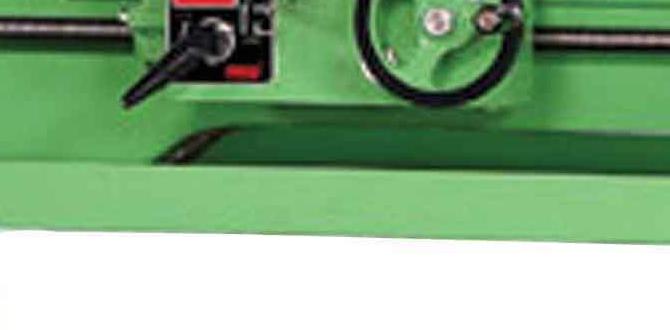

Have you ever wondered how metal objects are shaped into useful tools and parts? One of the best ways to do this is with a lathe. A lathe is a powerful machine that spins metal while cutting it into the right shape. But what makes it work? That’s where the metal lathe drive system comes in!

Think of the drive system as the heart of the lathe. It provides the power needed to spin the metal piece quickly and smoothly. Without it, a lathe simply wouldn’t function. This system can be electric or belt-driven, each with its own benefits. Have you seen how smoothly a lathe can shape metal when it’s working right?

Here’s a fun fact: The lathe design has been around for thousands of years! Even ancient craftsmen used simple lathes to create beautiful wooden and metal items. Today, we have modern metal lathes that can create complex designs and precise shapes.

In this article, we’ll explore the inner workings of the metal lathe drive system. You’ll learn how it works and why it’s essential for metal shaping. Are you ready to dive into the world of lathes? Let’s get started!

Understanding The Lathe Metal Shaping Metal Lathe Drive System

Lathe Metal Shaping and Drive Systems

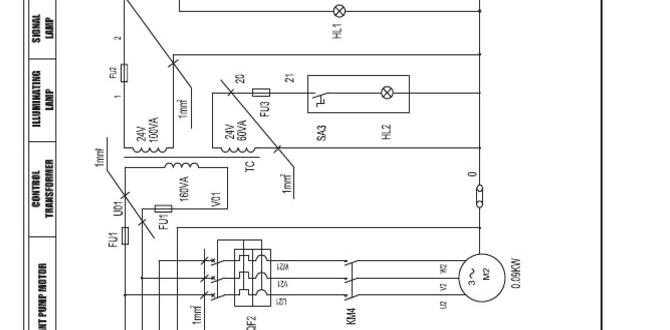

Metal lathes are fascinating machines used for turning and shaping metal. They have different drive systems that affect how they work. A common type is the belt-driven system. It connects the motor to the lathe, transferring power efficiently. Did you know that many lathes can also use gears to control speed? This versatility lets users create various shapes and sizes. Understanding these drive systems can help you choose the right lathe for your projects.

What is a Metal Lathe?

Definition and function of a metal lathe. Brief history and evolution of lathe technology.

A metal lathe is a machine used to shape metal. It spins metal pieces while cutting them into desired forms. This tool helps create round shapes, like poles or tubes. Lathes have evolved over time. The earliest versions date back to ancient Egypt. Today’s lathes are much more advanced and efficient.

- Definition: A tool for shaping metal.

- Functions: Cuts, drills, and sands metal.

- History: Evolved from simple hand tools to complex machines.

What does a metal lathe do?

A metal lathe shapes materials by rotating them against a cutting tool. This allows for precise measurements and smooth surfaces. It is important in many industries, from manufacturing to crafting.

Types of Metal Lathe Drive Systems

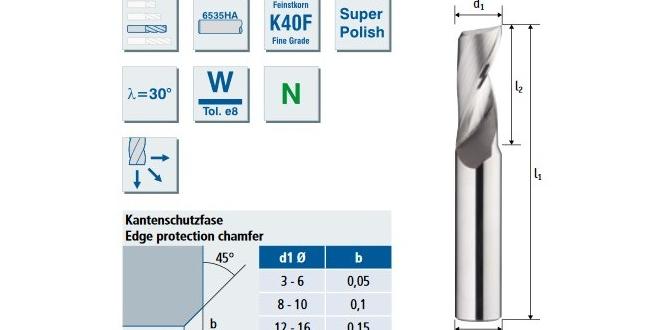

Description of different drive systems (belts, gears, directdrive). Advantages and disadvantages of each type.

