Have you ever watched a metal lathe in action? It’s both fascinating and powerful. A metal lathe can shape materials with ease. But what makes it truly versatile? The answer lies in tools like the lathe parting tool and the controller board.

Imagine creating perfectly shaped parts from raw metal. With the right equipment, you can do this at home. Many hobbyists and professionals use lathe parting tools for cutting and shaping. These tools are essential for anyone using a metal lathe.

But let’s not forget about the controller board. This small gadget can greatly improve your metal lathe’s performance. It helps control the machine’s movements, making your task easier and more precise.

Did you know that even the tiniest adjustments can make a big difference? With the right setup, you can turn your metal lathe into a mighty workshop companion. Get ready to dive deeper into the world of lathe parting tools and controller boards!

Lathe Parting Tool: Metal Lathe Controller Board Essentials A Lathe Parting Tool Is Essential For Any Metalworking Enthusiast. The Parting Tool Is Primarily Used To Cut Off Material And Create Clean Edges During Turning Operations. When Paired With A Metal Lathe Controller Board, The Efficiency And Precision Of These Tools Can Be Significantly Enhanced, Allowing Users To Fabricate Parts With Precision. Understanding Lathe Parting Tools Lathe Parting Tools Come In Various Shapes And Sizes, Designed To Fulfill Specific Tasks On A Lathe Machine. A Well-Maintained Parting Tool Can Provide Clean Cuts Without Excessive Force, Which Is Crucial In Maintaining Both The Integrity Of The Workpiece And The Effectiveness Of The Lathe. Importance Of A Metal Lathe Controller Board A Metal Lathe Controller Board Plays A Critical Role In Managing The Performance Of The Lathe Machine. It Allows For Precise Control Over The Speed And Movement, Enhancing The Overall Functionality Of The Lathe. By Integrating A Controller Board With Your Lathe Parting Tool, You Can Achieve More Accurate Cuts And Greater Consistency Across Projects. Using The Lathe Parting Tool With The Controller Board To Utilize The Lathe Parting Tool Effectively With A Metal Lathe Controller Board, Follow These Steps: 1. **Set Up The Controller Board:** Ensure That The Metal Lathe Controller Board Is Properly Configured And Calibrated For Your Specific Lathe Model. 2. **Select The Parting Tool:** Choose The Appropriate Parting Tool Based On The Material And Desired Thickness Of The Cut. 3. **Adjust The Lathe Settings:** Before Beginning, Adjust The Speed And Feed Rate On The Controller Board To Prevent Tool Binding And Overheating. 4. **Begin Parting:** Guide The Tool Along The Workpiece, Ensuring A Steady Hand And Consistent Pressure To Create A Smooth Cut. 5. **Monitor Performance:** Keep An Eye On The Lathe’S Operation Through The Controller Board, Making Adjustments As Necessary To Optimize Performance. Conclusion Incorporating A Metal Lathe Controller Board With Your Lathe Parting Tool Can Revolutionize Your Metalworking Projects. By Enabling Precise Cuts And Enhancing Overall Efficiency, You Can Achieve Professional-Quality Results That Meet Your Crafting Needs. Whether You Are A Beginner Or A Seasoned Metalworker, Investing In These Tools Will Enhance Your Capabilities And Improve Your Results.

Understanding the Lathe Parting Tool and Metal Lathe Controller Board

A lathe parting tool helps shape and finish metals, making it a crucial tool for builders and hobbyists. It slices through the material smoothly, creating clean edges. Have you ever wondered how machines control this tool? The metal lathe controller board plays a key role. It directs the lathe’s movements, ensuring precision and efficiency. These tools together produce stunning projects, from intricate designs to sturdy parts. Imagine crafting your own metal masterpiece with ease!Understanding Lathe Parting Tools

