Have you ever wondered how metal shapes into precise parts? A lathe is like a magical tool that does just that! With a metal lathe, you can turn raw metal into beautiful designs. The secret lies in a special part called the saddle.

This part helps hold the metal securely while it spins. Picture a riding saddle on a horse, keeping the rider steady as they go. Similarly, the lathe metal shaping process relies on the saddle for accuracy. Isn’t it amazing how one piece can make such a difference?

Many people don’t realize how important these machines are in our everyday lives. From car parts to tiny gadgets, lathes shape the world around us. So, let’s dive into the fascinating world of metal lathes and discover how the metal lathe saddle plays a vital role in creating parts that keep everything running smoothly!

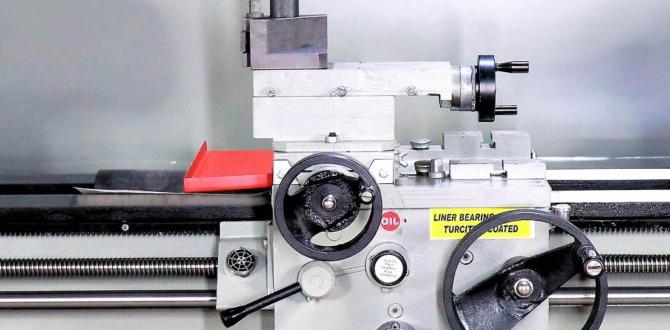

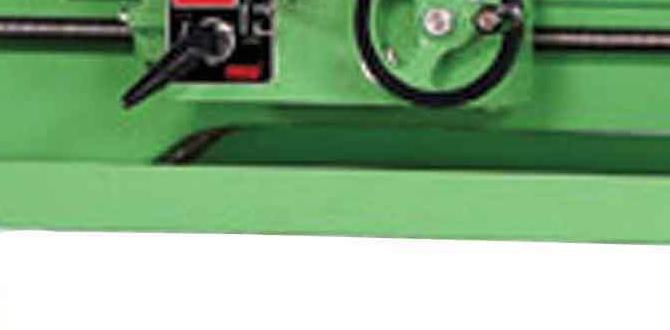

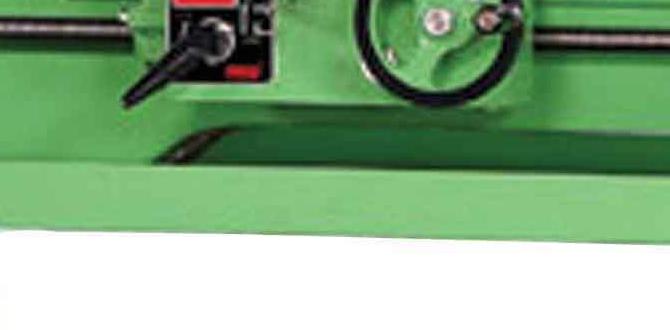

Lathe Metal Shaping: Understanding The Metal Lathe Saddle Lathe Metal Shaping Is An Essential Process In Machining That Involves Using A Lathe To Shape Various Materials, Primarily Metals. One Critical Component Of This Process Is The Metal Lathe Saddle, Which Plays A Vital Role In Ensuring Precision And Accuracy During The Operation. In This Article, We Will Explore The Functions And Significance Of The Metal Lathe Saddle, Its Components, And How It Contributes To Effective Metal Shaping. What Is A Metal Lathe? A Metal Lathe Is A Machine Tool Used For Shaping Metal By Removing Material Through A Process Known As Turning. It Rotates The Workpiece Against A Cutting Tool To Achieve The Desired Shape, Size, And Finish. The Lathe Is Indispensable In Various Industries, Including Manufacturing, Automotive, And Aerospace, Making It Crucial For Machinists And Engineers. The Metal Lathe Saddle: Its Role And Components The Metal Lathe Saddle Is A Crucial Part Of The Lathe’S Design. It Serves As A Support Platform For The Carriage, Which Houses The Cutting Tool. The Saddle Moves Along The Bed Of The Lathe, Enabling The Tool To Cut The Metal Workpiece Accurately. Here Are Some Of The Key Components Of The Saddle: 1. **Base:** The Foundation That Secures The Saddle To The Lathe Bed And Provides Stability During Operation. 2. **Guideways:** These Are The Tracks Along Which The Carriage Slides. They Ensure Smooth Movement And Precise Alignment. 3. **Locking Mechanisms:** These Allow The Operator To Secure The Saddle In Place When Necessary, Preventing It From Shifting During Machining. 4. **Feed Mechanism:** This Controls The Movement Of The Saddle, Allowing For Precise Adjustments In Cutting Depth And Length. Importance Of The Metal Lathe Saddle The Metal Lathe Saddle’S Importance Can Be Summarized As Follows: – **Precision:** A Well-Designed Saddle Ensures Accurate Positioning Of The Cutting Tool In Relation To The Workpiece, Which Is Vital For Achieving High-Quality Finishes. – **Stability:** The Saddle’S Construction Provides The Necessary Stability To Withstand The Forces Generated During Cutting, Reducing Vibrations And Improving Accuracy. – **Versatility:** The Saddle Allows For Various Operations, Including Turning, Facing, And Threading, Making It Adaptable For Different Machining Tasks. Conclusion In Summary, The Metal Lathe Saddle Is A Fundamental Component In The Process Of Lathe Metal Shaping. Its Design And Functionality Significantly Affect The Overall Performance Of The Metal Lathe, Making It Essential For Machinists Who Seek Precision And Efficiency In Their Work. Understanding The Role Of The Saddle Helps Improve Machining Practices And Ultimately Enhances The Quality Of Produced Metal Components. Whether You Are A Seasoned Machinist Or A Newcomer To The Field, Familiarizing Yourself With The Intricacies Of The Metal Lathe Saddle Is Crucial For Achieving Success In Metal Shaping.

