Have you ever wondered what makes a lathe machine work so smoothly? It’s not just the machine itself. One important factor is the oil used in its operation.

Lathe machine oil is designed specifically for machines like metal lathes. It helps keep the parts moving without friction. Imagine trying to ride a bike with rusty wheels! It wouldn’t be fun, right? The same goes for a lathe without the right oil.

Now, think about the power feed feature. This handy function lets the lathe work automatically. It’s like having an extra pair of hands! But without the right oil, that power feed could struggle, slowing down your work.

Did you know that using the wrong oil can actually harm your lathe? Many users may not realize this. Let’s explore the importance of selecting the right lathe machine oil for your metal lathe and its power feed. Your projects might just depend on it!

Lathe Machine Oil For Metal Lathe Power Feed Performance

Understanding Lathe Machine Oil for Metal Lathe Power Feed

Lathe machine oil plays a crucial role in metal lathes. It helps the power feed system run smoothly. Without proper lubrication, the machine can wear out quickly. Did you know that using the right oil can extend the life of your lathe? It’s vital for efficient operation. Whether you are a hobbyist or a pro, choosing the right oil makes a big difference. Don’t risk damaging your equipment by skimping on maintenance!Understanding Lathe Machines

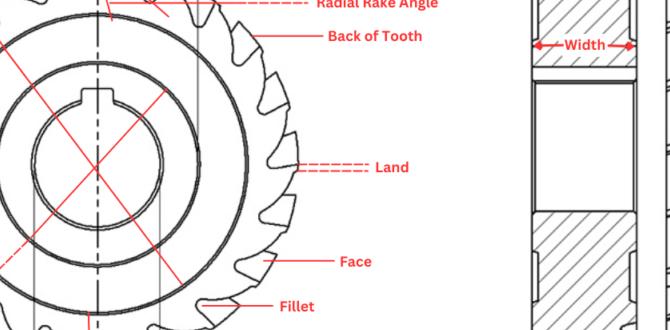

Definition and types of lathe machines. The importance of lubrication in lathe operations.A lathe machine is a tool that shapes metal and wood. It spins the material while cutting tools sculpt it. There are different types of lathes, such as bench lathes for small jobs and industrial lathes for larger projects. Proper lubrication is very important for lathe operations. It reduces friction, allowing smooth movement and longer tool life.

- Increases precision and finish

- Prevents overheating

- Extends the life of the machine

What types of lathe machines exist?

Common types of lathe machines include:

- Wood lathes

- Metal lathes

- CNC lathes

What is Lathe Machine Oil?

Composition and types of lathe machine oil. Benefits of using specialized lathe oil.Lathe machine oil is specially made to keep machines running smoothly. It usually contains base oils and additives. These ingredients help reduce friction and heat. There are many types, including mineral oil and synthetic oil.

Using special lathe oil offers great benefits:

- Prevents rust

- Adds lubrication

- Improves machine life

Choosing the right oil can keep your tools in tip-top shape! It’s worth it for good performance.

What is the composition of lathe machine oil?

The composition consists mainly of base oils and special additives. This mix helps in lubrication and protection.

What are the types of lathe machine oil?

Common types include:

- Mineral Oil

- Synthetic Oil

What are the benefits of specialized lathe oil?

The benefits of using specialized lathe oil include better performance and less wear and tear on your machine.

Choosing the Right Oil for Metal Lathe Power Feed

Factors to consider when selecting lathe oil. Comparison of popular lathe oil brands.Picking the right oil for your metal lathe’s power feed is crucial. Consider factors like viscosity, which helps the oil flow smoothly. You should also look at additives that protect against wear. Popular brands include Mobil, Shell, and Vactra. Each has unique features. Always check user reviews to find the best fit for your machine.

What should I look for in lathe oil?

Focus on viscosity, additives, and compatibility with your lathe. Choose oil that reduces wear and improves performance.

Popular Lathe Oil Brands:

- Mobil – Known for high-quality protection.

- Shell – Offers great viscosity options.

- Vactra – Reliable choice for smooth operation.

Application Techniques for Lathe Machine Oil

Best practices for applying oil to a lathe machine. Frequency of oil application for optimal performance.Applying oil to your lathe machine is like giving it a nice spa day. Regular maintenance keeps it running smoothly and helps prevent wear and tear. A good rule of thumb is to oil the machine every time you change tools or at least once a day during heavy use. Too little oil can make it cranky, just like when you skip breakfast. Remember, too much oil can be messy, like a raccoon in a peanut butter jar!

| Application Frequency | Best Practice |

|---|---|

| After tool changes | Apply oil to the ways and slides |

| Daily (heavy use) | Check oil levels and refill as needed |

| Weekly | Inspect for wear and shine |

Keeping an eye on oil levels is key. This simple routine can prolong your lathe’s life, making you the proud parent of a happy machine! Who knew machinery could be so needy?

Common Mistakes in Using Lathe Machine Oil

Misconceptions about oil types and usage. Signs of inadequate lubrication and their consequences.Many people think any oil works for a lathe machine. This is not true! Different oils have special jobs. Using the wrong one can cause trouble. Signs you need more oil include strange noises or metal parts heating up. These problems can lead to serious damage.

- Wrong oil choice can cause wear.

- Not enough lubrication can overheat parts.

- Strange noises mean something is wrong.

What to consider when choosing lathe machine oil?

Look for oil that suits your machine’s needs. Consider viscosity and temperature ranges.

