Have you ever wondered how metal objects get their perfect shapes? It’s often thanks to a tool called a lathe. This amazing machine helps in metal shaping and can create parts with impressive precision.

Using a metal lathe is not just about turning metal. It involves various techniques, like threading, which allows for creating screw-like shapes. Do you know how a threading dial works? It helps the operator line up cuts accurately, making tasks easier and more efficient.

Imagine a world where everything is handmade. Each piece, like a gear or a handle, is crafted on a lathe. It’s fascinating to think that skilled workers use these machines to bring designs to life.

When you dive into the world of metal work, you’ll discover the art behind it. The lathe is like a trusted friend for craftsmen. It helps them shape metal into useful tools and parts every day. That’s the magic of a metal lathe and its threading dial!

Lathe Metal Shaping: Understanding Metal Lathe Threading Dial

Understanding Metal Lathes for Shaping and Threading

Metal lathes are fascinating tools used for shaping metal. They rotate the metal piece while a cutting tool shapes it. Have you ever wondered how metal turns into perfectly threaded rods? The threading dial helps make those perfect threads. This dial ensures accuracy when cutting threads. Knowing how to use a lathe opens doors to many projects. Whether crafting gifts or building furniture, metal lathes make creations possible. Enjoy exploring this powerful tool and its endless possibilities!

Understanding the Basics of Lathe Machines

Definition and purpose of lathe machines. Different types of lathes used in metal shaping.

A lathe machine is a tool used to shape metal and other materials. It spins the material while a cutting tool shapes it. This helps create smooth, precise objects. Lathes are important in many industries, from car making to furniture design. There are different types of lathes, each for specific tasks.

- **Engine Lathe:** A versatile lathe for general work.

- **Turret Lathe:** Great for mass production and repetitive tasks.

- **CNC Lathe:** Uses computer control for precise cuts.

- **Bench Lathe:** Smaller, ideal for hobbies or light tasks.

Each type has a special purpose. This makes them useful for different jobs. Understanding these basics helps in choosing the right lathe for your needs.

What is a lathe machine?

A lathe machine is a tool that shapes materials by spinning them while cutting tools reshape them into desired forms.

What are the different types of lathes?

There are several types of lathes including engine lathes, turret lathes, CNC lathes, and bench lathes. Each type serves a unique purpose.

The Importance of Metal Shaping in Manufacturing

Role of metal shaping in industrial applications. Benefits of using metal lathes for precision work.

Metal shaping is like a craft party for machines! It plays a major role in making products we use every day. From car parts to toys, metal shaping helps industries work smoothly. Using a metal lathe is like having a magic wand. It shapes metal with pinpoint accuracy, making sure each piece fits perfectly. This precision not only saves time but also cuts costs. Plus, who wouldn’t want to impress their friends with shiny, well-made items?

| Benefits of Metal Shaping | Details |

|---|---|

| Precision | Ensures accurate dimensions for every part. |

| Cost-Effective | Reduces waste and production time. |

| Versatility | Used in various industries like automotive and aerospace. |

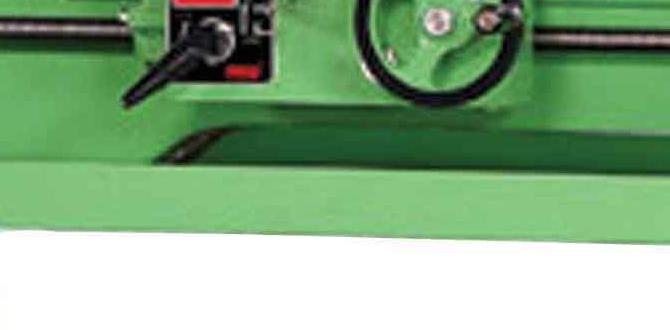

Anatomy of a Metal Lathe

Key components of a metal lathe and their functions. How each part contributes to metal shaping and threading.

Metal lathes are like the superheroes of the workshop! Their key parts work together to turn metal into stunning shapes. The tailstock holds the end of the metal while the headstock spins it like a DJ! The carriage moves the cutting tool, giving precision cuts. Wouldn’t it be funny if your pencil could do that? Check out the table below to learn more about each part:

| Component | Function |

|---|---|

| Tailstock | Supports the free end of the metal |

| Headstock | Holds the motor and spins the metal |

| Carriage | Moves the cutting tool for shaping and threading |

Together, these parts let you shape metal with ease, like turning dough into cookies! Without them, we’d just have a bunch of unshaped metal. Boring, right?

Setting Up Your Metal Lathe for Threading

Stepbystep guide to preparing the lathe for operation. Essential tools and materials needed for effective threading.

