Have you ever watched a machine spin and shape metal? It’s like magic! A lathe is that amazing machine. It can turn a simple block of metal into a beautiful shape. But did you know that lathe metal shaping needs something special to work well? That’s where metal lathe coolant comes in.

Metal lathe coolant keeps the tool and metal cool while they work hard. Without it, things can heat up and even break. Imagine trying to build a sandcastle on a hot day. The sand melts and falls apart. This is similar to what happens without coolant.

In this article, we’ll explore how metal lathe coolant helps in shaping metal. We’ll look at the different types of coolant and why they matter. So, are you ready to dive into the fascinating world of metal shaping with lathes? Let’s get started!

Lathe Metal Shaping: Essential Metal Lathe Coolant Tips

Lathe Metal Shaping: Metal Lathe Coolant

Using a metal lathe can turn raw metal into amazing shapes. But did you know coolant is key for this process? It keeps the metal cool and reduces wear on the tools. Too much heat can cause damage, leading to mistakes or broken tools. Imagine shaping a piece of metal without it melting. Coolant not only helps, but also makes cutting smoother. Next time you think about metal shaping, remember the importance of coolant! It really makes a big difference.

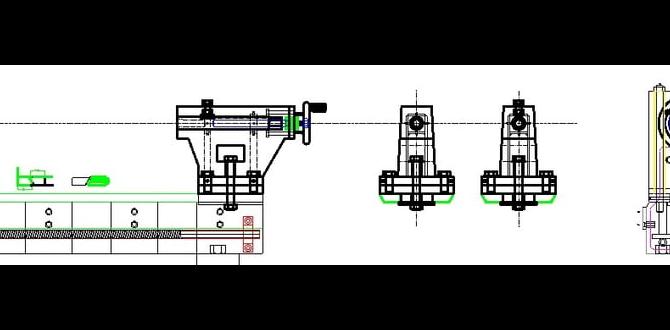

Understanding Metal Lathes

Definition and components of a metal lathe. Types of metal lathes and their applications.

A metal lathe is a machine tool that spins metal pieces to shape them into different forms. It has several parts, like the chuck, tailstock, and bed. These parts work together to hold and move the metal. There are various types of metal lathes, each serving a specific purpose. Some are used for small projects, while others tackle large tasks like making car parts. Think of it as a fancy pizza wheel, just for metal!

| Type of Metal Lathe | Application |

|---|---|

| Engine Lathe | General purpose machining |

| Bench Lathe | Small-scale projects |

| CNC Lathe | Automated production |

The Importance of Coolant in Lathe Operations

Role of coolant in metal shaping processes. Benefits of using coolant: heat reduction, surface finish improvement, and tool life extension.

Coolant plays a vital role in metal shaping processes. It helps to cool down the tools and metal during cutting. This cooling prevents overheating, which can damage both the metal and the lathe. Using coolant has many advantages:

- Reduces heat build-up, keeping tools safe.

- Improves surface finish, making pieces look smooth and professional.

- Extends tool life, saving money on replacements.

In fact, using the right coolant can boost efficiency and product quality. Remember, a cool tool is a happy tool!

Why is coolant important in lathe operations?

Coolant is crucial because it reduces heat, enhances surface finish, and increases the life of tools.

Types of Coolants for Lathe Operations

Waterbased vs oilbased coolants. Synthetic vs semisynthetic coolants.

Coolants help keep lathes working smoothly. There are different types of coolants. Water-based coolants are easy to clean and good for your health. However, they can rust machines. Oil-based coolants provide excellent lubrication but can be harder to clean. Synthetic coolants are made from chemicals. They last long and don’t foam. Meanwhile, semi-synthetic coolants mix water and oil. They offer good cooling and lubrication. Choosing the right coolant makes a big difference for your lathe!

What are the main types of coolants?

There are two main types of coolants:

- Water-based coolants

- Oil-based coolants

What types of synthetic coolants exist?

- Synthetic coolants – made from chemicals

- Semi-synthetic coolants – a mix of water and oil

Choosing the Right Coolant for Your Metal Lathe

Factors to consider: material type, cutting speed, and machining operation. Best coolant practices for different metals.

