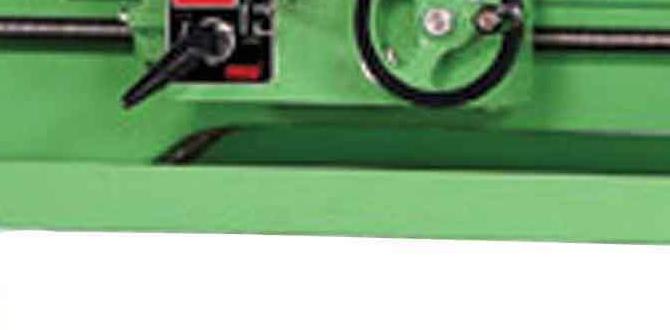

Have you ever watched a lathe machine in action? It can transform a simple piece of metal into a beautiful, smooth shape. Watching the process is like magic! But did you know that the right lathe machine oil is crucial for keeping this magic going? Without proper lubrication, a metal lathe can get damaged quickly.

Imagine you are in a workshop. The sun shines through the window as you hear the steady hum of a lathe bench working hard. There’s a sense of excitement in the air. You might wonder, how do these machines run so smoothly? The secret often lies in the oil used to lubricate them. A good lathe machine oil ensures that everything runs smoothly and prevents wear and tear.

So, what should you look for in lathe machine oil? Is there a special type for metal lathes? Let’s dive into this fascinating topic and explore how the right oil can make all the difference in your woodworking projects.

