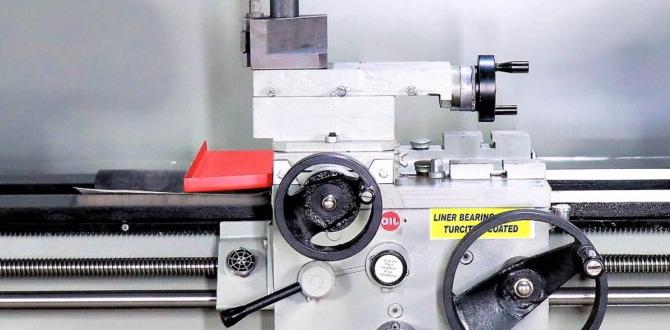

Have you ever seen a piece of metal turn into a perfectly shaped part? That’s the magic of a lathe! This amazing machine helps metalworkers create everything from tiny screws to large industrial parts. But what if we told you that you can take your old lathe and give it a new life?

Many people are discovering the benefits of a CNC retrofit for their metal lathe. This upgrade turns a simple machine into a smart, automated tool. Imagine being able to shape metal with higher accuracy and less effort!

In this article, we will explore how lathe metal shaping transforms your workshop. You will learn about the steps to retrofit your machine. Plus, we’ll share tips and fun facts that will help you on your metalworking journey!

If you’ve ever wanted to create something amazing with metal, keep reading. You might be ready to take your lathe to the next level!

Lathe Metal Shaping: Metal Lathe Cnc Retrofit Explained

Lathe Metal Shaping: CNC Retrofit Insights

Discover how a metal lathe can transform your workshop! Lathes shape metal into precise forms. Imagine turning raw metal into beautiful parts with ease. Many hobbyists now retrofit their lathes with CNC (Computer Numerical Control) technology. This upgrade boosts efficiency and accuracy. Have you ever wished for more control over your projects? With CNC retrofitting, that wish comes true! It’s a fun way to bring old machines into the modern age. Plus, it helps you create stunning solutions with less effort!The Evolution of Lathes: From Manual to CNC

Differences between manual lathes and CNC lathes. Benefits of CNC technology in metal shaping.Machines have changed a lot over the years. Manual lathes need a skilled person to shape metal by hand. They are simple but can take a lot of time. In contrast, CNC lathes use computers to control the cutting process. This makes them faster and more precise. They can repeat the same cuts perfectly every time. Here are some benefits of CNC technology:

- Speed: CNC lathes work quickly.

- Accuracy: They create very exact shapes.

- Consistency: Every piece is the same.

- Less Waste: They cut material more efficiently.

As a result, both types have their place in metal shaping. However, CNC lathes offer many advantages for modern manufacturing.

What are the key benefits of CNC lathes?

CNC lathes save time, provide high accuracy, and ensure every part is consistent. They also minimize material waste and enhance production efficiency.

CNC Retrofit: What It Is and Why It Matters

Definition of CNC retrofit and its purpose. Advantages of retrofitting a manual lathe to CNC.CNC retrofit mixes old-school machines with new tech magic. It upgrades manual lathes to become smart CNC tools. This means you can make parts faster and with more precision. Why splurge on a new machine when you can sprinkle some CNC fairy dust on the old one? Upgrading helps save money while getting better results. Plus, you can impress your friends with your “high-tech” skills, even if you’re still wearing your favorite dinosaur pajamas!

| Advantage | Description |

|---|---|

| Cost-effective | Retrofitting is cheaper than buying new CNC machines. |

| Enhanced Precision | Your lathe will cut with pinpoint accuracy! |

| Improved Efficiency | Work speed increases, making you a machining superhero! |

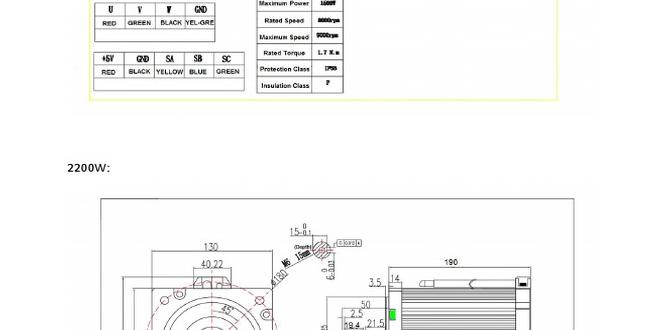

Choosing the Right CNC Retrofit Kit

Key features to look for in a retrofit kit. Popular manufacturers and their offerings.Choosing the right CNC retrofit kit is key to improving your lathe. Here are some important features to consider:

- Compatibility: Make sure it fits your current lathe model.