Lathe Metal Shaping: The Metal Lathe Saddle

The metal lathe saddle plays a vital role in shaping metal with precision. This part holds the workpiece steady, making it easy to carve smooth surfaces or complex shapes. Ever wonder how a block of metal turns into a beautiful part? It’s all about control and speed! With a lathe, even beginners can create impressive projects. Fun fact: the earliest lathes date back to ancient Egypt! Understanding the saddle’s function opens up new possibilities in metalworking.The Anatomy of a Metal Lathe

Key components of a metal lathe. Importance of each component in the shaping process.Every metal lathe has key parts that make it work. Let’s take a look at these components!

| Component | Importance |

|---|---|

| Saddle | Holds the workpiece tight while it spins. Think of it as a seatbelt for metal! |

| Headstock | Controls the spindle speed. It’s like the brain telling the body how fast to dance! |

| Tailstock | Supports the other end of the workpiece. The cheerleader ensuring everything stays balanced! |

| Carriage | Moves tools during shaping. Like a magical robot arm doing the waltz! |

Each part plays a big role in shaping metal. Without them, it would be chaos—like a dance without music! Understanding how these components work together is key to mastering the art of metal shaping.

Understanding the Metal Lathe Saddle

Definition and role of the metal lathe saddle. How the saddle influences precision and accuracy in machining.The metal lathe saddle is a key part of a lathe machine. It holds the cutting tool in place and helps it move smoothly. Think of it as a trusty sidekick in a superhero movie—always there to assist! The saddle plays a big role in making sure the cuts are precise and accurate. A well-aligned saddle means better results, like turning a block of metal into a fine piece of art.

| Feature | Benefit |

|---|---|

| Stability | Prevents vibrations and unwanted movements. |

| Adjustability | Can be fine-tuned for accuracy. |

| Durability | Lasts longer, saving you money. |

In machining, precision is everything! A steady saddle ensures every cut is spot on. So, treat your saddle well; it’s the unsung hero of the workshop!

Types of Metal Lathe Saddles

Fixed vs. adjustable saddles. Comparison of designs and functionalities.Metal lathe saddles come in two main types: fixed and adjustable. Fixed saddles stay in one position, giving steady support during shaping. They are simple and reliable. Adjustable saddles, however, can change height and position. This allows for more flexibility when working with different materials. Here’s a quick comparison:

- Fixed Saddles: Stable and easy to use.

- Adjustable Saddles: Versatile and adaptable for different tasks.

Each design has its strengths, making them suited for various projects in metal shaping.

What are the advantages of fixed and adjustable saddles?

Fixed saddles provide stability, while adjustable saddles offer flexibility and versatility. This allows users to choose the best option based on their specific needs.

Saddle Adjustments and Their Impact on Machining

Techniques for adjusting the saddle for optimal performance. Effects of improper adjustments on the machining process.Getting the saddle just right can make a big difference in machining. Start by loosening the adjustment screws and moving the saddle slowly. This helps set it at the perfect place for smooth operation. Remember, if the saddle is off, you could end up with uneven cuts. That’s like wearing two different shoes—awkward and not very useful!

| Improper Adjustments | Effects on Machining |

|---|---|

| Loose Saddle | Creates rough surfaces |

| Tight Saddle | Overheating and wear |

So, keep an eye on those adjustments! They are key to happy machining and smooth metal shaping.

Applications of Metal Lathes in Industry

Common industries utilizing metal lathes. Examples of projects and products made using metal lathes.Metal lathes are vital in many industries. They help create accurate parts quickly. Common sectors include:

- Aerospace

- Automotive

- Manufacturing

- Construction

These industries use metal lathes for various projects. Examples include:

- Engine components

- Machine parts

- Structural supports

Metal lathes shape metals into useful items. They turn raw materials into precise, finished products that improve our daily lives. This tool makes tasks easier and faster.

What products are made using metal lathes?

Many useful products come from metal lathes. Common items include bolts, gears, and custom fittings. These products help build our cars, planes, and machines.

