Have you ever wondered how metal parts are made? Many people might overlook the importance of a lathe. A lathe is a tool used in machining. It spins the metal to create shapes and sizes. However, one key component of the lathe often goes unnoticed: the pulley.

Metal lathe pulleys play a vital role in ensuring the machine runs smoothly. Without them, the lathe wouldn’t work as effectively. Imagine trying to drive a car without its wheels! That’s how crucial pulleys are.

Here’s a fun fact: the first lathes date back thousands of years. Ancient craftsmen used them to create beautiful shapes. Today, technology has advanced, but the basic idea remains the same.

In this article, we will explore the fascinating world of lathe machining. We’ll dive deep into how metal lathe pulleys work and their significance. Get ready to uncover the magic behind the machinery!

Lathe Machining: Metal Lathe Pulley Crafting Techniques

Lathe Machining: Discovering Metal Lathe Pulley

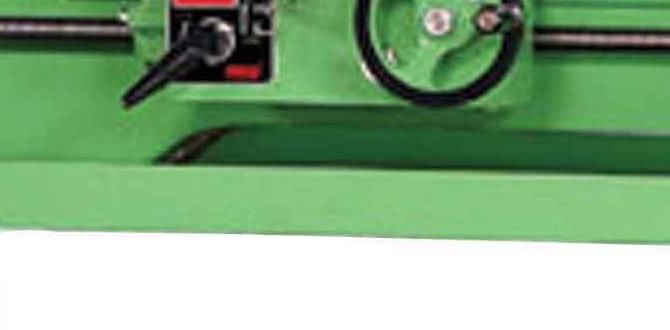

Lathe machining plays a vital role in shaping metal parts. A key component is the metal lathe pulley. It helps transfer motion effectively, allowing the lathe to function smoothly. Did you know that the right pulley can increase your machine’s efficiency? Understanding the importance of these pulleys can improve your projects. With the right knowledge, you’ll see how they impact accuracy and performance in various metalworking tasks. Embrace lathe machining to unleash your creativity!Understanding Lathe Machining

Definition and basic principles of lathe machining. Types of lathes and their applications in metalworking.Lathe machining is like a magical dance between metal and machines! It involves spinning a piece of metal while cutting it into different shapes. This process helps create everything from bowling balls to iron gates. There are different types of lathes, such as engine lathes, turret lathes, and CNC lathes. Each has unique strengths for metalworking tasks like precise drilling, shaping, or even playing hide and seek!

| Type of Lathe | Application |

|---|---|

| Engine Lathe | General purpose machining |

| Turret Lathe | Producing multiple identical parts |

| CNC Lathe | High-precision and automated operations |

In the world of metal, lathe machining is like the big boss, shaping and molding with ease!

Components of a Metal Lathe

Key parts of a metal lathe and their functions. The role of the pulley system in lathe operation.A metal lathe has several key parts that work together to shape metal. Each part plays an important role:

- Bed: The base that holds everything steady.

- Headstock: Contains the motor and keeps the tool spinning.

- Tailstock: Supports the other end of the metal piece.

- Tool Post: Holds the cutting tool in place.

- Pulley System: Helps control the speed of the lathe.

The pulley system is essential. It connects the motor to other parts. This system allows the operator to change speeds easily. As a result, you get cleaner cuts and better results.

What are the main parts of a metal lathe?

The main parts of a metal lathe include the bed, headstock, tailstock, tool post, and pulley system. Each part has its functions to shape and cut metal accurately.

Designing a Metal Lathe Pulley

Factors to consider in pulley design (size, shape, material). Common design software used for pulley modeling.Creating a metal lathe pulley involves careful planning. You must think about three main factors: size, shape, and material. These can affect how well your pulley works. For example, a larger pulley can move heavier loads, while the shape influences balance and speed. Common materials include steel or aluminum, known for their strength.

Designers often use special software for modeling pulleys. This helps them visualize and test their ideas before making a real pulley. Programs like SolidWorks and AutoCAD are popular for this purpose.

What factors should you consider in pulley design?

Size, shape, and material are the key factors. These elements impact performance, safety, and durability.

Common software used for pulley modeling:

- SolidWorks

- AutoCAD

- Inventor

Machining Techniques for Pulley Production

Stepbystep guide to machining a metal pulley. Best practices for ensuring precision and quality.Making a metal pulley can be fun and interesting. Here’s a step-by-step guide:

- Start with selecting quality metal.

- Measure carefully for size.

- Secure the metal on the lathe.

