Have you ever wondered how a metal lathe works? These machines shape metal into precise parts. But to do this, they need power. Understanding lathe power requirements is key to using them safely and effectively.

Imagine turning a block of metal into a shiny tool. It seems simple, right? But the truth is, the lead screw plays a major role in this process. It helps the lathe move smoothly. Without the right power, your lathe can’t work well.

Here’s a fun fact: the first lathes were made thousands of years ago! People crafted them from wood. Today, they use powerful motors to turn metal. The power needed depends on many factors, like the type of metal and the thickness.

Why is this important for you? Knowing about power requirements can save you time and effort. It helps you choose the right lathe for your projects. So, let’s dive deeper into the world of metal lathes and explore these power needs!

Lathe Power Requirements For Metal Lathe Lead Screw Explained

Lathe Power Requirements: Metal Lathe Lead Screw

Understanding lathe power requirements is crucial for any metalworking project. A metal lathe relies on a lead screw to control the movement of the cutting tool. This screw needs enough power to handle different materials. Did you know that choosing the right motor can make or break your project? Consider your workspace and materials when selecting a lathe. With the right setup, you can create precise parts efficiently. Always check your machine’s specifications for the best results!Basics of Metal Lathes

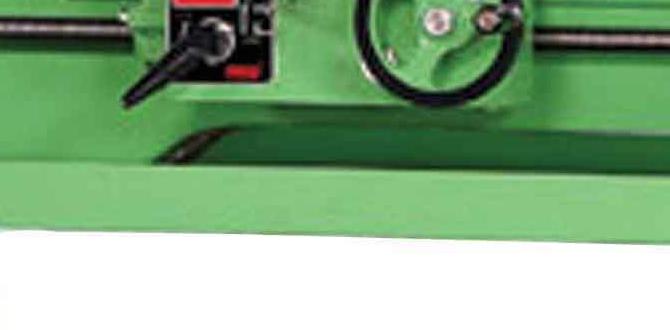

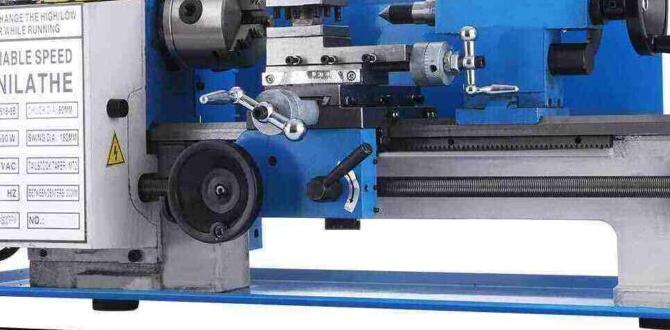

Definition and purpose of metal lathes. Key components of a metal lathe.A metal lathe is a special machine used for shaping metal pieces. It spins the metal while tools cut and smooth it into different shapes. People use lathes to make parts for cars, machines, and even jewelry. Key parts of a metal lathe include:

- Bed: The main body that supports everything.

- Headstock: Houses the motor and controls the spinning.

- Tailstock: Supports the other end of the metal piece.

- Carriage: Moves the cutting tool along the metal.

- Lead Screw: Helps in precise cutting.

What is the purpose of a metal lathe?

The purpose of a metal lathe is to shape metal into specific designs. It allows workers to create parts accurately. By using a lathe, one can easily make round shapes, grooves, and other features. This helps in making many products we use daily.

People often learn about metal lathes in school or workshops. They find it interesting to see how raw metal turns into useful items.

Understanding Lead Screws

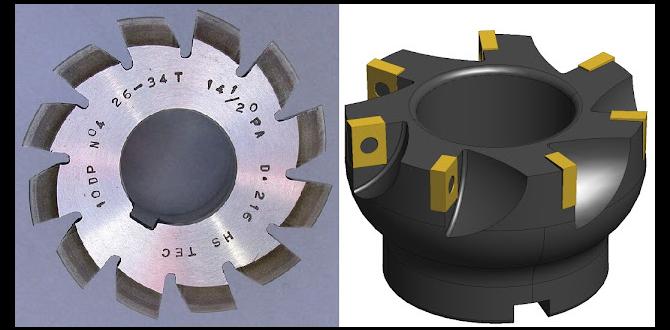

Functionality of lead screws in a lathe. Differences between lead screws and ball screws.Lead screws are key parts of a lathe. They help move the tool or workpiece in a straight line. This movement is essential for making precise cuts. Lead screws have threads that grip tightly, allowing smooth action.

In comparison, ball screws use balls instead of threads. This design reduces friction and increases efficiency. They are often used in high-speed machines.

