Have you ever wondered how metal parts are made? Lathe machining is a fascinating process that lets us shape metal into various forms. Imagine a tool that can spin metal and carve it into precise pieces. That’s what a lathe does! Using a metal lathe bench, workers create everything from tiny screws to large machinery parts.

In workshops around the world, lathe machining plays a crucial role. It helps build cars, airplanes, and even toys. What if I told you that a lathe bench can be a craftsman’s best friend? With the right skills, you can craft amazing projects! The sound of metal being shaped is almost music to the ears of a skilled worker.

So, why should you learn more about lathe machining? Understanding this process can open up exciting possibilities. Whether you’re a hobbyist or just curious, there’s so much to discover. Let’s explore the world of lathe machining and see how it works!

Lathe Machining: Essential Guide To Metal Lathe Bench Use

Understanding Lathe Machining with Metal Lathes

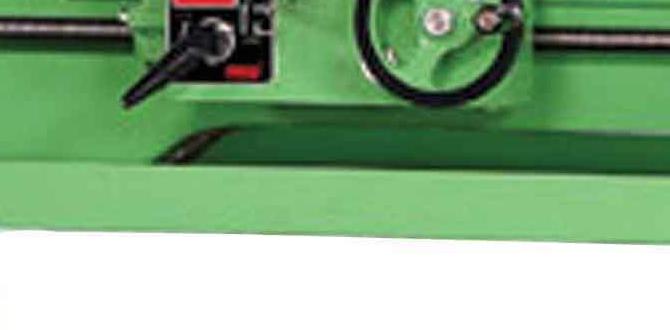

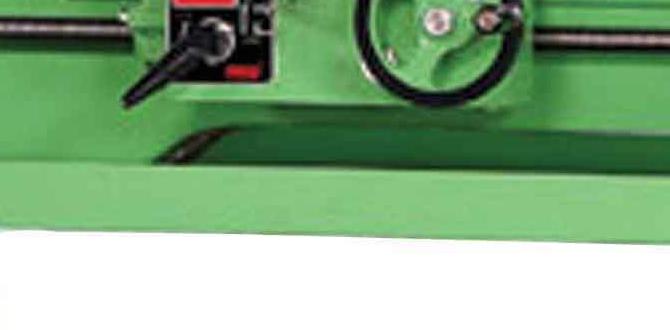

Lathe machining is a fascinating process that shapes metal into useful items. Picture a craftsman turning a piece of metal on a spinning lathe. This machine cuts the metal, creating smooth and precise shapes. A bench lathe is perfect for hobbyists, fitting neatly on a worktable. Did you know that lathes can make anything from simple knobs to intricate parts? Learning about lathe machining opens up endless creative possibilities!What is a Metal Lathe Bench?

Description and features of a metal lathe bench. Comparison between metal lathe benches and other types of lathes.A metal lathe bench is a sturdy worktable designed to hold a metal lathe. Think of it as the lathe’s best friend, ready to support it like a trusty sidekick. These benches are often heavy and made from solid materials, making them perfect for preventing unwanted wobbling while you work. They usually have space for tools, making it easier to stay organized.

Unlike wood lathes, which are like the lightweights of the lathe world, metal lathe benches are built for serious work. They offer stability and strength, features you won’t find in a standard workbench. It’s like comparing a sturdy elephant to a wobbly giraffe—both have their charm, but one is clearly better for heavy lifting!

| Feature | Metal Lathe Bench | Wood Lathe Bench |

|---|---|---|

| Material | Heavy-duty metal | Lightweight wood |

| Stability | High | Low |

| Durability | Long-lasting | May warp |

So, when you’re looking for the perfect spot to set up your lathe, think of a metal lathe bench. It’s the superhero of work surfaces, ready to support your metal marvels!

Key Components of a Metal Lathe Bench

Detailed breakdown of essential parts (bed, tailstock, headstock, etc.). Discussing the functionality of each component in the machining process.A metal lathe bench has key parts that work together. Each part helps shape metal into useful tools or pieces. Here’s a look at these essential components:

- Bed: The strong base that holds everything in place.

