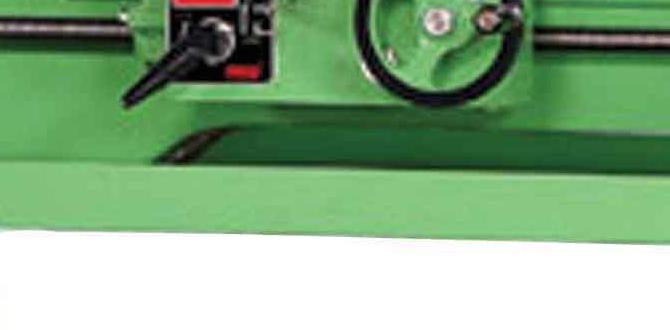

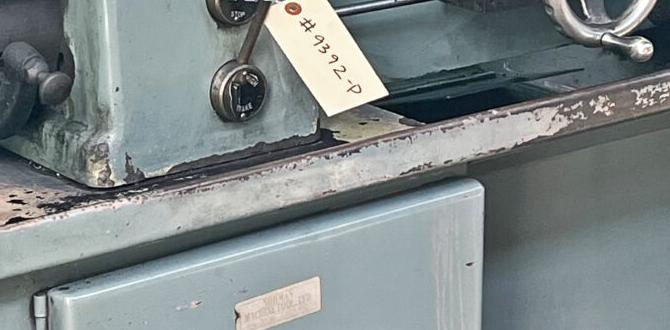

Have you ever wondered how a metal lathe works smoothly? One key aspect is the right lathe oil change. Keeping the quill well-lubricated can make a big difference in your projects.

Imagine trying to cut metal with a rusty tool. It wouldn’t work well, right? Just like a car needs oil, your lathe needs the right oil too. Regular oil changes keep the quill functioning properly.

Did you know that a simple oil change can extend the life of your lathe? Many new users overlook this step. They don’t realize how easy it is to maintain their machine.

In this article, we’ll explore how to perform a lathe oil change. You’ll learn why it’s important and how it can enhance your metalworking experience. Let’s dive in!

Lathe Oil Change: Essential For Your Metal Lathe Quill

Lathe Oil Change: Keeping Your Metal Lathe Quill Smooth

Does your metal lathe quill feel gritty? Regular lathe oil changes are essential. They can keep the quill running smoothly. Using fresh oil helps prevent wear and tear. Did you know that dirty oil can lead to costly repairs? By changing the oil, you extend the life of your lathe. Plus, the machine performs better! Remember to check the oil regularly and clean any build-up. It’s a simple step that brings big benefits!

Understanding the Importance of Lathe Oil

Function of lathe oil in maintaining performance. Consequences of neglecting proper lubrication.

Lathe oil plays a crucial role in keeping your metal lathe running smoothly. It helps reduce friction, which means parts can move without getting stuck. Imagine trying to ride a bike with sticky wheels—no fun, right? Neglecting to change the oil can lead to overheating and damage. This turns a fun project into a nightmare! So, keep your quill filled with fresh lathe oil, and your machine will thank you by working like a charm!

| Importance of Lathe Oil | Consequences of Neglect |

|---|---|

| Reduces friction | Overheating |

| Enhances performance | Parts wear out quickly |

| Extends machine life | Expensive repairs |

When to Change Lathe Oil

Indicators that oil change is necessary. Recommended oil change intervals based on usage.

Changing lathe oil is important for keeping your machine happy. You’ll know it’s time for a swap if the oil looks dirty or has a funny smell. Also, if the lathe starts making strange noises, it might be screaming for rescue!

To keep things running smoothly, follow this oil change schedule based on how much you use your lathe:

| Frequency of Use | Recommended Oil Change Interval |

|---|---|

| Light Use | Every 6 months |

| Moderate Use | Every 3 months |

| Heavy Use | Monthly |

Remember, a well-oiled lathe is a happy lathe. It might even purr like a kitten if you’re lucky!