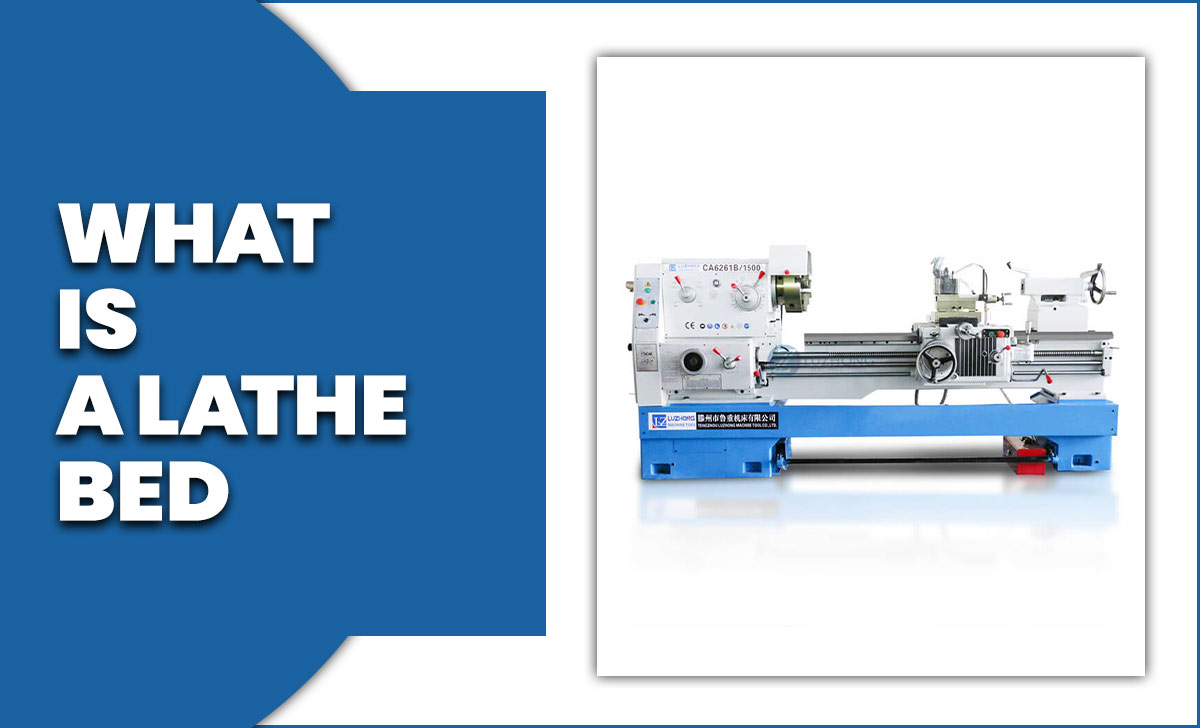

Choosing The Right Lathe Machine Oil For Your Metal Lathe Bench Lathe Machines Are Essential Tools In Metalworking, Providing Precision And Efficiency For Various Tasks. One Crucial Aspect Of Maintaining A Lathe Machine Is The Use Of Appropriate Lubrication, Specifically Lathe Machine Oil. The Right Oil Not Only Ensures Smooth Operation But Also Prolongs The Life Of The Machine And Enhances The Quality Of The Finished Product. In This Article, We Will Explore The Importance Of Lathe Machine Oil, The Types Suitable For A Metal Lathe Bench, And How To Properly Apply It. Importance Of Lathe Machine Oil Lathe Machine Oil Serves Several Critical Functions. It Reduces Friction Between Moving Parts, Which Minimizes Wear And Tear. This Not Only Helps Maintain The Accuracy Of Cuts But Also Reduces Heat Generation, Preventing Potential Damage To The Machine. Additionally, Oil Creates A Barrier Against Moisture And Contaminants, Further Protecting The Integrity Of The Lathe. Types Of Lathe Machine Oil When Selecting Lathe Machine Oil For Your Metal Lathe Bench, Several Options Are Available: 1. **Mineral Oil**: Commonly Used For Its Excellent Lubricating Properties And Cost-Effectiveness. Ideal For General-Purpose Lathing. 2. **Synthetic Oil**: Offers Superior Performance, Particularly At High Temperatures Or Under Heavy Loads. It Tends To Have Better Stability And A Longer Service Life. 3. **Cutting Oils**: Specifically Designed For Machining Processes, These Oils Often Contain Additives To Enhance Performance. They Can Be Oil-Based Or Water-Soluble. 4. **Way Lubricants**: Formulated To Provide High Adhesion And Ensure A Consistent Film Strength On The Ways (The Flat Surfaces On Which The Carriage Moves). How To Apply Lathe Machine Oil To Ensure Optimal Performance Of Your Metal Lathe Bench, Follow These Steps For Proper Oil Application: 1. **Clean The Surfaces**: Before Applying New Oil, Clean The Machine Surfaces To Remove Old Oil And Debris. 2. **Apply Evenly**: Use A Lint-Free Cloth Or A Dedicated Oil Applicator To Spread An Even Layer Of Oil On The Moving Parts. 3. **Check Levels**: Ensure That The Oil Level Is Adequate And Top Off As Necessary To Maintain Consistent Lubrication. 4. **Regular Maintenance**: Establish A Consistent Schedule For Oiling Your Lathe. Regular Maintenance Will Prevent Potential Issues And Keep Your Machine Running Smoothly. Conclusion Choosing The Right Lathe Machine Oil For Your Metal Lathe Bench Is Vital For Optimal Performance And Longevity Of Your Equipment. By Understanding The Importance Of Lubrication And Selecting The Appropriate Type Of Oil, You Can Enhance The Efficacy Of Your Machine And Ensure High-Quality Output On Your Projects. Regular Application And Maintenance Will Keep Your Lathe In Excellent Working Condition.

Understanding Lathe Machine Oil for Metal Lathes

Lathe machine oil is vital for metal lathe benches. It helps lubricate and cool metal parts during operation, ensuring smooth functioning. Using the right oil can extend the life of your lathe. Did you know that different metals require different types of oil to perform optimally? Proper maintenance, including regular oil checks, is key to avoiding breakdowns. A well-oiled lathe can help you achieve precise cuts and enhance your projects. Isn’t that worth a little extra care?Understanding Lathe Machine Oil

Definition and purpose of lathe machine oil. Types of lathe machine oil and their characteristics.Lathe machine oil is a special lubricant for metal lathes. It helps machines work better and last longer. The oil reduces friction and heat. That keeps the parts from wearing out. There are different types of lathe machine oil, including:

- Mineral Oil: Common and affordable, it works well for most tasks.

- Synthetic Oil: Offers better protection and lasts longer.

- Vegetable Oil: Eco-friendly, but may not last as long.

Choosing the right oil helps your machine run smoothly and efficiently.

What is the purpose of lathe machine oil?

The purpose of lathe machine oil is to lubricate and protect machinery, reducing wear and overheating.