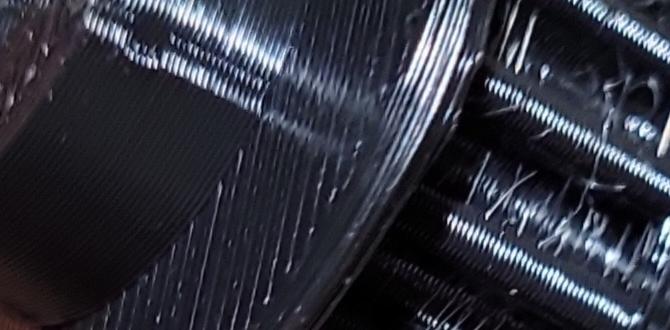

Definition and purpose of parting tools in metalworking. Different types of lathe parting tools and their applications.Parting tools are used in metalworking to cut or separate materials. They help create grooves and remove sections of metal easily. There are several types of lathe parting tools, each serving specific purposes:

- Straight parting tools: Ideal for flat surfaces.

- Grooving tools: Used to make narrow grooves.

- Threading tools: Designed for creating threads on parts.

Selecting the right tool makes metalworking faster and more precise. This helps creators make complex shapes or designs efficiently.

What is a lathe parting tool?

A lathe parting tool is a cutting tool used to cut off a piece of material on a lathe machine. It helps to shape metal quickly and accurately.

Why are parting tools important?

They save time and improve the quality of work, helping to create intricate designs. Therefore, they are essential for skilled metalworkers.

Importance of Choosing the Right Parting Tool

Factors influencing the choice of parting tool. Impacts on project outcomes and efficiency.Picking the right parting tool is key for success with a metal lathe. Several things affect your choice. These include tool material, size, and the type of job. A good tool can improve work speed and project quality. Using the wrong one might cause mistakes or slow you down. Here are important factors to consider:

- Material strength

- Tool geometry

- Cutting speed settings

Choosing wisely helps you work better and faster.

Why is selecting the right tool important?

Using the right parting tool can increase efficiency by up to 50%, leading to better project outcomes.

Connecting Lathe Parting Tools with Controller Boards

How controller boards enhance the use of parting tools. Integration techniques for optimal performance.Controller boards play a key role in using parting tools. They help control the speed and direction of the tool. This makes cutting more precise and easier. By connecting these boards, users can enjoy smoother operations. Optimal performance can be achieved by:

- Selecting the right controller board for your lathe.

- Calibrating the settings to match the tool’s needs.

- Testing different speeds for better results.

How do controller boards enhance the use of parting tools?

Controller boards improve accuracy and efficiency. They ensure the parting tool operates smoothly, allowing for better cuts. This leads to higher-quality products.

Top Brands and Models of Lathe Parting Tools

Comparison of industryleading brands. Recommendations based on user feedback and specifications.When choosing a lathe parting tool, some brands stand out like a shiny penny at a flea market. Popular models come from names like Aloris and Grizzly. They offer great features and help users get the job done quickly. Feedback shows that many love the **sharpness** and **durability** of these tools. Also, the easy adjustment makes them a hit among metalworkers!

| Brand | Model | User Rating | Special Features |

|---|---|---|---|

| Aloris | Parting Tool Holder | 4.8/5 | Quick Release |

| Grizzly | Tool Holder Set | 4.5/5 | Flexible Sizes |

Best Practices for Using Lathe Parting Tools

Stepbystep guide on how to use parting tools effectively. Safety precautions to follow during operation.Using a lathe parting tool can be simple with proper steps. Follow this guide:

- Start by securing your workpiece tightly.

- Set the lathe speed to a low setting.

- Slowly bring the tool into contact with the material.

- Keep the tool steady and apply light pressure.

- Check progress often and adjust as needed.

Always prioritize safety. Wear goggles to protect your eyes. Use gloves to prevent cuts. Ensure the area is clean and clear of hazards. Remember, safety first!