- Lead screws: Simple design, suitable for slower speeds.

- Ball screws: More complex, better for fast operations.

How do lead screws work in a lathe?

They turn to move the tool, creating accurate shapes. Lead screws can be very strong, making them reliable for heavy tasks.

Power Requirements in Metal Lathes

Importance of power requirements for optimal operation. Factors influencing power requirements (material type, cutting speed, etc.).Power is the heart of any metal lathe. Without enough of it, your machine might as well be a fancy paperweight. The type of material, how fast you want to cut, and your tool choices all affect how much power you need. For example, cutting hard metal requires more juice than slicing through a soft piece of cheese. Remember, too little power can ruin your work, but too much can cause chaos! So, always check your lathe’s needs before starting.

| Factor | Impact on Power Requirement |

|---|---|

| Material Type | Harder materials need more power. |

| Cutting Speed | Higher speeds require increased power. |

| Tool Condition | Dull tools demand more energy. |

Calculating Power Requirements

Formula for calculating power for different materials. Example calculations for common materials used in metal lathes.Power for a lathe isn’t like magic; there’s a formula for it! To calculate power needs based on different materials, you can use the formula: Power (HP) = Torque (lb-ft) × RPM / 5252. For example, steel needs more power than aluminum since it’s tougher, almost like comparing a bear to a kitten!

Here’s a quick example with common materials.

| Material | Torque (lb-ft) | RPM | Power (HP) |

|---|---|---|---|

| Aluminum | 2 | 1000 | 0.38 |

| Steel | 4 | 800 | 0.61 |

So, knowing how to balance these numbers helps keep your lathe happy and running smoothly. Remember, a well-fed lathe makes better parts!

Impact of Lead Screw Design on Power Efficiency

Relationship between lead screw pitch and power consumption. Improving efficiency through lead screw adjustments.Lead screw design matters more than we think! The pitch of the lead screw can impact power consumption significantly. A steeper pitch means more movement per turn, but it can also drain more power. Adjusting the lead screw can improve efficiency and reduce energy use. Imagine a hamster wheel; the right angle means faster running with less energy wasted! Getting the pitch just right helps machines save power while doing heavy lifting, so they don’t become lazy couch potatoes!

| Lead Screw Pitch | Power Consumption |

|---|---|

| Low Pitch | Lower Power |

| High Pitch | Higher Power |

Common Issues and Solutions

Common powerrelated problems in metal lathes. Maintenance tips to ensure consistent power delivery.Many metal lathes face power problems. Common issues include poor power supply and overloaded circuits. These can lead to uneven performance. Regular maintenance helps keep power steady. Here are some effective tips:

- Check wiring often.

- Inspect the motor for wear.

- Keep all connections tight.

- Clean the machine regularly.

- Use quality parts for replacements.

Taking care of your lathe can prevent many issues. Do regular checks to ensure everything runs smoothly.

What should I do if my lathe loses power?

If your lathe loses power, check the power supply first. Make sure the plug is connected. Look for blown fuses as well. If the problem continues, consider seeking help from an expert. Regular maintenance can help avoid these problems.

Real-World Applications and Case Studies

Examples of metal lathe projects requiring specific power needs. Case studies showcasing successful power management in machining.Many metal lathe projects need certain power levels to work well. For example, building parts for cars or machines often requires high torque and steady power. Successful power management can improve production. Here are some examples:

- Precision parts for racing cars, needing consistent power for speed.

- Industrial machines that require heavy-duty power for big tasks.

- Artistic metalwork demanding delicate power control for fine details.

These projects show how careful power choice leads to great results.

What are some real-world examples of lathe projects?

One example is creating engine components that need precise measurements. Another is making custom tools for other machines. Each project shows how power choices matter.

Future Trends in Lathe Technology

Innovations in lathe power requirements. Future developments in lead screw technology and their implications.Exciting changes are coming to lathe technology! Innovators are working on power requirements that make machines quieter and more efficient. Imagine a lathe that runs on less energy but works even better—it’s like a superhero for your workshop!

Meanwhile, lead screws are getting a makeover. Future designs may use smart materials that adapt to the job, making them stronger and more precise. Think of it as upgrading from a bicycle to a jetpack! With these advancements, we can expect smoother operations and more creative possibilities in metalworking.

| Innovation | Benefit |

|---|---|

| Energy-efficient motors | Lower power bills! |

| Adaptive lead screws | Increased accuracy! |

The future looks bright for lathe technology, and the possibilities are endless!

