Imagine walking into a workshop filled with buzzing tools and shining machines. There, you might spot a lathe, a powerful tool that shapes metal with precision.

Have you ever wondered how metal parts get their perfect form? It all starts with the lathe and its metal lathe chuck. This special device holds the metal piece securely while it spins. It’s fascinating to think about how something so simple can create complex shapes.

But what about the lathe chuck key? This small tool is essential for tightening and loosening the chuck. Without it, the lathe wouldn’t work efficiently. You might not think about the chuck key, but it plays a huge role in every machining project.

In this article, we will explore the interesting world of lathe machining. From understanding the lathe itself to the importance of the metal lathe chuck key, you will discover how these tools come together to create amazing products.

Lathe Machining: Understanding Metal Lathe Chuck Key Usage

Lathe Machining Metal Lathe Chuck Key

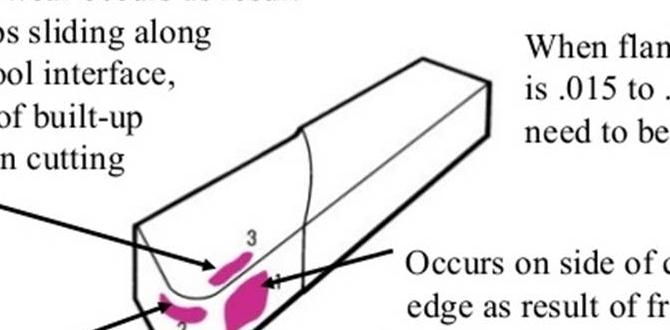

Lathe machining is essential in creating precise metal parts. A vital tool in this process is the metal lathe chuck key. This small yet powerful device secures the workpiece tightly in place. Imagine trying to carve a statue from stone while your tools keep slipping! The chuck key ensures that the metal stays still, allowing for accurate cuts. Understanding how to use this tool can make all the difference in your machining projects.What is a Metal Lathe Chuck Key?

Definition and purpose of a chuck key in lathe machining. Types of chuck keys commonly used in metal lathes.A metal lathe chuck key is a small tool used in lathe machining. Its main job is to tighten or loosen the chuck, which holds the metal workpiece. Think of it as a tiny wrench that makes sure your metal doesn’t go flying off like a rollercoaster ride! You can find different types of chuck keys. Some are t-shaped, while others are foldable or even have a ratchet to make things easier. Each type has its own quirks, making lathe work smoother!

| Type of Chuck Key | Description |

|---|---|

| T-shaped | Classic style; easy to use and find. |

| Foldable | Compact design; great for tight spaces. |

| Ratchet | Makes tightening smooth and quick. |

Types of Chuck Keys and Their Applications

Different designs of chuck keys (standard, Thandle, etc.). When to use each type based on project requirements.Chuck keys come in many designs, each helping with different tasks. The standard key is common for everyday use. It’s easy to handle and works for most projects. The T-handle key offers better grip and torque. Use it when you need extra power. Understanding these options lets you pick the right key for your work.

- Standard Key: Good for normal tasks.

- T-handle Key: Best for tougher jobs.

What is the best type of chuck key for my project?

The best type depends on the task you have. Use a standard key for simple work and a T-handle key for more strength.

How to Properly Use a Lathe Chuck Key

Stepbystep guide on inserting and removing the chuck key. Tips for ensuring secure clamping of materials.Using a lathe chuck key is simple, but it requires care. First, grab the chuck key and insert it into the chuck. Spin it gently until it locks in place. Next, give it a little twist to ensure it’s snug. To remove, just twist again in the opposite direction. Remember, a good grip is like a warm hug – it keeps your materials safe and tight! For extra safety, always check your setup to avoid surprises.

| Step | Description |

|---|---|

| 1 | Insert the chuck key into the chuck. |

| 2 | Turn gently to lock it in. |

| 3 | Twist to ensure snugness. |

| 4 | To remove, twist in the opposite way. |

Always remember: a good chuck key helps hold your work like a friend holding your hand while crossing the street!

Maintenance of Metal Lathe Chuck Keys

Best practices for keeping your chuck key in good condition. Common issues and troubleshooting for damaged keys.Keeping your chuck key in tip-top shape is like giving your lathe a high-five! Start by regularly cleaning it to remove any grease or metal shavings. Store it in a safe spot—maybe even give it a little pillow to rest on! If you notice any cracks or if it feels loose, it’s time for a replacement. Don’t let a damaged chuck key ruin your day at the machine; a new one can make a world of difference!

| Best Practices | Common Issues | Troubleshooting Tips |

|---|---|---|

| Clean regularly | Cracks or chips | Replace immediately |

| Store safely | Loose fit | Tighten or replace |

| Inspect before use | Rust buildup | Remove rust, then lubricate |

Choosing the Right Chuck Key for Your Lathe

Factors to consider (size, compatibility, material). Recommendations for purchasing quality chuck keys.Picking the right chuck key for your lathe is important. You need to consider a few key factors:

- Size: The chuck key must fit your lathe perfectly.

- Compatibility: It should match your lathe’s specific model.

- Material: Strong materials like steel last longer and work better.

For quality, look for trusted brands and read customer reviews. Investing in a good chuck key makes your work easier and safer.

What size chuck key do I need for my lathe?

You need the correct size to fit your lathe’s chuck. Always check your lathe’s manual for the exact size. It’s key to ensure the best fit and performance.

