Have you ever wondered how metal parts are shaped with such precision? In workshops around the world, one tool stands out: the lathe. A lathe is a powerful machine that helps mold and shape metal into various forms. Whether creating custom grips or intricate gears, the lathe is essential for many makers.

Using a metal lathe can be exciting and a bit daunting. Imagine spinning a block of metal and shaping it into something useful! It might sound like magic, but it’s all about understanding the right techniques. That’s where a DRO, or Digital Readout, comes into play.

A DRO makes it easier to get those exact measurements needed for any project. It shows you the position of the tool in real time, eliminating guesswork. Have you ever tried to measure while in the middle of a project? It can be tricky! But with the right tools, anyone can master the art of metal shaping.

In this article, we will explore how to use a lathe for metal shaping. We will also dive into the exciting world of metal lathe DRO systems. These systems not only improve accuracy but also make metalworking more fun!

Lathe Metal Shaping: Unlocking Precision With Metal Lathe Dro

Understanding Lathe and Metal Shaping

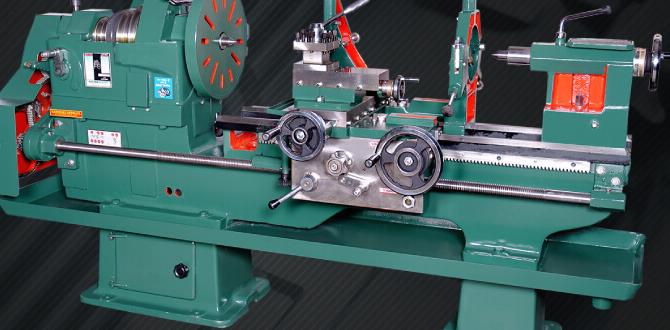

A lathe is a powerful tool used for shaping metal. It spins material while shaping, making it smooth and precise. Metal lathes are popular in workshops worldwide due to their versatility. They can create various parts for machines or projects. Have you ever wondered how intricate designs are made? The metal lathe DRO (Digital Readout) system helps operators measure and adjust with accuracy. This tech makes work easier and faster. With lathes, you’re not just shaping metal; you’re crafting possibilities!

Understanding Metal Lathes

Definition and purpose of metal lathes. Different types of metal lathes and their applications.

Metal lathes are machines that shape metal into different forms. They work by spinning the metal piece while cutting tools reshape it. Their main purpose is to create accurate and smooth objects, like tools and parts for machines.

There are different types of metal lathes:

- Engine Lathes: These are used for general machining tasks.

- CNC Lathes: These use computers for precise cutting.

- Toolroom Lathes: Ideal for small, detailed projects.

- Turret Lathes: Good for mass production of parts.

Each type has its special uses in factories and workshops.

What are the applications of metal lathes?

Metal lathes have numerous applications. They help in making automotive parts, precise tools, and even sculptures. Their versatility makes them key machines in many industries.

The Importance of DRO in Metal Shaping

Explanation of Digital Readout (DRO) and its functionality. Benefits of using DRO with a metal lathe.

A Digital Readout, or DRO, is a handy tool for metal shaping. It shows exact measurements of your lathe. This makes cutting and shaping metal easier and more accurate. Using a DRO has many benefits:

- Increases precision in cuts.

- Reduces errors and saves time.

- Helps with complex shapes and designs.

With a DRO, your project can be smoother. You’ll achieve better results and have more fun while working!

Why is a DRO important in metal shaping?

A DRO is vital because it improves accuracy and efficiency. Without it, mistakes can happen, which can waste material and time. It guides your work, ensuring you get the right shape every time.

Setting Up Your Metal Lathe

Stepbystep guide for installation and calibration. Tips for ensuring safety and efficiency during setup.

Setting up your metal lathe requires attention and care. Follow these simple steps for installation and calibration:

- Choose a level surface to place your lathe.

- Securely attach the legs or base of the lathe.

- Install the DRO according to the manual.

- Calibrate the lathe for accurate measurements.

