Have you ever wondered how machines stay in top shape? Just like your bicycle needs oil, metal lathes need a special kind of oil too. The process of changing lathe oil is important for smooth operations.

Think about it: what happens when you don’t take care of your tools? They wear out faster, right? The same goes for metal lathe operations. Regular maintenance, including an oil change, keeps everything running perfectly.

Here’s a fun fact: Did you know that fresh oil can make your lathe last longer? It helps reduce friction and keeps parts clean. That means fewer repairs and more time creating! So, are you ready to dive into the world of lathe oil changes? Your metal lathe will thank you!

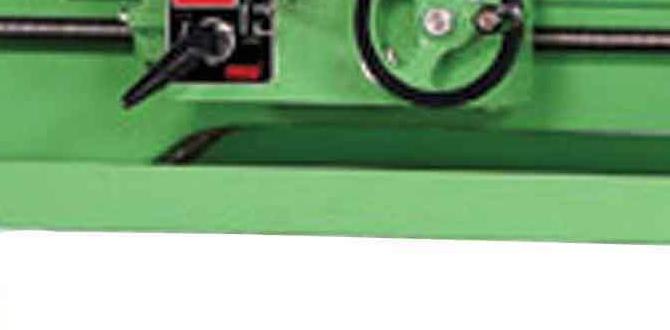

Essential Lathe Oil Change For Smooth Metal Lathe Operations

Lathe Oil Change in Metal Lathe Operations

Keeping your metal lathe in top shape is crucial. Regular lathe oil changes help maintain its performance. Did you know that using fresh oil can extend the life of your machine? Oil reduces friction, allowing parts to move smoothly. Without proper lubrication, your lathe can suffer damage. Many beginners forget this step and risk costly repairs. To avoid issues, check your oil regularly and keep it clean. A little maintenance goes a long way!

Understanding Lathe Oil and Its Importance

Define lathe oil and its primary functions.. Discuss the impact of oil on lathe performance and longevity..

Lathe oil is like a magic potion for your metal lathe. It helps machines run smoothly by reducing friction and keeping parts cool. Imagine trying to ride a bike with no oil on the gears—yikes! Regular oil changes can improve lathe performance and extend its life. When lathe oil is fresh, it works wonders; old oil? Not so much. Think of it as giving your lathe a spa day!

| Function | Impact |

|---|---|

| Reduces wear | Increases lifespan of parts. |

| Cools components | Prevents overheating and damage. |

| Lubricates | Ensures smoother operations. |

Types of Lathe Oil

Explore different types of lathe oils suitable for metal lathe operations.. Compare synthetic versus mineral oil options..

Choosing the right lathe oil can make or break your metal lathe operations. There are two main types: synthetic oil and mineral oil. Synthetic oil is like the superhero of oils. It offers great protection and can handle high heat. In contrast, mineral oil is more traditional and often more affordable, but it might not hold up as well under tough conditions. Think of it like choosing between a fancy sports car and a reliable old truck!

| Type of Oil | Pros | Cons |

|---|---|---|

| Synthetic Oil | High heat resistance, longer-lasting | More expensive |

| Mineral Oil | Cost-effective, easy to find | May break down faster |

Using the right oil can keep your lathe happy and running smoothly. Remember, a well-lubricated lathe is a happy lathe!

Signs Indicating Oil Change is Needed

Identify visual and performance indicators for oil changes.. Explain the risks of using old or contaminated oil..

Pay attention to your lathe like a proud parent. If it starts squeaking or smelling funny, it might be time for an oil change. Look for dark, dirty oil or oil that has a jelly-like consistency. These are signs that the old oil is ready to retire. If you keep using it, your lathe could suffer overheating or damage — yikes! Better oil means smoother operations and a happier machine.

| Signs You Need an Oil Change | What Happens If You Don’t |

|---|---|

| Dark or dirty oil | Overheating |

| Squeaky sounds | Serious damage |

| Lumpy or jelly-like texture | Poor performance |

Step-by-Step Guide to Changing Lathe Oil

Provide a detailed procedure for safely changing lathe oil.. List essential tools and safety precautions to take before starting..

Changing lathe oil is a simple yet crucial task. First, gather your tools: a clean container, oil, wrenches, and a funnel. Always wear safety glasses and gloves for protection. Start by turning off the lathe and unplugging it. Then, drain the old oil into the container. Next, clean the oil pan before adding new oil. Finally, run the lathe briefly to ensure the oil circulates properly.

What tools do I need to change lathe oil?

You’ll need:

- Wrenches

- Clean container

- New oil

- Funnel

- Safety gloves

- Safety glasses

What safety measures should I take?

Key safety steps include:

- Turn off and unplug the lathe.

- Wear safety glasses and gloves.

- Keep a clean workspace to avoid spills.

Maintenance Tips for Lathe Oil Management

Recommend best practices for maintaining oil quality over time.. Suggest a maintenance schedule based on operational usage..

To keep your lathe oil fresh, follow some easy tips. First, check the oil regularly for dirt or discoloration. If it looks bad, it’s time to change it. Second, use a clean container when adding new oil. This prevents any dirt from mixing in. Third, store your oil in a cool, dry place away from sunlight. Here’s a simple schedule:

- For heavy use: change oil every 50 hours.

