Have you ever wondered how metal parts for machines are made? It’s often a fascinating process called lathe machining. Imagine a machine that spins metal and shapes it just the way you want. That’s what a metal lathe machine does! It’s like a magical tool that can create various objects, from simple screws to complex gears.

Lathe machining uses a turning motion. This helps cut the metal into the desired shape. Did you know that lathes have been around for thousands of years? Early craftsmen used simple versions to create wooden items. Today, we have advanced metal lathe machines that can do even more!

Every time you see a shiny metal part, think about the lathe machining behind it. From bicycles to airplanes, these machines help make our world. Wouldn’t it be interesting to learn how they work? Let’s dive deeper into the amazing world of lathe machining and discover the secrets of metal lathe machines!

Lathe Machining: Essential Guide To Metal Lathe Machines

Understanding Lathe Machining with a Metal Lathe Machine

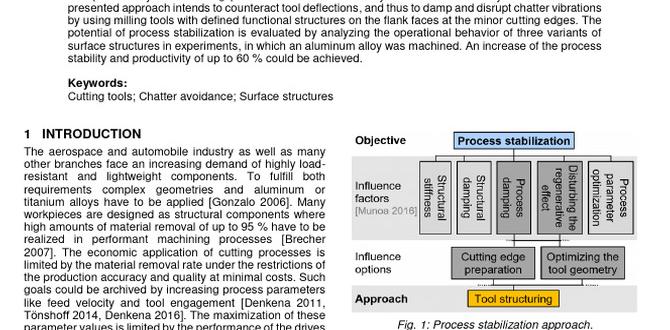

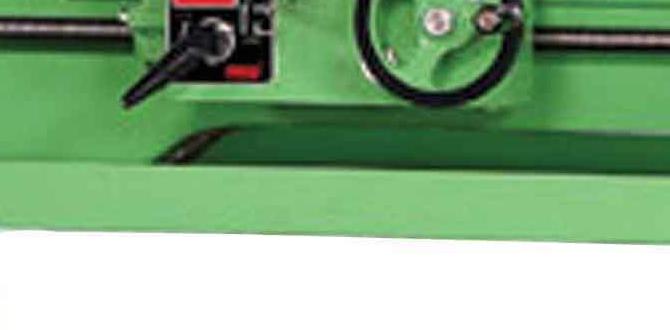

Lathe machining is a fascinating process that shapes materials, usually metal. A metal lathe machine spins the material while cutting tools shape it. Ever seen a woodturner? It’s quite similar but for metal! These machines can create everything from intricate parts to simple objects, making them essential in many industries. Did you know that lathes have been used for thousands of years? The combination of speed and precision they offer is remarkable, revolutionizing manufacturing.Components of a Metal Lathe Machine

Detailed description of key components such as the bed, spindle, and tailstock.. Explanation of how each component contributes to the machining process..A metal lathe machine has several key parts that work together like a well-oiled machine—pun intended! The bed is the sturdy base, supporting everything like a loyal puppy. Then we have the spindle, which holds the workpiece. It spins at different speeds, making it very cool and essential. Finally, the tailstock slides along the bed. It helps keep the workpiece steady, almost like a friend holding your hand in a scary movie. Each part plays a vital role in creating precise and beautiful shapes from metal.

| Component | Function |

|---|---|

| Bed | Supports the machine and provides stability. |

| Spindle | Holds and rotates the workpiece during machining. |

| Tailstock | Stabilizes the workpiece and aids in drilling. |

With these parts working together, a metal lathe can create amazing things, like intricate jewelry or even parts for rockets! Who knew metal could be this much fun?

Types of Metal Lathe Machines

Comparison of various metal lathe types: manual, CNC, and mini lathes.. Pros and cons of each type based on usage scenarios..There are different types of metal lathe machines. Each has its strengths and weaknesses. Manual lathes are simple to use. They are great for crafting one item. However, they take more time and skill. CNC lathes are automatic. They are fast and precise, making them ideal for large projects. The downside is they need programming knowledge. Lastly, mini lathes are small and portable. They are great for beginners but may not handle big tasks.

- Manual Lathes: Best for small projects. Requires more skill.

- CNC Lathes: Fast and precise, perfect for large jobs. Needs programming skills.

- Mini Lathes: Portable and fun for beginners. Not suitable for heavy work.

