Have you ever wondered how metal shapes take on their final forms? The answer often lies in the world of lathe metal shaping. A metal lathe is a machine that can cut, shape, and smooth metal pieces. It works wonders in workshops, helping to create everything from small parts to large structures.

Picture this: a shiny block of metal sits in front of you. With the right tools and skills, you can turn that block into something amazing. But how do you get from raw metal to a finished piece? That’s where metal lathe operations come into play.

Not everyone knows about the incredible capabilities of a lathe. Did you know that lathes have been around for thousands of years? They started in ancient Egypt and have evolved into the powerful machines we see today. This article will guide you through the fascinating world of lathe metal shaping. You’ll discover how various operations can create stunning metal parts for all kinds of projects.

So, are you ready to dive into the exciting realm of metal lathe operations? Let’s explore how these machines turn ideas into reality!

Lathe Metal Shaping: Essential Metal Lathe Operations Explained

Lathe Metal Shaping: Metal Lathe Operations Unveiled

Metal lathes are fascinating tools for shaping metal into precise forms. They rotate the metal while cutting tools carve out unique designs. Did you know that even ancient cultures used similar methods to create beautiful objects? Understanding metal lathe operations helps you appreciate craftsmanship. You learn about different lathe types, safety tips, and basic techniques involved. With practice, anyone can transform raw metal into stunning pieces. Why not explore this amazing process and try it yourself?

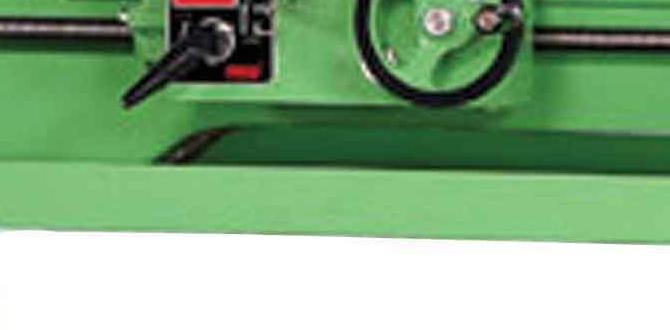

Understanding Lathe Machinery

Definition and components of a lathe. Types of lathes used in metal shaping.

A lathe is a machine that turns materials like metal into lovely shapes. It holds the metal piece steady while it spins. Think of it like a merry-go-round for metal! Key parts of a lathe include the bed, headstock, tailstock, and tool rest. There are many types of lathes used for metal shaping, each with its unique job. Here’s a quick look:

| Type of Lathe | Description |

|---|---|

| Engine Lathe | Common for many tasks, great for precision work. |

| CNC Lathe | Computer-controlled, perfect for complex designs. |

| Turret Lathe | Can hold multiple tools, fast and efficient. |

Knowing about lathes can make you feel like a metal wizard. So, grab your wand (or tools), and let’s make something amazing!

Key Metal Shaping Techniques

Turning: Description and applications. Facing: Steps and significance in the process.

Metal shaping is all about making things fit just right. One key technique is turning. During this process, a piece of metal spins while a cutting tool smooths it down. Think of it as giving the metal a haircut! It’s perfect for creating round shapes like knobs or pulleys.

Another important method is facing. This involves cutting a flat surface on the end of a metal piece. It’s like polishing the front of a cake to make it look nice. This step ensures parts fit together snugly. Without it, metal pieces might play a game of “wobble” instead of staying in place!

| Technique | Description | Applications |

|---|---|---|

| Turning | Spinning metal to shape it | Knobs, pulleys, and more |

| Facing | Cutting a flat surface | Ensures parts fit together |

Advanced Lathe Operations

Threading: Methods and tools required. Boring: Techniques and considerations for accuracy.

Welcome to the world of advanced lathe operations! Let’s tackle two cool topics: threading and boring. First up, threading. This involves making spiraled grooves on a workpiece. It can be done using tools like taps or dies. Imagine turning a screw—pretty neat, right?

Now, onto boring! This technique helps create larger holes in metal. Accuracy is key, or you might end up with a “whoops” moment instead of a perfect fit. Always double-check your measurements! Trust me, your future self will thank you.

| Operation | Tools Required | Accuracy Tips |

|---|---|---|

| Threading | Taps, Dies | Use cutting oil for smoother operation |

| Boring | Boring Bars, Reamers | Check measurements twice! |

Workpiece Selection and Preparation

Materials suitable for lathe operations. Essential preparation steps before machining.

