Have you ever wondered how to keep your metal lathe running perfectly? A lathe motor replacement might be just what you need. When a lathe motor fails, it can cause big problems. The lathe won’t work well, and you may struggle to complete your projects.

But it’s not just about replacing the motor. It’s also crucial to focus on tailstock alignment. When the tailstock is out of line, it can lead to inaccuracies in your work. Imagine trying to create a beautiful design, only to find it’s crooked! That can be frustrating for any maker.

So, how can you ensure everything runs smoothly? Understanding lathe motor replacement and how it affects tailstock alignment is vital. In this article, we will explore tips and tricks to help you get your lathe back in shape.

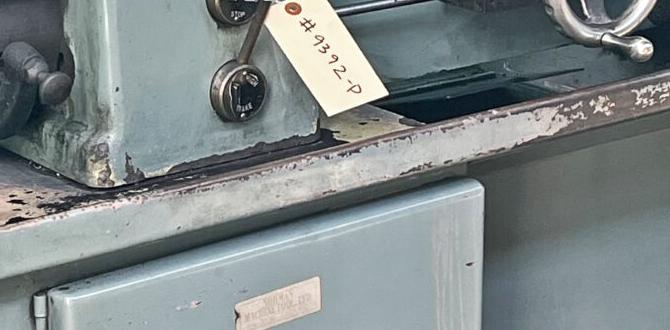

Essential Lathe Motor Replacement For Metal Lathe Tailstock Alignment

Lathe Motor Replacement and Tailstock Alignment

Replacing a lathe motor can improve your machine’s performance and extend its life. Proper alignment of the tailstock is vital for accurate work. Misalignment can cause issues like uneven cuts. Have you ever noticed a wobbling tool? That’s often due to poor tailstock setup. To check alignment, make simple adjustments. This keeps your projects precise and professional. Knowing these tips can help both beginners and experienced users achieve better results when using a metal lathe.Understanding Lathe Motors

Types of lathe motors commonly used in metalworking. Importance of selecting the right motor for your lathe.Lathe motors play a key role in metalworking. They help turn materials for precise shaping. There are a few common types of motors found in lathes:

- AC Motors – These are reliable and great for steady work.

- DC Motors – Perfect for tasks needing speed control.

- Brushless Motors – These motors are efficient and last long.

Selecting the right motor is crucial. It affects how well your lathe works and how long it lasts. Using a suitable motor helps achieve accurate results and boosts performance.

What should I consider when choosing a lathe motor?

Think about power requirements, speed settings, and motor type. Each factor can change how well your lathe performs.Signs Your Lathe Motor Needs Replacement

Common warning signs indicating motor failure. Testing methods to diagnose motor issues.Is your lathe motor acting a bit like a grumpy cat? Watch for signs of trouble! If you hear strange noises, feel excessive vibrations, or see smoke, it’s time to investigate. You can test the motor by checking the voltage and watching for weird behavior, like stalling. Below is a handy table to help you spot common warning signs:

| Warning Sign | What to Look For |

|---|---|

| Noisy Operation | Weird grinding or squeaking sounds |

| Excessive Vibration | Feeling shaky? Check the stability! |

| Smoke Emission | Yikes! Time to turn off the machine |

Keeping an eye on these signs can save your lathe from a melt-down. Remember, a well-aligned motor is happier and more productive!

Steps for Replacing a Lathe Motor

Tools and materials required for replacement. Stepbystep guide for removing and installing a new motor.To replace a lathe motor, you need some tools and materials. Gather items like a screwdriver, wrenches, a new motor, and safety gear. Follow these steps:

- Turn off the power.

- Remove the old motor by unscrewing it.

- Disconnect wires carefully.

- Install the new motor by connecting wires and securing it in place.

- Double-check connections and test it.

With these steps, you’ll have your lathe running again!

What tools do I need for lathe motor replacement?

For lathe motor replacement, you need basic tools like a screwdriver, wrenches, and safety gear. Having a new motor ready is also essential.

