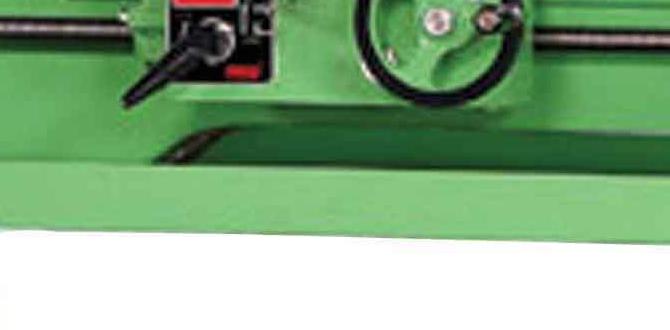

Have you ever wondered how metal parts are made with such precision? Lathe machining is one incredible process! A metal lathe is a special tool used to shape metal into various forms. Imagine a puppet master controlling strings to create beautiful movements. That’s how a lathe control panel works! It lets users guide the metal lathe to cut and shape materials just right.

It’s fascinating to think about all the gadgets around us. Many of them start their journey at a lathe machine. Did you know that with just a few clicks, a skilled operator can create complex designs? This makes lathe machining an important skill in many industries.

Get ready to dive deeper into the world of lathe machining! You’ll learn about how the metal lathe control panel helps in crafting amazing pieces. Who knows? You might even discover a passion for machining yourself!

Lathe Machining: Understanding Metal Lathe Control Panel

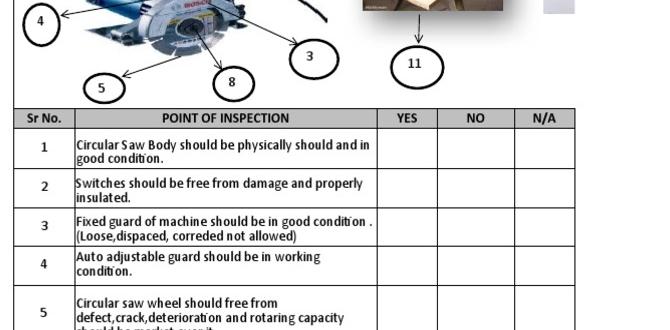

Lathe Machining Metal Lathe Control Panel

Lathe machining is a vital skill in metalworking. The control panel is key to making it work. It helps operators set speed and direction. Have you ever wondered how precision parts are created? With the right settings, a lathe can shape metal into anything! Each button has a purpose, ensuring smooth cutting and shaping. Understanding the control panel boosts efficiency and reduces errors. Mastering this tool opens doors to exciting projects and creative opportunities.The Importance of Control Panels in Metal Lathes

Explanation of control panels and their role in lathe operation.. Benefits of advanced control systems in metal lathes..Control panels are the brains behind metal lathes. They help operators manage speed, direction, and power. Think of them like the steering wheel of a car—without it, you’d be lost! Advanced control systems make life easier. They allow for precise adjustments, which leads to better results. Imagine a chef with the perfect recipe. That’s what these panels do for metalworking!

| Benefits of Control Panels | Why They Matter |

|---|---|

| Precision Control | Helps create accurate shapes and finishes. |

| User-Friendly Interface | Operators can easily make changes. |

| Safety Features | Reduces risks of accidents. |

In summary, control panels are essential for smooth and safe operation. They make metal lathes efficient and fun, just like a well-tuned roller coaster ride!

Components of a Metal Lathe Control Panel

Detailed description of key components (e.g., switches, displays, knobs).. Functionality of each component in the machining process..In a metal lathe control panel, you’ll find several key components that make machining smooth and easy. First, there are switches to start or stop the machine. They are like the magic buttons of the lathe world! Next, we have displays that show numbers and speeds. They help the user keep track of everything. Last but not least, knobs allow users to change settings like speed or direction. It’s like tuning a radio, but instead, you’re tuning metal!

| Component | Function |

|---|---|

| Switches | Control the power to the machine |

| Displays | Show speed, settings, and measurements |

| Knobs | Adjust speed and direction |

Setting Up a Metal Lathe Control Panel

Stepbystep guide on installation and configuration.. Common issues and troubleshooting tips..To set up a metal lathe control panel, follow these steps:

- First, gather all your tools and materials.

