Have you ever noticed how important a small tool can be? A lathe repair kit is one of those unsung heroes in any workshop. It often includes a metal lathe chuck key, which may seem minor, but it plays a big role in your projects. Imagine trying to adjust a piece of work without it!

These kits help keep metal lathes running smoothly. Regular maintenance is key to avoid bigger problems later on. A few simple tools can save you time and money. Did you know that even the smallest parts need care to function well?

Think about all the cool things you can make with a lathe. From custom furniture to intricate designs, the possibilities are endless. With a reliable lathe repair kit and a metal lathe chuck key, you can unleash your creativity and tackle any project that comes your way.

Comprehensive Guide To Lathe Repair Kit: Metal Lathe Chuck Key

Understanding Lathe Repair Kits and Chuck Keys

A lathe repair kit is essential for keeping your metal lathe in top shape. One important part of this kit is the lathe chuck key. It helps secure your workpiece, making cutting easier and safer. Without it, you might struggle or damage your projects. Did you know that using the right tools can save time and frustration? Invest in a reliable lathe repair kit to enhance your workshop experience. Keep your lathe running smoothly to achieve great results!Understanding Lathe Repair Kits

Definition and purpose of a lathe repair kit. Key components included in a typical repair kit.Lathe repair kits are special tool boxes, kind of like superhero capes for your lathe! They help fix any issues that pop up and keep your machines running smoothly. A typical repair kit includes essential parts such as bearings, screws, and that famous lathe chuck key, which helps you tighten and loosen the chuck (that’s where the magic happens!).

| Component | Purpose |

|---|---|

| Bearings | Make things spin like a top! |

| Screws | Hold everything together, like friendship! |

| Lathe Chuck Key | Unlocks the chuck, like finding a treasure map! |

With these components, you can avoid panic mode and keep your lathe in tip-top shape. Who knew fixing stuff could be this much fun?

Importance of a Metal Lathe Chuck Key

Explanation of a chuck key’s function in metal lathes. Types of chuck keys available and their applications.A metal lathe chuck key is like the trusty sidekick of a superhero. It tightens and loosens the chuck, which holds the workpiece in place. Without it, your metal lathe would be like a pizza without toppings—pretty useless! There are a few types of chuck keys, including the T-handle and the pin type. Each serves a purpose, whether for tight spaces or larger projects. Remember, a well-chosen chuck key keeps tools from flying off unexpectedly, and that’s always a good thing!

| Type of Chuck Key | Application |

|---|---|

| T-handle | Great for quick adjustments. |

| Pin type | Ideal for tight spaces. |

| Hex key | Good for specific machines. |

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a repair kit. Compatibility with different lathe models.Finding the right lathe repair kit is like choosing a pizza topping—some combos just work better! First, check compatibility with your lathe model. Not every kit fits every machine. Look for kits designed for your specific model. The wrong key could turn your lathe into a fancy paperweight! Make sure the parts match, like peanut butter and jelly. A good kit will also have all the essential pieces you need to keep things spinning smoothly.

| Factor | Description |

|---|---|

| Compatibility | Ensure it fits your lathe model! |

| Complete Set | Includes all necessary parts for fixes. |

| Quality Materials | Made to last, not just for the weekend! |

How to Use a Lathe Repair Kit Effectively

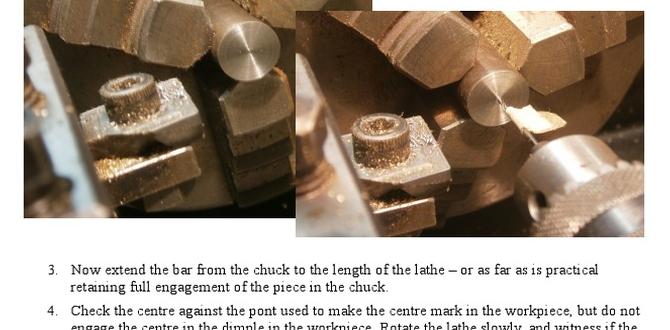

Stepbystep guide to repairing common lathe issues. Tips for maintaining your lathe after repairs.Repairing your lathe can seem tricky, but it isn’t too hard! Start by identifying the problem. Is it the chuck key that won’t turn? Grab your lathe repair kit and get started! Follow these steps:

| Step | Action |

|---|---|

| 1 | Inspect the chuck key and any loose parts. |

| 2 | Replace worn-out components with the new ones from your kit. |

| 3 | Test the lathe to ensure everything moves smoothly. |

To keep your lathe happy after repairs, clean it regularly and check for any strange noises. Remember, a happy lathe makes for happy projects! If your lathe starts acting like a moody teenager again, don’t panic—just repeat these steps!

Top Features to Look for in a Metal Lathe Chuck Key

Material durability and design considerations. Ergonomic features for ease of use.When choosing a metal lathe chuck key, look for a few key features. First, consider material durability. A strong key can last longer and perform better. Next, design matters too. An ergonomic design helps users grip it comfortably. This makes work easier and safer. Here are some highlights:

- Strong materials like steel or aluminum.

- Good design for easy grip.

- Lightweight for easy handling.

These factors make a big difference. A well-made chuck key can save time and effort.

What should I look for in a metal lathe chuck key?

Focus on durable materials and an ergonomic design. These two features ensure comfort and longevity, making your tasks smoother and quicker.

