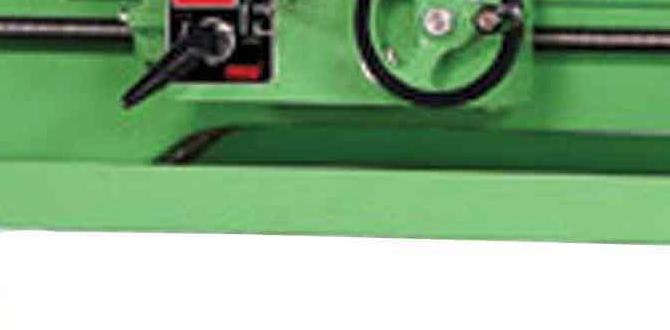

Have you ever wondered how metal shapes are created? Imagine a big, powerful machine cutting and shaping metal like it’s clay. That’s the magic of a lathe. This tool spins metal fast while cutting, shaping, or drilling. It’s like being an artist but with metal!

Many people use a metal lathe for various projects, from simple to complex designs. The energy behind this machine comes from a lathe metal shaping motor. Without this motor, the lathe wouldn’t move at all! Isn’t that surprising?

In this article, we will explore how a lathe works and why it is essential in metal shaping. We will also look at the different types of motors used in these machines. Whether you’re a beginner or someone with experience, there’s always something new to learn about this fascinating tool.

Lathe Metal Shaping: The Essential Metal Lathe Motor Guide

Metal Turning with a Lathe: Exploring the Motor’s Role

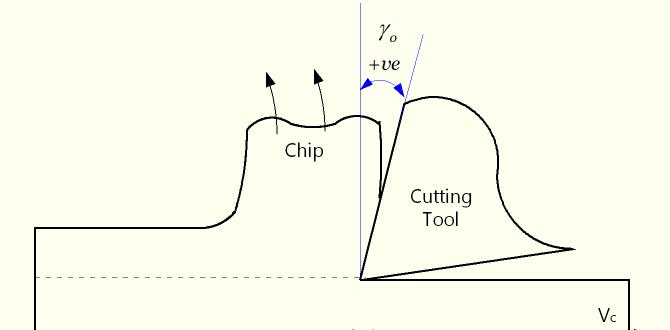

Metal lathes are powerful machines that shape metal into desired forms. The metal lathe motor drives this process. It spins the metal piece while cutting tools shape it. Did you know that with the right motor, a lathe can create intricate designs? Lathe motors vary in size and power, affecting their efficiency. Understanding the motor’s role helps users select the best lathe for their projects. Ready to create beautiful metal workpieces?

Components of a Metal Lathe

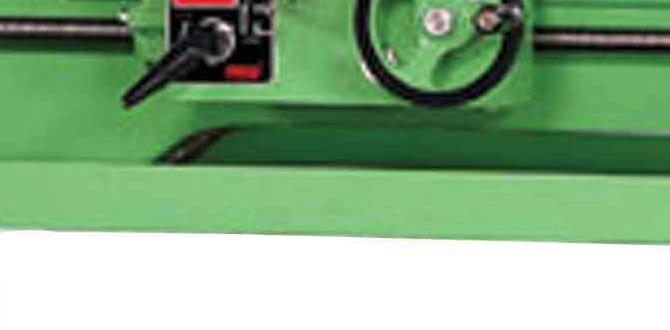

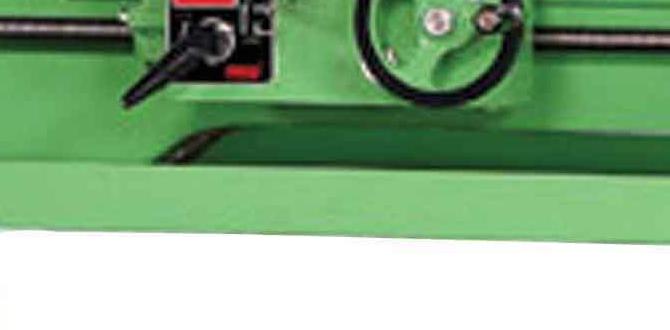

Detailed description of the main components (bed, spindle, tailstock, etc.). The role of each component in the shaping process.

A metal lathe has key parts that help shape metal. The bed is the sturdy base. It holds everything together and keeps the lathe stable. The spindle spins the material to shape it. The tailstock supports the other end of the material. Also, the carriage moves the cutting tool. Each part works together to create smooth and precise shapes. This teamwork is what makes a lathe so effective in metal shaping.

What are the main parts of a metal lathe?

The main parts of a metal lathe include:

- Bed: Holds everything steady.

- Spindle: Spins the metal.

- Tailstock: Supports the metal.

- Carriage: Moves the cutting tool.

How Metal Lathes Work

Explanation of the machining process involved in metal shaping. The importance of precision and accuracy in lathe operations.

