Have you ever watched a metalworker shape metal into something amazing? A metal lathe is a magical tool that turns solid metal into precise shapes. Imagine transforming a dull piece of metal into a shiny part that fits perfectly in a machine.

In many workshops, the lathe metal shaping process happens right on a sturdy metal lathe bench. This bench is not just any table; it’s specially designed to hold heavy tools steady. Working with a lathe can feel like an art form. It requires skill and patience, just like drawing or painting.

Did you know that the lathe is one of the oldest machines in the world? It has been used for thousands of years! People even created beautiful wooden pieces with it long before metal was common. Isn’t it cool to think about how something so ancient is still vital for modern engineers?

So, what can you create with a metal lathe? From gears to elegant sculptures, the possibilities are endless! Let’s dive into the fascinating world of lathe metal shaping and discover how you can start your own metalworking journey!

Mastering Metal Shaping With A Lathe Metal Lathe Bench

Understanding Metal Lathes for Shaping Metal

A metal lathe bench is exciting for anyone who loves crafting. This tool shapes metal by spinning it at high speed while cutting tools carve out designs. Did you know that ancient Egyptians used similar tools thousands of years ago? Today, hobbyists and professionals find lathes essential for making precise, detailed pieces. Knowing how to use a lathe opens doors to endless projects, from decorative items to useful tools. Are you ready to explore this fascinating world of metalworking?Choosing the Right Bench Lathe for Your Projects

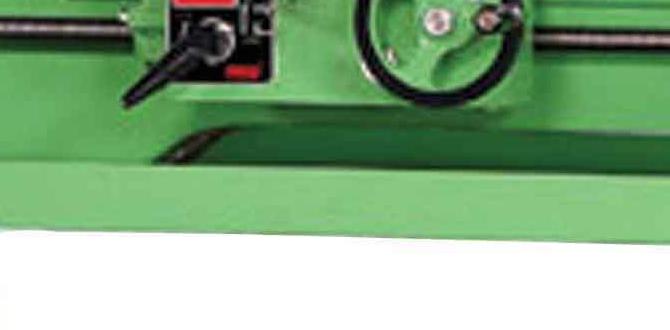

Key features to look for in a bench lathe. Comparisons of popular bench lathe models on the market.Picking the right bench lathe makes a big difference in your projects. Key features to consider include motor power, speed settings, and bed length. A sturdy frame is important for stability. Popular models like the Grizzly G0768 and Jet JWL-1221vs stand out for their performance.

- Grizzly G0768: Great for beginners, offers solid motor power.

- Jet JWL-1221vs: Known for its adjustable speed and user-friendly design.

With an ideal lathe, you can create precise shapes and designs with ease!

What should I look for in a bench lathe?

Look for motor strength, speed options, and bed length for your specific needs. These features help make your work easier and more efficient.

Setting Up Your Bench Lathe for Optimal Performance

Stepbystep guide to assembling and calibrating your lathe. Tips for creating a safe and efficient workspace.Setting up your bench lathe properly helps it work best. Start by carefully assembling your lathe using the manual. Check all parts and tighten screws. Next, calibrate the machine. This means adjusting the speed and alignment. For a safe workspace, follow these steps:

- Keep the area clean and organized.

- Ensure there’s good lighting.

- Wear safety glasses.

- Keep tools within reach.

By doing these, you’ll create a safe and efficient space to shape metal!

How do I calibrate my lathe properly?

To calibrate your lathe, follow these simple steps: check the alignment, adjust the speed settings, and make sure all parts move freely. Proper calibration improves the performance of your lathe.

Maintenance and Care for Longevity of Your Bench Lathe

Routine maintenance practices to keep your lathe in top condition. Troubleshooting common issues with bench lathes.Keeping your lathe in good shape is simple. Regular care makes it last longer and work better. Here are some easy steps:

- Clean dust and debris after use.

- Check and tighten loose parts every month.

- Oil moving parts to prevent rust.

- Inspect belts for wear and tear.

- Replace worn tools as needed.

If your lathe has problems, don’t worry! Common issues are easy to fix. Make sure to check the power supply and see if everything is plugged in. If it won’t turn, look for blockages or damaged parts. A little care goes a long way!

What can you do if the lathe makes strange noises?

If your lathe is noisy, check for loose parts or missing lubrication. Tightening screws and adding oil can solve many problems.

How often should you service your lathe?

It’s best to service your lathe every three months. This simple routine helps spot small issues before they become big problems.