Choosing the Right Metal Lathe for Your Needs

Factors to consider when selecting a metal lathe. Benefits of investing in a highquality saddle for performance.Finding the best metal lathe is like picking a favorite ice cream flavor—there’s a lot to think about! Start with size; make sure it fits your workspace. Consider how often you’ll use it and what you’ll make. A high-quality saddle is key too! It helps the lathe perform better and makes your projects smoother. Think of it as the comfy seat of your creativity. You wouldn’t want to sit on a wobbly chair, right? Here’s a quick table to guide your choice:

| Factor | Importance |

|---|---|

| Size | Must fit your space |

| Quality saddle | Enhances performance |

| Price | Stay within budget |

Future Trends in Metal Lathe Technology

Innovations in saddle design and machining technologies. The impact of automation and smart technology on metal lathes.New designs in lathe saddles are changing how metal is shaped. Manufacturers focus on lighter, sturdier materials. This makes machines faster and easier to use. Automation is also playing a big role. Smart technology can help reduce mistakes and improve safety. Machines can even talk to each other! This means better efficiency and production speeds.

What are new innovations in lathe technology?

Many exciting updates come with metal lathes. Some key points include:

- New saddle designs: They improve balance and speed.

- Automation technology: Makes tasks easier and faster.

- Smart systems: Help track performance and find problems.

Conclusion

In summary, the lathe is a powerful tool for shaping metal. The metal lathe saddle holds the workpiece securely while you cut and shape it. Understanding how it works helps you create precise parts. If you’re interested, try watching videos or reading more about metal lathes. By practicing, you can master this exciting skill!FAQs

What Is The Primary Function Of A Saddle In A Metal Lathe, And How Does It Influence The Machining Process?The saddle in a metal lathe helps hold and move the cutting tool in the right place. It slides back and forth to adjust the tool’s position. This makes sure the tool can cut the metal accurately. If the saddle works well, it helps create smoother and better-shaped pieces of metal.

How Does The Design Of The Lathe Saddle Impact The Accuracy And Stability Of The Workpiece During Operation?The lathe saddle holds the workpiece in place. A good design keeps it stable while you work. This means your cuts are straight and smooth. If the saddle is wobbly, the workpiece can move, leading to mistakes. So, a strong and steady saddle helps you make better things!

What Are The Common Materials Used In The Construction Of Lathe Saddles, And How Do They Affect Performance And Wear Resistance?Lathe saddles are often made from cast iron, steel, or aluminum. Cast iron is heavy and helps keep the machine steady. Steel is strong and resists wear, while aluminum is light and easy to move. These materials affect how well the lathe works and how long it lasts.

What Maintenance Practices Are Essential For Ensuring The Longevity And Precision Of The Lathe Saddle?To keep the lathe saddle in good shape, we should clean it regularly. You can wipe off dust and oil with a soft cloth. Always check for rust and fix it quickly. We should also oil the moving parts to help them work smoothly. Finally, make sure everything is tight and not loose.

How Do Different Types Of Lathe Saddles (E.G., Flat Vs. Cross Slide) Affect The Versatility Of A Metal Lathe In Various Machining Applications?Different types of lathe saddles change how we use a metal lathe. A flat saddle lets us move the cutting tool up and down easily. This is good for making straight cuts. A cross slide saddle allows us to move the tool side to side too. This makes it better for shapes and detailed work. So, the right saddle can help us do more things.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Primary Function Of A Saddle In A Metal Lathe, And How Does It Influence The Machining Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The saddle in a metal lathe helps hold and move the cutting tool in the right place. It slides back and forth to adjust the tool’s position. This makes sure the tool can cut the metal accurately. If the saddle works well, it helps create smoother and better-shaped pieces of metal.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Lathe Saddle Impact The Accuracy And Stability Of The Workpiece During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe saddle holds the workpiece in place. A good design keeps it stable while you work. This means your cuts are straight and smooth. If the saddle is wobbly, the workpiece can move, leading to mistakes. So, a strong and steady saddle helps you make better things!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used In The Construction Of Lathe Saddles, And How Do They Affect Performance And Wear Resistance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe saddles are often made from cast iron, steel, or aluminum. Cast iron is heavy and helps keep the machine steady. Steel is strong and resists wear, while aluminum is light and easy to move. These materials affect how well the lathe works and how long it lasts.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Longevity And Precision Of The Lathe Saddle? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lathe saddle in good shape, we should clean it regularly. You can wipe off dust and oil with a soft cloth. Always check for rust and fix it quickly. We should also oil the moving parts to help them work smoothly. Finally, make sure everything is tight and not loose.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Lathe Saddles (E.G., Flat Vs. Cross Slide) Affect The Versatility Of A Metal Lathe In Various Machining Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different types of lathe saddles change how we use a metal lathe. A flat saddle lets us move the cutting tool up and down easily. This is good for making straight cuts. A cross slide saddle allows us to move the tool side to side too. This makes it better for shapes and detailed work. So, the right saddle can help us do more things.”}}]}