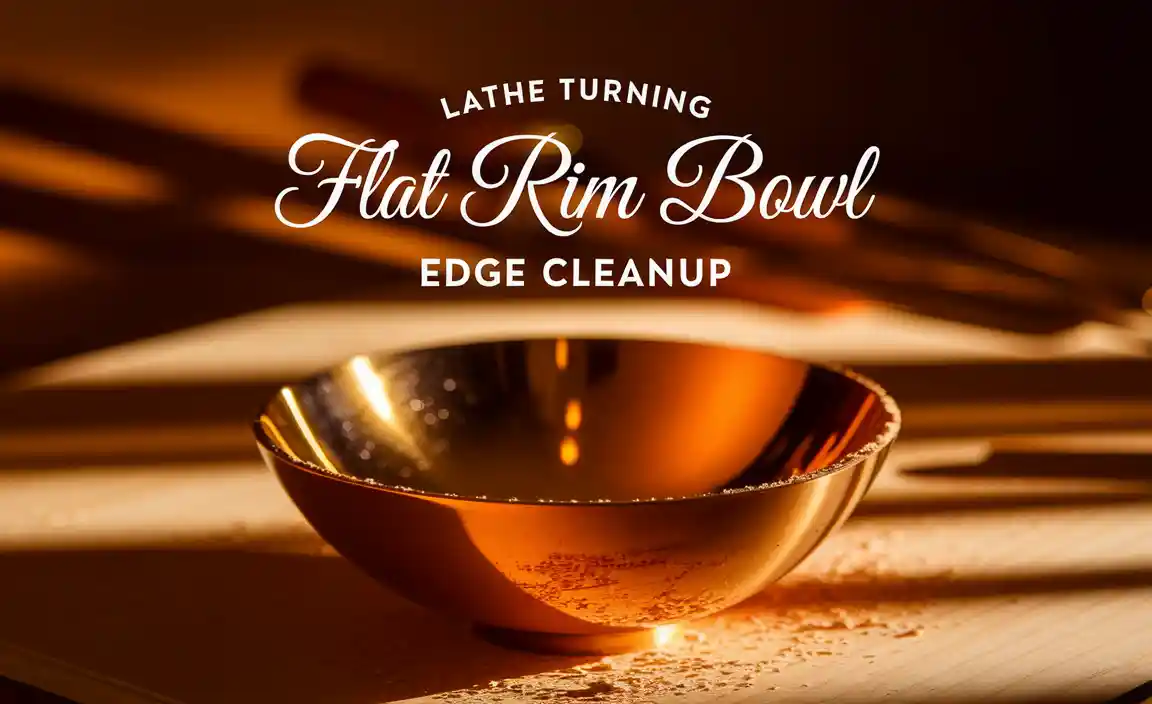

Have you ever watched a lathe machine spin and create amazing shapes from solid metal? It’s a fascinating sight! Lathe machines are powerful tools that shape materials with precision. Recently, there’s been some buzz about mixing lathe machines with machine learning. Sounds cool, right?

Imagine a lathe that can learn what you want it to do. With machine learning, these machines could become even smarter. They could figure out the best way to cut and shape metal. This means you get better products, made faster and with less waste. Who wouldn’t want that?

Fun fact: A skilled operator can make beautiful designs with a lathe machine. But what if a machine could help and improve the process? Combining lathe tools with modern technology might just change how we work with metal forever!

