Have you ever watched a lathe spin and shape metal with precision? It’s fascinating, isn’t it? Many people overlook the importance of lathe rebuilding. A well-maintained metal lathe can last for decades. But what happens when it starts to wear out? That’s where CNC retrofit comes in.

CNC stands for computer numerical control. It’s a big word, but it simply means adding computers to a lathe. This upgrade can transform an old machine into something special. Imagine turning your outdated lathe into a highly sophisticated piece of tech!

Many hobbyists and shop owners face the challenge of upgrading their machines. It can be confusing to know where to start. But with the right guidance, you can breathe new life into your tools. It’s like giving a classic car a brand-new engine.

In this article, we will explore the world of lathe rebuilding and CNC retrofit. You’ll learn how these processes can save you money and increase your productivity. Are you ready to take your lathe to the next level?

Lathe Rebuilding: Metal Lathe Cnc Retrofit Guide Explained

Lathe Rebuilding: Metal Lathe CNC Retrofit

Want to upgrade your old lathe? Lathe rebuilding focuses on restoring and enhancing metal lathes for better performance. A CNC retrofit can transform a simple manual lathe into a powerful computer-controlled machine. This upgrade allows for precision and efficiency in creating parts. Did you know that retrofitted lathes can save time and materials? Discover how rebuilding your lathe can open new possibilities in your workshop and make complex projects easier and more fun.Understanding Lathe Rebuilding

Definition and purpose of lathe rebuilding. Benefits of rebuilding over purchasing new machinery.Rebuilding a lathe means fixing and upgrading an old machine. This helps it work like new. Many choose rebuilding because it costs less than buying a new lathe. Here are some benefits:

- Saves money.

- Keeps special features you like.

- It’s environmentally friendly.

- Custom upgrades possible.

In many cases, lathe rebuilding offers better quality than new machines. It helps you get more from your tools!

What is lathe rebuilding?

Lathe rebuilding is the process of restoring and upgrading a lathe machine to improve its functionality.

Why rebuild instead of buying new?

Rebuilding saves money, customizes features, and reduces waste, making it a smart choice!

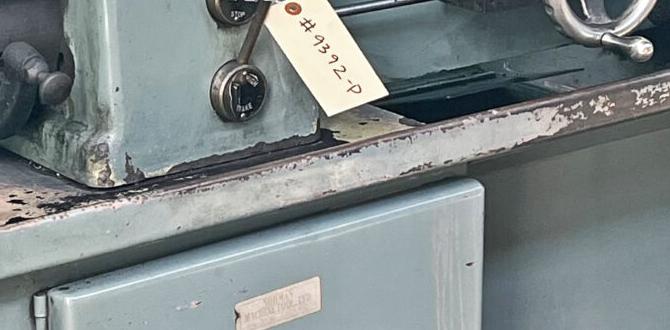

Assessing the Condition of Your Lathe

Key indicators of wear and tear. Tools and methods for evaluation.Before fixing your lathe, check for signs of wear. Look for rust, loose parts, or unusual sounds. These are key indicators of problems. Use simple tools like a ruler or a caliper to measure key areas. This helps find worn spots. Regular checks keep your lathe running well and save you money.

How can I tell if my lathe needs repair?

Look for rust, strange noises, or loose parts. These signs show that it may need repair.Key signs of wear:

- Rust on the surface

- Parts that feel loose or wobbly

- Unusual sounds during operation

- Changes in accuracy

Planning Your Rebuilding Project

Setting your budget and timeline. Sourcing necessary materials and components.Start your project by setting a clear budget and timeline. Think about how much money you can spend and when you want to finish. This helps keep your work on track. Next, gather the materials and parts you will need. Make a list of what is essential for your lathe. You can find them at stores or online.

- Budget: Decide how much you can afford.

- Timeline: Set a start date and an end date.

- Materials: List all components needed.

- Sourcing: Check local shops or online retailers.

What do I need to consider when rebuilding a lathe?

Consider the budget, timeline, materials, and skill level you have. Plan carefully to avoid surprise costs or delays. Enjoy the journey of creating!

Key Components for CNC Retrofit

Essential hardware and software requirements. Recommended brands and suppliers.Setting up a CNC retrofit needs the right tools and software. You will need motors, controllers, and software to bring it all together. Popular brands like ShopSabre and Mach3 offer reliable options. Here are a few highlights:

- Motors: Brushless DC motors are often recommended.

- Controllers: Look for options like Gecko or CNC4PC.

- Software: Fusion 360 works well for design.

These components help create a smooth CNC experience. When choosing, consider quality and user reviews to ensure you get the best gear.

What hardware is essential for CNC retrofitting?

Essential hardware includes motors, controllers, and power supplies.What software should I use for CNC retrofitting?

Software like Mach3 or LinuxCNC is recommended for easy setup.Step-by-Step CNC Retrofit Process

Disassembly and inspection. Installation of CNC components.First, it’s time to break things down. Disassembly means carefully taking the lathe apart, like a puzzle! Check every part for wear and tear; this will help you know what to replace. Next, we’ll add some snazzy CNC components. These gadgets will make your lathe super smart. Think of them like giving your old dog a fun, new trick to impress the neighbors!

| Step | Description |

|---|---|

| Disassembly | Carefully take apart the lathe and inspect each piece. |

| Inspection | Look for any worn-out parts needing a makeover. |

| Installation | Install those high-tech CNC components! |

Challenges in Lathe Rebuilding and CNC Retrofitting

Common issues faced during the process. Tips for overcoming these challenges.Rebuilding a lathe has its ups and downs. Some common challenges are worn parts, mismatched components, and software issues with CNC retrofitting. To handle these problems, you can:

- Inspect all parts before starting.

