Have you ever watched someone use a lathe? It can seem like magic. With just a metal lathe, they shape raw metal into beautiful, precise parts. But have you ever thought about how important the tailstock alignment is?

The tailstock is a key part of a lathe. If it’s not aligned, nothing will work right. A small mistake can ruin a project. Imagine spending hours working on a piece, only to find that it’s not straight. Frustrating, right?

In this article, we will explore how to achieve perfect lathe metal shaping. We will dive into tailstock alignment and why it matters. You’ll learn some tips and tricks that make aligning your tailstock easier than ever.

So, are you ready to unlock the secrets of the lathe? Let’s get started on this journey together!

Lathe Metal Shaping: Metal Lathe Tailstock Alignment Guide

Lathe Metal Shaping and Tailstock Alignment

Lathe metal shaping is an exciting process for creating precise parts. A key focus is tailstock alignment, which ensures pieces remain straight and true. Ever struggled to keep your work steady? Proper alignment prevents errors and wasted material. Did you know that even minor misalignments can lead to major issues? Ensuring your tailstock is correctly aligned will improve your cuts and extend your tool’s life, helping you achieve the best results in your projects.

Understanding the Importance of Tailstock Alignment

Explanation of tailstock function and its role in machining accuracy. Key reasons for proper tailstock alignment to ensure workpiece stability.

The tailstock on a lathe helps to hold and stabilize the workpiece while it spins. Think of it as the trusty sidekick that keeps everything in place. If it’s not aligned properly, things can get wobbly. A wobbly workpiece is like trying to dance on a tightrope—definitely not fun! Proper alignment ensures the workpiece stays stable, leading to better accuracy in your machining. Without it, you risk uneven cuts and errors. So, always check that tailstock before unleashing your inner metal master!

| Reason for Proper Tailstock Alignment | Effect on Machining |

|---|---|

| Stability | Prevents wobbling during cuts |

| Accuracy | Ensures even cuts for better quality |

| Safety | Reduces risk of accidents |

Tools Required for Tailstock Alignment

List of essential tools for effective alignment. Explanation of tool purposes and best practices for use.

For proper tailstock alignment, you need a few helpful tools. These tools help ensure your lathe works well. Here’s a list of essential items:

- Ruler: Measure distances accurately.

- Dial Indicator: Check the tailstock’s position carefully.

- Wrenches: Tighten or loosen screws easily.

- Level: Ensure the lathe is even.

- Square: Keep everything at right angles.

Using these tools correctly helps make the alignment effective. Always double-check your measurements. This way, your projects will turn out better!

What tools do I need for tailstock alignment?

You will need tools like a ruler, dial indicator, and level for proper alignment. Each tool plays a critical role in achieving accuracy in your work.

Step-by-Step Guide to Tailstock Alignment

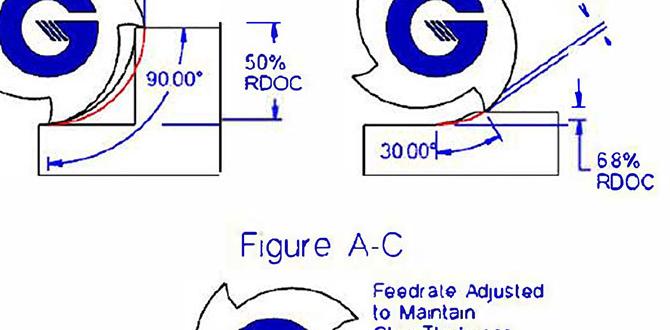

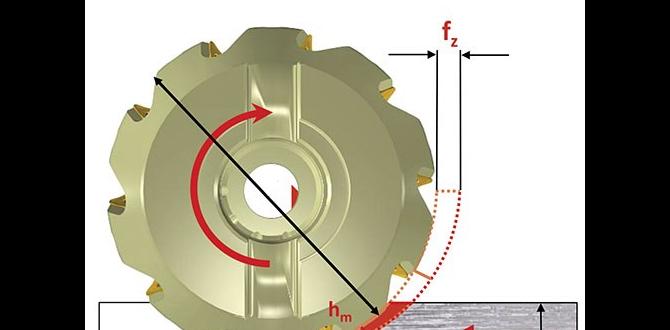

Detailed procedure for aligning the tailstock. Visual aids and diagrams to enhance understanding.

Aligning the tailstock of a metal lathe is key for smooth operation. First, check if the tailstock is level. Use a precision level and adjust it until it’s just right. Next, examine the alignment with the spindle. You can use a thin rod—like a pencil for example. Insert it in the tailstock and spin it to see if it wobbles. If it does, it’s time to tweak that tailstock!

| Step | Action |

|---|---|

| 1 | Level the tailstock |

| 2 | Check spindle alignment |

| 3 | Tweak adjustments |

Lastly, do your adjustments with care. Test it again. If everything spins smoothly, high-five yourself! If not, arms up—and repeat the process! Remember, practice makes perfect!