- Control Type: Look for user-friendly options like touchscreen or manual controls.

- Precision: Higher precision yields better results in your metalwork.

- Support: A good manufacturer provides help when you need it.

Popular manufacturers include Haas, known for its reliable products, and Grizzly, which offers affordable options. Do some research to find the perfect fit for your project!

What features are important in a CNC retrofit kit?

Key features include compatibility, control type, precision, and support from the manufacturer.

Who are the popular manufacturers of CNC retrofit kits?

Popular manufacturers are Haas, Grizzly, and others that cater to your specific needs.

Preparation for Retrofits: Tools and Requirements

Essential tools needed for CNC retrofit installation. Electrical and software considerations before the retrofit.To kick off your CNC retrofit adventure, gathering the right tools is a must. Think of it like packing for a camping trip—nobody wants to forget the s’mores! Essential items include a good drill, screwdrivers, and a sturdy wrench set. Also, keep your computer handy for the software setup. Don’t forget about electrical requirements! Ensure you have a reliable power supply and the right cables. Here’s a quick look:

| Tool | Purpose |

|---|---|

| Drill | For making holes and fixing parts. |

| Screwdrivers | To tighten all the bits and pieces. |

| Wrench Set | For final adjustments that matter! |

| Power Supply | Keep the machine running smoothly. |

Before diving in, remember to check software compatibility too. You want your lathe to dance, not hesitate! Lastly, a funny reminder: don’t start the retrofit with your old music playlist unless you want to drill to oldies!

Step-by-Step Guide to CNC Retrofits on Metal Lathes

Detailed installation process for a CNC retrofit kit. Common challenges and solutions during installation.Installing a CNC retrofit kit on your metal lathe can transform your projects. Start by reading the manual carefully. Gather your tools, and clear your workspace. Follow these steps for smooth installation:

- Remove old parts.

- Install new motors.

- Connect wiring.

- Set up the software.

During the process, you might face some challenges. Common issues include misaligned parts and wiring errors. To fix these, double-check your connections. Ask for help on forums if needed. With patience, you’ll have a working CNC lathe!

What are common issues with CNC retrofit installation?

Common issues include alignments, wiring mistakes, and software setup errors.Quick tips to fix these problems:

- Recheck measurements.

- Verify wire connections.

- Update software regularly.

Enhancing Precision in Metal Shaping with CNC Technology

How CNC enhances accuracy and repeatability in machining. Case studies and examples of successful metal shaping projects.Today’s CNC technology makes metal shaping feel like magic. With CNC, machines can cut and shape metal with amazing precision. This means you get the same results every time, like a perfect cookie cutter! For instance, a recent project involved creating custom metal parts for a bike. With CNC, every piece fit perfectly, and the project was finished in record time. No more guessing games—just great results!

| Project | Outcome |

|---|---|

| Bike Parts | Perfect Fit & Fast Completion |

| Art Installations | Consistent Quality & Detail |

Maintenance and Troubleshooting of CNC Retrofits

Tips for regular maintenance to ensure longevity. Troubleshooting common issues postretrofit.Keeping your CNC retrofit in top shape is like watering a plant; it needs attention! Regular maintenance includes cleaning, checking for wear, and lubricating parts. Think of it as giving your machine a spa day. It hurts to see a lathe go on strike, especially if it starts making weird noises. Common problems can be fixed by tightening loose belts or checking electrical connections. Remember, a happy lathe makes for smooth metal shaping!

| Maintenance Tips | Common Issues | Solutions |

|---|---|---|

| Clean regularly | Unusual noises | Tighten loose belts |

| Lubricate parts | Faulty electrical connections | Check and reconnect |

| Inspect wear and tear | Inconsistent cutting | Sharpen or replace tools |

The Future of Metal Shaping and CNC Technology

Emerging trends in CNC technology for lathes. Predictions on the evolution of metal shaping processes.Many exciting changes are happening in CNC technology for lathes. New tools will help shape metals faster and better. Automation is becoming common. Machines will work more on their own, reducing human error. 3D printing is also making waves, allowing for more creative designs. We may even see lathes that learn and improve on their own!