- For moderate use: change every 100 hours.

- For light use: change every 200 hours.

Following these tips helps your lathe run smoothly.

How often should I change my lathe oil?

Change your lathe oil every 50, 100, or 200 hours, based on your usage. Regular checks keep the oil clean and your machine happy.

Common Mistakes to Avoid When Changing Lathe Oil

Highlight frequent errors made during oil changes and their consequences.. Provide corrective actions to ensure proper oil change..

Changing lathe oil sounds simple, right? Well, watch out for common slip-ups! One big mistake is skipping the cleaning step. Dirt can ruin your new oil and create a grumpy lathe. Another error is using the wrong type of oil. That’s like trying to charge a flip phone with a tablet charger—no good! Always double-check the oil’s label before you pour.

| Common Mistake | Consequence | Corrective Action |

|---|---|---|

| Skipping cleaning | Dirt ruins oil | Clean the lathe first |

| Wrong oil type | Lathe dysfunction | Check the oil label |

Remember, a happy lathe means smoother operations! So keep it clean and use the right stuff. It’ll save you time and make your lathe dance like no one’s watching.

Frequently Asked Questions about Lathe Oil

Compile a list of common questions and their concise answers.. Address misconceptions related to lathe oil and maintenance..

Many people wonder about lathe oil and its importance in metal lathe operations. Here are some common questions people ask.

What does lathe oil do?

Lathe oil keeps the machine parts moving smoothly. It reduces friction and helps prevent wear.

How often should I change the lathe oil?

Change lathe oil every 50 hours of use. This keeps the machine in good shape.

Can I use any oil for my lathe?

No, always use the oil recommended by the manufacturer. This ensures the best performance.

Is it okay to mix different oils?

Mixing oils can cause problems. Stick to one type for best results.

Conclusion

In summary, changing lathe oil is vital for smooth metal lathe operations. Regular oil changes keep your machine running efficiently and prevent damage. Always check the oil level and type for optimal performance. We encourage you to practice this maintenance routine and explore more tips on caring for your lathe. This will help you achieve better results in your projects!

FAQs

What Are The Signs That Indicate It’S Time To Change The Oil In A Metal Lathe?

You know it’s time to change the oil in a metal lathe when the oil looks dirty or won’t flow well. If you hear strange noises while using it, that’s also a sign. Check the oil level too. If it’s low, you need to add or change it. Keeping the oil fresh helps your lathe work better!

What Type Of Oil Is Recommended For Lubrication In Metal Lathe Operations?

For metal lathe operations, you should use cutting oil or machine oil. Cutting oil helps the tools stay cool and cuts better. Machine oil is good for keeping the lathe parts moving smoothly. Always check your lathe’s manual for the best oil to use.

How Often Should You Perform An Oil Change On A Metal Lathe Based On Usage?

You should change the oil in a metal lathe based on how much you use it. If you use it a lot, change the oil every month. If you use it less often, you can wait three months. Always check the oil level and color to see if it needs changing. Keeping the oil clean helps the lathe work better!

What Are The Steps Involved In Changing The Oil On A Metal Lathe?

To change the oil on a metal lathe, first, turn off the machine and unplug it. Then, find the oil drain plug and let the old oil spill out into a container. Next, clean the area around the oil hole to keep it nice. After that, pour in the new oil through the hole. Finally, plug everything back and check if it’s working well.

How Does Proper Lubrication And Oil Maintenance Impact The Performance And Lifespan Of A Metal Lathe?

Proper lubrication keeps a metal lathe running smoothly. It helps the parts move without getting stuck. When we oil the lathe, it lasts longer and doesn’t break down. This means we can use it more often and make better pieces. Regular maintenance is like giving the lathe a drink, keeping it healthy and happy!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Signs That Indicate It’S Time To Change The Oil In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You know it’s time to change the oil in a metal lathe when the oil looks dirty or won’t flow well. If you hear strange noises while using it, that’s also a sign. Check the oil level too. If it’s low, you need to add or change it. Keeping the oil fresh helps your lathe work better!”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubrication In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For metal lathe operations, you should use cutting oil or machine oil. Cutting oil helps the tools stay cool and cuts better. Machine oil is good for keeping the lathe parts moving smoothly. Always check your lathe’s manual for the best oil to use.”}},{“@type”: “Question”,”name”: “How Often Should You Perform An Oil Change On A Metal Lathe Based On Usage? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a metal lathe based on how much you use it. If you use it a lot, change the oil every month. If you use it less often, you can wait three months. Always check the oil level and color to see if it needs changing. Keeping the oil clean helps the lathe work better!”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Changing The Oil On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil on a metal lathe, first, turn off the machine and unplug it. Then, find the oil drain plug and let the old oil spill out into a container. Next, clean the area around the oil hole to keep it nice. After that, pour in the new oil through the hole. Finally, plug everything back and check if it’s working well.”}},{“@type”: “Question”,”name”: “How Does Proper Lubrication And Oil Maintenance Impact The Performance And Lifespan Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Proper lubrication keeps a metal lathe running smoothly. It helps the parts move without getting stuck. When we oil the lathe, it lasts longer and doesn’t break down. This means we can use it more often and make better pieces. Regular maintenance is like giving the lathe a drink, keeping it healthy and happy!”}}]}