Common Issues and Solutions with Metal Lathe Chuck Keys

Troubleshooting common problems encountered with chuck keys. Preventative measures to avoid chuck key issues.Metal lathe chuck keys can act a bit stubborn sometimes. Common problems include them getting stuck or not fitting properly. If your key is refusing to turn, try a bit of lubricant to loosen it up. Prevention is better than cure! Always clean your chuck key after use to keep it happy. Even a chuck key gets cranky when dirty!

| Issue | Solution | Prevention |

|---|---|---|

| Key stuck | Use lubricant | Clean after use |

| Poor fit | Check for damage | Store properly |

| Slippage | Adjust tension | Regular maintenance |

By keeping it clean and checking for wear, your chuck key will work like a charm and avoid unnecessary drama. Happy lathing!

Best Practices for Maintaining Lathe Repair Kits and Chuck Keys

Storage and organization tips. Regular maintenance routines to extend lifespan.Keeping your lathe repair kit and chuck keys organized can save you from a tool hunt that resembles a treasure hunt, minus the gold! Store them in a designated toolbox or drawer, so they won’t play hide and seek. Regularly check and clean your tools; a tiny bit of oil can work wonders. Think of it as giving your tools a spa day. Use a soft cloth and wipe them after each use to keep rust away.

| Maintenance Tips | Frequency |

|---|---|

| Check for rust | Every use |

| Clean with a soft cloth | After each use |

| Apply oil | Weekly |

By following these simple steps, your lathe repair kit and chuck keys will stay happy and last longer! Remember, happy tools make for happy projects!

Conclusion

In summary, a lathe repair kit with a metal lathe chuck key is essential for keeping your lathe working well. It helps you fix problems quickly and easily. Knowing how to use these tools can save you time and money. We encourage you to explore more about lathe maintenance to become a skilled craftsman. Happy tinkering!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Repair Kits And Metal Lathe Chuck Keys:A lathe repair kit helps fix problems with lathes, which are machines that shape metal. It usually has tools and parts you need. A metal lathe chuck key is a special tool that helps you tighten or loosen parts on the lathe. If you break something, having a repair kit is super handy. It helps you get back to your project faster!

Of course! Please provide the question you want me to answer, and I’ll be happy to help!

What Components Are Typically Included In A Lathe Repair Kit For Metal Lathes?A lathe repair kit for metal lathes usually includes a few important parts. You might find wrench tools to help tighten things. There are also bearings, which make moving parts smooth. Some kits have a cleaning brush to keep everything tidy. Lastly, you’ll find oil to help everything run well.

How Do You Determine The Correct Size Of A Chuck Key For Your Metal Lathe?To find the right size of a chuck key for your metal lathe, first, check the lathe’s manual. It usually tells you the required size. You can also measure the teeth of the chuck (the part that holds the tool) with a ruler. If you can’t measure it, try using different keys until you find one that fits snugly. Remember, a good fit is important for safety and work.

What Are The Common Signs That A Lathe Chuck Key May Need To Be Replaced?You should check your lathe chuck key for signs of wear. If it has cracks or breaks, it needs a new one. If the teeth are worn down and don’t grip well, it’s time to replace it. Also, if it feels loose and doesn’t turn easily, you should get a new key. Keeping a good chuck key helps your tools work better!

Can You Repair A Damaged Chuck Key, Or Is It Better To Replace It Entirely?You can try to repair a damaged chuck key, but it’s often better to replace it. If the teeth are broken or if it doesn’t fit well, a new one works much better. A good chuck key helps you use your tools safely. It’s usually not very expensive, so buying a new one can save you time and trouble.

What Safety Precautions Should Be Taken When Using A Metal Lathe With A Chuck Key?When using a metal lathe with a chuck key, always wear safety glasses to protect your eyes. Keep your hands away from the spinning parts. Make sure the chuck key is fully removed before starting the machine. Don’t wear loose clothes or jewelry that could get caught. Lastly, stay focused and don’t distract others while they work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Repair Kits And Metal Lathe Chuck Keys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit helps fix problems with lathes, which are machines that shape metal. It usually has tools and parts you need. A metal lathe chuck key is a special tool that helps you tighten or loosen parts on the lathe. If you break something, having a repair kit is super handy. It helps you get back to your project faster!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you want me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Components Are Typically Included In A Lathe Repair Kit For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for metal lathes usually includes a few important parts. You might find wrench tools to help tighten things. There are also bearings, which make moving parts smooth. Some kits have a cleaning brush to keep everything tidy. Lastly, you’ll find oil to help everything run well.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Size Of A Chuck Key For Your Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right size of a chuck key for your metal lathe, first, check the lathe’s manual. It usually tells you the required size. You can also measure the teeth of the chuck (the part that holds the tool) with a ruler. If you can’t measure it, try using different keys until you find one that fits snugly. Remember, a good fit is important for safety and work.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That A Lathe Chuck Key May Need To Be Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check your lathe chuck key for signs of wear. If it has cracks or breaks, it needs a new one. If the teeth are worn down and don’t grip well, it’s time to replace it. Also, if it feels loose and doesn’t turn easily, you should get a new key. Keeping a good chuck key helps your tools work better!”}},{“@type”: “Question”,”name”: “Can You Repair A Damaged Chuck Key, Or Is It Better To Replace It Entirely?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can try to repair a damaged chuck key, but it’s often better to replace it. If the teeth are broken or if it doesn’t fit well, a new one works much better. A good chuck key helps you use your tools safely. It’s usually not very expensive, so buying a new one can save you time and trouble.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Metal Lathe With A Chuck Key?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with a chuck key, always wear safety glasses to protect your eyes. Keep your hands away from the spinning parts. Make sure the chuck key is fully removed before starting the machine. Don’t wear loose clothes or jewelry that could get caught. Lastly, stay focused and don’t distract others while they work.”}}]}