Have you ever wondered how a small change can lead to big improvements? The lathe motor pulley swap process is one such change. By swapping out your lathe’s motor pulley, you can enhance its performance significantly.

Picture this: you’re working on a project, and your lathe isn’t spinning as fast as you want. It can be frustrating! What if a simple pulley swap could solve that problem? It might sound too easy, but many people use this method to upgrade their machines.

Did you know that the right pulley can save energy and make your lathe run smoother? It’s true! When you choose the correct size, your machine works better and lasts longer. This guide will help you understand the lathe motor pulley swap process step by step. Get ready to dive into the world of lathes and discover how this simple swap can make a huge difference!

Lathe Motor Pulley Swap Process: A Comprehensive Guide

Lathe Motor Pulley Swap Process

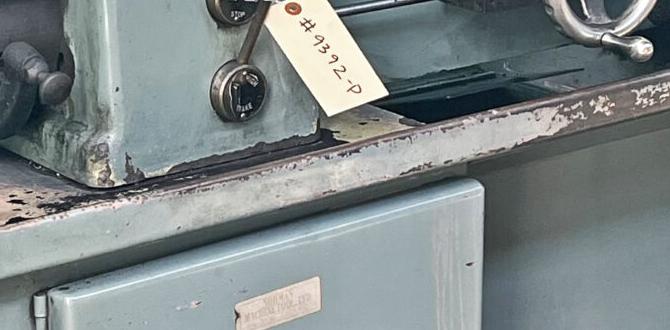

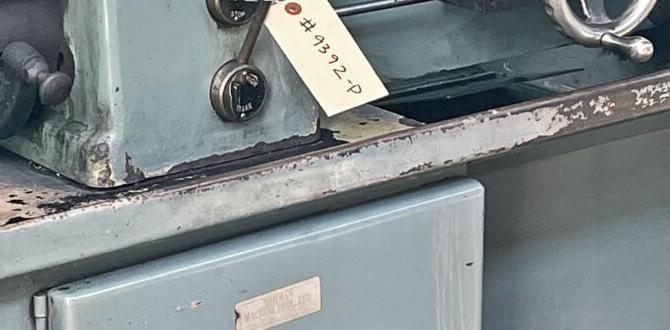

Swapping a lathe motor pulley can improve machine performance. This simple task starts with turning off the lathe and unplugging it for safety. A wrench is often needed to remove old pulleys. Many find it surprising how much smoother the machine runs after the swap. Did you know that the right pulley size can boost torque? With basic tools and a little effort, anyone can tackle this task and enjoy better lathe performance. Are you ready to give it a try?Identifying the Need for a Pulley Swap

Common signs that indicate a pulley swap is necessary. Benefits of upgrading or replacing pulleys.When your lathe starts making strange noises or feels sluggish, that’s your cue: it’s time for a pulley swap! Common signs include excessive vibration or slipping while in use. Perhaps your machine isn’t even spinning like it used to—talk about a major letdown! Upgrading pulleys can lead to smoother operation and better performance. Think of it as giving your lathe a lively cup of coffee. Everyone needs a boost now and then!

| Signs You Need a Pulley Swap | Benefits of Upgrading |

|---|---|

| Excessive noise | Improved performance |

| Slipping or slipping belts | Smoother operation |

| Vibrations | Longer lifespan |

Tools and Materials Required for the Swap

List of essential tools for the pulley swap. Recommended materials and components for optimal performance.Before starting your pulley swap adventure, gather some important tools and materials. You’ll need a wrench set, screwdrivers, and a belt removal tool. Don’t forget a good flashlight for those tight spots—because who doesn’t love a little light on their “darkest” moments?

| Tool/Material | Purpose |

|---|---|

| Wrench set | To loosen and tighten bolts |

| Screwdrivers | For any screws lurking around |

| Belt removal tool | Easily swap out the old belt |

| Safe gloves | To protect those precious hands! |

| Replacement pulley | Your shiny new component |

Using the right parts ensures your lathe runs smoothly. Be sure to grab a sturdy replacement pulley for optimal performance. A little preparation goes a long way, and you’ll feel like a pro in no time! Remember, even a small mistake can turn your project into a comedy show!

Step-by-Step Process for Swapping the Pulley

Detailed instructions for safely removing the old pulley. Guide to installing the new pulley, including alignment tips.Start by safely turning off the machine and unplugging it. Next, use a wrench to carefully loosen the screws on the old pulley. Gently pull it off the shaft. Be careful not to damage any parts. Now, take your new pulley. Fit it onto the shaft and make sure it aligns perfectly. Tighten the screws securely to hold it in place.

What are the key steps for removing an old pulley?

First, unplug the machine. Next, loosen the screws and carefully pull the old pulley off. This way, you keep everything safe.

Tips for alignment:

- Check the shaft’s center.

- Ensure the pulley is snug against the shaft.

- Tighten screws evenly to avoid wobbling.