Step-by-Step Guide to Changing Lathe Oil

Preparing the metal lathe for oil change. Detailed process for draining and replacing oil.

To get ready for an oil change, first, unplug the metal lathe. This helps to keep you safe. Clean around the oil reservoir. Make sure you have the right tools and oil ready. Next, locate the drain plug at the bottom of the reservoir.

- Place a container underneath to catch the oil.

- Open the drain plug carefully to let the old oil flow out.

- Once drained, close the plug securely.

- Pour in the new oil through the filling hole.

After filling, check for leaks. If everything is tight, your lathe is ready to go!

Why is changing lathe oil important?

Changing lathe oil keeps the machine running smoothly and helps it last longer.

Tools and Materials Needed for Oil Change

List of essential tools required for the task. Recommended oil brands and products.

Changing the oil in your lathe is simple but needs the right tools and materials. Here’s what you need:

- Wrench set

- Drain pan

- Oil filter wrench

- Clean rags

- New oil

For oil brands, consider these:

- Mobil 1

- Royal Purple

- Castrol

Having these items ready will make your oil change smooth and quick.

What tools do I need to change lathe oil?

To change lathe oil, you need basic tools like a wrench set and a drain pan. Don’t forget clean rags and the correct new oil.

Common Mistakes to Avoid During Oil Change

Frequent errors made by users when changing oil. Tips for ensuring a smooth oil change process.

Changing oil in a lathe is important, but people often make mistakes. Here are some frequent errors and tips to help you:

- Skipping the manual. Always read the machine’s manual first.

- Using the wrong oil type. Make sure to use the right oil for your quill.

- Neglecting to clean parts. Clean old oil and dirt before adding new oil.

- Overfilling the reservoir. Too much oil can cause leaks.

Following these tips can lead to a smoother oil change process. Always take your time and double-check everything!

What are common mistakes during an oil change?

The most common mistakes include using the wrong oil type, skipping cleaning parts, and overfilling the oil reservoir.

Maintaining the Quill for Optimal Performance

Best practices for quill care and maintenance. Troubleshooting common quill issues related to oiling.

Taking care of your lathe quill is like caring for a pet—ignore it, and you’ll end up with a cranky machine! Regular oil changes are key. Give your quill fresh oil often to keep it running smoothly. If you notice weird sounds or stiff movements, don’t panic! Check the oil level first; it may be time for a top-up. Remember, a happy quill makes a happy lathe!

| Quill Issue | Possible Cause | Solution |

|---|---|---|

| Sticking quill | Low oil | Refill with lathe oil |

| Weird noises | Dirty parts | Clean the quill mechanism |

| Rust build-up | Moisture exposure | Dry it well and apply protective oil |

Additional Resources and References

Recommended manuals and guides for lathe maintenance. Online forums and communities for lathe enthusiasts.

Maintaining your lathe is important for its performance. For valuable tips, check out manuals and guides. They provide step-by-step instructions for keeping your machine in top shape.

Joining online forums can also help. You can learn from other lathe enthusiasts and share your own experiences. Here are some useful resources:

- Lathe Maintenance Manual – A great guide for beginners.

- Community Forums – Connect with others who share your interests.

- Video Tutorials – Visual help for complicated tasks.

Where can I find lathe maintenance resources?

You can find resources in manuals, community forums, and online video tutorials. These tools will help you become a lathe expert!

Conclusion

In conclusion, changing lathe oil in your metal lathe’s quill is essential for smooth operation. Regular oil changes keep your machine running well and prevent damage. You should check the oil levels frequently. Remember to choose the right oil for your lathe. For more tips, we encourage you to explore beginner’s guides on lathe maintenance. Happy machining!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And Metal Lathe Quills:

Changing the oil in a lathe is important. It keeps the machine running smoothly. You do this by draining old oil and adding new oil. Make sure to check the manufacturer’s instructions for details. Always use the right oil for your lathe.