Lathe Machine Learning: Enhancing Metal Lathe Tools Efficiency

Lathe Machine Learning and Metal Lathe Tools

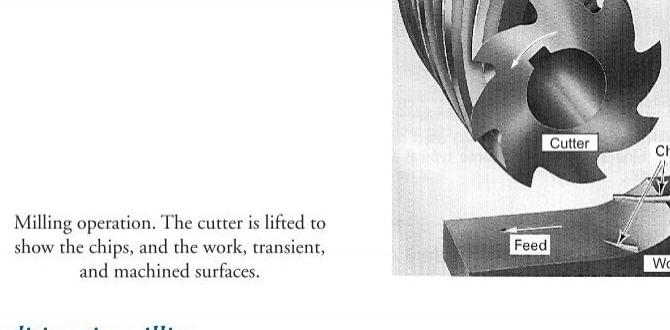

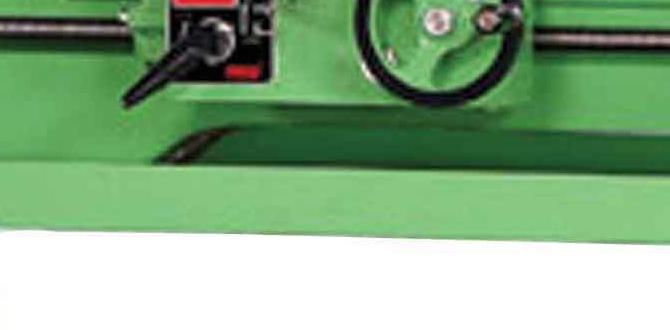

Lathe machines shape and cut materials into precise forms. They’re essential in metalworking, where accuracy is key. Ever wondered how technology improves these tools? Machine learning analyzes patterns and optimizes designs. Imagine a lathe that learns from past jobs to enhance future performance. This blend of traditional craftsmanship and modern technology leads to better tools. With advanced lathe features, workers can produce intricate designs faster than ever. Curious about how this technology shapes the future of manufacturing?What is a Lathe Machine?

Definition and basic function of a lathe machine. Brief history of lathe machines in manufacturing.A lathe machine is a tool used to shape materials like metal or wood. It spins these materials while cutting tools carve them into the desired shape. Think of it as a giant pencil sharpener, but instead of pencils, it shaves off pieces of metal!

The lathe has been around for thousands of years, dating back to ancient Egypt. It has played a big role in making everything from furniture to car parts. Without it, we might still be using square wheels! So, whether you’re a budding engineer or just someone who enjoys tinkering, the lathe machine is a handy tool to know.

| Year | Key Development |

|---|---|

| 3000 BC | First known lathe used in ancient Egypt |

| 18th Century | Modern lathe designs emerge with the Industrial Revolution |

| 21st Century | Introduction of CNC lathes with computer controls |

Importance of Lathe Machines in Metalworking

Roles of lathe machines in metal shaping and production. Industries that heavily utilize metal lathe tools.Lathe machines are like magic wands in metalworking. They spin metal and shape it into amazing designs. This helps industries create everything from tiny screws to big engine parts. Can you imagine how we’d build things without them? Many businesses, like automotive and aerospace, rely on metal lathe tools daily. They ensure parts fit together like puzzle pieces! Here’s a look at some key industries:

| Industry | Uses |

|---|---|

| Automotive | Engine parts, shafts |

| Aerospace | Aircraft components |

| Manufacturing | Small and large tools |

Without lathe machines, our favorite vehicles might not zoom around, and planes could struggle to take off. They truly make the metal world go round!

Applications of Machine Learning with Lathe Tools

Predictive maintenance and its benefits. Quality control improvements through machine learning algorithms.Machine learning is becoming a superhero for lathe tools! Predictive maintenance can spot problems before they happen. Imagine your lathe yelling, “Hey! I need a break!” This saves time and keeps money in your pocket. On the other side, quality control gets an upgrade with fancy algorithms. They help catch mistakes faster than a cheetah on roller skates. Let’s take a peek at how they work:

| Application | Benefits |

|---|---|

| Predictive Maintenance | Prevents breakdowns, saves costs |

| Quality Control | Improves accuracy, reduces waste |

Challenges in Implementing Machine Learning in Lathe Operations

Common obstacles faced by manufacturers. Strategies to overcome these challenges.Using machine learning in lathe operations can be tough. Manufacturers face issues like data shortages, lack of skilled workers, and expenses. A few ways to tackle these challenges are:

- Invest in employee training to boost skills.