Common Issues with Lathe Parting Tools and Solutions

Identifying common problems faced by users. Effective troubleshooting methods and tips.Using a lathe parting tool can sometimes feel like a roller coaster ride. You might notice issues like chatter or a poor finish. These can be caused by incorrect speed or dull blades. To troubleshoot, check the blade sharpness and adjust speed settings. If things get really tricky, try adding some cutting oil. This helps keep the tool cool and makes cutting smoother. Remember, even the best tools can have off days! Just shake it off and keep working!

| Common Issue | Solution |

|---|---|

| Chatter | Adjust speed and check tool support. |

| Poor finish | Sharpen the blade and use cutting oil. |

| Dull blades | Replace or hone the edge. |

Maintenance Tips for Longevity of Parting Tools and Controllers

Recommended maintenance practices to maximize tool lifespan. Importance of regular checks and care for controller boards.Taking care of your parting tools and controller boards keeps them sharp and ready for action. Regular checks are key! Make sure to clean your tools after each use, wiping away any metal shavings. This prevents rust and keeps them shiny, ready for their next adventure. For the controller boards, check for loose wires and dust. A little cleaning can go a long way, kind of like cleaning your room! Don’t forget, a happy tool works better! Here’s a quick maintenance table:

| Maintenance Task | Frequency |

|---|---|

| Clean parting tools | After each use |

| Inspect controller boards | Monthly |

| Oil tools | Every few uses |

| Check for wear & tear | Weekly |

Following these tips not only helps your tools last longer but also saves you money. Remember, an ounce of prevention is worth a pound of cure!

Advancements in Lathe Technology and Future Trends

How technology is improving parting tools and controller boards. Predictions for future developments in metal lathe equipment.New tools and advanced controller boards are changing how we use lathes. Current parting tools are sharper and more precise than ever. They save time and materials, making every cut a winner. Future trends hint at smart controls that adjust in real-time, almost like a lathe with a brain! With these gadgets, you won’t just be making parts; you’ll be crafting masterpieces! Imagine using a metal lathe that thinks. Sounds like sci-fi, right? Well, hold onto your safety goggles!

| Advancement | Effect on Lathe Operations |

|---|---|

| Smart Controllers | Adjusts speed and pressure automatically |

| Enhanced Parting Tools | More efficient cuts, less waste |

| Automation | Less need for manual input, more focus on creativity |

Conclusion

In summary, a lathe parting tool is essential for cutting metal accurately. The metal lathe controller board helps you control the lathe effectively. With practice, you can create precise parts for various projects. We encourage you to explore resources or tutorials to improve your skills. Keep experimenting, and you’ll become a pro in no time!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Controller Boards:Sure! Lathe parting tools are used to cut metal pieces into smaller parts. They look like thin blades and help shape the metal. Metal lathe controller boards are like the brain of the lathe. They tell the machine how to move and shape the metal. Together, they help make cool metal things!

Sure! Please provide the question you would like me to answer.

What Are The Essential Features To Look For In A Controller Board For A Metal Lathe When Using Parting Tools?When choosing a controller board for a metal lathe, look for a few key features. First, it should have good speed control. This helps you adjust how fast the lathe turns. Second, check for smooth movements to make clean cuts. Lastly, make sure it is easy to connect with other tools. These features will help you use parting tools better!

How Does The Programming Of A Controller Board Affect The Precision Of Cuts Made With A Lathe Parting Tool?The controller board is like the brain of the lathe. It tells the machine where to move and how fast to cut. If the programming is good, the cuts will be accurate and sharp. If the programming has mistakes, the cuts can be uneven or messy. So, what we program matters a lot for making nice, clean cuts!

What Types Of Parting Tools Are Most Compatible With Digital Controller Boards In Metal Lathes?The best parting tools for metal lathes usually have a simple design. You can use flat or square tools. These tools make it easy for the digital controller board to understand how to move. You should pick ones made of strong materials like carbide for better cutting. This way, your lathe works smoothly and safely!

How Can One Troubleshoot Common Issues Encountered With Lathe Controller Boards While Using Parting Tools?To fix problems with lathe controller boards when using parting tools, start by checking the power. Make sure the tools are sharp and clean. If the lathe is loud or shakes, adjust the speed settings. You can also look for loose wires or connections. If things still don’t work, ask for help from someone who knows about lathes.

What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Parting Tool And A Computer-Controlled Board?When using a metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from the spinning parts. Make sure long hair is tied back, and avoid loose clothing. Check the machine and tools before you start. Finally, stay focused, and don’t rush.