Maintenance Tips for Enhancing Lathe Performance

Regular maintenance routines for lathe machines. How oil quality affects machine longevity and precision.Keeping your lathe machine in top shape is essential for smooth operation. Regular maintenance is key. Check lubricants and filters often, as this helps prevent wear and tear. Dirty oil is like trying to run a race with muddy shoes! High-quality oil boosts machine life and accuracy. It ensures everything runs like a well-oiled machine—literally! Here’s a quick look at oil quality on performance:

| Oil Quality | Machine Longevity | Precision |

|---|---|---|

| High Quality | Longer | Better |

| Low Quality | Shorter | Worse |

So, treat your lathe like a pet. A little care goes a long way!

Environmental Considerations in Lathe Oil Use

Safe disposal methods for lathe machine oil. Development of ecofriendly lathe oils.Using lathe machine oil can be tricky, especially when it comes to caring for the environment. First, it’s important to avoid pouring used oil down the drain or in the trash. Instead, look for local recycling centers that accept oil. They’ll handle it safely, and you won’t have to worry about creating a mini oil spill in your backyard!

Also, some companies are now developing eco-friendly lathe oils. These oils are made with natural ingredients, ensuring they are both effective and less harmful. Going green with your lathe oil is like having your cake and eating it too! Why not help the planet while you work?

| Disposal Method | Eco-Friendly Option |

|---|---|

| Recycle at a center | Use biodegradable oil |

| Contact hazardous waste facilities | Choose plant-based oils |

Remember, every small action counts. Let’s keep our earth spinning smoothly, just like our trusty lathe machines!

Conclusion

In summary, using lathe machine oil keeps your metal lathe running smoothly. It protects parts and enhances the power feed’s performance. Regular maintenance is key to long-lasting tools. You can find more tips online to improve your skills. Remember, a well-oiled lathe leads to better results. Let’s keep learning and get the most out of our machines!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Oil, Metal Lathe, And Power Feed:Sure! Lathe machine oil helps metal lathes run smoothly. You need it to keep the machine clean and working well. A metal lathe shapes metal into different forms. It often uses power feed to move the metal automatically. This makes it easier and faster to work!

Sure! Please go ahead and ask your question. I’m here to help!

What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Does It Affect The Machine’S Performance?You should use machine oil or cutting oil to lubricate a metal lathe. This oil helps the machine move smoothly. It reduces friction, which can cause wear. Good lubrication keeps the lathe working well and lasts longer. Always check the oil level to keep your machine happy!

How Can Proper Lubrication With Lathe Machine Oil Enhance The Longevity And Precision Of The Power Feed Mechanism?Using lathe machine oil helps keep the power feed mechanism running smoothly. When we add oil, it reduces friction between moving parts. This means less wear and tear, so the parts last longer. It also helps make sure everything lines up correctly, improving accuracy. In simple terms, oil keeps things moving well, so you can work better and longer!

What Are The Signs That Indicate A Lathe Machine May Be Running Low On Oil Or Requires Maintenance?If a lathe machine is low on oil, you might hear strange noises or see parts moving slower. The machine might feel hot to touch. You could also notice a dirty or grimy appearance. If it shakes or vibrates more than usual, it needs care. These signs mean it’s time to check oil or get help.

How Often Should You Change The Oil In A Metal Lathe’S Power Feed System To Ensure Optimal Performance?You should change the oil in a metal lathe’s power feed system every 100 hours of use. If you use it a lot, check the oil more often. Clean oil helps the machine run better and last longer. Always follow the machine’s manual for specific advice. Keeping it clean is important!

What Are The Potential Consequences Of Using The Wrong Type Of Oil In A Lathe Machine’S Power Feed System?Using the wrong oil in a lathe machine can cause problems. The machine may not work as smoothly, which can lead to mistakes. It might even get damaged, making it stop working completely. Plus, you could spend a lot of money fixing it. So, it’s very important to use the right oil.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Oil, Metal Lathe, And Power Feed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe machine oil helps metal lathes run smoothly. You need it to keep the machine clean and working well. A metal lathe shapes metal into different forms. It often uses power feed to move the metal automatically. This makes it easier and faster to work!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question. I’m here to help!”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Does It Affect The Machine’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use machine oil or cutting oil to lubricate a metal lathe. This oil helps the machine move smoothly. It reduces friction, which can cause wear. Good lubrication keeps the lathe working well and lasts longer. Always check the oil level to keep your machine happy!”}},{“@type”: “Question”,”name”: “How Can Proper Lubrication With Lathe Machine Oil Enhance The Longevity And Precision Of The Power Feed Mechanism?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using lathe machine oil helps keep the power feed mechanism running smoothly. When we add oil, it reduces friction between moving parts. This means less wear and tear, so the parts last longer. It also helps make sure everything lines up correctly, improving accuracy. In simple terms, oil keeps things moving well, so you can work better and longer!”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Lathe Machine May Be Running Low On Oil Or Requires Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe machine is low on oil, you might hear strange noises or see parts moving slower. The machine might feel hot to touch. You could also notice a dirty or grimy appearance. If it shakes or vibrates more than usual, it needs care. These signs mean it’s time to check oil or get help.”}},{“@type”: “Question”,”name”: “How Often Should You Change The Oil In A Metal Lathe’S Power Feed System To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a metal lathe’s power feed system every 100 hours of use. If you use it a lot, check the oil more often. Clean oil helps the machine run better and last longer. Always follow the machine’s manual for specific advice. Keeping it clean is important!”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Using The Wrong Type Of Oil In A Lathe Machine’S Power Feed System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the wrong oil in a lathe machine can cause problems. The machine may not work as smoothly, which can lead to mistakes. It might even get damaged, making it stop working completely. Plus, you could spend a lot of money fixing it. So, it’s very important to use the right oil.”}}]}