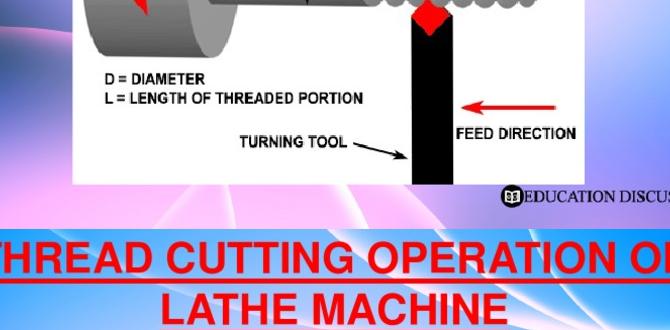

Have you ever wondered how a metal lathe works? These machines shape metal pieces with amazing precision. But did you know that a lathe also needs regular maintenance to perform well? One key maintenance task is an oil change. Just like a car, your lathe needs clean oil to run smoothly.

In this article, we will dive into the importance of lathe oil change for your metal lathe. Many people think it’s a complicated process. However, it’s easier than you might think! Plus, if you own or are considering a CNC retrofit for your lathe, proper oil maintenance becomes even more crucial.

Imagine your lathe sitting idle because of poor maintenance. You could miss out on crafting incredible projects. So, let’s explore how to take care of your lathe, keep it running better, and avoid those frustrating breakdowns.

Lathe Oil Change: Essential Tips For Metal Lathe Cnc Retrofit

Lathe Oil Change for CNC Retrofit: Key Insights

Regular lathe oil changes are essential for maintaining your metal lathe. Fresh oil keeps the machine running smoothly and extends its life. Did you know that old oil can cause rust and wear? By retrofitting your CNC lathe, you can improve precision. This means better cuts and less waste! Always remember to check your oil levels. Quick maintenance can make a big difference in your projects. Keep your lathe happy, and it will work wonders for you!Understanding Lathe Oil and Its Importance

Definition of lathe oil and its various types. Importance of oil for metal lathe performance and longevity.Lathe oil is a special lubricant that keeps your metal lathe running smoothly. There are different types of lathe oils, each designed for specific tasks. This oil is like a superhero for your machine; it helps reduce friction and wear, making your lathe last longer. Without it, your lathe could suffer, like a car without gas—stuck and useless! Just remember, a well-oiled machine is a happy machine!

| Type of Lathe Oil | Uses |

|---|---|

| Mineral Oil | General lubrication |

| Synthetic Oil | High-performance tasks |

| Way Oil | For slideways |

Signs It’s Time for an Oil Change

Indicators of degraded oil quality. General timeline and maintenance schedules.Have you noticed your lathe sounding like a tired old man? It might be time for an oil change! Signs of degraded oil include a dark color or strange smell. If your lathe starts to sound rough, it’s a clear sign. Generally, you should check the oil every 100 hours of use or once a month. Remember, a happy lathe is a well-oiled lathe!

| Oil Change Signs | Maintenance Schedule |

|---|---|

| Dark color | 50-100 hours of operation |

| Strange smell | Monthly checks |

| Unusual sounds | Every 6 months |

Choosing the Right Oil for Your CNC Retrofit

Factors to consider when selecting lathe oil. Comparison of conventional vs. synthetic oils.Choosing the right oil is key for your CNC retrofit. Consider these factors:

- Viscosity: The oil thickness affects how easily it flows.

- Temperature: Check if the oil works well at high or low temperatures.

- Metal Type: Use oil that suits the metal you are working with.

There are two main types of oil: conventional and synthetic. Conventional oil works well but breaks down quicker. Synthetic oil lasts longer and performs better in extreme conditions. Many users prefer synthetic oil for its ability to handle rough jobs.

What oil should I use for my CNC system?

For CNC systems, synthetic oil is often the best choice due to its high performance and durability.Step-by-Step Guide to Changing Lathe Oil

Required tools and materials for the oil change. Detailed procedure for draining and replacing oil.Changing lathe oil is easy with the right tools and steps. You will need a few items. Gather the following:

- Lathe oil

- Oil collection pan

- Wrenches

- Funnels

- Clean rags

Start by draining the old oil. Locate the drain plug under the lathe. Use a wrench to loosen it. Let the oil flow into the collection pan. Once empty, replace the plug. Next, add the new oil. Use a funnel to avoid spills. Check the oil level with the dipstick. Ensure it is full but not overflowing. Your lathe is now ready!

Why is changing lathe oil important?

Changing lathe oil keeps your machine running smoothly. Old oil can cause wear and tear. It’s best to change the oil regularly to avoid damage.

Best Practices for Lathe Oil Maintenance

Recommended frequency of oil changes. Tips for monitoring oil condition regularly.To keep your lathe running well, remember to change the oil regularly. It’s best to change the oil every 50 hours of use or at least once every month. Even if you don’t use it much, check the oil often.

How can you check the oil condition?

- Look at the color.

- Check for dirt or debris.

- Feel the oil’s viscosity; it should be smooth.

- Smell the oil; if it smells burnt, it’s time for a change.

By staying on top of these tips, your metal lathe will stay in great shape!

How often should I change lathe oil?

You should aim to change lathe oil every 50 hours or at least once a month.

Common Mistakes to Avoid During Oil Change

Missteps that can damage your lathe. How to prevent contamination during the oil change.Changing your lathe oil can feel like a circus act if you’re not careful! One common mishap is using the wrong oil. This can harm your lathe instead of helping it. It’s like putting soda in your car—yikes! Also, remember to keep everything clean. Dirt can sneak into your oil, leading to contamination. Use fresh rags and clean containers to avoid this risk.

| Mistake | Solution |

|---|---|

| Wrong oil type | Always check the manufacturer’s recommendation. |

| Not cleaning before changing | Wipe down surfaces and tools to prevent dirt. |

Following these tips makes your oil change smoother than a buttered slide! Keep your lathe happy, and it’ll treat you well.