Choosing the right material is key for successful lathe operations. Steel, aluminum, and brass are great choices. They are strong and easy to shape. Before starting, it’s important to prepare the workpiece well. Here are some essential steps:

- Check for any cracks or damage.

- Clean the surface to remove dirt.

- Measure dimensions accurately.

This preparation helps avoid mistakes and ensures a smooth machining process.

What should I check for in a workpiece?

Look for cracks, dirt, and correct measurements. These checks help you work safely and effectively.

Tooling and Accessories for Metal Lathe

Types of cutting tools and their uses. Essential accessories to enhance production efficiency.

Cutting tools shape metal in exciting ways. Each tool has its special job. Here are some common types:

- Lathe Tools: Used for shaping and smoothing metal.

- Drills: Create holes in metal pieces.

- Chisels: Cut sharp edges or grooves.

- Form Tools: Make specific shapes in metal.

Accessories also boost production. For example, tool holders keep tools secure. A steady platform helps in precise work. Safety gear, like goggles, protects users. Using the right tools and accessories makes every metal project easier and faster.

What are the essential tools for lathe operations?

The essential tools include lathe tools, drills, chisels, and form tools. These help in accurately shaping and cutting metal.

Safety Practices in Lathe Operations

Importance of safety gear and equipment. Common safety precautions to observe during operations.

Staying safe while using a lathe is like putting on a superhero cape! Wearing proper safety gear, like goggles and gloves, keeps you safe from flying metal shavings. Always check your equipment too; a faulty lathe can turn into a metal monster! Common safety precautions include keeping your work area clean and ensuring that your hair and clothes are secure. Don’t be a loose part in the machine – stay safe!

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protect eyes from metal shavings |

| Gloves | Keep hands safe and warm |

| Ear Protection | Reduce noise levels |

Remember, safety first! The only flying objects should be superhero capes, not metal shards!

Common Challenges in Metal Lathe Shaping

Identifying issues related to vibration and chatter. Troubleshooting common problems during metal lathe operations.

Metal lathe operations can be fun, but they come with their own set of challenges. One common issue is vibration and chatter. This annoying shaking can ruin your perfectly shaped metal piece. Think of it like trying to ride a bike with a flat tire—it’s just not smooth! To fix this, ensure you’ve set up everything right and check your tools.

| Common Problems | Solutions |

|---|---|

| Vibration | Check tool balance and speed. |

| Chatter | Adjust feed rate and cut depth. |

Keep these tips in mind, and your metal lathe will feel like a well-oiled machine. No more unexpected dance parties with your tools!

Maintenance Tips for Longevity of Lathe Machines

Routine maintenance practices to follow. Signs of wear and necessary repairs.

Taking good care of your lathe machine is like giving it a cozy blanket. Regular maintenance helps it stay happy and healthy. Check and clean it often. Look for strange noises or parts that don’t move smoothly. Those signs mean it might need some love, like oil or a new part. Keep an eye on the tools too. Dull tools can make the lathe grumpy!

| Maintenance Task | Frequency | Signs of Wear |

|---|---|---|

| Clean machine | Weekly | Dust and grime buildup |

| Lubricate moving parts | Monthly | Weird noises or stiffness |

| Check alignment | Monthly | Uneven cuts or vibrations |

With these tips, your lathe will last longer. Remember, a happy lathe machine makes for smooth cutting! Who wouldn’t want that?

Future Trends in Metal Lathe Technology

Innovations in lathe machinery and operations. The impact of automation and CNC lathes on traditional methods.

Bright lights, whirring sounds, and shiny parts! The world of metal lathes is changing fast. New machines are smarter and more efficient. Thanks to innovations like CNC lathes, tasks that took hours now happen in minutes. Automation means less manual work too. Now, instead of sweating over a piece, you just press a button. It’s like having a robot buddy helping you in the shop. The next generation of lathes might even make coffee—who knows? Let’s take a look:

| Innovation | Impact |

|---|---|

| CNC Lathes | Increased speed and accuracy. |

| Automation | Reduces labor and error. |

| Smart Technology | Real-time monitoring and adjustments. |

With these trends, it’s exciting to think about where lathes are headed next. Your metal shapes might just become masterpieces of the future!

Conclusion

In summary, a lathe is a powerful tool for shaping metal. You can turn raw metal into precise shapes with careful lathe operations. We encourage you to explore how lathes work and consider trying beginner projects. Understanding this tool can boost your skills in metalworking. Keep learning, and soon you’ll create amazing things!

FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Operations:

A lathe is a tool that helps shape metal. It spins metal while we use cutting tools to shape it. You can make things like parts for machines or even toys. Using a lathe needs care and practice. It’s fun to see how metal changes into something useful!

Sure! Just ask your question, and I’ll give you a short and simple answer.

What Are The Primary Types Of Cutting Tools Used In Metal Lathe Operations, And How Do They Differ In Application?

In metal lathe operations, we mainly use three types of cutting tools: flat tools, round tools, and parting tools. Flat tools help shape the metal into flat surfaces. Round tools are good for making curved shapes or grooves. Parting tools cut pieces of metal off, like slicing. Each tool has a special job to make different shapes and finishes on the metal.

How Do You Properly Set Up A Metal Lathe For Turning Operations To Ensure Accuracy And Safety?

To set up a metal lathe, first, make sure it is on a flat surface. Next, check that all parts are clean and in good shape. You should then securely attach the metal piece you want to work on. Finally, adjust the tool so it touches the metal lightly. Always wear safety glasses and keep your hands clear while the lathe is running.

What Are The Key Differences Between Manual And Cnc (Computer Numerical Control) Lathes In Metal Shaping Applications?

Manual lathes are machines you use by hand. You directly control the tools to shape metal. CNC lathes, or computer numerical control lathes, use a computer to guide the machine. This means they can make very precise shapes without you needing to control everything. CNC lathes are usually faster and easier for repeating the same task.

How Can You Determine The Appropriate Cutting Speed And Feed Rate When Machining Various Types Of Metals On A Lathe?

To find the right cutting speed and feed rate on a lathe, you can follow a few steps. First, check the type of metal you’re using. Different metals need different speeds; softer metals go faster while harder metals go slower. Next, look up a chart or guide for cutting speeds. You can also ask an expert or use a machine manual for help. Finally, do some practice cuts and adjust based on how the metal reacts.

What Are Some Common Troubleshooting Techniques For Addressing Issues Like Chatter Or Poor Surface Finish During Lathe Operations?

To fix chatter or bad surface finishes on a lathe, we can try a few simple things. First, check if the tool is sharp. A dull tool can cause rough cuts. Next, make sure the part is held tightly in place. If it’s loose, it can wobble and make noise. Finally, try slowing down the machine speed. Sometimes, going slower helps make a smoother finish.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Operations:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe is a tool that helps shape metal. It spins metal while we use cutting tools to shape it. You can make things like parts for machines or even toys. Using a lathe needs care and practice. It’s fun to see how metal changes into something useful!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll give you a short and simple answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Types Of Cutting Tools Used In Metal Lathe Operations, And How Do They Differ In Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathe operations, we mainly use three types of cutting tools: flat tools, round tools, and parting tools. Flat tools help shape the metal into flat surfaces. Round tools are good for making curved shapes or grooves. Parting tools cut pieces of metal off, like slicing. Each tool has a special job to make different shapes and finishes on the metal.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Metal Lathe For Turning Operations To Ensure Accuracy And Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, first, make sure it is on a flat surface. Next, check that all parts are clean and in good shape. You should then securely attach the metal piece you want to work on. Finally, adjust the tool so it touches the metal lightly. Always wear safety glasses and keep your hands clear while the lathe is running.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Manual And Cnc (Computer Numerical Control) Lathes In Metal Shaping Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual lathes are machines you use by hand. You directly control the tools to shape metal. CNC lathes, or computer numerical control lathes, use a computer to guide the machine. This means they can make very precise shapes without you needing to control everything. CNC lathes are usually faster and easier for repeating the same task.”}},{“@type”: “Question”,”name”: “How Can You Determine The Appropriate Cutting Speed And Feed Rate When Machining Various Types Of Metals On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right cutting speed and feed rate on a lathe, you can follow a few steps. First, check the type of metal you’re using. Different metals need different speeds; softer metals go faster while harder metals go slower. Next, look up a chart or guide for cutting speeds. You can also ask an expert or use a machine manual for help. Finally, do some practice cuts and adjust based on how the metal reacts.”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Techniques For Addressing Issues Like Chatter Or Poor Surface Finish During Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix chatter or bad surface finishes on a lathe, we can try a few simple things. First, check if the tool is sharp. A dull tool can cause rough cuts. Next, make sure the part is held tightly in place. If it’s loose, it can wobble and make noise. Finally, try slowing down the machine speed. Sometimes, going slower helps make a smoother finish.”}}]}