Choosing the right coolant for your metal lathe can make a big difference. Consider these factors: material type, cutting speed, and machining operation. Each metal needs different care. For example, aluminum may need one type of coolant while steel needs another.

- Aluminum: Use a water-soluble coolant.

- Steel: Oil-based coolants work well.

- Brass: Go with a light oil for best results.

This helps you keep your lathe running smoothly.

What should I consider when choosing coolant?

Think about the metal you are working with, how fast you cut, and what you’re making. Each metal has its own needs. For best results, match the coolant to the job.

How to Properly Apply Coolant on a Lathe

Techniques for effective coolant application. Tools and equipment for coolant delivery.

Applying coolant on a lathe is key to a smooth operation. First, use a misting system for even distribution. It’s like sprinkling water on a plant but with metal—don’t drown it! You can also try a flooding technique for big jobs; it’s like giving your lathe a refreshing shower. Tools like coolant pumps are great for delivery. Remember, proper coolant helps reduce wear on tools and keeps everything cool—just like ice cream on a hot day!

| Coolant Application Techniques | Tools for Delivery |

|---|---|

| Misting System | Coolant Pumps |

| Flooding Technique | Spray Nozzles |

Maintenance Tips for Lathe Coolant Systems

Regular maintenance practices. Signs of coolant contamination and how to address them.

Keeping lathe coolant systems in top shape is key to smooth operation. Regularly check and change your coolant to avoid gunk buildup. Look for signs of contamination, like a weird smell or color changes. If you see any nasty stuff floating around, it’s time for a cleanup. Remember, a happy lathe makes for a happy maker! Don’t forget to keep an eye on the temperature. Too hot? Your coolant might need some TLC.

| Signs of Contamination | Action |

|---|---|

| Bad smell | Replace coolant |

| Dark color | Check for bacteria |

| Floating debris | Clean the tank |

So keep it fresh, and your lathe will thank you with better performance!

Safety Considerations When Using Lathe Coolant

Potential hazards associated with coolants. Recommended safety measures and personal protective equipment (PPE).

Using lathe coolant is like inviting a friend to a party – it can make things smoother, but you have to watch out for spills! Coolants can be slippery and might cause slips and falls. They may also be harmful if they splash in your eyes or skin. Always wear protective goggles and gloves to stay safe. Keep the area tidy; it’s not a dance floor! A little prevention goes a long way in avoiding hiccups in your metal shaping adventure.

| Hazard | Recommended Safety Measure |

|---|---|

| Skin irritation | Wear gloves |

| Eye splashes | Use safety goggles |

| Slips and falls | Keep the floor clean |

Remember, safety first! It’s all fun and games until someone slips on coolant. Stay sharp and keep those fingers happy and intact!

Environmental Impact and Disposal of Lathe Coolant

Ecofriendly coolant options. Proper disposal methods for used coolant.

Using lathe coolant is like choosing your favorite drink, but it should also be eco-friendly! There are many green coolant options out there. These alternatives help keep our planet in tip-top shape, just like a good lathe helps shape metal. Remember, you can’t just toss used coolant anywhere. Proper disposal is key. Always check local regulations—some places have special recycling programs.

| Coolant Type | Eco-Friendly Options | Disposal Method |

|---|---|---|

| Water-Based | Biodegradable | Recycle through local facility |

| Synthetic | No harmful oils | Follow hazardous waste guidelines |

Remember, saving the environment is just as fun as making that perfect metal shape! So let’s keep it shiny and clean.

Conclusion

In summary, lathe machines help us shape metal effectively. Using coolant keeps the metal cool during cutting, which protects tools and improves results. You can explore different types of coolants for specific projects. By learning about these essentials, you can enhance your metalworking skills. Keep practicing, and don’t hesitate to read more on lathe techniques!

FAQs

Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Coolant:

Sure! A lathe is a machine that shapes metal into different forms. It spins the metal while tools cut it into the shape we want. Coolant is a special liquid we use to keep the metal cool and reduce heat while we work. This helps prevent the metal from burning or breaking. Using coolant makes our work easier and safer!

Sure! Just let me know what question you want me to answer.

What Types Of Coolant Are Commonly Used In Metal Lathes, And How Do They Differ In Effectiveness?