- Next, read the manual carefully to understand the wiring.

- Install the panel by connecting all the wires properly.

- Check all connections to make sure they are secure.

- Finally, power on the lathe and test the controls.

Some common issues include:

- Loose connections may cause the machine to malfunction.

- If the panel lights do not turn on, check the power supply.

- Calibration problems can occur, requiring a reset.

For troubleshooting, always refer to the manual.

Be patient. With practice, you will become an expert!

What are common problems with metal lathe control panels?

Common problems include faulty wiring, unresponsive buttons, and incorrect settings. To fix these, check connections, replace faulty parts, and recalibrate settings. Understanding these helps improve your lathe usage.

Quick Tips:

- Always ensure the machine is off while working on it.

- Regularly clean the control panel to avoid dust build-up.

- Keep the manual handy for quick reference.

Operational Techniques for Efficient Lathe Machining

Best practices for using a lathe control panel effectively.. Safety measures to consider during operation..Using a lathe control panel is like driving a car. You need to know where everything is before you hit the road! Always check the settings before starting your work. This helps avoid mistakes and surprises. Safety is a must—wear goggles and keep hands clear of moving parts. Remember, the lathe is not a ride at the fair! Here’s a quick checklist:

| Best Practices | Safety Measures |

|---|---|

| Familiarize yourself with the panel | Wear safety goggles |

| Set correct speeds | Stay clear of moving parts |

| Use sharp tools | Keep a first aid kit nearby |

Follow these tips, and you’ll be a lathe pro in no time. Just remember, no one wants metal shavings in their hair!

Future Trends in Lathe Technology

Innovations in control panel design and functionality.. How automation and AI are shaping the future of lathe machining..New technology is changing how we use lathes. Control panels are now easier to use and have more features. This makes it simple for operators to adjust settings quickly. Automation and AI are also becoming part of lathe machining. They help make processes faster and reduce errors. With these advancements, machines can work smarter, not harder.

- Touchscreen controls are user-friendly.

- Real-time data improves performance.

- AI helps in predictive maintenance.

How is AI used in lathe technology?

AI is used to predict problems with machines. This helps avoid breakdowns and keeps production smooth. It saves time and costs.

Future trends will wow everyone and make work easier. Lathes will become even more advanced. Imagine controlling a machine with just a few taps!

Resources and Further Reading

Recommended books, websites, and forums for lathe machining enthusiasts.. Industry organizations and certifications related to lathe machining..For those who love lathe machining, finding good resources can make a big difference. Here are some helpful suggestions:

- Books: Check out “Machining Fundamentals” by Michael Fitzpatrick for clear concepts.

- Websites: Visit MachinistNet.com for tips and tricks.

- Forums: Join Practical Machinist to ask questions and share ideas.

- Organizations: Look into the National Institute for Metalworking Skills (NIMS) for certifications.

These tools can help you learn and connect with others who enjoy lathe machining too.

What are good resources for lathe machining?

Helpful resources include books, websites, and forums. Local classes and industry groups also provide knowledge and support. Explore these options for your lathe machining journey!

Conclusion

In conclusion, a lathe machining metal lathe control panel is vital for operating lathes effectively. It helps you manage settings and monitor projects. Understanding how to use this panel enhances your skills and results. We encourage you to explore more about lathe operation and try hands-on practice. The more you learn, the better your machining will become!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Control Panels:Sure! A lathe is a machine that spins metal to shape it. You can make objects like pipes or toys. The control panel helps you choose how fast to spin the metal. You can also change the cutting tools. This way, we can create many cool shapes!

Sure! Please share your question, and I’d be happy to answer it.

