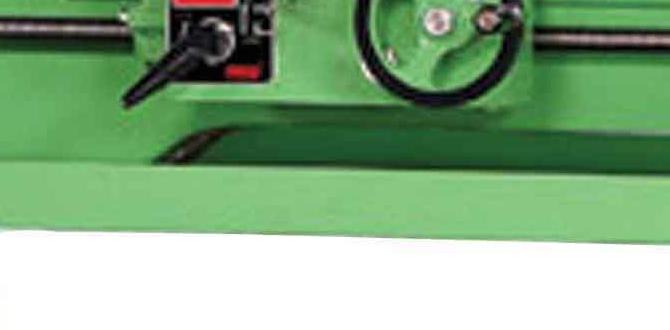

Have you ever had a machine break down right when you needed it the most? A lathe can be a powerful tool, but its motor might fail at the worst times. When this happens, you may wonder how to handle a lathe motor replacement.

Replacing the motor can seem tricky at first. It’s like trying to solve a puzzle without all the pieces. But don’t worry! With the right steps, you can get your metal lathe back up and running smoothly.

Many people don’t realize that the compound rest plays a big role in the lathe’s performance. It helps hold your workpiece steady while you shape it. A good replacement motor can make all the difference in the world. Imagine cutting through metal with ease, just like a knife through butter!

In this article, we’ll guide you through the journey of lathe motor replacement and how it connects to the compound rest. You’ll learn how to keep your metal lathe in top shape. So, are you ready to dive in?

Lathe Motor Replacement For Metal Lathe Compound Rest Guide

Lathe Motor Replacement for Metal Lathe Compound Rest

Replacing a lathe motor can seem daunting, but it’s a straightforward task. When your metal lathe compound rest starts to lag or vibrate, it might be time for a motor replacement. Choosing the right motor ensures smooth operation and improved accuracy. Did you know that a high-quality motor can extend your lathe’s lifespan? A little knowledge on specifications can make all the difference in your projects. With the right tools and guidance, you’ll have your lathe back in action in no time!

Understanding Lathe Motors

Types of lathe motors used in metal lathes. Importance of a reliable motor in lathe performance.

Lathe motors come in different types. The two main types are AC motors and DC motors. AC motors are popular because they are durable and provide steady power. DC motors, however, allow for speed control, making them a favorite for detailed work. A reliable motor is vital for a lathe’s performance. Think of it as the heartbeat of your machine—if it skips, your project could go out of rhythm! Without a dependable motor, you risk bad cuts and time wasted. Keeping your lathe running smoothly is key to a job well done!

| Motor Type | Advantages | Disadvantages |

|---|---|---|

| AC Motor | Durable, steady power | Difficult speed control |

| DC Motor | Speed control, precision | Less durable |

Signs It’s Time to Replace Your Lathe Motor

Common symptoms of motor failure. How to diagnose motor issues effectively.

Pay attention to your lathe motor. If it shows signs of trouble, it may need replacement. Common symptoms include:

- Strange noises like grinding or buzzing.

- Motor overheating during use.

- Unusual vibrations while running.

- Loss of power or slow operation.

To check for problems, listen and observe. If you notice any of these signs, it’s time for an inspection. A quick check can save you time and help you make the right choice.

How do I know if my lathe motor is failing?

Look out for odd sounds or heating issues. These can signal trouble. If your machine works slower than usual, motor failure might be around the corner. Act quickly to avoid more problems.

Regular checks keep your lathe running smoothly. Monitoring performance helps catch issues early.

Selecting the Right Replacement Motor

Key specifications to consider (horsepower, voltage, RPM). Comparison of different motor brands and models.

Choosing a new motor can feel like hunting for buried treasure. First, check horsepower: it needs to match your lathe’s needs. Next is voltage. Don’t plug in a 110V motor into a 220V outlet—yikes! Lastly, consider RPM or how fast it spins; higher isn’t always better. Take a look at different brands, too. A solid motor can make all the difference.

| Brand | Horsepower | Voltage | RPM |

|---|---|---|---|

| Brand A | 1 HP | 110V | 1725 |

| Brand B | 1.5 HP | 220V | 3450 |

| Brand C | 2 HP | 110V | 1725 |

Preparing for Motor Replacement

Tools and materials needed for the replacement process. Safety precautions to follow before starting.