- Turn on the lathe and adjust the speed.

- Shape the pulley by cutting slowly.

- Check your work often for smoothness.

To ensure precision and quality, follow these best practices:

- Always double-check measurements.

- Use sharp tools for clean cuts.

- Wear safety gear to stay safe.

Machining can create amazing pieces with just a few steps! Remember, patience makes perfect.

What is the importance of precision in pulley machining?

Precision is crucial in pulley machining because it ensures smooth operation. A well-made pulley reduces friction and wear, leading to longer-lasting equipment and better performance.

Common Challenges in Lathe Machining

Potential issues faced during pulley production. Troubleshooting tips for common machining problems.Creating pulleys on a lathe can be tricky! You might face issues like uneven surfaces or strange noises—yikes! These problems can happen if the tools aren’t sharp or the speed is off. To fix things, ensure the lathe is clean and the measurements are right. Remember, a little oil can work wonders too! Here’s a quick table of common problems and fixes:

| Problem | Possible Solution |

|---|---|

| Uneven surface | Check tool sharpness and adjust speed |

| Strange noises | Lubricate the lathe and inspect for loose parts |

| Incorrect dimensions | Recheck measurements and re-align |

Don’t worry! With practice and these tips, you’ll master pulley making in no time. Keep calm and lathe on!

Safety Practices in Lathe Machining

Essential safety measures to follow while using a lathe. Personal protective equipment (PPE) for lathe operators.Using a lathe can be fun and creative, but safety is very important. Always wear the right personal protective equipment (PPE). This includes goggles for eye protection and gloves that fit snugly. Keep long hair tied back and avoid loose clothing. Here are some safety tips:

- Keep hands and objects away from moving parts.

- Check that tools are secure before starting.

- Stay focused and don’t rush.

Following these steps helps keep everyone safe while using a lathe.

What is the best PPE for lathe operators?

The best PPE for lathe operators includes safety goggles, gloves, earmuffs, and dust masks. Each piece protects against flying debris, noise, and harmful dust.

Advanced Techniques in Pulley Production

Innovative technologies enhancing lathe pulley machining. Future trends in metal lathe manufacturing.Modern technologies are changing how we make lathe pulleys. For example, machines now use computer-aided design (CAD) to create more precise shapes. This means pulleys fit well and work better. People are also talking about 3D printing in pulley production. Imagine a machine printing a pulley like a giant cookie! As we look to the future, automation and artificial intelligence will lead to even smarter manufacturing processes.

| Technique | Description |

|---|---|

| CAD | Helps design intricate shapes quickly. |

| 3D Printing | Creates pulleys layer by layer, like magic! |

| Automation | Makes production faster and reduces errors. |

Future trends show that these innovations will make metal lathe manufacturing more efficient. Think of a factory where machines do most of the work. It’s like having robots as your hardworking sidekicks!

Cost Analysis of Machining Metal Lathe Pulleys

Breakdown of costs associated with materials and labor. Tips for reducing manufacturing costs without compromising quality.Understanding costs is important when making metal lathe pulleys. Break down costs into materials and labor. Materials often include types of metal, while labor costs depend on worker time and skill. You can reduce costs by:

- Buying materials in bulk.

- Using less expensive but quality materials.

- Training workers to improve efficiency.

- Avoiding unnecessary overtime.

These tips help save money while keeping quality high. Remember, spending less doesn’t mean losing quality.

How can I reduce costs when machining metal lathe pulleys?

You can lower costs by buying materials in bulk, optimizing production processes, and training workers. These methods keep expenses down without hurting quality.

Real-World Applications of Metal Lathe Pulleys

Industries that heavily rely on pulleys in their operations. Case studies showcasing effective pulley implementations.Pulleys are essential in many industries. They help lift and move heavy items easily. Here are a few industries that depend on them:

- Manufacturing

- Construction

- Aerospace

- Automotive

- Entertainment

Many companies have used pulleys to improve their work. For example, a car factory uses the metal lathe pulley to assemble parts faster. This saves time and money. In a construction site, workers use pulleys to lift materials up high, making their job simpler and safer.

What are some common uses for metal lathe pulleys?

Metal lathe pulleys are often used in machining, assembly lines, and lifting heavy loads.

Why are pulleys important?

They reduce effort and increase efficiency in various tasks.