- More automated features

- Advanced materials for better strength

- Greater precision in shaping

Experts believe that in the future, metal shaping will be quicker and easier. As we embrace new tech, possibilities are endless!

What trends shape the future of CNC technology?

Automation is key. Machines will become smarter and more efficient. New materials will also play a big role in improving products. Expect faster and more precise lathes!

Conclusion

In conclusion, a lathe is essential for shaping metal accurately. A CNC retrofit adds precision and can modernize older machines. With these tools, you can create amazing projects. If you’re interested, consider learning more about CNC technology or trying a simple lathe project. Dive into the world of metalworking and see what you can create!FAQs

What Are The Key Benefits Of Retrofitting A Manual Metal Lathe With Cnc Technology For Increased Precision And Automation?Retrofitting a manual metal lathe with CNC technology means adding computer controls to it. This helps you make parts more accurately and quickly. It’s like turning a regular bike into an electric one—easier and faster! You will save time on each project, and you can create the same part over and over with perfect results. This makes your work more fun and efficient!

What Specific Components Are Commonly Upgraded During A Cnc Retrofit Of A Traditional Metal Lathe?When we upgrade a traditional metal lathe to a CNC lathe, we usually replace a few important parts. We install new motors to make it move better. We also add a computer to control everything. Finally, we use special sensors to make sure it works correctly. These upgrades help the lathe do its job more accurately and quickly.

How Does One Determine Whether A Metal Lathe Is Suitable For A Cnc Retrofit, And What Factors Should Be Considered?To see if a metal lathe can be changed to a CNC type, we need to check a few things. First, look at its size and weight. They should be enough to support new parts. Next, check if it has a good motor and enough power. Finally, consider how easily you can add new electronics. Good design makes the change easier!

What Are Some Of The Common Challenges Or Pitfalls Faced During The Cnc Retrofit Process Of A Metal Lathe?When you retrofit a metal lathe to use CNC, you might face a few challenges. First, finding the right parts can be tricky. They need to fit the old machine well. Also, programming the CNC can be hard if you’re not used to it. Lastly, not testing properly can lead to mistakes when the lathe is running.

How Can Software Integration Play A Role In The Performance And Functionality Of A Retrofitted Cnc Metal Lathe?Software integration helps a retrofitted CNC (Computer Numerical Control) metal lathe work better. It allows the machine to follow your commands more easily. You can make changes quickly and improve how the machine cuts metal. With good software, we can add new features and fix problems faster. This makes the lathe more useful and efficient.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Benefits Of Retrofitting A Manual Metal Lathe With Cnc Technology For Increased Precision And Automation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Retrofitting a manual metal lathe with CNC technology means adding computer controls to it. This helps you make parts more accurately and quickly. It’s like turning a regular bike into an electric one—easier and faster! You will save time on each project, and you can create the same part over and over with perfect results. This makes your work more fun and efficient!”}},{“@type”: “Question”,”name”: “What Specific Components Are Commonly Upgraded During A Cnc Retrofit Of A Traditional Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we upgrade a traditional metal lathe to a CNC lathe, we usually replace a few important parts. We install new motors to make it move better. We also add a computer to control everything. Finally, we use special sensors to make sure it works correctly. These upgrades help the lathe do its job more accurately and quickly.”}},{“@type”: “Question”,”name”: “How Does One Determine Whether A Metal Lathe Is Suitable For A Cnc Retrofit, And What Factors Should Be Considered?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To see if a metal lathe can be changed to a CNC type, we need to check a few things. First, look at its size and weight. They should be enough to support new parts. Next, check if it has a good motor and enough power. Finally, consider how easily you can add new electronics. Good design makes the change easier!”}},{“@type”: “Question”,”name”: “What Are Some Of The Common Challenges Or Pitfalls Faced During The Cnc Retrofit Process Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you retrofit a metal lathe to use CNC, you might face a few challenges. First, finding the right parts can be tricky. They need to fit the old machine well. Also, programming the CNC can be hard if you’re not used to it. Lastly, not testing properly can lead to mistakes when the lathe is running.”}},{“@type”: “Question”,”name”: “How Can Software Integration Play A Role In The Performance And Functionality Of A Retrofitted Cnc Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Software integration helps a retrofitted CNC (Computer Numerical Control) metal lathe work better. It allows the machine to follow your commands more easily. You can make changes quickly and improve how the machine cuts metal. With good software, we can add new features and fix problems faster. This makes the lathe more useful and efficient.”}}]}