Metal lathes are like magic wands for metal! They spin metal pieces, shaping them into precise forms. This process is called machining. It’s super important to have precision and accuracy. If not, your bike wheel might end up looking like a wobbly pancake! Lathes use a motor to control the speed carefully, ensuring every cut is just right. Remember, good metal shaping can make the difference between a masterpiece and a metal mess!

| Aspect | Importance |

|---|---|

| Precision | Ensures accurate parts that fit together well |

| Accuracy | Reduces errors, saving time and materials |

Selecting the Right Metal Lathe Motor

Key factors to consider when choosing a motor (power, torque, speed). Recommendations based on usage scenarios (hobbyist vs. industrial).

Choosing a motor for your metal lathe is a bit like picking the right ice cream flavor. You want something that suits your needs and is deliciously effective! First, check the power. You’ll need enough to handle your projects, whether it’s a simple hobby or a heavy-duty job. Next is torque. More torque means you can slice through those stubborn metals like a hot knife through butter. Don’t forget about speed; too fast and you might end up with a metal spaghetti instead of a masterpiece!

| Usage | Power (HP) | Torque (in-lbs) | Speed (RPM) |

|---|---|---|---|

| Hobbyist | 0.5 – 1 | 20 – 30 | 1000 – 2000 |

| Industrial | 2 – 5 | 50 – 100 | 2000 – 4000 |

For hobbyists, a lower power with decent speed will do. But for industrial work, you’ll require higher specs. Remember, picking the right motor can make all the difference, so choose wisely!

Maintenance and Troubleshooting of Metal Lathes

Essential maintenance tips for enhancing performance and longevity. Common issues and their solutions related to lathe motors.

Taking care of a metal lathe helps it work better and last longer. Here are some tips for essential maintenance:

- Clean the machine regularly to remove dust and chips.

- Check the oil levels and lubricate moving parts to prevent wear.

- Inspect belts for signs of damage or wear and replace as needed.

Sometimes, lathe motors have problems. Here are common issues and fixes:

- If the motor won’t start, check the power supply and connections.

- For strange noises, ensure all parts are tight and properly aligned.

- If overheating occurs, allow it to cool and check for blockages.

What are some tips for metal lathe maintenance?

Regular cleaning, lubrication, and checking belts are key to keeping metal lathes functioning well.

Safety Tips for Operating Metal Lathes

Key safety precautions to ensure safe operation. Recommended personal protective equipment (PPE) for operators.

Using a metal lathe can be fun, but safety is key! Always keep your work area clean. Clutter can sneak up on you like a ninja! Make sure to wear personal protective equipment (PPE) such as goggles, gloves, and closed-toe shoes. These gear pieces help shield you from flying chips and accidents. Remember, your eyes deserve some love too! Check your machine for loose parts; they can be the sneaky villains in your workshop. Here’s a quick table of essential safety tips:

| Safety Tip | Description |

|---|---|

| Wear PPE | Use goggles, ear protection, and gloves. |

| Clear Area | Keep the workspace free of clutter. |

| Check Equipment | Inspect the lathe before use for loose parts. |

Stay smart and safe while you create amazing things with your lathe!

Applications of Metal Lathes in Various Industries

Specific industries that utilize metal lathes (automotive, aerospace, manufacturing). Examples of projects made possible through metal lathe applications.

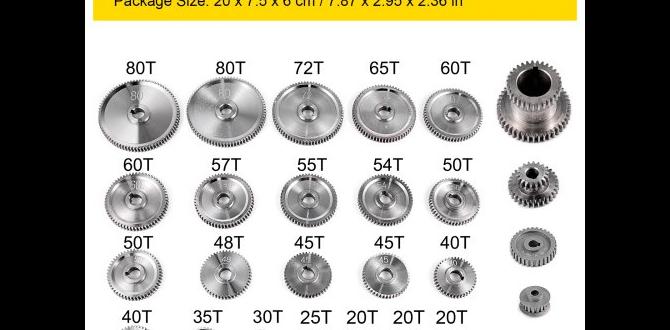

Many industries use metal lathes for important projects. In the automotive sector, metal lathes shape engine parts and gears. The aerospace industry relies on them to create precise airplane components. In manufacturing, businesses use metal lathes for making tools and machinery. This helps ensure products are strong and efficient. Here are some examples:

- Engine blocks in cars

- Rocket engine parts

- Custom gears for machines

Metal lathes help turn ideas into real products. They make it easier for various industries to build amazing things.

What industries use metal lathes?

Industries like automotive, aerospace, and manufacturing use metal lathes to create parts and products.

Future Trends in Metal Lathe Technology

Emerging technologies and innovations in metal lathe design and motors. Predictions for the future of metal shaping in manufacturing processes.