Conclusion

In conclusion, lathe machining is a vital technique for shaping metal. A metal lathe pulley helps control speed and movement in many machines. You can start exploring this topic by watching videos or reading guides online. Practice using a lathe can build your skills and confidence. Remember, learning more about metalworking can open up exciting career opportunities!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On Metal Lathe Pulleys:Sure! When you use a lathe machine, it helps shape metal very precisely. A pulley is a round wheel that can help move things or change direction. We can attach pulleys to a lathe to help control how fast the metal spins. Using pulleys makes it easier to make different products. So, lathes and pulleys work together to create many metal items!

Of course! Please share the question you would like answered, and I’ll do my best to help you.

What Are The Key Factors To Consider When Selecting A Pulley Type For A Metal Lathe?When choosing a pulley for a metal lathe, you should think about a few important things. First, consider the weight of the materials you will work with. Heavier materials need stronger pulleys. Next, check how fast you want the lathe to turn. Different pulleys can spin at different speeds. Lastly, make sure the pulley fits the size of your lathe. A good fit is important for safety and to work well.

How Does Pulley Size Impact The Speed And Torque Of A Metal Lathe During Machining Operations?The size of a pulley on a metal lathe affects how fast it spins and how much force it has. A bigger pulley makes the lathe go faster, while a smaller one gives it more power or torque. You can think of it like bike gears. When you change the size, you change how easy it is to cut or shape the metal. So, choosing the right pulley helps you get the job done better!

What Materials Are Commonly Used For Manufacturing Pulleys In Metal Lathes, And Why Are They Chosen?Pulleys in metal lathes are usually made from steel, aluminum, or plastic. Steel is strong and lasts a long time. Aluminum is lighter but still strong. Plastic is easy to shape and can be quiet. We choose these materials to make sure the pulleys work well and don’t break easily.

How Can You Properly Align And Install A Pulley On A Metal Lathe To Ensure Optimal Performance?To align and install a pulley on a metal lathe, first, make sure the lathe is turned off. Next, check that the pulley is straight and not wobbly. You can do this by looking at it closely. Then, attach the pulley tightly with screws or bolts. Finally, test the lathe to ensure it runs smoothly without any noise.

What Maintenance Practices Should Be Followed To Prolong The Lifespan Of Pulleys In A Metal Lathe System?To keep pulleys in a metal lathe working well, you should check them often for wear and tear. Clean them regularly to remove dust and grease. Use the right lubricant to keep them moving smoothly. Make sure the belts are tight but not too tight. Finally, listen for unusual sounds when the lathe is running.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On Metal Lathe Pulleys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you use a lathe machine, it helps shape metal very precisely. A pulley is a round wheel that can help move things or change direction. We can attach pulleys to a lathe to help control how fast the metal spins. Using pulleys makes it easier to make different products. So, lathes and pulleys work together to create many metal items!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please share the question you would like answered, and I’ll do my best to help you.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Pulley Type For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a pulley for a metal lathe, you should think about a few important things. First, consider the weight of the materials you will work with. Heavier materials need stronger pulleys. Next, check how fast you want the lathe to turn. Different pulleys can spin at different speeds. Lastly, make sure the pulley fits the size of your lathe. A good fit is important for safety and to work well.”}},{“@type”: “Question”,”name”: “How Does Pulley Size Impact The Speed And Torque Of A Metal Lathe During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size of a pulley on a metal lathe affects how fast it spins and how much force it has. A bigger pulley makes the lathe go faster, while a smaller one gives it more power or torque. You can think of it like bike gears. When you change the size, you change how easy it is to cut or shape the metal. So, choosing the right pulley helps you get the job done better!”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Manufacturing Pulleys In Metal Lathes, And Why Are They Chosen?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Pulleys in metal lathes are usually made from steel, aluminum, or plastic. Steel is strong and lasts a long time. Aluminum is lighter but still strong. Plastic is easy to shape and can be quiet. We choose these materials to make sure the pulleys work well and don’t break easily.”}},{“@type”: “Question”,”name”: “How Can You Properly Align And Install A Pulley On A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and install a pulley on a metal lathe, first, make sure the lathe is turned off. Next, check that the pulley is straight and not wobbly. You can do this by looking at it closely. Then, attach the pulley tightly with screws or bolts. Finally, test the lathe to ensure it runs smoothly without any noise.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Prolong The Lifespan Of Pulleys In A Metal Lathe System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep pulleys in a metal lathe working well, you should check them often for wear and tear. Clean them regularly to remove dust and grease. Use the right lubricant to keep them moving smoothly. Make sure the belts are tight but not too tight. Finally, listen for unusual sounds when the lathe is running.”}}]}