Impact of Proper Oil Change on CNC Performance

Benefits of regular maintenance on lathe efficiency. Reallife case studies showcasing performance improvements.Changing oil regularly offers many perks for your trusty metal lathe. It helps keep everything running smoothly, kind of like how a good haircut makes you feel fresh. Regular maintenance boosts the efficiency of your lathe, making it whirl without a hitch. In fact, a study showed that machines with regular oil changes saw a 20% jump in performance! Don’t let your lathe run on old oil; think of it as giving your best buddy a nice bath!

| Maintenance Task | Efficiency Boost |

|---|---|

| Oil Change | Up to 20% |

| Filter Replacement | 15% |

| Calibration Check | 25% |

So, keep it oily and happy! Your lathe will thank you with smoother cuts and fewer surprises.

FAQs About Lathe Oil Change

Common queries related to lathe oil and maintenance. Expert answers to ensure clarity and understanding.Many people have questions about lathe oil change and how to take care of their machines. Here are some answers to common queries:

How often should I change the lathe oil?

It’s best to change lathe oil every 50 hours of use or every month. This keeps your machine running smoothly and prevents damage.

What type of oil should I use?

Always check the manual. Most lathes use specially formulated oil for the best performance.

Do I need to clean before changing the oil?

Yes! Always clean the area and the oil reservoir before adding new oil.

Can I use used oil again?

No, reusing oil can harm your lathe. Always use fresh oil to ensure safety.

Remember, properly changing lathe oil helps your metal lathe work better and last longer!

Conclusion

In conclusion, changing lathe oil is essential for keeping your metal lathe in great shape. Regular oil changes improve performance and extend your machine’s life. If you’re considering a CNC retrofit, it can enhance precision and efficiency. We recommend reading more about lathe maintenance and CNC upgrades to help you make informed choices. Stay curious and keep learning!FAQs

What Type Of Oil Is Recommended For Changing The Lathe Oil In A Cnc Retrofit Metal Lathe?For a CNC retrofit metal lathe, you should use a light machine oil. This type of oil helps keep the machine running smoothly. You can also use oil that is specially made for lathes. Just make sure it is clean and not too thick. Always check the machine’s manual for specific recommendations!

How Often Should Lathe Oil Be Changed To Ensure Optimal Performance And Longevity Of A Cnc Retrofitted Metal Lathe?You should change the lathe oil every 3 to 6 months. If you use the lathe a lot, change it more often. Clean oil keeps your machine running smoothly. Always check the oil level and look for any dirt. This helps your lathe last longer and work better!

What Steps Should Be Followed To Properly Change The Lathe Oil In A Cnc Retrofitted Metal Lathe?To change the lathe oil, first, turn off the machine and unplug it for safety. Next, find the oil reservoir and open the drain plug. Let the old oil flow out completely into a container. Then, replace the drain plug and fill the reservoir with new oil. Finally, clean up any spills and plug the machine back in.

Are There Specific Considerations To Keep In Mind When Retrofitting A Cnc Metal Lathe For Oil Lubrication?When you retrofit a CNC metal lathe for oil lubrication, you need to think about a few things. First, make sure the oil system fits the lathe correctly. You also need to choose the right type of oil to keep the machine running smoothly. It’s important to place oil tubes where they can reach all parts easily. Finally, check for any leaks to keep everything clean and safe.

How Can You Identify Signs That The Lathe Oil Needs To Be Changed In A Cnc Retrofitted Metal Lathe?You can tell when lathe oil needs changing by looking for a few signs. First, check if the oil is dark or dirty. If it smells bad, that’s another sign. You should also see if it’s thicker than normal. Lastly, if the machine starts making strange noises, it might need new oil.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Changing The Lathe Oil In A Cnc Retrofit Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a CNC retrofit metal lathe, you should use a light machine oil. This type of oil helps keep the machine running smoothly. You can also use oil that is specially made for lathes. Just make sure it is clean and not too thick. Always check the machine’s manual for specific recommendations!”}},{“@type”: “Question”,”name”: “How Often Should Lathe Oil Be Changed To Ensure Optimal Performance And Longevity Of A Cnc Retrofitted Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the lathe oil every 3 to 6 months. If you use the lathe a lot, change it more often. Clean oil keeps your machine running smoothly. Always check the oil level and look for any dirt. This helps your lathe last longer and work better!”}},{“@type”: “Question”,”name”: “What Steps Should Be Followed To Properly Change The Lathe Oil In A Cnc Retrofitted Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the lathe oil, first, turn off the machine and unplug it for safety. Next, find the oil reservoir and open the drain plug. Let the old oil flow out completely into a container. Then, replace the drain plug and fill the reservoir with new oil. Finally, clean up any spills and plug the machine back in.”}},{“@type”: “Question”,”name”: “Are There Specific Considerations To Keep In Mind When Retrofitting A Cnc Metal Lathe For Oil Lubrication? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you retrofit a CNC metal lathe for oil lubrication, you need to think about a few things. First, make sure the oil system fits the lathe correctly. You also need to choose the right type of oil to keep the machine running smoothly. It’s important to place oil tubes where they can reach all parts easily. Finally, check for any leaks to keep everything clean and safe.”}},{“@type”: “Question”,”name”: “How Can You Identify Signs That The Lathe Oil Needs To Be Changed In A Cnc Retrofitted Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell when lathe oil needs changing by looking for a few signs. First, check if the oil is dark or dirty. If it smells bad, that’s another sign. You should also see if it’s thicker than normal. Lastly, if the machine starts making strange noises, it might need new oil.”}}]}