Different drive systems power metal lathes, each with its own quirks. First, we have belts. These are like rubber bands that move the lathe. They are quiet and easy to replace, but can slip if too much pressure is applied. Next are gears. These sturdy teeth handle heavy loads well but can sometimes be noisy and complex to maintain. Lastly, there’s direct drive, which connects the motor directly to the spindle. This system is powerful and efficient but may lack the flexibility of the others. Choosing the right drive system is like picking ice cream flavors—everyone has their favorite!

| Drive System | Advantages | Disadvantages |

|---|---|---|

| Belts | Quiet, easy to replace | Can slip under pressure |

| Gears | Handles heavy loads | Noisy, complex maintenance |

| Direct Drive | Powerful and efficient | Less flexible |

How Drive Systems Affect Performance

Impact of drive systems on precision and speed. Correlation between drive system choice and metalworking applications.

The type of drive system you choose greatly influences the performance of a metal lathe. A good drive system improves both precision and speed. Precision is important for making exact shapes, while speed helps you finish tasks faster. Different metalworking jobs need different drive systems.

- High precision lathes need smooth, stable drives.

- Speed is less crucial for large parts than for small, detailed work.

Choosing the right drive system can lead to better results in your projects!

How does the drive system impact performance?

The drive system affects how accurately and quickly the lathe operates. A suitable drive enhances work quality. For example, belts offer smooth motion, while direct drives are faster.

Maintenance Tips for Metal Lathe Drive Systems

Essential maintenance practices to prolong lifespan. Common issues and troubleshooting methods.

To keep your metal lathe drive system running well, follow these maintenance tips. Regular cleaning is a must. Remove dust and chips daily, and grease the moving parts regularly. Check for worn-out belts and change them as needed. Listen for unusual noises, as they can indicate problems. Most issues can be fixed quickly. Here are some common problems to watch for:

- Belt slipping: Tighten the belt or replace it.

- Strange sounds: Check for loose screws or damaged parts.

- Too much vibration: Balance the workpiece properly.

By keeping up with these practices, your lathe will last longer and work better!

What are key maintenance tips for a metal lathe drive system?

Regular cleaning, checking for worn parts, and tightening belts are key tips for maintenance. This helps prevent breakdowns and keeps your lathe in good shape.

Advancements in Metal Lathe Drive Technologies

Innovations currently shaping the market. Future trends and their potential impact on metal shaping.

New technologies are changing the way we shape metal. Today’s metal lathes use advanced drive systems. These machines are smarter, faster, and more efficient. They help workers create precise shapes with ease. In the future, we might see machines that can think for themselves—not quite like “Terminator,” but pretty clever! Growth in automation and robotics will drive this progress. Staying updated with these trends can make a big difference in the shop.

| Current Innovations | Future Trends |

|---|---|

| Smarter drive systems | More automation |

| Energy-efficient motors | AI integration |

| Improved precision tools | Self-learning machines |

Choosing the Right Metal Lathe for Your Needs

Factors to consider when selecting a lathe and drive system. Comparisons of popular models and their features.

Choosing a metal lathe is important. You should look at several factors before buying. First, decide what type of work you will do. Do you need a small or large lathe? Next, consider the drive system. There are manual and automatic options. Popular metal lathes include:

- South Bend SB1002 – Great for beginners.

- Grizzly G0602 – Strong and versatile.

- Jet 321360 – Easy to use and reliable.

Each model has unique features. Reading reviews helps too. This way, you can find the best fit for your needs.

What factors should you consider when selecting a lathe?

Look at the size, type, and drive system. Think about how you will use it. Also, consider your budget and space available.

Which popular metal lathes are recommended?

South Bend, Grizzly, and Jet are top choices. They offer different sizes and features to meet various needs.

Safety Considerations with Metal Lathes

Important safety precautions while operating lathes. Use of protective equipment and safe handling practices.

Using a metal lathe can be fun, but safety is very important. Always wear protective gear like safety glasses and gloves to protect yourself. Make sure to keep long hair tied back and wear tight clothing. Here are some important safety tips:

- Check the machine for any damage before you start.

- Never remove safety guards while operating the lathe.

- Keep hands and tools away from the spinning parts.

- Always turn off the lathe before making adjustments.

Following these safety rules helps you stay safe while enjoying your metalworking adventures!

What are safety precautions for metal lathes?

Always wear protective equipment, check for damages, and keep your work area tidy. These actions can prevent accidents and ensure a smooth operation.

Conclusion

In summary, a lathe is great for shaping metal. The drive system makes it run smoothly and efficiently. You can create precise parts with practice. If you’re interested, start by learning more about different types of lathes or try a hands-on project. Exploring these tools can lead to exciting opportunities in metalworking!