What are the benefits of each type of lathe?

Manual lathes help develop skills. CNC lathes offer speed and accuracy. Mini lathes are friendly for kids or hobbyists.

Setting Up Your Metal Lathe Machine

Stepbystep instructions for proper setup and calibration.. Tips for choosing the right tools and accessories for different projects..Setting up your metal lathe machine is like preparing for a fun craft project. First, make sure your machine is on a steady surface. Check all parts for any damage. Next, calibrate the machine correctly to get accurate results. Here’s how:

- Connect power safely.

- Adjust the tailstock and carriage.

- Set the correct speed for your material.

Don’t forget to choose the right tools and accessories. Plan your project first. Then:

- Select cutting tools based on the material you use.

- Have spare tools for different tasks.

Happy crafting! You’re ready to create amazing things.

What tools do I need for my lathe?

To set up your lathe machine, you need essential tools like cutting tools, chucks, and tool holders. These help make precise cuts and smooth shapes.

Safety Practices in Lathe Machining

Essential safety tips to follow when operating a lathe machine.. Common hazards and how to mitigate risks in the workshop..Using a lathe machine can be fun, but safety is key! Always wear goggles to protect your eyes. Get your hair tied back; loose strands can turn into a spinning mess! Make sure your clothes fit snugly too. Keep hands clear when the machine is running. Never talk to someone else while operating. And remember, if you feel tired, take a break. Safety first, right? After all, we want your fingers to stay where they belong!

| Common Hazards | Safety Tips |

|---|---|

| Hair or clothing getting caught | Tie back hair and wear fitted clothes |

| Flying metal shavings | Wear safety goggles |

| Accidental contact with moving parts | Keep hands away from spinning area |

By following these tips, you can keep your workshop safe and sound, so you can enjoy your projects without any drama! And remember, safety is cool, so let’s be cool while we’re at it!

Maintenance of Metal Lathe Machines

Routine maintenance tasks to ensure optimal performance.. Troubleshooting common issues encountered with lathe machines..Keeping your metal lathe machine happy can make a huge difference! Regular cleaning and oiling are must-dos. This helps it run smoothly and avoids sluggish movements. Don’t forget to check the belts and gears too! If you hear strange noises, it might not be your lathe trying to tell you a joke! It could need some fixing. For quick troubleshooting, refer to this handy table:

| Issue | Possible Cause | Solution |

|---|---|---|

| Lathe won’t start | Power source problem | Check the plug and switch |

| Strange noises | Loose parts | Tighten the screws |

| Inaccurate cuts | Dull tools | Sharpen or replace the tool |

These steps can help keep your lathe in fighting shape! Because who wants a lazy lathe? Not me!

Applications of Lathe Machining in Various Industries

Examples of industries that benefit from lathe machining: automotive, aerospace, and more.. How custom lathe machining solutions can enhance production efficiency..Many industries, like automotive and aerospace, count on lathe machining to keep things running smoothly. In automotive, it helps make engine parts, while aerospace uses it for creating lighter, stronger components. Custom lathe machining can make production faster. Imagine trying to bake a cake with only two spoons! With more tools available, it’s easier to whip up exactly what you need.

| Industry | Application |

|---|---|

| Automotive | Engine parts and fittings |

| Aerospace | Lightweight parts like brackets |

| Manufacturing | Custom tools and fixtures |

This magic machine helps industries become more efficient, turning metal into masterpieces. Efficiency is key, and with lathe machining, it’s possible to make parts quicker and better.

Future Trends in Lathe Machining

Insights into technological advancements in lathe machines.. The impact of automation and AI on metal lathe machining practices..New technology is changing the way lathe machines work. Advanced features make them faster and more precise. Automation helps machines do tasks without much human help. This makes work easier and safer. AI also plays a big role. It helps with decision-making and can spot problems before they happen. Here are some key trends in lathe machining:

- Smart technology to track progress

- Robots doing repetitive tasks

- Data analysis for better performance

These trends keep improving the way we make things, making factories more efficient and reliable.

How will automation change lathe machining?

Automation will make metal lathe machines faster and reduce mistakes. Workers can focus on important tasks while machines handle routine jobs.