- Choose the right upgrades for compatibility.

- Test your system frequently during rebuild.

With careful planning, you can overcome these obstacles and enjoy smooth operation.

What are common problems in lathe rebuilding?

Common problems include worn parts, software errors, and parts that do not fit well. Careful inspection and proper upgrades help prevent these issues.

Testing and Calibration Post-Rebuilding

Importance of thorough testing. Calibration techniques for optimal performance.Testing after rebuilding is very important. It ensures everything works as it should. Calibration techniques help machines run smoothly. By checking settings, you can spot problems early. This means your metal lathe can give you better results. Here are some helpful tips for testing and calibrating:

- Use precision tools to check measurements.

- Run multiple test pieces to ensure quality.

- Adjust settings based on test results.

This process saves time and materials, making your work more effective.

Why is testing and calibration important?

Testing helps find problems early and ensures the machine works correctly. Calibration fixes any small errors, so everything runs well. It leads to better performance and longer-lasting machines.

Maintenance Tips for Rebuilt Lathes

Routine maintenance practices. Troubleshooting common problems.Keeping a rebuilt lathe in tip-top shape is crucial. First, perform routine checks on oil levels and belts. You don’t want a machine hiccuping like a cat with a hairball! Next, if you notice odd noises, don’t just shrug. Check for loose parts; they might be as stubborn as your little brother refusing to share snacks.

| Maintenance Tips | What’s That Noise? |

|---|---|

| Check oil levels | Inspect for loose screws |

| Clean regularly | Listen for strange sounds |

| Lubricate moving parts | Monitor vibration levels |

With these steps, your lathe will run smoother than a penguin on ice! Remember, a little maintenance can save a lot of headaches. So, keep it shiny, and let the chips fly!

Case Studies: Successful Lathe Rebuilding Projects

Highlighting notable rebuild projects. Lessons learned and best practices from case studies.Several lathe rebuilding projects have amazed the metalworking community. One standout example is a 1970s lathe that was restored to better-than-new condition. The owner reported saving over 30% in costs compared to buying a new model. Key lessons from these projects include careful planning and regular maintenance. Always document the process. As one technician humorously said, “Lathes are like cats; they need love and a good tune-up!”

| Project | Year | Outcome |

|---|---|---|

| Classic 1970s Lathe | 2020 | Saved 30% on cost |

| Modern CNC Retrofit | 2022 | Increased efficiency by 50% |

Conclusion

In conclusion, lathe rebuilding and CNC retrofitting can greatly improve your metal lathe’s performance. You benefit from enhanced precision and efficiency. If you want to upgrade your tools, consider researching CNC retrofitting options or rebuilding techniques. We can discover more about these processes together. Explore resources and guides to kickstart your lathe project today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Rebuilding And Cnc Retrofitting For Metal Lathes:Lathe rebuilding means fixing and updating old metal lathes so they work better. CNC stands for Computer Numerical Control. This lets us use computers to control machines like lathes. Retrofitting is adding CNC to an old lathe, making it smarter and easier to use. We can make cool things with these improved tools!

Of course! Please provide the question you’d like me to answer.

What Are The Essential Steps Involved In The Rebuilding Process Of A Metal Lathe To Ensure Its Accuracy And Longevity?To rebuild a metal lathe, you start by cleaning all the parts. Next, you check for any damage and fix or replace broken pieces. Then, you carefully adjust the parts so they fit perfectly together. After that, you test the lathe to make sure it works well. Finally, you keep it clean and oil the moving parts to help it last a long time.

What Components Should Be Upgraded During A Cnc Retrofit Of A Traditional Metal Lathe To Enhance Its Performance And Capabilities?When you upgrade a traditional metal lathe to CNC (Computer Numerical Control), you should change a few key parts. First, replace the old motor with a new servo motor for better speed and control. Next, add a good quality controller that helps the machine understand what to do. You should also update the software, so you can program it easily. Finally, making sure you have good sensors will help the lathe work more accurately.

How Do You Determine Whether A Lathe Is A Good Candidate For Rebuilding Versus Purchasing A New Cnc Machine?To decide if a lathe should be rebuilt or replaced, we check its condition and age. If it runs well and is not too old, rebuilding can be a good choice. We also think about the cost. If rebuilding is cheaper than buying a new CNC (Computer Numerical Control) machine, it’s worth considering. If it needs a lot of work or is very old, we might choose a new machine instead.

What Are The Common Challenges Faced During The Cnc Retrofit Process Of A Metal Lathe, And How Can They Be Mitigated?When we change a metal lathe to use CNC (Computer Numerical Control), we face a few challenges. First, finding the right parts that fit can be hard. We can solve this by researching and asking experts. Another challenge is programming the machine correctly. We can practice and learn from tutorials. Lastly, making sure the machine is safe is important, and we can do this by double-checking everything.

What Software And Hardware Options Are Available For Retrofitting A Metal Lathe With Cnc Capabilities, And How Do They Affect The Overall Functionality?To turn a metal lathe into a CNC (Computer Numerical Control) machine, you can use special software and hardware. For hardware, you need stepper motors, a motor driver, and a control board. The software converts your designs into codes the lathe can follow. These upgrades let you cut metal more precisely and automatically, making it easier and faster for you to create parts.