For safety, wear protective gear like goggles. Keep the work area clean to avoid accidents. Regular checks will ensure efficiency. Make sure tools are in good shape too!

How do you ensure safety during setup?

Always wear safety goggles and gloves. Check for loose parts before starting. Make sure nothing is in the way while you work. Keeping tools organized will help keep you safe.

Choosing the Right Tools for Metal Shaping

Types of cutting tools and their applications. Considerations for selecting the best tools for your projects.

Picking the right tools for metal shaping is key to getting the job done well. There are different types of cutting tools for various tasks. For example, you might need a high-speed steel (HSS) tool for tougher materials or a carbide tool for more precision. When selecting tools, think about size, shape, and the material you’re working with. It’s like finding the right shoes for a race; the wrong pair will definitely slow you down. Just remember, a good metal lathe is your best friend when shaping metal—after your dog, of course!

| Tool Type | Application |

|---|---|

| High-Speed Steel (HSS) | Versatile for general use. |

| Carbide | Great for hard metals. |

| Cobalt | Best for tougher tasks. |

| Indexable Inserts | Easy to change for various tasks. |

Maintenance Tips for Longevity

Routine maintenance practices to keep your lathe in optimal condition. Troubleshooting common issues that may arise.

Keeping your lathe in great shape is important for smooth operation. Regular checks can prevent big problems later on. Here are some routine maintenance practices to follow:

- Keep it clean. Remove dust and shavings after use.

- Lubricate moving parts. This prevents wear and tear.

- Check for loose bolts. Tighten them to keep everything secure.

- Inspect belts and gears. Replace them if they look worn.

If you face issues, don’t worry! Here are some common problems and quick fixes:

- If the lathe makes strange noises, check for loose parts.

- For uneven cuts, ensure the tool is sharp and properly aligned.

- If the motor won’t start, check the power supply first.

By following these tips, your lathe will last much longer and work better.

What are some common lathe issues?

Common lathe issues include strange noises, uneven cuts, and motor problems. Regular checks help avoid these issues.

Advanced Metal Shaping Techniques

Exploration of specialized methods such as taper turning and grooving. Importance of experimentation in mastering advanced techniques.

Mastering advanced metal shaping helps create precise parts. Techniques like taper turning and grooving offer unique ways to shape metal. Taper turning lets you form cones and angles, while grooving creates slots and patterns. Experimenting with these methods is important. It builds skills and confidence. Each practice session reveals new possibilities. Don’t hesitate to try different approaches!

What are specialized metal shaping techniques?

Specialized techniques include taper turning and grooving, which enhance precision and creativity in metalworking.

Benefits of Experimenting with Techniques

- Improves skill level

- Encourages creativity

- Increases confidence

Future Trends in Metal Shaping Technology

Innovations in metal lathe technology. The impact of automation and digital advancements in metal shaping processes.

New ideas are changing how we shape metal. Innovations in lathe technology make machines smarter. Automation helps machines work faster and more accurately. Digital tools let workers control processes with ease. Here are some future trends:

- Increased use of robotics in metal shaping.

- Improvements in machine precision and speed.

- Advanced software for better design and planning.

These changes can lead to stronger products and less waste. The future looks bright for metal shaping!

What is the impact of automation on metal shaping?

Automation makes metal shaping quicker and more precise. Machines can repeat tasks without tiring. This leads to fewer mistakes and higher quality products.

Conclusion

In summary, a lathe is a powerful tool for shaping metal. A metal lathe with a Digital Readout (DRO) helps you make precise measurements. This accuracy improves your projects and makes your work easier. Explore how to use a lathe for your own creations. Dive deeper into online resources or local workshops to enhance your skills!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Shaping With A Metal Lathe And Digital Readout (Dro) Systems:

Sure! Here’s a short answer about using a metal lathe and DRO systems. A metal lathe shapes metal by spinning it. You hold a tool against the metal to cut it into shapes. A Digital Readout (DRO) system helps you measure accurately. It shows exact numbers, so you get your work just right!

Sure! Please provide the question you’d like me to answer.