Coolants used in metal lathes include water-soluble oil, straight oil, and synthetic fluids. Water-soluble oil mixes with water and cools well. Straight oil is thicker and is good for tough jobs but might not cool as fast. Synthetic fluids are man-made and can work well without oiliness. Each type helps keep the metal cool and makes cutting easier, but they work differently depending on what you need.

How Does The Use Of Coolant During Machining Processes Impact The Lifespan Of Cutting Tools In A Lathe?

Using coolant while machining helps keep the cutting tools cool. When tools get too hot, they wear out faster. Coolant also helps wash away tiny bits of metal. This means tools stay sharp longer, so we can use them for more projects. Overall, using coolant makes our cutting tools last much longer.

What Are The Advantages Of Using Synthetic Vs. Soluble Oil Coolants For Metal Shaping Applications?

Synthetic coolants are made from chemicals, while soluble oil coolants mix oil with water. One advantage of synthetic coolants is that they often last longer, which saves you money. They also keep machines cleaner, which makes them work better. Soluble oil coolants can sometimes be softer on your skin, but they may need to be changed more often. Choosing the right coolant helps your machines and makes work easier for you!

How Can Improper Coolant Application Affect The Quality Of The Finished Metal Components Produced On A Lathe?

If you use coolant wrong while working on metal, it can cause problems. The metal might get too hot, which can make it warp or bend. This can lead to parts that don’t fit together well. You might also see scratches or rough spots on the finished piece. In the end, the quality of the metal part can be poor.

What Best Practices Should Be Followed For Coolant Maintenance And Management In A Metalworking Environment To Ensure Optimal Performance?

To keep coolant working well, you should check it often for dirt and bubbles. Change the coolant when it gets dirty or smells bad. Always keep your machines clean to avoid mixing dirt into the coolant. When you add water, use fresh water, not old or dirty water. With these steps, your coolant will last longer and work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Coolant:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal into different forms. It spins the metal while tools cut it into the shape we want. Coolant is a special liquid we use to keep the metal cool and reduce heat while we work. This helps prevent the metal from burning or breaking. Using coolant makes our work easier and safer!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Coolant Are Commonly Used In Metal Lathes, And How Do They Differ In Effectiveness?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Coolants used in metal lathes include water-soluble oil, straight oil, and synthetic fluids. Water-soluble oil mixes with water and cools well. Straight oil is thicker and is good for tough jobs but might not cool as fast. Synthetic fluids are man-made and can work well without oiliness. Each type helps keep the metal cool and makes cutting easier, but they work differently depending on what you need.”}},{“@type”: “Question”,”name”: “How Does The Use Of Coolant During Machining Processes Impact The Lifespan Of Cutting Tools In A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using coolant while machining helps keep the cutting tools cool. When tools get too hot, they wear out faster. Coolant also helps wash away tiny bits of metal. This means tools stay sharp longer, so we can use them for more projects. Overall, using coolant makes our cutting tools last much longer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using Synthetic Vs. Soluble Oil Coolants For Metal Shaping Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Synthetic coolants are made from chemicals, while soluble oil coolants mix oil with water. One advantage of synthetic coolants is that they often last longer, which saves you money. They also keep machines cleaner, which makes them work better. Soluble oil coolants can sometimes be softer on your skin, but they may need to be changed more often. Choosing the right coolant helps your machines and makes work easier for you!”}},{“@type”: “Question”,”name”: “How Can Improper Coolant Application Affect The Quality Of The Finished Metal Components Produced On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you use coolant wrong while working on metal, it can cause problems. The metal might get too hot, which can make it warp or bend. This can lead to parts that don’t fit together well. You might also see scratches or rough spots on the finished piece. In the end, the quality of the metal part can be poor.”}},{“@type”: “Question”,”name”: “What Best Practices Should Be Followed For Coolant Maintenance And Management In A Metalworking Environment To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep coolant working well, you should check it often for dirt and bubbles. Change the coolant when it gets dirty or smells bad. Always keep your machines clean to avoid mixing dirt into the coolant. When you add water, use fresh water, not old or dirty water. With these steps, your coolant will last longer and work better!”}}]}