- Gather and store data effectively.

- Consider affordable technology options.

By understanding these problems, companies can improve their processes. That means creating better products in less time.

What barriers exist in machine learning for lathe tools?

Common obstacles include insufficient data, high costs, and limited expertise.

How can manufacturers overcome these challenges?

Investing in training and technology is key.

Future Trends in Lathe Machine Learning

Innovations on the horizon for lathe technology. Potential impacts of AI and machine learning on metalworking.New ideas are coming for lathe machines! Soon, AI and machine learning may make metalworking faster and better. These technologies can help machines learn from their experiences. This will allow them to create improved parts with less waste. Here are some exciting trends:

- Smart sensors that check quality in real-time.

- Predictive maintenance to avoid problems before they happen.

- Customization options to fit individual needs.

These changes will help workers be more efficient and create amazing products. Imagine a world where lathe machines think for themselves!

What impact will AI have on metalworking?

AI will help metalworkers be more productive and create better products. It can analyze data quickly. It finds ways to improve designs and reduces errors.

Choosing the Right Metal Lathe Tool

Factors to consider (size, specifications, and power). Guidelines for selecting tools based on specific projects.Choosing the best metal lathe tool can be exciting but tricky. First, consider the size. A small lathe is good for simple projects. A bigger lathe can handle heavier work. Next, look at specifications. Each tool has features that change how it works. Power matters too. A stronger motor can do more tasks easily.

- Size: small for toys, large for furniture

- Specifications: check speed and capacity

- Power: higher power for tough jobs

Think about your project. Do you need a precise cut or just shaping? Understanding these factors will help you make a good choice.

What should you consider when choosing a metal lathe tool?

Consider size, specifications, and power to make the right choice. Select based on your project needs and expected outcomes to ensure success.

Tips for Optimizing Lathe Machine Performance

Maintenance best practices. Utilizing software and machine learning for efficiency.To keep a lathe machine running well, follow good maintenance practices. Check and clean the machine regularly. This helps avoid problems. Also, use software and machine learning to boost efficiency. They help find issues early and schedule repairs. This saves time and energy. Here are some ways to optimize performance:

- Inspect parts often and oil moving parts.

- Keep your workspace clean to avoid accidents.

- Use software tools for monitoring machine status.

- Train your team on new technologies.

How can software improve lathe machine performance?

Software helps identify problems early, allowing for quick fixes and better performance.Regular care and smart technology can save money and time. It’s worth the effort! Remember, a well-maintained lathe lasts longer and can create better work. Why not make your tasks easier and faster? It’s simple when you stay on top of things!

Resources for Further Learning

Recommended books, websites, and industry publications. Online courses and workshops for enthusiasts and professionals.Learning about lathe machines can be fun! Here are some helpful resources:

- Books: “Machining Fundamentals” and “Lathe Basics” for clear insights.

- Websites: Check out Machinery’s Handbook and Instructables for tutorials.

- Online Courses: Look for courses on Udemy or Coursera designed for both beginners and experts.

- Industry Publications: Subscribe to magazines like Modern Machine Shop for the latest news.

These resources will help you learn more about metal lathe tools and their uses!

What are the best ways to learn about lathe machines?

Try books, videos, and online courses! They make learning easy and fun.

Conclusion

In summary, lathe machines are powerful tools for shaping metal. Learning how to use them opens up creative possibilities for projects. You can explore different metal lathe tools to improve your skills. We encourage you to practice and learn more about lathe techniques. With the right knowledge, you can create amazing things with your own hands!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Tools:Sure! Let’s talk about lathe machines. A lathe is a tool that spins metal to shape it. Machine learning helps improve how these machines work. For example, it can make them faster and safer. You can use metal lathe tools to create things like parts for cars or toys!

Sure! Just ask your question, and I will provide you with a simple answer.