Importance of Using the Right Oil for Metal Lathes

Benefits of proper lubrication for performance and longevity. Consequences of using incorrect oil in metal lathes.Using the right oil for your metal lathe is like giving it a big hug! Proper lubrication helps keep your machine running smoothly and lasts longer. It minimizes wear and tear, allowing for better performance. On the flip side, using the wrong oil can lead to sludge and overheating. Imagine trying to run a marathon in flip-flops—it’s just not going to end well! Look at the table below for a quick comparison:

| Type of Oil | Benefits | Consequences of Wrong Oil |

|---|---|---|

| Correct Oil | Better performance, longer life | Nothing! |

| Wrong Oil | N/A | Sludge buildup, overheating |

So, remember: the right oil is key to keeping your metal lathe happy and healthy!

Choosing the Best Lathe Machine Oil

Factors to consider when selecting lathe oil. Comparison of synthetic vs. mineral oils.Choosing the right lathe machine oil is important for good performance. Here are some factors to think about:

- Viscosity: This affects how well the oil flows.

- Additives: Some oils contain special ingredients for better protection.

- Working temperature: Make sure the oil suits your working conditions.

Now, let’s compare two types of oils:

- Synthetic oils: They last longer and resist heat.

- Mineral oils: They are cheaper but may need to be changed more often.

Choosing the best oil keeps your lathe running smoothly. Remember, what you select can affect your work quality.

What should I consider when choosing lathe machine oil?

Think about viscosity, additives, and working temperature. These factors are crucial for your lathe’s performance.

Application of Lathe Machine Oil

Steps for properly applying oil on a metal lathe. Frequency of oil application based on usage.Applying oil to a metal lathe is easy peasy! First, make sure the machine is off and cool. Use a clean cloth to wipe down the lathe, removing any dust or dirt. Then, apply a small amount of lathe machine oil to the moving parts. Just think of it like giving your lathe a nice spa day!

| Usage Level | Oil Application Frequency |

|---|---|

| Heavy Use | Every shift |

| Moderate Use | Weekly |

| Light Use | Monthly |

Make sure to follow these steps for smooth operations. A well-oiled lathe can last long, just like your favorite pair of shoes! So, keep that oil flowing and enjoy your working time!

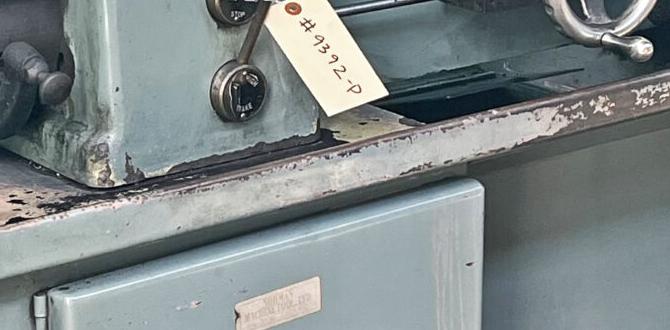

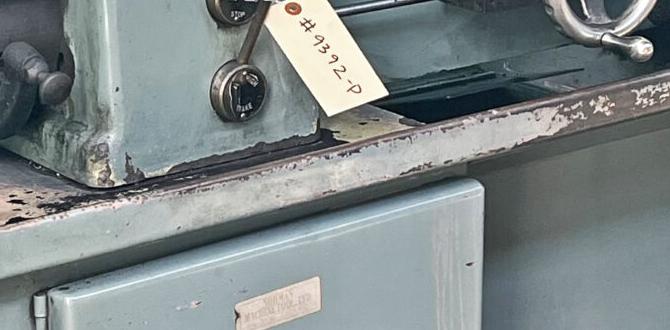

Maintenance Tips for Metal Lathe Benches

Best practices for oiling to ensure optimal lathe operation. Common maintenance mistakes to avoid.To keep your metal lathe bench running smoothly, oiling is key! Use lathe machine oil on all moving parts. This helps them glide like a superhero on a slick slide! Consistent oiling prevents rust and wear. Don’t forget to wipe away excess oil—too much can turn into a slippery slip-and-slide. Watch out for common mistakes, like forgetting to check for dirt buildup. Dust is not your friend; it’s like confetti in a clean room!