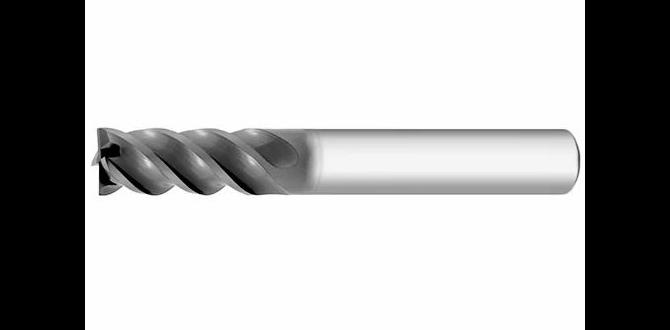

Before you start swapping out that motor, grab your trusty toolbox! You’ll need some essential tools like pliers, wrenches, and screwdrivers. Don’t forget about materials like a new motor and screws. Safety first, folks! Wear goggles and gloves to protect your eyes and hands. Make sure the lathe is unplugged, or you might just end up with a surprise makeover—zaps are not fashionable!

| Tools and Materials | Safety Precautions |

|---|---|

| Pliars | Wear safety goggles |

| Screwdrivers | Use gloves |

| Wrenches | Unplug before starting |

| Replacement motor | Keep a clean workspace |

Following these steps will make your motor replacement smooth sailing—or should we say, smooth lathe-ing!

Step-by-Step Motor Replacement Process

Detailed instructions for removing the old motor. Installation tips for the new motor.

Replacing a lathe motor doesn’t have to be hard. Follow these steps to make it simple:

- **Turn off the power** to the lathe for safety.

- **Remove the old motor** by taking off screws or bolts holding it in place.

- **Unplug the motor** wires carefully, noting where each wire connects.

- **Install the new motor** by connecting wires in the same order.

- **Secure the motor** with screws or bolts.

- **Turn on the power** and test it!

Always check for loose connections. Keeping things tight helps your lathe run smoothly. With a few simple steps, your lathe will be up and ready for your next project!

What are the safety tips for lathe motor replacement?

Always unplug your machine before starting any work. Wear safety goggles to protect your eyes. Use gloves to avoid cuts. Keep your workspace clean and organized.

Tweaking Your Compound Rest for Optimal Performance

Adjustment techniques for improved precision. Maintenance tips for enhancing the lifespan of the compound rest.

Tweak your metal lathe’s compound rest for better results! Start by adjusting the gibs. This will help with precision and make sure your cuts are smooth. Keep the sliding surfaces clean to avoid slippage—think of it as giving your sloth a spa day! Also, regular lubrication is key. A well-oiled machine lasts longer. Check the bolts too; a simple twist can prevent future headaches. Treat your tools well, and they’ll treat you back!

| Tip | Benefit |

|---|---|

| Adjust gibs | Improves precision |

| Clean surfaces regularly | Prevents slippage |

| Lubricate moving parts | Enhances lifespan |

| Check bolts | Reduces future issues |

Common Mistakes to Avoid When Replacing Lathe Motors

Errors in selecting the wrong motor type. Neglecting proper alignment during installation.

Replacing a lathe motor can be tricky. First, many folks pick the wrong motor type. It’s like choosing a cat to fetch—it just won’t work! Always check the specs before buying. Next, don’t ignore alignment during installation. If things are off, you might end up with a fancy paperweight instead of a smooth-running lathe. Remember, proper installation is key to avoiding headaches down the road!

| Common Mistakes | Effects |

|---|---|

| Selecting the wrong motor type | Can cause performance issues |

| Neglecting proper alignment | Could lead to uneven cuts |

Benefits of Upgrading Your Lathe Motor

Enhanced performance and efficiency. Impact on overall machining capabilities.

Upgrading your lathe motor can be a game changer. It boosts performance and makes your machine run smoother. With stronger motors, you can cut through materials faster and with better accuracy. Your overall machining will improve, allowing for sharper details and cleaner edges. Plus, who doesn’t love the idea of spinning metal like a pro? Think of it as giving your old lathe a much-needed energy drink!

| Benefit | Impact |

|---|---|

| Enhanced Performance | Quicker, more precise cuts |

| Improved Efficiency | Less downtime, more productivity |

Frequently Asked Questions about Lathe Motor Replacement

Common concerns and troubleshooting advice. Merits of professional vs. DIY motor replacement.

Many people worry about replacing their lathe motor. It’s important to know common issues, like unusual noises or power troubles. Troubleshooting can help fix these problems before thinking of replacement. You can choose to hire a professional or try to replace it yourself. Each option has benefits:

- Professional: They have experience and tools.

- DIY: Saves money and offers learning.

Weigh the pros and cons to figure out what’s best for you!

What are common concerns when replacing a lathe motor?

Common concerns include noise issues and power failures. Monitoring these can save time and trouble.

Is it better to hire a pro or do it yourself?

It depends on your skill level. Hiring a pro ensures quality, while DIY can be cost-effective and educational.

