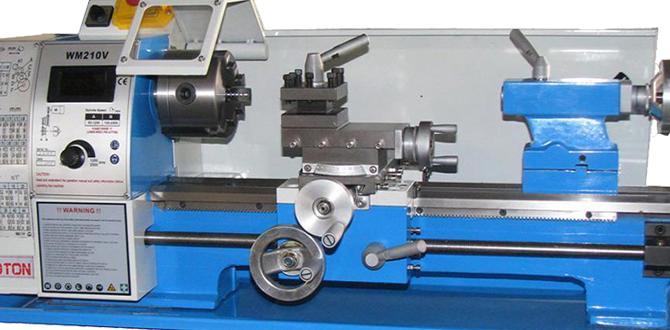

Imagine you’re in a workshop, surrounded by tools and machines. A metal lathe stands proudly in the corner. But wait! Does it work like it used to? Over the years, lathes can wear out. They often need a little TLC, especially when it comes to their controller board.

Have you ever thought about what makes a lathe run smoothly? The controller board is the brain of the lathe. It tells the machine what to do. Without a proper controller board, your metal lathe may struggle to function. This can lead to poor precision and frustration.

In this article, we will explore the exciting world of lathe rebuilding. You’ll learn about the importance of a reliable metal lathe controller board. We’ll dive into why upgrading or replacing it can make all the difference in your projects. Grab your tools, and let’s get started on this journey of repair and improvement!

Lathe Rebuilding: Upgrading Your Metal Lathe Controller Board

Lathe Rebuilding: Metal Lathe Controller Board

Rebuilding a metal lathe can be an exciting challenge. A controller board is key for smooth operation. These boards manage speed, direction, and precision of cuts. Did you know you can upgrade your old lathe with modern technology? This can make your projects faster and more accurate. It’s like giving your tools a new life! When considering rebuilding, think about compatibility and features. The right controller board can transform your metalworking experience.Understanding Metal Lathe Controller Boards

Definition and purpose of a metal lathe controller board. Importance of upgrading and maintaining controller boards.A metal lathe controller board is like the brain of your lathe machine. It tells the machine what to do. These boards help control speed, direction, and movement. Keeping your controller board in good shape is important. Upgrading can make your lathe work better and last longer. Did you know that a small upgrade can boost efficiency by up to 20%? That’s like finding extra fries at the bottom of the bag! Regular maintenance also prevents big problems down the road, saving you time and money.

| Benefit | Description |

|---|---|

| Increased Precision | Better control means more accurate cuts. |

| Longer Lifespan | Regular upkeep prevents unexpected failures. |

| Cost Savings | Upgrading can save you repair costs over time. |

Common Issues with Metal Lathe Controller Boards

Typical problems faced by users. Signs that indicate a need for rebuilding.Users often face issues with metal lathe controller boards. Common problems can include sudden power failures or erratic movements. These signs might suggest a need for rebuilding. Watch for:

- Unusual noises during operation.

- Inconsistent speed control.

- Frequent error messages on the display.

Addressing these issues quickly can save time and effort, making your work more efficient!

What are the signs you need to rebuild your lathe controller board?

If you notice signs like frequent error messages or strange noises, it’s time to rebuild. Ignoring these can lead to damage or safety risks.

Tools and Materials Needed for Rebuilding

Essential tools for the rebuilding process. Recommended materials and replacement parts.To rebuild your lathe, start with some key tools. You will need a wrench, screwdriver, and pliers. Additionally, a protective face shield is important for safety. For replacement parts, consider new bearings, belts, and seals. Choosing the right materials can greatly affect your project.

- Wrench

- Screwdriver

- Pliers

- Face shield

- Bearings

- Belts

- Seals

What tools do I need for lathe rebuilding?

You will need tools like wrenches, screwdrivers, and pliers. A face shield keeps you safe while you work!

Step-by-Step Rebuilding Process

Detailed steps for disassembling the controller board. Instructions for cleaning and repairing components.To rebuild the controller board, start by carefully taking it apart. This means removing all screws and clips. Make sure to draw a simple map of where each part goes. Next, it’s time to clean. Use gentle soap and water on the surface. For stubborn dirt, a small brush helps. Look for broken pieces, too. If you find damage, replace these parts with new ones. This step ensures everything works smoothly.

What tools do I need to rebuild a lathe controller board?

You’ll need basic tools like a screwdriver, a cleaning brush, and a multimeter. These tools help you safely take apart and check the parts. Make sure you have spare parts ready for repair.

Upgrading Components for Enhanced Performance

Best practices for selecting new components. How upgraded parts can improve efficiency and accuracy.Choosing the right components is key to better machine performance. First, consider quality over price. Upgraded parts can lead to better efficiency and greater accuracy. High-quality components last longer and need less maintenance. Here are some tips:

- Pick reliable brands.

- Check reviews before buying.

- Ensure compatibility with your machine.