Safety Considerations When Using a Lathe Chuck Key

Personal protective equipment (PPE) recommendations. Safety practices to avoid accidents during operation.Safety is important when using a lathe chuck key. You should always wear personal protective equipment (PPE). This includes:

- Safety glasses to protect your eyes.

- Noise-canceling headphones to protect your hearing.

- Gloves to keep your hands safe.

Also, follow these safety practices:

- Keep your workspace clean and organized.

- Always check the lathe and tools before use.

- Don’t wear loose clothing that can get caught.

- Always pay attention while operating the machine.

These steps help prevent accidents and keep you safe while working.

What are the main safety tips for using a lathe?

Key safety tips include wearing PPE, keeping your workspace clean, and checking equipment before use. Staying focused and avoiding loose clothing can also help prevent injuries.

Frequently Asked Questions About Lathe Chuck Keys

Common queries regarding usage and maintenance. Expert tips to enhance user experience and efficiency.When it comes to lathe chuck keys, many users have questions. One common query is how to properly maintain them. To keep your key in shape, always clean it after use and store it in a safe place. Another question is about the right size. The key should fit snugly into the chuck for better grip. Here’s a helpful tip: always check the key’s fit before starting your work. This can save you from unexpected surprises, like pieces flying off! Check out the table below for quick tips on usage and maintenance.

| Tip | Description |

|---|---|

| Clean Regularly | Remove dirt and debris after each use. |

| Check Fit | Ensure the key fits tightly in the chuck. |

| Store Safely | Keep the key in a designated, safe spot. |

Conclusion

In summary, a lathe is a useful tool for shaping metal. The metal lathe chuck key helps us secure materials tightly. You should explore how to use these tools safely. It’s important to practice and learn proper techniques. By doing so, you’ll improve your skills and create amazing projects. Keep reading and experimenting with lathe machining!FAQs

What Are The Different Types Of Lathe Chuck Keys, And How Do They Vary In Design And Function?Lathe chuck keys help us tighten or loosen the chuck on a lathe machine. There are a few types of keys. A T-key is shaped like a “T” and gives good grip. A pin key has a round end and works well in small chucks. Some keys are adjustable, so they can fit different sizes! Each type makes it easier to control the tool.

How Do You Properly Use A Lathe Chuck Key To Ensure Safety And Accuracy During Machining Operations?To use a lathe chuck key safely, first, make sure the machine is off. Insert the key into the chuck and turn it to tighten or loosen the workpiece. Always remove the key when you finish, so it doesn’t get caught. Keep your fingers away from the moving parts. Wearing safety glasses is also a good idea to protect your eyes.

What Materials Are Commonly Used To Manufacture Lathe Chuck Keys, And How Do These Materials Affect Their Durability?Lathe chuck keys are often made from steel or aluminum. Steel is strong and lasts a long time. Aluminum is lighter but not as strong. The choice of material helps the key handle wear and tear better. This makes it last longer when you use it.

How Can You Troubleshoot Common Issues That Arise While Using A Lathe Chuck Key?To fix problems with a lathe chuck key, first, check if it’s tight. A loose key can make your work wobbly. Next, make sure the key fits snugly into the chuck. If it feels loose, get a different one that fits better. Lastly, clean the chuck and key to remove dirt, which can cause sticking. If it still doesn’t work, ask for help from an adult.

What Are The Benefits Of Using A Quick-Release Or Keyless Chuck System Compared To Traditional Lathe Chuck Keys?Using a quick-release or keyless chuck system is super easy. You can change tools without needing a key. This saves time and makes it more fun. You also won’t lose any keys. Plus, it keeps your hands safe from the spinning parts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Different Types Of Lathe Chuck Keys, And How Do They Vary In Design And Function? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe chuck keys help us tighten or loosen the chuck on a lathe machine. There are a few types of keys. A T-key is shaped like a T and gives good grip. A pin key has a round end and works well in small chucks. Some keys are adjustable, so they can fit different sizes! Each type makes it easier to control the tool.”}},{“@type”: “Question”,”name”: “How Do You Properly Use A Lathe Chuck Key To Ensure Safety And Accuracy During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a lathe chuck key safely, first, make sure the machine is off. Insert the key into the chuck and turn it to tighten or loosen the workpiece. Always remove the key when you finish, so it doesn’t get caught. Keep your fingers away from the moving parts. Wearing safety glasses is also a good idea to protect your eyes.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Manufacture Lathe Chuck Keys, And How Do These Materials Affect Their Durability? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe chuck keys are often made from steel or aluminum. Steel is strong and lasts a long time. Aluminum is lighter but not as strong. The choice of material helps the key handle wear and tear better. This makes it last longer when you use it.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues That Arise While Using A Lathe Chuck Key? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with a lathe chuck key, first, check if it’s tight. A loose key can make your work wobbly. Next, make sure the key fits snugly into the chuck. If it feels loose, get a different one that fits better. Lastly, clean the chuck and key to remove dirt, which can cause sticking. If it still doesn’t work, ask for help from an adult.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Using A Quick-Release Or Keyless Chuck System Compared To Traditional Lathe Chuck Keys?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a quick-release or keyless chuck system is super easy. You can change tools without needing a key. This saves time and makes it more fun. You also won’t lose any keys. Plus, it keeps your hands safe from the spinning parts.”}}]}