Checking and Verifying Alignment

Methods to verify alignment accuracy postadjustment. Common indicators of accurate vs. misaligned tailstock.

After adjusting the tailstock, it’s time to check if everything is right. Here are a few easy ways to make sure it’s aligned correctly:

- Look down the length of the lathe. The tailstock should line up with the center of the lathe.

- Use a test bar. Run it through the tailstock. If it spins smoothly, you’re good!

- Check the gap. There should be no space between the tailstock and the workpiece.

Signs of a misaligned tailstock include uneven wear on tools and inconsistent cuts. If adjustments don’t help, check the tailstock’s locking mechanism.

How to know if the tailstock is aligned?

Check for smooth spinning and even cuts. Any wobbling or noise signals a problem.

Maintenance Tips for Sustaining Tailstock Alignment

Preventive measures to maintain alignment over time. Recommendations for regular checks and adjustments.

Keeping your tailstock aligned is key for perfect metal shaping. First, check alignment regularly. A quick test involves using a centering jig to spot any issues. Adjustments can be done with simple tools.

Try to assess the tailstock every month and more often if you’re working on tricky projects. Remember, a little maintenance goes a long way. After all, it’s easier to fix a little wobble than a big mess!

| Action | Frequency |

|---|---|

| Check Tailstock Level | Monthly |

| Adjust if Needed | As Required |

| Inspect for Wear | Quarterly |

Trust me, a well-aligned tailstock is like a well-cooked pizza—everyone loves it when it’s just right!

Case Studies: Real-life Examples of Tailstock Alignment Issues

Detailed analysis of case studies highlighting alignment failures. Lessons learned and best practices from experienced machinists.

Misalignments in the tailstock can cause a big headache for machinists. One case involved a shop losing precision on every cut. Picture a pizza cutter that wobbles—no one wants that mess! Experienced machinists found that keeping the tailstock aligned made a world of difference. The top lesson? Always check the alignment before starting! With some practice, even a novice can avoid those pesky errors.

| Case Study | Problem | Solution |

|---|---|---|

| Shop A | Wobbling cuts | Regular tailstock checks |

| Shop B | Dimensional inaccuracies | Using alignment tools |

Even small tweaks can save time and resources. Remember, a happy lathe equals a happy machinist!

Conclusion

In summary, aligning the tailstock on a metal lathe is crucial for accurate shaping. You need to check the alignment often to avoid mistakes. Proper alignment helps create smooth and precise metal pieces. Remember to use simple tools for adjustments. Now that you know the basics, take some time to practice. You can improve your skills and enjoy shaping metal!

FAQs

What Are The Key Steps To Ensure Proper Alignment Of The Tailstock On A Metal Lathe?

To align the tailstock on a metal lathe, start by loosening the tailstock lock. Move it so it’s lined up with the spindle. Use a test rod or a straight edge to check if they are straight and even. Tighten the tailstock lock when everything looks good. Finally, test it by running the lathe to make sure it works well.

How Can Misalignment Of The Tailstock Affect The Accuracy And Quality Of The Workpiece?

If the tailstock is not lined up right, it can cause problems. Your workpiece might wobble or not fit well. This means it won’t be shaped correctly. You might end up with scratches or rough edges, making it look bad. So, always check that the tailstock is aligned properly!

What Tools And Techniques Are Commonly Used To Check And Adjust The Tailstock Alignment On A Metal Lathe?

To check and adjust the tailstock on a metal lathe, we use some simple tools. A dial indicator helps us see if the tailstock is straight. We can also use a test bar, which is a metal rod placed in the tailstock. If it’s not aligned, we can adjust the tailstock by loosening screws and moving it slightly. Then, we check again until it’s just right.

What Troubleshooting Steps Should Be Taken If A Lathe’S Tailstock Is Consistently Out Of Alignment During Operation?

First, check if the tailstock is tight and not loose. You might need to loosen screws, adjust it, and then tighten them again. Next, look at the bed of the lathe. Make sure it’s clean and not damaged. Finally, you can use a tool to measure if the tailstock is straight. If it’s still off, ask for help from someone more experienced.

How Often Should Tailstock Alignment Be Checked And Adjusted In A Production Environment To Maintain Precision?

You should check and adjust the tailstock alignment every week in a busy workshop. If you notice mistakes in your work, check it sooner. Keeping it aligned helps your tools work better. This way, we make sure everything is precise and correct!