Before you start turning metal into masterpieces, it’s important to get your lathe ready for action! First, find your tools and make sure they shine like new pennies. You’ll need cutting tools, the right threading dial, and some coolant to keep things cool—pun intended! Next, check the lathe itself. Adjust the speed and ensure everything’s tight. Ready to spin? Here’s a handy table to help you keep track:

| Tool | Purpose |

|---|---|

| Cutting Tool | Shapes the metal |

| Threading Dial | Ensures accurate threading |

| Coolant | Keeps the metal cool |

Now, tweak those settings and let the magic happen! Remember, a well-set lathe is like a happy dog—always ready to roll!

Common Challenges in Metal Shaping and How to Overcome Them

Identifying potential issues in lathe operations. Practical solutions to improve metal shaping outcomes.

Lathe operations can face some common challenges. Issues like vibrations, poor cutting speed, or tool wear can hinder metal shaping. These challenges can lead to bad shapes or rough surfaces. Fortunately, there are solutions to improve outcomes.

- Check tools regularly for sharpness.

- Adjust cutting speed based on material type.

- Keep the lathe clean to avoid buildup.

These steps help achieve better results with less frustration.

What are some common problems with lathe operations?

Common problems include tool wear, incorrect speed, and vibrations. Each can affect the quality of metal shaping.

Safety Practices When Operating a Metal Lathe

Essential safety precautions and gear when using lathes. Common hazards and how to mitigate them.

Using a lathe can be fun, but safety comes first! Always wear your safety glasses to keep those flying metal chips away from your eyes. A dust mask is a smart idea too, just to avoid sneezing from the shavings. Make sure your hair and loose clothes are tied back. Handle the tools like they’re hot potatoes—because they kind of are! Here’s a quick list of safety tips to remember:

| Safety Gear | Common Hazards |

|---|---|

| Safety glasses | Flying debris |

| Dust mask | Inhaling dust |

| Ear protection | Noise from cutting tools |

| Gloves | Getting caught in moving parts |

Always double-check that the piece is secured before you start turning it. Remember, a little care means a lot of safety!

Maintenance Tips for Longevity of Your Metal Lathe

Regular maintenance routines to keep the lathe in top condition. Signs that indicate maintenance is needed.

Taking care of your metal lathe is very important. Regular maintenance keeps it running well. Here are some simple tasks to do:

- Clean it often to remove dust and chips.

- Lubricate moving parts to reduce wear.

- Check for loose screws and tighten them.

Watch for signs like strange noises, vibrations, or errors in your work. These mean it needs attention. Taking care of your lathe helps it last longer and work better!

What are common signs your lathe needs maintenance?

Look out for strange noises, vibrations, or inaccurate cuts.

Resources for Further Learning and Mastery

Recommended books, courses, and online resources for lathe craftsmanship. Community forums and groups for knowledge sharing and troubleshooting.

Learning about lathe craftsmanship can be exciting! To enhance your skills, check out these resources:

- Books: Look for titles like “The Metal Lathe” and “Machinery’s Handbook.” They offer easy-to-follow tips.

- Online courses: Platforms like Udemy and Coursera provide fantastic lessons for all levels.

- Community forums: Join groups on Reddit or Facebook. They are great for asking questions and sharing knowledge.

With these tools, you can master the metal lathe and enjoy your crafting journey!

What books are best for learning lathe skills?

Some of the best books include “The Metal Lathe” and “Machinery’s Handbook.” These books cover all the basics and advanced techniques. They are great for beginners and experienced users alike.

Conclusion

In summary, a metal lathe is a powerful tool for shaping and threading metal. The threading dial helps you make precise threads on your projects. Understanding how to use these tools can enhance your metalworking skills. We encourage you to practice using a lathe and explore more about its features. Happy crafting!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Shaping With A Metal Lathe And Threading Dial:

Sure! A metal lathe is a machine that helps us shape metal into different shapes. We can use it to make things like toys or tool parts. A threading dial helps us create threads, which are like grooves or ridges in metal. This makes it easy to screw things together. Working with a metal lathe is fun and lets us make all kinds of cool projects!

Sure! Please ask your question, and I’ll be happy to help.