| Maintenance Tips | Common Mistakes |

|---|---|

| Oil all moving parts regularly. | Neglecting dirt and dust. |

| Wipe off excess oil. | Using the wrong type of oil. |

| Check oil levels often. | Skipping regular clean-ups. |

FAQs About Lathe Machine Oil

Common questions and answers regarding lathe oil usage. Troubleshooting common lubrication issues on metal lathes.When it comes to using lathe machine oil, many users have questions. A big one is, “Why is the oil important?” The answer is simple: it keeps everything running smoothly! Without enough oil, lathes can squeak like a mouse on roller skates. Another common query is, “What if my lathe makes weird noises?” Well, it might just be thirsty for oil! Ask your lathe nicely, and give it a drink. If problems persist, you might need to check for clogs or replace the oil. It’s like checking if your pet goldfish has enough water!

| Question | Answer |

|---|---|

| How often should I add oil? | Every time you use it! |

| Can I use any type of oil? | No, use lathe-specific oil! |

| What happens if I forget to oil? | Your lathe might just throw a tantrum! |

Conclusion

In summary, using lathe machine oil on a metal lathe bench is essential for smooth operation. Proper lubrication prevents rust and wear, keeping your tools in good shape. Always choose the right oil for your machine. You can enhance your skills by exploring more about lathe maintenance. Start your research today and ensure your lathe is always ready for your next project!FAQs

What Type Of Oil Is Best Suited For Lubricating A Metal Lathe Machine?The best oil for a metal lathe machine is usually a heavy machine oil. This type of oil is thick and sticks to the metal parts. It helps keep everything moving smoothly. You can also use way oil, which is made just for machines. Always check the machine’s manual to see what oil it recommends!

How Often Should You Change The Oil In A Lathe Machine To Ensure Optimal Performance?You should change the oil in a lathe machine every 50 to 100 hours of use. If you use it a lot, change it more often. Check the oil level regularly to keep it clean. This helps the machine work better and last longer. Taking care of it is important!

What Are The Consequences Of Using The Wrong Type Of Oil In A Metal Lathe?Using the wrong type of oil in a metal lathe can cause problems. The machine can get too hot and might break down. It could also make parts wear out faster. If the oil doesn’t protect the metal, rust can form. This means we might have to fix or replace the lathe more often.

Are There Specific Maintenance Practices For The Lathe Bench That Can Extend The Life Of The Machine?Yes, there are simple ways to take care of your lathe bench. First, always clean it after using it. This means wiping off dust and shavings. Second, check for loose parts and tighten them if needed. Lastly, keep it lubricated by adding oil to moving parts. This helps everything work smoothly and lasts longer.

How Do You Properly Clean And Oil The Moving Parts Of A Lathe Machine?To clean the moving parts of a lathe machine, first, unplug it for safety. Use a cloth to wipe away dust and dirt. For oiling, use a small amount of machine oil on a clean cloth. Rub the oil on the moving parts gently. This keeps the machine running smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Type Of Oil Is Best Suited For Lubricating A Metal Lathe Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The best oil for a metal lathe machine is usually a heavy machine oil. This type of oil is thick and sticks to the metal parts. It helps keep everything moving smoothly. You can also use way oil, which is made just for machines. Always check the machine’s manual to see what oil it recommends!”}},{“@type”: “Question”,”name”: “How Often Should You Change The Oil In A Lathe Machine To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a lathe machine every 50 to 100 hours of use. If you use it a lot, change it more often. Check the oil level regularly to keep it clean. This helps the machine work better and last longer. Taking care of it is important!”}},{“@type”: “Question”,”name”: “What Are The Consequences Of Using The Wrong Type Of Oil In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the wrong type of oil in a metal lathe can cause problems. The machine can get too hot and might break down. It could also make parts wear out faster. If the oil doesn’t protect the metal, rust can form. This means we might have to fix or replace the lathe more often.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Practices For The Lathe Bench That Can Extend The Life Of The Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are simple ways to take care of your lathe bench. First, always clean it after using it. This means wiping off dust and shavings. Second, check for loose parts and tighten them if needed. Lastly, keep it lubricated by adding oil to moving parts. This helps everything work smoothly and lasts longer.”}},{“@type”: “Question”,”name”: “How Do You Properly Clean And Oil The Moving Parts Of A Lathe Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean the moving parts of a lathe machine, first, unplug it for safety. Use a cloth to wipe away dust and dirt. For oiling, use a small amount of machine oil on a clean cloth. Rub the oil on the moving parts gently. This keeps the machine running smoothly.”}}]}