Lathe Parting Tool: Metal Lathe Cad Design Insights

Lathe Parting Tool Metal Lathe CAD Design

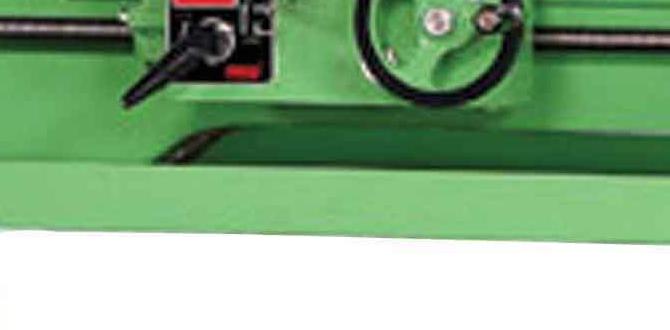

The lathe parting tool is essential for metalworking. It helps create clean cuts when shaping materials. Using CAD design for lathe tools can boost precision and efficiency. Imagine designing tools on a computer first; this saves time and minimizes mistakes. Fun fact: CAD designs can even be shared globally! By understanding these tools, makers can elevate their projects. Ready to enhance your metal lathe skills? Dive into the world of CAD design today!

Importance of CAD Design in Toolmaking

Benefits of using CAD software for tool design. How CAD improves precision and efficiency in manufacturing parting tools.

Using CAD software is very helpful in making tools. It helps designers create accurate shapes and sizes. This leads to better parts and less waste. Professionals can make changes quickly, saving time. CAD also speeds up the process, ensuring tools are ready faster.

- Better Accuracy: Designs are precise, which improves tool quality.

- Faster Prototyping: Changes can be made easily on the computer.

- Less Waste: Better designs mean fewer mistakes and lost materials.

What are the main benefits of CAD in tool design?

CAD makes designing tools smoother, quicker, and more accurate. It also helps save resources and time, which is important in today’s fast world.

Key Features of an Effective Parting Tool Design

Critical dimensions and geometry for optimal performance. Material selection considerations for durability and longevity.

Creating a great parting tool design is like baking a cake: get the recipe right, and you’ll have a masterpiece. First, focus on the critical dimensions. The shape and size make all the difference in performance. Next, materials matter. Choose the strongest metals for durability—nobody wants a tool that gives up halfway through a job! Lastly, remember to keep it sharp. A dull tool is like trying to eat soup with a fork—just silly!

| Feature | Importance |

|---|---|

| Dimensions | Ensure precise cutting |

| Material | Enhances tool life |

| Sharpness | Improves efficiency |

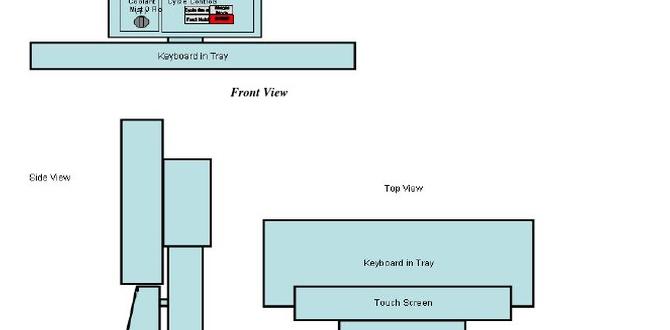

Step-by-Step Guide to Designing a Parting Tool in CAD

Initial design considerations and sketches. Detailed CAD modeling process: tools and techniques to use.

Creating a parting tool in CAD can be fun! Start with some sketches of your design. Think about what shape and size you need. Next, dive into your CAD software. Use tools like extrude and revolve for 3D modeling. It’s like playing with digital clay! Don’t forget to check your dimensions. The right size is key; nobody wants a rubber chicken instead of a tool!

| Tool/Technique | Description |

|---|---|

| Sketching | Make initial ideas visual. |

| Extrude | Shape your tool into 3D. |

| Revolve | Create round parts easily. |

Testing and Prototyping Your CAD Design

Methods for testing the effectiveness of your parting tool design. Importance of prototyping and iteration in tool development.

Testing your design is like trying out a new recipe. You don’t want to serve your guests a burnt cake! Start by making small-scale models. Use materials that mimic your final product. This will help you see how well your parting tool works. Prototyping is key; it’s where ideas become real! Don’t shy away from making changes. Remember, no one gets it right on the first try—except maybe chefs with a bit too much seasoning!

| Method | Purpose |

|---|---|

| Scale Models | Test for size and fit |

| Material Testing | Evaluate durability |

| Feedback Loop | Refine design from user input |

Iterate after each test. With every tweak, your parting tool gets closer to perfection. Like a funny chef who learns to stop adding salt after the first five batches! So, keep experimenting and laugh at the process. The goal is a tool that works, and maybe a funny story for later!

Case Studies: Successful Parting Tool Designs

Examples of innovative designs and their impact on machining efficiency. Analyses of design modifications leading to improved performance.

Innovative designs greatly boost machining efficiency. For example, some parting tools have special shapes. These shapes help cut better and faster. A few key changes can lead to much better performance. Here are some examples:

- **Enhanced Cutting Edges**: Updated edges help slice through materials easily.

- **Improved Tool Length**: Longer tools reduce the number of tool changes.