Conclusion

In summary, understanding lathe power requirements helps you choose the right metal lathe. The lead screw plays a vital role in movement and precision. By knowing these aspects, you can work more effectively. Explore more about lathes and their components to enhance your skills. Remember, practice makes perfect, so keep experimenting with your tools!FAQs

Here Are Five Related Questions On The Topic Of Lathe Power Requirements, Specifically Focusing On Metal Lathes And Lead Screws:Sure! When you use a metal lathe, it needs power to spin the metal and cut shapes. The lead screw helps move the tool up and down or side to side. For small tasks, a less powerful machine works well. But for big jobs, you need a stronger lathe. Always check the power needs before starting a project!

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Power Requirements Of A Metal Lathe When Machining Different Materials?The power needed for a metal lathe depends on the material you’re using. Hard materials, like steel, need more power than soft ones, like aluminum. The shape of what you’re making also matters. If it’s a complicated shape, the lathe requires more energy to cut. Lastly, the speed you choose can affect the power too; faster speeds usually need more power.

How Does The Size And Design Of The Lead Screw Impact The Overall Efficiency And Power Consumption Of A Metal Lathe?The lead screw is part of a metal lathe that helps move the tool. If the lead screw is bigger or designed better, it can move more smoothly. This smooth movement means the machine uses less power. When we use less power, it helps save energy and makes everything work better. So, the right size and design can make a big difference in how well the lathe works.

What Are The Typical Power Ratings For Various Sizes Of Metal Lathes, And How Do They Relate To Lead Screw Performance?Metal lathes come in different sizes, and their power ratings usually range from 1 to 10 horsepower (HP). A small lathe might have around 1 HP, while a big lathe can have 10 HP or more. The power helps the lathe turn and shape metal smoothly. The lead screw, which helps move the tool, works better with more power. So, stronger lathes often make cutting easier and more precise.

How Can Improper Alignment Or Wear In The Lead Screw Affect The Power Requirements During Machining Operations On A Metal Lathe?If the lead screw isn’t lined up right or it’s worn out, it makes the lathe work harder. This means you need more power to turn the metal. You might also notice the lathe moving unevenly or sticking. Overall, it can slow down your work and make it less smooth.

What Considerations Should Be Taken Into Account When Selecting A Motor For A Metal Lathe To Ensure Adequate Power For The Lead Screw And Overall Machining Process?When picking a motor for a metal lathe, you need to think about its power. The motor should be strong enough to turn the lead screw and handle different materials. You also need to look at the speed of the motor. Faster speeds can help you work quicker. Lastly, make sure the motor fits well with your lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Power Requirements, Specifically Focusing On Metal Lathes And Lead Screws:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you use a metal lathe, it needs power to spin the metal and cut shapes. The lead screw helps move the tool up and down or side to side. For small tasks, a less powerful machine works well. But for big jobs, you need a stronger lathe. Always check the power needs before starting a project!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Power Requirements Of A Metal Lathe When Machining Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power needed for a metal lathe depends on the material you’re using. Hard materials, like steel, need more power than soft ones, like aluminum. The shape of what you’re making also matters. If it’s a complicated shape, the lathe requires more energy to cut. Lastly, the speed you choose can affect the power too; faster speeds usually need more power.”}},{“@type”: “Question”,”name”: “How Does The Size And Design Of The Lead Screw Impact The Overall Efficiency And Power Consumption Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw is part of a metal lathe that helps move the tool. If the lead screw is bigger or designed better, it can move more smoothly. This smooth movement means the machine uses less power. When we use less power, it helps save energy and makes everything work better. So, the right size and design can make a big difference in how well the lathe works.”}},{“@type”: “Question”,”name”: “What Are The Typical Power Ratings For Various Sizes Of Metal Lathes, And How Do They Relate To Lead Screw Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes come in different sizes, and their power ratings usually range from 1 to 10 horsepower (HP). A small lathe might have around 1 HP, while a big lathe can have 10 HP or more. The power helps the lathe turn and shape metal smoothly. The lead screw, which helps move the tool, works better with more power. So, stronger lathes often make cutting easier and more precise.”}},{“@type”: “Question”,”name”: “How Can Improper Alignment Or Wear In The Lead Screw Affect The Power Requirements During Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lead screw isn’t lined up right or it’s worn out, it makes the lathe work harder. This means you need more power to turn the metal. You might also notice the lathe moving unevenly or sticking. Overall, it can slow down your work and make it less smooth.”}},{“@type”: “Question”,”name”: “What Considerations Should Be Taken Into Account When Selecting A Motor For A Metal Lathe To Ensure Adequate Power For The Lead Screw And Overall Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a motor for a metal lathe, you need to think about its power. The motor should be strong enough to turn the lead screw and handle different materials. You also need to look at the speed of the motor. Faster speeds can help you work quicker. Lastly, make sure the motor fits well with your lathe.”}}]}