- Headstock: This part drives the spindle and holds the workpiece. It rotates the metal.

- Tailstock: It supports the other end of the workpiece and can hold tools.

- Carriage: Moves the cutting tool along the metal piece, helping to shape it.

Each part plays a big role in the machining process. They work together to make cutting metal easy and precise!

What is the function of each metal lathe component?

The bed supports the machine. The headstock holds and turns the metal. The tailstock supports other tools. Lastly, the carriage guides the cutting tool. Each part is important for smooth operation.

Setting Up Your Metal Lathe Bench

Stepbystep guide on installation and setup. Tips for proper alignment and securing the lathe.Getting your metal lathe bench ready is like making a perfect sandwich; it requires the right steps! First, find a sturdy spot in your workshop. Next, level the bench using a bubble level—because nobody wants a wobbly machine! Secure the lathe with bolts to keep it from dancing around. Check alignment with a ruler; misalignment is no joke. Lastly, double-check everything. If it feels right, then you’re ready to turn metal into magic!

| Step | Action |

|---|---|

| 1 | Choose a sturdy spot |

| 2 | Level the bench |

| 3 | Secure the lathe |

| 4 | Check alignment |

| 5 | Double-check everything |

Safety Precautions for Lathe Machining

Essential safety gear and measures while operating a lathe. Common hazards and how to prevent accidents.Before using any lathe, wearing proper safety gear is key. Essential items include safety glasses, gloves, and ear protection. These help protect against flying debris and loud noises. Here are some common hazards to keep in mind:

- Noise level can be high.

- Parts may fly off unexpectedly.

- Fingers or clothing can get caught.

To avoid accidents, always keep your area clean and free of clutter. Never wear loose clothing. Stay alert and focus on the task at hand.

What safety gear should I wear while using a lathe?

Wear safety glasses, gloves, and ear protection to stay safe.Common Hazards in Lathe Machining:

- High noise levels

- Flying materials

- The risk of entanglement

Techniques for Effective Lathe Machining

Best practices for turning, facing, and threading. Tips for achieving precision and quality in machining tasks.Using a lathe machine can be exciting if you know the right techniques. Here are some best practices:

- Turning: Always keep the cutting tool sharp and steady. This helps make clean cuts.

- Facing: Ensure the piece is well-secured. This gives you better stability while working.

- Threading: Use the right tool for the size of the thread. This makes the threads strong and precise.

To achieve precision and quality, remember these tips:

- Work slowly and carefully.

- Measure often with calipers.

- Adjust the speed for different materials.

With practice, you’ll become better at lathe machining!

What are the common lathe machining techniques?

The common lathe machining techniques include turning, facing, and threading. Each method has its specific tools and steps to ensure quality results.

Maintenance of Metal Lathes

Routine maintenance tasks to ensure optimal performance. Troubleshooting common issues and when to seek professional help.Keeping your metal lathe in great shape is important for smooth work. Regular maintenance helps avoid problems. Make sure to do the following tasks:

- Clean the lathe often to remove dust and debris.

- Check oil levels and add lubricant as needed.

- Tighten loose parts to prevent accidents.

- Inspect belts and replace them if worn out.

If you face issues like strange noises or decreased performance, check for simple fixes first. If problems continue, consider asking a professional for help.

What are common problems with metal lathes?

Common problems include vibration and inaccurate cuts. These usually come from worn parts or incorrect settings. Checking and adjusting your lathe can often solve these problems.

Conclusion

In conclusion, a metal lathe bench is essential for practicing lathe machining. It helps you create precise shapes from metal. Remember to prioritize safety while you work. You can start with simple projects to improve your skills. For more tips and techniques, explore books or online resources about lathe machining. Get to work and enjoy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathes:Sure! A lathe is a machine that spins metal or wood to shape it. You can make parts like screws or gears using a lathe. It helps us create smooth shapes by cutting away extra material. Lathes can work with different materials, like steel or plastic. They are important tools in factories and workshops.