Conclusion

In summary, replacing your lathe motor can improve performance and precision. The compound rest is vital for smooth cuts and adjustments. Make sure you know the specifications before buying parts. We encourage you to explore guides or videos on lathe maintenance. With the right tools and knowledge, you can enhance your metalworking skills and enjoy better results!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Motor Replacement And Metal Lathe Compound Rests:

Sure! Replacing a lathe motor means you take out the old motor and put in a new one. This helps the lathe work better. A metal lathe compound rest is a part that holds tools in place while cutting metal. You need it to be strong and steady. If it’s broken, you should fix or replace it for safety and good work!

Sure! Please go ahead and ask your question, and I’ll do my best to answer it simply and clearly.

What Are The Steps For Safely Replacing The Motor On A Metal Lathe?

First, turn off the power to the lathe and unplug it. Then, remove any guards or covers to get to the motor. Next, carefully disconnect the old motor by unscrewing it and unplugging the wires. After that, put the new motor in place and connect the wires. Finally, replace the covers, plug the lathe back in, and test it to make sure it works.

How Do I Determine The Appropriate Motor Size And Specifications For My Metal Lathe Model?

To find the right motor for your metal lathe, start by checking the lathe’s manual. The manual shows the power needed. You also need to consider how heavy the metal is that you’ll use. A motor with higher horsepower (HP) works better for tougher jobs. Lastly, make sure the motor fits well in your lathe.

What Tools And Materials Are Required To Perform A Lathe Motor Replacement Effectively?

To replace a lathe motor, you need a few tools and materials. First, grab a wrench to loosen the bolts. You’ll also need a screwdriver to take off any screws. Make sure to have a replacement motor ready. Don’t forget safety goggles to protect your eyes while you work.

How Can I Troubleshoot A Malfunctioning Compound Rest On My Metal Lathe Before Considering A Motor Replacement?

To troubleshoot your compound rest, first, check for loose screws or parts. Tighten anything that feels wobbly or moves too freely. Next, look for dirt or chips stuck in the moving parts; clean them out carefully. If it still doesn’t work, make sure the gears are not broken and are lubricated. Trying these steps can help fix the problem before thinking about a new motor.

What Maintenance Practices Can Extend The Lifespan Of Both The Lathe Motor And The Compound Rest In A Metal Lathe?

To keep your lathe motor and compound rest working well, you should always keep them clean. Regularly wipe off any dust and chips. Check the oil levels and add oil where needed to keep parts moving smoothly. Tighten any loose screws or bolts to avoid damage. Finally, don’t forget to unplug the lathe when you’re not using it. This helps keep it safe and long-lasting!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Motor Replacement And Metal Lathe Compound Rests:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Replacing a lathe motor means you take out the old motor and put in a new one. This helps the lathe work better. A metal lathe compound rest is a part that holds tools in place while cutting metal. You need it to be strong and steady. If it’s broken, you should fix or replace it for safety and good work!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll do my best to answer it simply and clearly.”}},{“@type”: “Question”,”name”: “What Are The Steps For Safely Replacing The Motor On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, turn off the power to the lathe and unplug it. Then, remove any guards or covers to get to the motor. Next, carefully disconnect the old motor by unscrewing it and unplugging the wires. After that, put the new motor in place and connect the wires. Finally, replace the covers, plug the lathe back in, and test it to make sure it works.”}},{“@type”: “Question”,”name”: “How Do I Determine The Appropriate Motor Size And Specifications For My Metal Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right motor for your metal lathe, start by checking the lathe’s manual. The manual shows the power needed. You also need to consider how heavy the metal is that you’ll use. A motor with higher horsepower (HP) works better for tougher jobs. Lastly, make sure the motor fits well in your lathe.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Required To Perform A Lathe Motor Replacement Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To replace a lathe motor, you need a few tools and materials. First, grab a wrench to loosen the bolts. You’ll also need a screwdriver to take off any screws. Make sure to have a replacement motor ready. Don’t forget safety goggles to protect your eyes while you work.”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot A Malfunctioning Compound Rest On My Metal Lathe Before Considering A Motor Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot your compound rest, first, check for loose screws or parts. Tighten anything that feels wobbly or moves too freely. Next, look for dirt or chips stuck in the moving parts; clean them out carefully. If it still doesn’t work, make sure the gears are not broken and are lubricated. Trying these steps can help fix the problem before thinking about a new motor.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Extend The Lifespan Of Both The Lathe Motor And The Compound Rest In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe motor and compound rest working well, you should always keep them clean. Regularly wipe off any dust and chips. Check the oil levels and add oil where needed to keep parts moving smoothly. Tighten any loose screws or bolts to avoid damage. Finally, don’t forget to unplug the lathe when you’re not using it. This helps keep it safe and long-lasting!”}}]}