- **Special Coatings**: New coatings can lower friction and increase lifespan.

These changes not only speed up work but also save money and time.

What are some successful designs of parting tools?

Successful designs include unique shapes, better materials, and coatings that reduce wear. These features lead to smoother cuts and better overall machining. They allow users to work faster and more accurately.

Future Trends in Lathe Parting Tool Design

Emerging technologies in CAD and materials science influencing tool design. Predictions for the future of lathe parting tools in the industry.

New tools and materials are sprouting up faster than mushrooms after the rain! With advances in CAD technology, experts can now create lathe parting tools that are lighter and stronger. Imagine tools so efficient they could make even a sloth look speedy. In fact, many predict lathe parting tools will become even more versatile, potentially incorporating smart features like sensors that shout, “Hey! You’re using me wrong!” The future looks bright, so keep those safety goggles on—who knows what fun new tricks await!

| Future Trends | Emerging Technologies |

|---|---|

| Advanced CAD Software | Improved design accuracy |

| New Materials | Stronger and lighter tools |

| Smart Features | Real-time feedback |

Conclusion

In summary, using a lathe parting tool is essential for shaping metal pieces. CAD design helps you plan your projects accurately. You can create detailed designs easily, making your work more efficient. Remember to practice regularly to improve your skills. We encourage you to explore CAD tutorials online for more tips and tricks on using these tools effectively!

FAQs

What Are The Essential Dimensions And Geometry To Consider When Designing A Lathe Parting Tool For A Metal Lathe In Cad Software?

When designing a lathe parting tool, think about its length, width, and angle. The tool should be about 1/4 inch thick. You also need to shape the tip into a sharp point for cutting. Make sure the handle is easy to hold, too. Finally, check that everything fits well with the lathe.

How Can The Material Selection For A Lathe Parting Tool Impact Its Performance And Durability In Cad Design?

Choosing the right material for a lathe parting tool is very important. If we use strong materials, the tool lasts longer. Strong tools cut better and don’t break easily. In CAD design, we should pick materials that fit the job well, so we get the best results. This helps us make good parts without wasting time or resources.

What Are The Best Practices For Creating A Parting Tool Profile In Cad That Minimizes Vibration And Improves Cutting Efficiency?

To create a good parting tool profile in CAD, you should start with a simple shape. Make sure the edges are smooth and not too sharp. You can also make the tool slightly thicker to help it stay strong. It’s important to keep the tool balanced to reduce vibrations while cutting. Lastly, check your design often to make sure it works well.

How Can You Integrate Custom Features Into A Lathe Parting Tool Cad Design To Accommodate Specific Machining Applications Or Materials?

To add custom features to a lathe parting tool in a CAD design, you start by thinking about what you need. You can change the shape of the tool to make it work better with different materials. You might want to make the tool sharper or thicker, depending on what you’re cutting. We can also add special grooves or notches to help with holding and cutting. Finally, we test our design to make sure it works well before using it.

What Software Tools And Techniques Are Recommended For Simulating The Cutting Action Of A Lathe Parting Tool In A Cad Environment?

To simulate how a lathe parting tool cuts, you can use CAD software like Fusion 360 or SolidWorks. These tools let you create 3D models of your parts. You can also add cutting motions to see how the tool works. Watching the simulation helps you understand the cutting action better. You might also find videos online that show these software tools in action.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Dimensions And Geometry To Consider When Designing A Lathe Parting Tool For A Metal Lathe In Cad Software? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a lathe parting tool, think about its length, width, and angle. The tool should be about 1/4 inch thick. You also need to shape the tip into a sharp point for cutting. Make sure the handle is easy to hold, too. Finally, check that everything fits well with the lathe.”}},{“@type”: “Question”,”name”: “How Can The Material Selection For A Lathe Parting Tool Impact Its Performance And Durability In Cad Design? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right material for a lathe parting tool is very important. If we use strong materials, the tool lasts longer. Strong tools cut better and don’t break easily. In CAD design, we should pick materials that fit the job well, so we get the best results. This helps us make good parts without wasting time or resources.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Creating A Parting Tool Profile In Cad That Minimizes Vibration And Improves Cutting Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create a good parting tool profile in CAD, you should start with a simple shape. Make sure the edges are smooth and not too sharp. You can also make the tool slightly thicker to help it stay strong. It’s important to keep the tool balanced to reduce vibrations while cutting. Lastly, check your design often to make sure it works well.”}},{“@type”: “Question”,”name”: “How Can You Integrate Custom Features Into A Lathe Parting Tool Cad Design To Accommodate Specific Machining Applications Or Materials? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To add custom features to a lathe parting tool in a CAD design, you start by thinking about what you need. You can change the shape of the tool to make it work better with different materials. You might want to make the tool sharper or thicker, depending on what you’re cutting. We can also add special grooves or notches to help with holding and cutting. Finally, we test our design to make sure it works well before using it.”}},{“@type”: “Question”,”name”: “What Software Tools And Techniques Are Recommended For Simulating The Cutting Action Of A Lathe Parting Tool In A Cad Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To simulate how a lathe parting tool cuts, you can use CAD software like Fusion 360 or SolidWorks. These tools let you create 3D models of your parts. You can also add cutting motions to see how the tool works. Watching the simulation helps you understand the cutting action better. You might also find videos online that show these software tools in action.”}}]}