Resources and Communities for Lathe Enthusiasts

Recommended books, websites, and online forums for learning. Benefits of joining local or online metalworking communities.For anyone diving into the world of lathes, resources are everywhere! Books like “The Metal Lathe” and websites such as www.lathes.co.uk offer tons of insights. Online forums, like those on Reddit, let you chat with fellow metal nerds. Joining local clubs is even better! You get to share tips, tricks, and maybe even a donut or two (lathe enthusiasts love treats!). The more you connect, the more fun you have!

| Resource Type | Recommended Resources |

|---|---|

| Books | The Metal Lathe, How to Run a Lathe |

| Websites | www.lathes.co.uk, www.metalworking.com |

| Forums | Reddit Metalworking, CNCZone |

Conclusion

In summary, a lathe is a powerful tool for shaping metal. With a metal lathe bench, you can create precise parts easily. Understanding its features will help you use it effectively. We encourage you to explore tutorials online and practice your skills. By doing so, you’ll become more confident and innovative in your metalworking projects. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping, Particularly Focusing On Metal Lathes And Their Benches:Metal lathes are machines that help shape metal into different forms. You place a metal piece on the lathe, and it spins while cutting tools shape it. A lathe bench is where you set up the lathe, keeping it steady and safe. We need to keep our workspace clean and organized to work better. Always remember to wear safety gear when using a lathe!

Of course! Please provide the question you want me to answer.

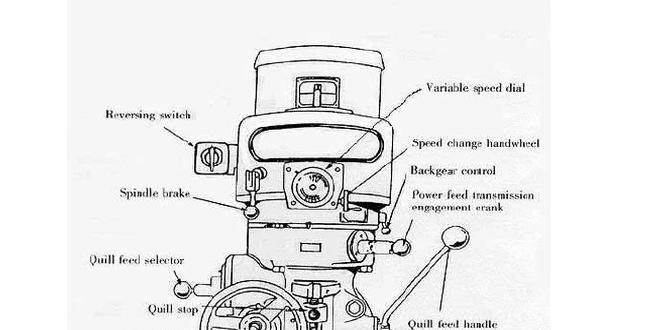

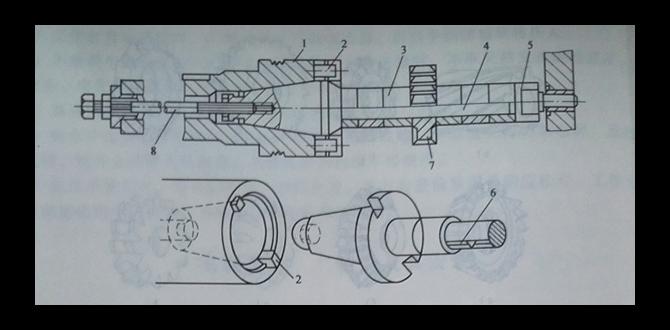

What Are The Key Components Of A Metal Lathe And How Do They Contribute To The Shaping Process?A metal lathe has a few important parts. First, there is a **bed**, which is the base that holds everything steady. Then, we have the **tailstock**, where you place the tool to shape the metal. The **headstock** holds the metal piece and spins it around. Finally, the **tool rest** supports the cutting tool as you move it to shape the metal. Each part works together to help you create smooth and precise shapes.

How Do You Properly Set Up A Metal Lathe Bench For Optimal Performance And Safety During Machining Operations?To set up a metal lathe bench safely, first, find a stable, level surface. Make sure the lathe is securely attached to the bench. Keep tools and materials organized and within reach, so you don’t have to look for them. Always clear away any clutter that could cause accidents. Lastly, wear safety goggles to protect your eyes while working.

What Materials Are Best Suited For Turning On A Metal Lathe, And How Do Their Properties Affect The Machining Process?You can use materials like aluminum, brass, and mild steel on a metal lathe. These materials are soft enough to cut easily but strong enough to hold their shape. Softer metals like aluminum make smooth parts quickly. Harder metals, like stainless steel, take longer and might need special tools. Choosing the right material helps you make better parts more easily.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of A Metal Lathe And Its Bench Setup?To keep a metal lathe working well, you should clean it often. Use a soft cloth to wipe off metal shavings and dust. Check the parts for any wear and tear. Make sure to oil the moving parts to help them run smoothly. Always adjust the settings carefully to keep it accurate.

How Can You Troubleshoot Common Issues Encountered While Using A Metal Lathe, Such As Tool Wear Or Vibrations During Operation?To fix tool wear, check your cutting tools often. If they look dull, replace them with new ones. For vibrations, make sure the lathe is steady and all parts are tight. You can also reduce the speed or feed rate. These steps will help you work better and make your projects smoother!