With these new parts, you may notice your tasks get done faster and more precisely, making your work easier and more fun!

What are the best components to upgrade for improved lathe performance?

Upgrading the controller board, motor, and bearings improves speed and accuracy. These changes help your lathe work better and last longer.

Testing and Calibration After Rebuilding

Techniques for testing the functionality of the rebuilt board. Calibration methods to ensure optimal performance.After rebuilding your metal lathe controller board, testing and calibration are key steps. First, check all connections. Then, use a multimeter to ensure proper voltage. Verify functionality by running simple programs. For calibration, adjust settings based on your machine’s specifications. This ensures accurate performance. Remember, regular tests keep your lathe working smoothly.

What are some effective testing techniques?

Effective techniques include checking connections, using a multimeter, and running test programs.

Calibration methods include:

- Adjusting settings based on machine specs.

- Testing responses during operation.

- Making small adjustments for accuracy.

Preventive Maintenance Tips for Longevity

Routine maintenance practices to extend the life of the controller board. Signs to watch for to prevent future issues.To keep your controller board running smoothly, practice routine maintenance. Clean it regularly to remove dust and dirt. Check the connections for loose wires. Monitor its temperature; overheating can cause issues. Pay attention to strange sounds or behaviors. These can be warning signs of problems. If you notice flickering lights or errors, address them quickly.

- Clean dust and debris.

- Check wire connections.

- Watch for overheating.

- Listen for odd sounds.

- Address errors promptly.

What are the signs of problems with a controller board?

Watch for flickering lights, error messages, or unusual sounds. These signs can indicate that the board needs attention.

Resources and Support for Lathe Owners

Recommended forums, communities, and support groups. Additional reading materials and tutorials for further learning.Joining forums and communities is a great way to meet other lathe owners. They share tips and ask questions. Popular online places include:

- Reddit Lathe Community: Great for advice and stories.

- Garage Journal: Engage with experienced members.

- Facebook Groups: Many groups focused on metal lathes.

For further learning, check out tutorials and books about lathes. Websites like YouTube are full of helpful videos. These resources can help you improve your skills.

What should I read to learn more about lathes?

Check out books like “Machinery’s Handbook” or online tutorials. They offer step-by-step guides on using lathes and maintenance tips.

Conclusion

In conclusion, rebuilding a lathe with a new controller board can improve its performance and precision. You will enjoy better control and efficiency in your projects. Consider researching different controller boards to find the best option for your needs. We encourage you to explore tutorials and guides to help you with this exciting upgrade. Happy crafting!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Rebuilding And Metal Lathe Controller Boards:Sure! Rebuilding a lathe means fixing it to make it work like new. A metal lathe is a machine that shapes metal into different forms. Controller boards help control how the lathe works. We can use them to make our lathes do more things. It’s fun to learn how machines work!

Sure! Just let me know what question you’d like me to answer.

What Are The Key Components Of A Metal Lathe Controller Board That Should Be Checked Or Replaced During A Rebuild?When rebuilding a metal lathe controller board, check the power supply first. This part gives energy to the whole board. Next, look at the main microcontroller, which is like the brain of the machine. We should also check any wiring for frays or breaks. Finally, make sure the resistors and capacitors are working well, as they help control the electric flow.

How Can Upgrading The Controller Board Improve The Performance And Capabilities Of An Older Metal Lathe?Upgrading the controller board helps an old metal lathe work better and faster. You can get more precise cuts, which means your parts will fit together nicely. Newer boards often have extra features, like easier speed control. This makes it more fun and easier to use the lathe for projects. Overall, you can do more with it and make better things!

What Specific Features Should Be Looked For In A Modern Controller Board For Metal Lathes To Enhance Precision And Control?When choosing a controller board for metal lathes, look for a few important features. First, it should have high accuracy. This means it helps the machine make very small, precise cuts. Next, choose one with good speed control, so you can adjust how fast it works. Finally, make sure it has a user-friendly display. This helps you see and control everything easily.

What Are The Most Common Issues Faced During The Rebuilding Of A Lathe’S Controller Board, And How Can They Be Mitigated?When rebuilding a lathe’s controller board, we might face some common issues. One problem is connecting the wires incorrectly. To avoid this, we can label all the wires before we start working. Another issue is soldering parts poorly, which can cause bad connections. We can fix this by practicing soldering on a spare piece first. Lastly, it’s important to check if all parts are compatible to avoid problems later.

Can You Outline The Step-By-Step Process For Installing A New Controller Board In A Vintage Metal Lathe?Sure! Here’s how you can install a new controller board in a vintage metal lathe: 1. First, unplug the lathe so it’s safe to work on. 2. Open the lathe’s cover to reach the old controller board. 3. Carefully take out the old board by unscrewing it. 4. Connect the new controller board the same way the old one was connected. 5. Screw the new board in place and close the cover. 6. Finally, plug in the lathe and test it to see if it works.