adjust feed rates and speeds for better results. |

With machine learning, lathes can operate smarter, reducing errors and boosting productivity. So, let the machines learn, and watch them shine!

Case Studies: Successful Implementations

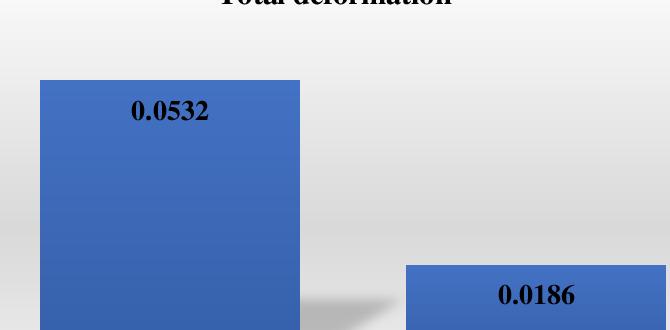

Realworld examples of lathe machines enhanced by machine learning. Insights gained from data analysis and operational efficiency.Many factories are using machine learning to make lathe machines even smarter. For instance, a company improved their metal lathe operations by keeping close watch on lead screw performance. They gathered lots of data and found that tiny adjustments could save time and materials. With machine learning, they increased efficiency by 20%! That’s like finding a hidden stash of candy in your backpack. Data analysis can truly transform operations and help businesses run smoother than ever.

| Company | Improvement Area | Efficiency Gain |

|---|---|---|

| Factory A | Lead Screw Quality | 20% |

| Factory B | Speed Optimization | 15% |

Challenges in Implementing Machine Learning in Lathe Operations

Common obstacles faced in machine learning integration. Solutions and strategies to overcome these challenges.Integrating machine learning into lathe operations can feel like solving a Rubik’s cube blindfolded. Common challenges include data quality, which can be worse than a soggy sandwich. There’s also the need for skilled workers who know both machine learning and metal lathes—a rare breed! To tackle these issues, companies can invest in training and use better sensors for data collection. Making a plan is key, like checking twice before you cut!

| Challenge | Solution |

|---|---|

| Data Quality | Improve sensors and monitoring systems |

| Lack of Skills | Provide training for workers |

| Integration Issues | Develop a clear action plan |

The Future of Lathe Technology and Machine Learning

Trends in lathe machine technology and automation. Predictions for the evolution of lead screws and machine learning integration.Lathe technology is spinning into the future with exciting trends! Machines are getting smarter, thanks to automation. Picture a lathe that can adjust itself while you take a coffee break. Cool, right? Predictions suggest that lead screws will also evolve. They might become more durable and efficient, making our jobs easier. Plus, combining machine learning with lathe operations will help catch mistakes before they happen. Say goodbye to surprise hiccups! Get ready for a smoother and more fun ride in metalwork!

| Trend | Description |

|---|---|

| Automation | Makes machines smarter and more efficient. |

| Lead Screws | Will become more durable and easy to use. |

| Machine Learning | Helps catch mistakes early, saving time and effort. |

Conclusion

In conclusion, a lathe machine is crucial for shaping metal and has a vital part called the lead screw. By understanding how these machines and their components work, you can create precise objects. Explore more about lathe operations and practice with real tools. You’ll gain valuable skills and confidence in metalworking. Keep learning and experimenting!FAQs

What Role Does Machine Learning Play In Optimizing The Performance And Accuracy Of Metal Lathe Lead Screws?Machine learning helps improve how metal lathe lead screws work. It looks at a lot of data to find patterns. We can then use these patterns to make better screws that fit perfectly. This means the machines work more smoothly and last longer. In the end, we get stronger and more accurate lead screws!

How Can Predictive Maintenance Using Machine Learning Algorithms Enhance The Longevity And Efficiency Of Lead Screws In Lathe Machines?Using machine learning, we can predict when lead screws in lathe machines might break. This helps us fix them before they stop working. When we take care of them early, they last longer and work better. It’s like getting a check-up before you get sick. By doing this, we save time and money!

What Are The Common Failure Modes For Lead Screws In Metal Lathes, And How Can Machine Learning Help In Detecting These Failures Early?Lead screws in metal lathes can fail in a few common ways. They might wear out from too much friction or get bent. Sometimes, dirt, oil, or rust can also cause problems. We can use machine learning, which is a way computers learn from data, to spot issues early. This helps us fix problems before they get worse!

How Does The Integration Of Sensors And Machine Learning Analytics Improve The Precision Of Lead Screw Operation In Metal Lathes?Using sensors and machine learning in metal lathes helps us make better cuts. Sensors detect how the machine is working. Machine learning then helps us learn from this data. Together, they make the lead screw move more accurately. This means we get smoother and better-shaped metal pieces every time!

What Data Is Essential For Training Machine Learning Models To Improve The Design And Functionality Of Lead Screws In Lathe Machines?To train machine learning models, we need important data about lead screws. This includes their size, shape, and materials. We also need information about how they perform while cutting materials. Lastly, data on how long they last and any problems they have is important. This helps us make lead screws that work better and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Role Does Machine Learning Play In Optimizing The Performance And Accuracy Of Metal Lathe Lead Screws? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning helps improve how metal lathe lead screws work. It looks at a lot of data to find patterns. We can then use these patterns to make better screws that fit perfectly. This means the machines work more smoothly and last longer. In the end, we get stronger and more accurate lead screws!”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Using Machine Learning Algorithms Enhance The Longevity And Efficiency Of Lead Screws In Lathe Machines? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using machine learning, we can predict when lead screws in lathe machines might break. This helps us fix them before they stop working. When we take care of them early, they last longer and work better. It’s like getting a check-up before you get sick. By doing this, we save time and money!”}},{“@type”: “Question”,”name”: “What Are The Common Failure Modes For Lead Screws In Metal Lathes, And How Can Machine Learning Help In Detecting These Failures Early? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lead screws in metal lathes can fail in a few common ways. They might wear out from too much friction or get bent. Sometimes, dirt, oil, or rust can also cause problems. We can use machine learning, which is a way computers learn from data, to spot issues early. This helps us fix problems before they get worse!”}},{“@type”: “Question”,”name”: “How Does The Integration Of Sensors And Machine Learning Analytics Improve The Precision Of Lead Screw Operation In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using sensors and machine learning in metal lathes helps us make better cuts. Sensors detect how the machine is working. Machine learning then helps us learn from this data. Together, they make the lead screw move more accurately. This means we get smoother and better-shaped metal pieces every time!”}},{“@type”: “Question”,”name”: “What Data Is Essential For Training Machine Learning Models To Improve The Design And Functionality Of Lead Screws In Lathe Machines? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To train machine learning models, we need important data about lead screws. This includes their size, shape, and materials. We also need information about how they perform while cutting materials. Lastly, data on how long they last and any problems they have is important. This helps us make lead screws that work better and last longer.”}}]}