What Are The Essential Components Of A Metal Lathe Control Panel, And How Do They Function?A metal lathe control panel has a few key parts. First, there’s the power switch, which turns the machine on and off. Next, you’ll find speed controls that let you change how fast the lathe spins. There are also buttons for different functions, like starting and stopping. Finally, we have emergency stop buttons that can quickly shut everything down if needed.

How Does A Digital Control Panel Enhance The Precision And Efficiency Of Lathe Machining Compared To A Manual Control Panel?A digital control panel helps you make very precise cuts on a lathe machine. It allows you to see and set exact numbers easily. This means you can work faster without mistakes. With a manual panel, you might make errors while reading dials or writing down measurements. Digital panels make everything smoother and more exact!

What Safety Features Should Be Included In A Metal Lathe Control Panel To Protect Operators During Machining Processes?A metal lathe control panel should have important safety features. First, there should be an emergency stop button. This lets you quickly turn off the machine if something goes wrong. Safety guards can protect your hands from getting too close to moving parts. We should also have warning lights to show when the machine is on. Lastly, a clear instruction manual can help you understand how to use the lathe safely.

How Can Advanced Programming Features On A Lathe’S Control Panel Improve Workflow And Production Rates In Machining Operations?Advanced programming features on a lathe’s control panel can make our work faster and easier. With these tools, we can set up machines quickly and run multiple tasks at once. This saves us time and helps us make more parts in less time. When we program the machine well, we get fewer mistakes too, which means better quality. Overall, we can produce more while spending less time!

What Common Troubleshooting Steps Can Be Taken When A Metal Lathe Control Panel Displays Error Messages Or Malfunctions?When a metal lathe shows error messages, we can try a few things. First, check if the machine is plugged in and turned on. Next, look for loose wires or connections that might need fixing. You can also restart the machine to see if that helps. If it still doesn’t work, ask for help from a grown-up or a technician.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Control Panels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that spins metal to shape it. You can make objects like pipes or toys. The control panel helps you choose how fast to spin the metal. You can also change the cutting tools. This way, we can create many cool shapes!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share your question, and I’d be happy to answer it.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe Control Panel, And How Do They Function?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe control panel has a few key parts. First, there’s the power switch, which turns the machine on and off. Next, you’ll find speed controls that let you change how fast the lathe spins. There are also buttons for different functions, like starting and stopping. Finally, we have emergency stop buttons that can quickly shut everything down if needed.”}},{“@type”: “Question”,”name”: “How Does A Digital Control Panel Enhance The Precision And Efficiency Of Lathe Machining Compared To A Manual Control Panel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital control panel helps you make very precise cuts on a lathe machine. It allows you to see and set exact numbers easily. This means you can work faster without mistakes. With a manual panel, you might make errors while reading dials or writing down measurements. Digital panels make everything smoother and more exact!”}},{“@type”: “Question”,”name”: “What Safety Features Should Be Included In A Metal Lathe Control Panel To Protect Operators During Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe control panel should have important safety features. First, there should be an emergency stop button. This lets you quickly turn off the machine if something goes wrong. Safety guards can protect your hands from getting too close to moving parts. We should also have warning lights to show when the machine is on. Lastly, a clear instruction manual can help you understand how to use the lathe safely.”}},{“@type”: “Question”,”name”: “How Can Advanced Programming Features On A Lathe’S Control Panel Improve Workflow And Production Rates In Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advanced programming features on a lathe’s control panel can make our work faster and easier. With these tools, we can set up machines quickly and run multiple tasks at once. This saves us time and helps us make more parts in less time. When we program the machine well, we get fewer mistakes too, which means better quality. Overall, we can produce more while spending less time!”}},{“@type”: “Question”,”name”: “What Common Troubleshooting Steps Can Be Taken When A Metal Lathe Control Panel Displays Error Messages Or Malfunctions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When a metal lathe shows error messages, we can try a few things. First, check if the machine is plugged in and turned on. Next, look for loose wires or connections that might need fixing. You can also restart the machine to see if that helps. If it still doesn’t work, ask for help from a grown-up or a technician.”}}]}