How to Align the Tailstock of Your Metal Lathe

Tools needed for tailstock alignment. Detailed instructions for aligning the tailstock correctly.To align your metal lathe’s tailstock properly, you’ll need a few simple tools. Grab a dial indicator, a straightedge, and an Allen wrench. Start by checking if the tailstock is square with the bed. If it’s not, loosen the bolts and adjust it until it is. Now, don’t fret, because this is easier than herding cats! Keep adjusting until your dial indicator is happy and shows no movement. Remember, even a tiny misalignment can cause big headaches later, like trying to bake a cake without measuring! Here’s a quick overview of the tools:

| Tool | Purpose |

|---|---|

| Dial Indicator | To measure any misalignment. |

| Straightedge | To check if the tailstock is straight. |

| Allen Wrench | To adjust the tailstock bolts. |

With these tools and some patience, your tailstock will be aligned in no time!

Common Mistakes During Motor Replacement and Tailstock Alignment

Mistakes to avoid when replacing a lathe motor. Common tailstock alignment errors and their consequences.Replacing a lathe motor and aligning the tailstock can be tricky. Many make mistakes that can affect performance. Here are common errors:

- Not disconnecting power before starting.

- Forgetting to check alignment after the motor swap.

- Ignoring worn parts during replacement.

- Failing to tighten all screws properly.

Errors in tailstock alignment can lead to uneven cuts. This not only wastes material but also creates unsafe conditions. Always double-check your setup!

What are the common mistakes during motor replacement?

Common mistakes include not checking the old motor’s wiring and avoiding further tool maintenance. This can cause immediate problems or future damage.

Common tailstock alignment errors:

- Misalignment leading to taper cuts.

- Improper height adjustments causing vibration.

Maintaining Your Lathe for Optimal Performance

Regular maintenance routines to prolong motor life. Tips for ensuring consistent tailstock alignment over time.Taking care of your lathe keeps it running well. Regular maintenance helps the motor last longer. Check the motor for dust and clean it. Oil the moving parts to keep everything smooth. It’s also important to align the tailstock properly. This helps you make precise cuts.

- Check alignment every time you use the lathe.

- Use a dial indicator to measure tailstock alignment.

- Make adjustments slowly for perfect alignment.

- Mark your settings for easy future adjustments.

Keeping your lathe in great shape makes your work easier. Everyone loves tools that work well, right?

How often should I maintain my lathe?

It’s best to maintain your lathe at least once a month. Regular checks prevent bigger problems later.

Recommendations for Upgrading Your Lathe Motor

Factors to consider when upgrading your motor. Product recommendations for highperformance lathe motors.Upgrading a lathe motor can boost your machine’s performance. It’s important to think about a few factors before you choose a new motor. Power is key. Ensure that the motor can handle the tasks you want. Also, consider size and efficiency to fit your workspace. Here are some popular high-performance options:

- 1 HP Grizzly G0630

- 2 HP Jet JWL-1442

- 3 HP Shop Fox W1819

Each of these options offers great reliability and power for different projects.

What should I look for in a lathe motor?

A good lathe motor should match your project needs in terms of power, efficiency, and size.Conclusion

In summary, replacing a lathe motor can enhance your metal lathe’s performance. Tailstock alignment is important for accurate cuts. Always check and adjust your tailstock for best results. We encourage you to explore tutorials and guides on these topics. With practice, you’ll improve your skills and create better projects. Keep learning, and enjoy your lathe work!FAQs

Sure! Here Are Five Questions Related To Lathe Motor Replacement And Tailstock Alignment:Sure! When replacing a lathe motor, first unplug the machine. Then, take out the old motor. Next, put in the new motor and connect the wires. Make sure it’s tight and safe. This helps your lathe work better! For tailstock alignment, check if it lines up with your tool. If it’s not straight, you might need to adjust it.

Of course! Please provide the question you would like me to answer.