Sure! Please provide the question you’d like me to answer.

What Type Of Oil Is Recommended For Lubricating The Quill On A Metal Lathe?

You should use light machine oil to lubricate the quill on a metal lathe. This oil helps keep the quill moving smoothly. Make sure to apply just a little bit. Avoid using heavy oil because it can make things stick. Always check your machine’s manual for specific recommendations!

How Often Should The Oil In The Quill Of A Metal Lathe Be Changed Or Topped Off?

You should check the oil in the quill of a metal lathe often. It’s good to top it off if it looks low. Change the oil completely every few months or as needed. Keeping the oil right helps the lathe work better. Always follow the instructions for your specific lathe.

What Are The Signs That Indicate The Quill Of A Metal Lathe Needs An Oil Change?

You might know it’s time to change the oil in a metal lathe quill if you see a few signs. First, if the machine makes strange noises, that’s a red flag. Second, if the quill moves roughly or feels stuck, it might need fresh oil. Also, if you notice any leaks or the oil looks dirty, it’s time for a change. Regular checks will help keep your lathe running smoothly!

What Is The Proper Procedure For Changing The Oil In A Lathe Quill?

To change the oil in a lathe quill, first, turn off the lathe and unplug it for safety. Then, find the oil drain plug at the bottom of the quill and remove it. Let the old oil drain out completely. Next, replace the drain plug and add new oil through the fill hole. Finally, check the level and make sure everything is tight before you start using the lathe again.

Can Using The Wrong Type Of Oil Affect The Performance And Longevity Of A Metal Lathe’S Quill?

Yes, using the wrong type of oil can hurt your lathe’s quill. The quill is a part that helps control tools. If the oil isn’t right, it can cause wear and tear. This makes your machine work poorly and break down faster. Always check the oil type to keep your lathe happy!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And Metal Lathe Quills:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Changing the oil in a lathe is important. It keeps the machine running smoothly. You do this by draining old oil and adding new oil. Make sure to check the manufacturer’s instructions for details. Always use the right oil for your lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating The Quill On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use light machine oil to lubricate the quill on a metal lathe. This oil helps keep the quill moving smoothly. Make sure to apply just a little bit. Avoid using heavy oil because it can make things stick. Always check your machine’s manual for specific recommendations!”}},{“@type”: “Question”,”name”: “How Often Should The Oil In The Quill Of A Metal Lathe Be Changed Or Topped Off?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the oil in the quill of a metal lathe often. It’s good to top it off if it looks low. Change the oil completely every few months or as needed. Keeping the oil right helps the lathe work better. Always follow the instructions for your specific lathe.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate The Quill Of A Metal Lathe Needs An Oil Change?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might know it’s time to change the oil in a metal lathe quill if you see a few signs. First, if the machine makes strange noises, that’s a red flag. Second, if the quill moves roughly or feels stuck, it might need fresh oil. Also, if you notice any leaks or the oil looks dirty, it’s time for a change. Regular checks will help keep your lathe running smoothly!”}},{“@type”: “Question”,”name”: “What Is The Proper Procedure For Changing The Oil In A Lathe Quill?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in a lathe quill, first, turn off the lathe and unplug it for safety. Then, find the oil drain plug at the bottom of the quill and remove it. Let the old oil drain out completely. Next, replace the drain plug and add new oil through the fill hole. Finally, check the level and make sure everything is tight before you start using the lathe again.”}},{“@type”: “Question”,”name”: “Can Using The Wrong Type Of Oil Affect The Performance And Longevity Of A Metal Lathe’S Quill?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, using the wrong type of oil can hurt your lathe’s quill. The quill is a part that helps control tools. If the oil isn’t right, it can cause wear and tear. This makes your machine work poorly and break down faster. Always check the oil type to keep your lathe happy!”}}]}