Adjusting the Lathe Settings Post-Swap

How to recalibrate the lathe after replacing the pulley. Importance of checking belt tension and tracking.After swapping the lathe motor pulley, adjusting the settings is vital. Start by recalibrating the speed settings. If you skip this step, you might have trouble getting the right cut. Checking the belt tension is also important. A loose belt can cause slipping or poor performance.

- Ensure the belt is snug, not too tight.

- Use a wrench to tighten or loosen the motor adjustments.

- Track the belt’s alignment along the pulleys.

This simple check can save time and improve quality. Proper settings help keep your project smooth and accurate.

Why is it important to check the belt tension?

Checking the belt tension ensures proper functioning of the lathe. A properly tightened belt helps avoid slipping and improves cutting precision.

Common Mistakes to Avoid During the Swap

List of pitfalls to watch for during the process. Tips for troubleshooting issues that may arise.Swapping a lathe motor pulley can be tricky. Here are some common mistakes to watch for:

- Forgetting to unplug the machine.

- Neglecting to clean the area first.

- Not measuring the old pulley size.

- Skipping the tightening process.

If you run into problems, try these tips:

- Double-check your measurements.

- Use the right tools for tight screws.

- Ask a friend for help if stuck.

With these tips, you can make the swap easier and safer!

What should I do if I face problems during the swap?

If problems arise during the lathe motor pulley swap, stay calm. Check your work and tools. Sometimes, a simple adjustment fixes the issue!

Maintaining Your New Pulley for Longevity

Best practices for maintaining pulleys in lathe machinery. How regular maintenance can prevent future issues.To keep your new lathe pulley in great shape, follow some simple rules. Regularly inspect the pulley for wear and tear. A worn-out pulley can ruin your day faster than forgetting your lunch! Clean the pulley often to avoid buildup that might affect its function. Schedule maintenance checks to catch any small problems before they become big headaches.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Cleaning | Monthly |

| Full Check-up | Every 6 months |

Regular care not only extends the life of your pulley but also saves you money in the long run. Think of maintenance like brushing your teeth; skip it, and you’ll regret it later!

Frequently Asked Questions About Lathe Motor Pulley Swaps

Common queries regarding the swap process. Responses to queries about compatibility, safety, and performance.Many people wonder about the lathe motor pulley swap process. It’s like switching out your old shoes for a shiny new pair! Common questions pop up, like whether the new pulleys fit. The answer is yes, if they match your motor’s specifications. Safety is key, so always ensure everything is properly tightened. Performance can improve too, as new pulleys can make your lathe run smoother. Isn’t it fun to make your tools better? Just remember to wear safety goggles!

| Question | Answer |

|---|---|

| Are all pulleys interchangeable? | No, check compatibility first! |

| Is it safe to swap pulleys? | Yes, but be careful and follow guidelines. |

| Will a new pulley improve performance? | Absolutely! It can enhance efficiency. |

Conclusion

In conclusion, swapping a lathe motor pulley can improve your machine’s performance. First, gather the right tools and parts. Remove the old pulley carefully, then install the new one. Make sure everything is secure before testing. Practice these steps, and you’ll gain confidence. For more tips, check out guides or videos online to deepen your understanding. Happy machining!FAQs

What Are The Key Steps Involved In Removing The Old Pulley From The Lathe Motor Before Installing A New One?To remove the old pulley from the lathe motor, first, make sure the machine is off and unplugged. Next, use a wrench to loosen the screws holding the pulley in place. Carefully lift the old pulley off the motor shaft. Now, clean the area to get rid of any dust. You can now install the new pulley by placing it on the motor shaft and tightening the screws.

How Do You Determine The Correct Size And Type Of Pulley Needed For A Lathe Motor Swap?To find the right pulley for your lathe motor, first measure the size of the old pulley. Then, check the motor’s power and speed. Next, match the new pulley to the motor’s size and speed needs. You can also look at a chart or ask someone for help. This way, you’ll get a pulley that works well with your lathe!

What Safety Precautions Should Be Taken When Performing A Lathe Motor Pulley Swap?When you change a lathe motor pulley, always wear safety goggles to protect your eyes. Turn off the machine and unplug it before you start. Keep your fingers away from moving parts. Make sure your work area is clean and free of clutter. Finally, ask for help from an adult if you’re unsure about anything.

How Can You Ensure Proper Alignment Of The New Pulley With The Lathe Motor And The Drive Belt?To make sure the new pulley lines up correctly with the lathe motor and the drive belt, start by checking that the motor is straight. You can loosen the screws on the motor to adjust its position. Next, look at the belt and make sure it sits nicely in the pulley grooves. Turn the pulley to see if it runs smoothly without wobbling. Finally, tighten everything back up to keep it in place.

What Tools Are Necessary For A Successful Lathe Motor Pulley Replacement, And How Do You Use Them Effectively?To replace a lathe motor pulley, you need a few tools. First, you’ll need a wrench to unscrew the bolts. Use a screwdriver to help remove any small parts. A new pulley is also important, of course! Ensure you follow the steps carefully to put everything back together the right way.