FAQs

Sure! Here Are Five Questions Related To The Topic Of Lathe Metal Shaping And The Metal Lathe Drive System:

Sure! A lathe is a machine that shapes metal. It spins the metal while cutting tools shape it. You can make things like rods or discs. The drive system helps the lathe turn the metal as we work on it. It’s like a motor that makes everything move smoothly.

Absolutely! Just ask your question, and I’ll be happy to help you with a short, easy-to-understand answer.

What Are The Key Components Of A Metal Lathe Drive System, And How Do They Work Together To Shape Metal Effectively?

A metal lathe drive system has a few important parts. First, there’s the motor, which gives power to the machine. Then, we have the gears, which help to change the speed of the lathe. The spindle holds the metal and spins it around. Finally, the cutting tool shapes the metal as it spins. All these parts work together to help us create smooth and nice shapes in metal.

How Do Different Types Of Drive Systems (E.G., Belt Drive, Gear Drive, And Direct Drive) Affect The Performance And Capabilities Of A Metal Lathe?

Different drive systems help a metal lathe move in different ways. A belt drive uses rubber belts, making the machine smoother but less powerful. A gear drive uses gears, giving you more strength but can be bumpier. Direct drive connects the motor straight to the lathe, offering speed and strength. Each drive type changes how we use the lathe for projects!

What Are The Advantages And Disadvantages Of Using A Variable Speed Drive System In Metal Lathes For Shaping Different Materials?

Using a variable speed drive system in metal lathes has some good and bad points. On the good side, it lets you change the speed easily. This helps you work with different materials better. You can shape soft metal and hard metal just right. On the downside, these systems can be more expensive. They also need more care and may be tricky to fix if they break.

How Does The Choice Of Motor Type (Such As Ac Vs. Dc Motors) Impact The Efficiency And Precision Of A Metal Lathe’S Operations?

The type of motor you choose affects how well the metal lathe works. AC motors usually run smoothly and can work for a long time without getting hot. DC motors, on the other hand, can start quickly and allow for better control. This means you can cut metal more accurately. So, choosing the right motor helps you do a better job!

What Maintenance Practices Are Essential For Ensuring The Longevity And Optimal Performance Of A Metal Lathe Drive System?

To keep your metal lathe drive system working well, you should check it regularly. Clean the parts to remove dirt and dust. Make sure to oil moving parts so they don’t get rusty. Check for any loose screws or parts and tighten them. Finally, follow the instructions in the manual for any special care tips.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of Lathe Metal Shaping And The Metal Lathe Drive System:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal. It spins the metal while cutting tools shape it. You can make things like rods or discs. The drive system helps the lathe turn the metal as we work on it. It’s like a motor that makes everything move smoothly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Absolutely! Just ask your question, and I’ll be happy to help you with a short, easy-to-understand answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Drive System, And How Do They Work Together To Shape Metal Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe drive system has a few important parts. First, there’s the motor, which gives power to the machine. Then, we have the gears, which help to change the speed of the lathe. The spindle holds the metal and spins it around. Finally, the cutting tool shapes the metal as it spins. All these parts work together to help us create smooth and nice shapes in metal.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Drive Systems (E.G., Belt Drive, Gear Drive, And Direct Drive) Affect The Performance And Capabilities Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different drive systems help a metal lathe move in different ways. A belt drive uses rubber belts, making the machine smoother but less powerful. A gear drive uses gears, giving you more strength but can be bumpier. Direct drive connects the motor straight to the lathe, offering speed and strength. Each drive type changes how we use the lathe for projects!”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Variable Speed Drive System In Metal Lathes For Shaping Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a variable speed drive system in metal lathes has some good and bad points. On the good side, it lets you change the speed easily. This helps you work with different materials better. You can shape soft metal and hard metal just right. On the downside, these systems can be more expensive. They also need more care and may be tricky to fix if they break.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Motor Type (Such As Ac Vs. Dc Motors) Impact The Efficiency And Precision Of A Metal Lathe’S Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of motor you choose affects how well the metal lathe works. AC motors usually run smoothly and can work for a long time without getting hot. DC motors, on the other hand, can start quickly and allow for better control. This means you can cut metal more accurately. So, choosing the right motor helps you do a better job!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Longevity And Optimal Performance Of A Metal Lathe Drive System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe drive system working well, you should check it regularly. Clean the parts to remove dirt and dust. Make sure to oil moving parts so they don’t get rusty. Check for any loose screws or parts and tighten them. Finally, follow the instructions in the manual for any special care tips.”}}]}