Conclusion

In conclusion, a lathe machining metal lathe machine shapes metal into various forms. It rotates the material while cutting tools reshape it. This tool is essential for creating parts for machines and everyday items. If you’re curious, consider exploring how to use a lathe or watch videos online. Learning more can spark your creativity and even inspire your next project!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Machines:Sure! Here’s a simple answer: Lathe machining is a way to shape metal. A metal lathe machine spins the metal while cutting tools shape it. You can make things like toys or parts for cars. It’s fun to see how shapes change as the machine works. Do you want to know more about how it all happens?

Sure! Please tell me what question you would like me to answer.

What Are The Different Types Of Lathe Machines Used In Metalworking, And How Do They Differ In Functionality?There are a few types of lathe machines used in metalworking. The most common ones are the engine lathe, the turret lathe, and the CNC lathe. An engine lathe is great for making different shapes by turning metal pieces. A turret lathe can change tools quickly to make more pieces. The CNC lathe uses a computer to control the cutting, making it very precise. Each type helps us create metal parts in different ways!

How Do You Properly Set Up A Metal Lathe For Precision Machining Of A Specific Metal Workpiece?To set up a metal lathe, start by choosing the right metal piece you want to work on. Next, secure the workpiece tightly in the lathe’s clamp. Then, adjust the cutting tool so it just touches the metal. Make sure to set the speed of the lathe to match the metal type. Finally, double-check everything before you start to ensure safety and precision.

What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Injuries?When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep loose clothing and hair away from the machine to avoid getting caught. Make sure the area is clean and free of clutter. Never reach into the machine while it is running. Always follow the machine’s instructions and listen to your teacher or supervisor.

How Can Tooling And Cutting Parameters Be Optimized For Different Materials When Using A Lathe Machining Process?To optimize tooling and cutting parameters, you need to think about the material you are using. Different materials, like plastic or metal, need different tools. You can change how fast the tool spins and how deep it cuts. By testing these settings, you can find what works best for each material. This helps make better and smoother pieces.

What Are Common Challenges Faced During Lathe Machining, And What Troubleshooting Techniques Can Be Used To Address These Issues?When using a lathe, you might face problems like broken tools, uneven surfaces, or strange noises. To fix them, check if your tools are sharp and replace them if they’re dull. Make sure the machine is running at the right speed for the material. If the surface is rough, you can adjust the cutting depth or speed to improve it. Always remember to keep your work area clean and organized to avoid accidents!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Machines:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a simple answer: Lathe machining is a way to shape metal. A metal lathe machine spins the metal while cutting tools shape it. You can make things like toys or parts for cars. It’s fun to see how shapes change as the machine works. Do you want to know more about how it all happens?”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Lathe Machines Used In Metalworking, And How Do They Differ In Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few types of lathe machines used in metalworking. The most common ones are the engine lathe, the turret lathe, and the CNC lathe. An engine lathe is great for making different shapes by turning metal pieces. A turret lathe can change tools quickly to make more pieces. The CNC lathe uses a computer to control the cutting, making it very precise. Each type helps us create metal parts in different ways!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Metal Lathe For Precision Machining Of A Specific Metal Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, start by choosing the right metal piece you want to work on. Next, secure the workpiece tightly in the lathe’s clamp. Then, adjust the cutting tool so it just touches the metal. Make sure to set the speed of the lathe to match the metal type. Finally, double-check everything before you start to ensure safety and precision.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep loose clothing and hair away from the machine to avoid getting caught. Make sure the area is clean and free of clutter. Never reach into the machine while it is running. Always follow the machine’s instructions and listen to your teacher or supervisor.”}},{“@type”: “Question”,”name”: “How Can Tooling And Cutting Parameters Be Optimized For Different Materials When Using A Lathe Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To optimize tooling and cutting parameters, you need to think about the material you are using. Different materials, like plastic or metal, need different tools. You can change how fast the tool spins and how deep it cuts. By testing these settings, you can find what works best for each material. This helps make better and smoother pieces.”}},{“@type”: “Question”,”name”: “What Are Common Challenges Faced During Lathe Machining, And What Troubleshooting Techniques Can Be Used To Address These Issues?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe, you might face problems like broken tools, uneven surfaces, or strange noises. To fix them, check if your tools are sharp and replace them if they’re dull. Make sure the machine is running at the right speed for the material. If the surface is rough, you can adjust the cutting depth or speed to improve it. Always remember to keep your work area clean and organized to avoid accidents!”}}]}