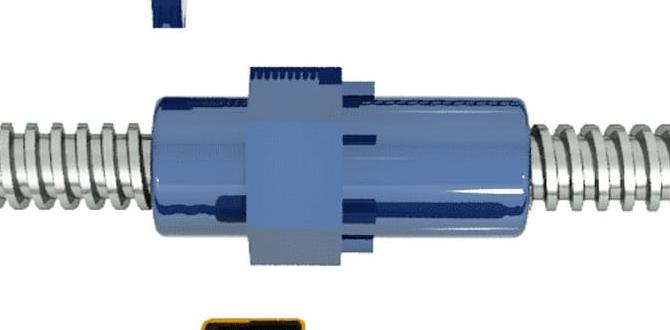

What Is The Primary Function Of A Threading Dial On A Metal Lathe, And How Does It Assist In Creating Threads?

The threading dial on a metal lathe helps you make threads on a piece of metal. It shows you exactly when to move the cutting tool to create even grooves. When you turn the dial, it helps you keep the tool in the right spot. This makes sure the threads are the same size and look nice. Using the threading dial makes your work easier and more accurate!

What Are The Differences Between Power Feed And Manual Feed When Shaping Metal On A Lathe, And In What Scenarios Might Each Be Preferred?

Power feed uses a motor to move the cutting tool automatically. This helps you work faster and more evenly. Manual feed means you move the tool by hand, giving you more control for small or tricky jobs. You might choose power feed for big projects, and manual feed for detailed work or small pieces.

How Do You Properly Set Up A Metal Lathe For Threading Operations, Including The Necessary Adjustments For The Threading Dial?

To set up a metal lathe for threading, first, you need to choose the right tool for cutting threads. Then, make sure the workpiece is tight and secure in the lathe. Next, you need to adjust the threading dial. You do this by finding a matching number on the dial and turning the handwheel until it reaches that number. This helps you make smooth threads. Always check your setup before starting!

What Are Some Common Issues Encountered While Using A Threading Dial, And How Can They Be Mitigated During The Threading Process?

When you use a threading dial, you might have trouble lining it up correctly. This can cause messy stitches. To fix this, make sure you check the numbers on the dial carefully before you start. Also, keep your machine clean and oiled so it works smoothly. If you run into problems, slow down and take your time.

In What Ways Can Precision And Accuracy In Metal Shaping Be Enhanced Through The Use Of A Metal Lathe’S Threading Dial And Other Accessory Tools?

You can make metal shapes more precise and accurate by using a threading dial on a metal lathe. The threading dial helps you keep track of how much you’ve turned the metal. This means you can cut grooves or threads evenly. You can also use other tools like calipers to measure things closely. This way, your metal work will fit together just right!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Shaping With A Metal Lathe And Threading Dial:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that helps us shape metal into different shapes. We can use it to make things like toys or tool parts. A threading dial helps us create threads, which are like grooves or ridges in metal. This makes it easy to screw things together. Working with a metal lathe is fun and lets us make all kinds of cool projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Threading Dial On A Metal Lathe, And How Does It Assist In Creating Threads?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial on a metal lathe helps you make threads on a piece of metal. It shows you exactly when to move the cutting tool to create even grooves. When you turn the dial, it helps you keep the tool in the right spot. This makes sure the threads are the same size and look nice. Using the threading dial makes your work easier and more accurate!”}},{“@type”: “Question”,”name”: “What Are The Differences Between Power Feed And Manual Feed When Shaping Metal On A Lathe, And In What Scenarios Might Each Be Preferred?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Power feed uses a motor to move the cutting tool automatically. This helps you work faster and more evenly. Manual feed means you move the tool by hand, giving you more control for small or tricky jobs. You might choose power feed for big projects, and manual feed for detailed work or small pieces.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Metal Lathe For Threading Operations, Including The Necessary Adjustments For The Threading Dial?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for threading, first, you need to choose the right tool for cutting threads. Then, make sure the workpiece is tight and secure in the lathe. Next, you need to adjust the threading dial. You do this by finding a matching number on the dial and turning the handwheel until it reaches that number. This helps you make smooth threads. Always check your setup before starting!”}},{“@type”: “Question”,”name”: “What Are Some Common Issues Encountered While Using A Threading Dial, And How Can They Be Mitigated During The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a threading dial, you might have trouble lining it up correctly. This can cause messy stitches. To fix this, make sure you check the numbers on the dial carefully before you start. Also, keep your machine clean and oiled so it works smoothly. If you run into problems, slow down and take your time.”}},{“@type”: “Question”,”name”: “In What Ways Can Precision And Accuracy In Metal Shaping Be Enhanced Through The Use Of A Metal Lathe’S Threading Dial And Other Accessory Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make metal shapes more precise and accurate by using a threading dial on a metal lathe. The threading dial helps you keep track of how much you’ve turned the metal. This means you can cut grooves or threads evenly. You can also use other tools like calipers to measure things closely. This way, your metal work will fit together just right!”}}]}