Sure! Please give me the question you’d like me to answer, and I’ll be happy to help!

What Are The Key Components Of A Metal Lathe, And How Do They Influence The Machining Process?A metal lathe has several important parts. The bed is the strong base where everything sits. The headstock holds the motor and spinning part called the spindle. The tailstock helps you hold tools and pieces in place. Finally, the carriage moves the cutting tool to shape the metal. These parts work together to help us create smooth and precise shapes when we carve the metal.

What Types Of Materials Can Be Machined Using A Metal Lathe, And What Are The Considerations For Each Material?You can use a metal lathe to machine different materials like metal, wood, and plastic. When working with metal, like aluminum or steel, you need to use the right cutting tools. Harder metals may slow you down and wear out tools faster. Wood shapes nicely but can splinter, so you should go slow and steady. Plastic can melt if too much heat builds up, so keep it cool while you work.

How Do You Set Up A Metal Lathe For A Specific Machining Operation, Such As Turning Or Facing?To set up a metal lathe, first, make sure it’s turned off. Then, choose the right tool for the job, like a cutter for turning or facing. Next, attach the tool to the lathe’s tool holder securely. After that, adjust the speed settings to fit your task. Lastly, check the material you will work on and make sure everything is lined up straight.

What Are Common Safety Practices To Follow When Operating A Metal Lathe, And Why Are They Important?When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing so nothing gets caught. Always check that tools are clean and in good shape before starting. It’s also important to keep your hands away from moving parts. These practices help keep you safe and prevent accidents.

How Can You Maintain And Troubleshoot A Metal Lathe To Ensure Optimal Performance And Extend Its Lifespan?To keep your metal lathe working well, always clean it after use. Check the oil levels and add more if needed. Tighten any loose parts to prevent problems. If something seems broken, find the issue and fix it right away. Regular care helps your lathe last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that spins metal or wood to shape it. You can make parts like screws or gears using a lathe. It helps us create smooth shapes by cutting away extra material. Lathes can work with different materials, like steel or plastic. They are important tools in factories and workshops.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe, And How Do They Influence The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has several important parts. The bed is the strong base where everything sits. The headstock holds the motor and spinning part called the spindle. The tailstock helps you hold tools and pieces in place. Finally, the carriage moves the cutting tool to shape the metal. These parts work together to help us create smooth and precise shapes when we carve the metal.”}},{“@type”: “Question”,”name”: “What Types Of Materials Can Be Machined Using A Metal Lathe, And What Are The Considerations For Each Material?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a metal lathe to machine different materials like metal, wood, and plastic. When working with metal, like aluminum or steel, you need to use the right cutting tools. Harder metals may slow you down and wear out tools faster. Wood shapes nicely but can splinter, so you should go slow and steady. Plastic can melt if too much heat builds up, so keep it cool while you work.”}},{“@type”: “Question”,”name”: “How Do You Set Up A Metal Lathe For A Specific Machining Operation, Such As Turning Or Facing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, first, make sure it’s turned off. Then, choose the right tool for the job, like a cutter for turning or facing. Next, attach the tool to the lathe’s tool holder securely. After that, adjust the speed settings to fit your task. Lastly, check the material you will work on and make sure everything is lined up straight.”}},{“@type”: “Question”,”name”: “What Are Common Safety Practices To Follow When Operating A Metal Lathe, And Why Are They Important?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing so nothing gets caught. Always check that tools are clean and in good shape before starting. It’s also important to keep your hands away from moving parts. These practices help keep you safe and prevent accidents.”}},{“@type”: “Question”,”name”: “How Can You Maintain And Troubleshoot A Metal Lathe To Ensure Optimal Performance And Extend Its Lifespan?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe working well, always clean it after use. Check the oil levels and add more if needed. Tighten any loose parts to prevent problems. If something seems broken, find the issue and fix it right away. Regular care helps your lathe last longer!”}}]}