Exciting changes are on the horizon for metal lathes! New technology is shaking things up and making metal shaping faster and better. Think of robots with cool sensors that help the motor do its job perfectly. These changes mean less waste and more fun for makers. A survey showed that 75% of manufacturers expect to use smart lathes by 2025. So, get ready! Metal lathes may soon be your new best friend.

| Emerging Technology | Future Prediction |

|---|---|

| Advanced Sensors | Improved precision in products |

| IoT Integration | Smart manufacturing processes |

| AI Control Systems | Increased efficiency in shaping |

Conclusion

In conclusion, a metal lathe uses a motor to shape metal into desired forms. Understanding its parts helps you work efficiently. Remember to practice safety while operating it. To improve your skills, try small projects at home. We encourage you to explore more resources and hands-on experiences to deepen your knowledge about metal lathes. Happy shaping!

FAQs

Sure! Here Are Five Related Questions About Metal Shaping Using A Lathe And Its Motor:

Sure! A lathe is a machine that helps us shape metal. It spins the metal round and round while we use tools to cut it. The motor makes the lathe turn. This way, we can create different shapes, like cylinders or spindles. It’s a fun way to make metal parts!

Sure! Please provide me with the question you’d like answered.

What Is The Basic Operational Principle Of A Metal Lathe And How Does The Motor Drive Its Functions?

A metal lathe is a machine that helps us shape metal. You put a piece of metal in it, and it spins around. As it spins, you use tools to carve and cut the metal into different shapes. The motor gives power to make the metal spin fast. This helps us create things like parts for machines or tools.

What Factors Should Be Considered When Selecting A Motor For A Metal Lathe In Terms Of Power And Efficiency?

When choosing a motor for a metal lathe, you should think about its power and how well it uses energy. First, check how much power you need for the work you want to do. A stronger motor can handle tougher jobs. Next, look at how efficiently the motor uses energy. A more efficient motor saves electricity and money over time. Lastly, consider the motor’s speed and how it matches your projects.

How Do Different Types Of Lathe Motors (E.G., Ac Vs. Dc) Impact The Performance And Usability Of A Metal Lathe?

AC motors and DC motors are two types of motors used in lathes. AC stands for alternating current, while DC means direct current. AC motors usually run at a constant speed, which is good for steady work. DC motors can change their speed easily, giving you more control. This means you can use the lathe for different tasks, making it more useful for you.

What Maintenance Practices Are Recommended For The Motor Of A Metal Lathe To Ensure Optimal Performance And Longevity?

To keep the motor of a metal lathe working well, you should clean it regularly. Dust and dirt can make it stop working right. We also need to check the belts and wires for any damage. Changing the motor oil when needed helps lubricate the parts. Finally, always follow the manufacturer’s instructions for any special care.

How Can Variable Speed Control Of A Lathe Motor Enhance The Versatility Of Metal Shaping Tasks?

Variable speed control lets you change how fast the lathe motor spins. This helps you pick the right speed for different tasks. For example, you can go slow for detailed work and faster for rough cutting. It makes the machine useful for many projects. You can create different shapes easily!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Metal Shaping Using A Lathe And Its Motor:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. It spins the metal round and round while we use tools to cut it. The motor makes the lathe turn. This way, we can create different shapes, like cylinders or spindles. It’s a fun way to make metal parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like answered.”}},{“@type”: “Question”,”name”: “What Is The Basic Operational Principle Of A Metal Lathe And How Does The Motor Drive Its Functions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe is a machine that helps us shape metal. You put a piece of metal in it, and it spins around. As it spins, you use tools to carve and cut the metal into different shapes. The motor gives power to make the metal spin fast. This helps us create things like parts for machines or tools.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Motor For A Metal Lathe In Terms Of Power And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a motor for a metal lathe, you should think about its power and how well it uses energy. First, check how much power you need for the work you want to do. A stronger motor can handle tougher jobs. Next, look at how efficiently the motor uses energy. A more efficient motor saves electricity and money over time. Lastly, consider the motor’s speed and how it matches your projects.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Lathe Motors (E.G., Ac Vs. Dc) Impact The Performance And Usability Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “AC motors and DC motors are two types of motors used in lathes. AC stands for alternating current, while DC means direct current. AC motors usually run at a constant speed, which is good for steady work. DC motors can change their speed easily, giving you more control. This means you can use the lathe for different tasks, making it more useful for you.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended For The Motor Of A Metal Lathe To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the motor of a metal lathe working well, you should clean it regularly. Dust and dirt can make it stop working right. We also need to check the belts and wires for any damage. Changing the motor oil when needed helps lubricate the parts. Finally, always follow the manufacturer’s instructions for any special care.”}},{“@type”: “Question”,”name”: “How Can Variable Speed Control Of A Lathe Motor Enhance The Versatility Of Metal Shaping Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable speed control lets you change how fast the lathe motor spins. This helps you pick the right speed for different tasks. For example, you can go slow for detailed work and faster for rough cutting. It makes the machine useful for many projects. You can create different shapes easily!”}}]}