What Are The Critical Steps For Safely Replacing The Motor On A Metal Lathe?To safely replace the motor on a metal lathe, first, you need to turn off the power and unplug it. Next, take off any covers to reach the motor. Then, carefully disconnect the old motor and remove it. After that, install the new motor by connecting it just like the old one. Finally, put everything back together, plug in the lathe, and test it to make sure it works!

How Can Improper Tailstock Alignment Affect The Accuracy Of Machining Operations On A Lathe?Improper tailstock alignment on a lathe can lead to mistakes while cutting. If the tailstock is not straight, the tool doesn’t cut evenly. This means your final product can be wobbly or not the right shape. Always check the alignment to make sure your work is accurate and looks good.

What Tools Are Necessary For Checking And Adjusting Tailstock Alignment After Replacing A Lathe Motor?To check and adjust the tailstock alignment after replacing the lathe motor, you need a few tools. First, get a ruler or caliper to measure distances. A straightedge helps you see if things are straight. You can also use a drill bit to check the holes align properly. Finally, have a wrench ready to tighten any loose parts.

What Common Symptoms Indicate That The Tailstock Of A Lathe May Be Misaligned?If the tailstock of a lathe is misaligned, you might notice some problems. Your workpiece can wobble or not spin straight. You may see uneven cuts or feel rough spots when you touch it. Also, it can be hard to make precise measurements. These signs tell you the tailstock needs adjustment.

How Can You Determine The Optimal Tension And Alignment Settings For The Tailstock After Completing A Motor Replacement?To find the best tension and alignment for the tailstock, you can follow a few steps. First, check the owner’s manual for your machine; it often has helpful numbers. Then, you can adjust the tailstock’s tension until it holds the tool snugly but not too tight. Next, make sure the tailstock is lined up straight with the rest of the machine. Finally, test it by running the machine and watching if everything stays in the right place.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Motor Replacement And Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When replacing a lathe motor, first unplug the machine. Then, take out the old motor. Next, put in the new motor and connect the wires. Make sure it’s tight and safe. This helps your lathe work better! For tailstock alignment, check if it lines up with your tool. If it’s not straight, you might need to adjust it.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Critical Steps For Safely Replacing The Motor On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely replace the motor on a metal lathe, first, you need to turn off the power and unplug it. Next, take off any covers to reach the motor. Then, carefully disconnect the old motor and remove it. After that, install the new motor by connecting it just like the old one. Finally, put everything back together, plug in the lathe, and test it to make sure it works!”}},{“@type”: “Question”,”name”: “How Can Improper Tailstock Alignment Affect The Accuracy Of Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper tailstock alignment on a lathe can lead to mistakes while cutting. If the tailstock is not straight, the tool doesn’t cut evenly. This means your final product can be wobbly or not the right shape. Always check the alignment to make sure your work is accurate and looks good.”}},{“@type”: “Question”,”name”: “What Tools Are Necessary For Checking And Adjusting Tailstock Alignment After Replacing A Lathe Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the tailstock alignment after replacing the lathe motor, you need a few tools. First, get a ruler or caliper to measure distances. A straightedge helps you see if things are straight. You can also use a drill bit to check the holes align properly. Finally, have a wrench ready to tighten any loose parts.”}},{“@type”: “Question”,”name”: “What Common Symptoms Indicate That The Tailstock Of A Lathe May Be Misaligned?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock of a lathe is misaligned, you might notice some problems. Your workpiece can wobble or not spin straight. You may see uneven cuts or feel rough spots when you touch it. Also, it can be hard to make precise measurements. These signs tell you the tailstock needs adjustment.”}},{“@type”: “Question”,”name”: “How Can You Determine The Optimal Tension And Alignment Settings For The Tailstock After Completing A Motor Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the best tension and alignment for the tailstock, you can follow a few steps. First, check the owner’s manual for your machine; it often has helpful numbers. Then, you can adjust the tailstock’s tension until it holds the tool snugly but not too tight. Next, make sure the tailstock is lined up straight with the rest of the machine. Finally, test it by running the machine and watching if everything stays in the right place.”}}]}