How Can Machine Learning Algorithms Improve The Efficiency And Precision Of Operations Performed By Metal Lathe Machines?Machine learning helps metal lathe machines work better and faster. It learns from past actions, so it knows how to cut metals more accurately. You can find problems before they happen, which saves time and materials. This makes the machines safer and helps us create better metal parts. Overall, machines can do their jobs more efficiently and accurately with this smart help!

What Types Of Data Are Most Valuable For Training Machine Learning Models In The Context Of Lathe Machining Processes?To train machine learning models for lathe machining, we need good data. This includes things like the speed of the lathe, the type of material being worked on, and the shape we want to create. We also look at measurements like how smooth the finished piece is. All this information helps the model learn how to make better parts. The more data we have, the better the results will be!

How Can Predictive Maintenance Powered By Machine Learning Reduce Downtime And Maintenance Costs For Metal Lathe Tools?Predictive maintenance uses smart tools to watch metal lathe machines. It helps us notice problems before they happen. This means we can fix things while they are still working, which prevents sudden breakdowns. When machines don’t break down, we save money and time on repairs. This way, we can keep making things and work better!

In What Ways Can Machine Learning Enhance The Toolpath Optimization For Cnc Lathes To Increase Productivity?Machine learning can help make CNC lathes work better and faster. It learns from past jobs to find the best ways to move tools. This means machines can cut shapes more quickly and with less waste. As a result, we can finish jobs faster and make more parts in less time. Machine learning is like having a smart helper for our machines!

What Are The Challenges And Limitations In Integrating Machine Learning Technologies With Traditional Metal Lathe Tools During Manufacturing Processes?Integrating machine learning with metal lathes can be tricky. First, we need good data to teach the machines. Sometimes, the old tools don’t work well with new technology. We may also face problems with setting everything up correctly. Finally, it can cost a lot of money and take a lot of time.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Let’s talk about lathe machines. A lathe is a tool that spins metal to shape it. Machine learning helps improve how these machines work. For example, it can make them faster and safer. You can use metal lathe tools to create things like parts for cars or toys!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I will provide you with a simple answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Improve The Efficiency And Precision Of Operations Performed By Metal Lathe Machines?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning helps metal lathe machines work better and faster. It learns from past actions, so it knows how to cut metals more accurately. You can find problems before they happen, which saves time and materials. This makes the machines safer and helps us create better metal parts. Overall, machines can do their jobs more efficiently and accurately with this smart help!”}},{“@type”: “Question”,”name”: “What Types Of Data Are Most Valuable For Training Machine Learning Models In The Context Of Lathe Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To train machine learning models for lathe machining, we need good data. This includes things like the speed of the lathe, the type of material being worked on, and the shape we want to create. We also look at measurements like how smooth the finished piece is. All this information helps the model learn how to make better parts. The more data we have, the better the results will be!”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Powered By Machine Learning Reduce Downtime And Maintenance Costs For Metal Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses smart tools to watch metal lathe machines. It helps us notice problems before they happen. This means we can fix things while they are still working, which prevents sudden breakdowns. When machines don’t break down, we save money and time on repairs. This way, we can keep making things and work better!”}},{“@type”: “Question”,”name”: “In What Ways Can Machine Learning Enhance The Toolpath Optimization For Cnc Lathes To Increase Productivity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can help make CNC lathes work better and faster. It learns from past jobs to find the best ways to move tools. This means machines can cut shapes more quickly and with less waste. As a result, we can finish jobs faster and make more parts in less time. Machine learning is like having a smart helper for our machines!”}},{“@type”: “Question”,”name”: “What Are The Challenges And Limitations In Integrating Machine Learning Technologies With Traditional Metal Lathe Tools During Manufacturing Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Integrating machine learning with metal lathes can be tricky. First, we need good data to teach the machines. Sometimes, the old tools don’t work well with new technology. We may also face problems with setting everything up correctly. Finally, it can cost a lot of money and take a lot of time.”}}]}