What Are The Key Advantages Of Using A Digital Readout (Dro) System On A Metal Lathe For Precision Shaping?

A digital readout (DRO) system helps you see exact measurements on a screen. This makes it easier to get the shape you want. With clear numbers, you can work faster and make fewer mistakes. It also shows you the depth and position, so you can cut with more safety and accuracy. Overall, a DRO helps you make better, more precise parts.

How Does The Programming Of A Dro Enhance The Efficiency And Accuracy Of Machining Operations On A Metal Lathe?

A DRO stands for Digital Readout. When you program a DRO on a metal lathe, it shows exact measurements. This helps you cut metal more precisely. It makes your work faster too because you don’t have to measure as much by hand. So, using a DRO means you can create better pieces more quickly!

What Are The Common Types Of Metal Lathe Operations That Can Be Performed Using A Dro?

When you use a metal lathe with a Digital Readout (DRO), you can do several things. You can cut shapes like cylinders and cones. You can also add grooves or flat spots to the metal. With a DRO, you get precise measurements, making your work easier and more accurate. It helps you make sure everything is just right!

How Can Operators Calibrate And Maintain A Dro System To Ensure Optimal Performance On A Metal Lathe?

To keep a Digital Readout (DRO) system working well on a metal lathe, you should start by checking its settings. First, make sure the DRO shows the right numbers by testing it with a ruler. Clean the DRO and the machine regularly to keep dirt away. You should also check wires and buttons to make sure everything is connected and working. Doing these things will help your DRO system perform its best.

What Safety Precautions Should Be Taken When Using A Metal Lathe Equipped With A Dro For Shaping Operations?

When using a metal lathe with a Digital Read Out (DRO), safety is important. Always wear safety glasses to protect your eyes. Keep your hair tied back and your clothes snug to avoid getting caught. Make sure the area is clean and free of tools. Never reach into the machine while it is running, and always follow the instructions to stay safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Shaping With A Metal Lathe And Digital Readout (Dro) Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a short answer about using a metal lathe and DRO systems. A metal lathe shapes metal by spinning it. You hold a tool against the metal to cut it into shapes. A Digital Readout (DRO) system helps you measure accurately. It shows exact numbers, so you get your work just right!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Advantages Of Using A Digital Readout (Dro) System On A Metal Lathe For Precision Shaping?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital readout (DRO) system helps you see exact measurements on a screen. This makes it easier to get the shape you want. With clear numbers, you can work faster and make fewer mistakes. It also shows you the depth and position, so you can cut with more safety and accuracy. Overall, a DRO helps you make better, more precise parts.”}},{“@type”: “Question”,”name”: “How Does The Programming Of A Dro Enhance The Efficiency And Accuracy Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A DRO stands for Digital Readout. When you program a DRO on a metal lathe, it shows exact measurements. This helps you cut metal more precisely. It makes your work faster too because you don’t have to measure as much by hand. So, using a DRO means you can create better pieces more quickly!”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Metal Lathe Operations That Can Be Performed Using A Dro?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe with a Digital Readout (DRO), you can do several things. You can cut shapes like cylinders and cones. You can also add grooves or flat spots to the metal. With a DRO, you get precise measurements, making your work easier and more accurate. It helps you make sure everything is just right!”}},{“@type”: “Question”,”name”: “How Can Operators Calibrate And Maintain A Dro System To Ensure Optimal Performance On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a Digital Readout (DRO) system working well on a metal lathe, you should start by checking its settings. First, make sure the DRO shows the right numbers by testing it with a ruler. Clean the DRO and the machine regularly to keep dirt away. You should also check wires and buttons to make sure everything is connected and working. Doing these things will help your DRO system perform its best.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Metal Lathe Equipped With A Dro For Shaping Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with a Digital Read Out (DRO), safety is important. Always wear safety glasses to protect your eyes. Keep your hair tied back and your clothes snug to avoid getting caught. Make sure the area is clean and free of tools. Never reach into the machine while it is running, and always follow the instructions to stay safe.”}}]}