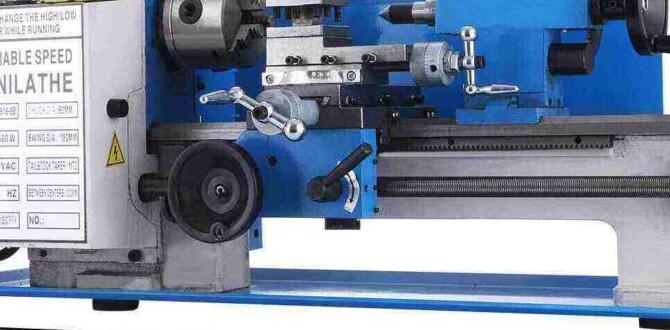

Have you ever wondered how machines make precise metal parts? One essential tool in many workshops is the metal lathe. These machines can shape, cut, and finish metal quickly and accurately. But what happens when a gear breaks? That’s where a lathe repair kit comes in.

Imagine you are in the middle of an important project. Suddenly, your lathe stops working. Frustrating, right? But don’t worry! With a lathe repair kit, you can fix it yourself. These kits include everything you need to get your machine back in shape.

Did you know that regular maintenance can double the life of your lathe? Using a lathe repair kit helps keep your metal lathe running smoothly. You’ll save time and money in the long run. Learning about lathe repair kits can empower you as a maker. It might even inspire you to start new projects!

So, let’s dive in and explore the world of lathe repair kits and gears. You never know what you might discover!

Essential Lathe Repair Kit: Metal Lathe Gear Components

Lathe Repair Kit: Metal Lathe Gear Insights

Choosing the right lathe repair kit for metal lathe gear can save you time and money. These kits often come with essential parts like gears, belts, and bearings. Imagine fixing your lathe with ease instead of facing costly repairs. Did you know that proper maintenance can extend the life of your lathe? With the right tools, you can keep your machines running smoothly. Invest in a quality kit and enjoy hassle-free projects!Understanding Lathe Repair Kits

Definition and purpose of lathe repair kits. Components commonly found in lathe repair kits.Lathe repair kits help fix and maintain lathe machines. These kits include everything needed for quick repairs. Key parts usually found in lathe repair kits are:

- Gears

- Bearings

- Screws

- Tools

- Seals

Having a repair kit makes it easier to keep your lathe running smoothly. This saves time and money in the long run.

What is in a lathe repair kit?

The main parts include gears, seals, and bearings. These components help fix minor issues. Knowing how to use these parts can extend the life of your lathe.

Importance of Proper Maintenance for Metal Lathes

Benefits of regular maintenance on performance and longevity. Common issues arising from neglecting lathe maintenance.Keeping your metal lathe happy is key to its success. Regular maintenance not only improves performance but can also make your machine last a long time. Think of it like giving your pet a good grooming – a little care goes a long way! On the flip side, ignoring maintenance can lead to common problems. You could face annoying breakdowns and costly repairs that could have been avoided. Here’s a quick look at why keeping up with those lathe love sessions is important:

| Maintenance Benefits | Neglect Issues |

|---|---|

| Increases performance | Frequent breakdowns |

| Extends lifespan | Decreased accuracy |

| Saves money on repairs | Unexpected downtime |

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a lathe repair kit. Compatibility with different types of metal lathes.Picking the right lathe repair kit is like choosing the best toppings for your pizza. You need to consider what fits your metal lathe best! First, think about compatibility. Not all kits work with every lathe. This means checking which type of gear matches your machine is a must. Next, consider the quality of parts. A great kit can be the difference between a smooth operation and a wobbly mess. Remember, you want your lathe to hum like a happy bee, not clank like a rusty gate!

| Factor | Description |

|---|---|

| Compatibility | Ensure the kit matches your lathe type. |

| Quality | Good parts mean better performance. |

| Ease of Installation | Look for kits that are easy to use. |

Step-by-Step Guide to Using a Lathe Repair Kit

Detailed instructions for repairing common gear issues. Best practices for effective repairs.Facing gear troubles? Don’t panic! Grab your lathe repair kit and let’s tackle those issues. Start by identifying which gear is making a fuss. Check for wear and tear or loose parts. Use the right tools to tighten screws or replace damaged gears. Remember, a little grease can go a long way in keeping things smooth! Here’s a handy guide to keep you on track:

| Step | Description |

|---|---|

| 1 | Identify the issue with your gear. |

| 2 | Tighten any loose screws. |

| 3 | Replace damaged parts if needed. |

| 4 | Add lubricant to keep gears moving. |

Following best practices makes repairs effective and can save you time and money. Keep your workspace organized and don’t forget to wear safety glasses. They make you look cool and protect your eyes!

Cost-Effectiveness of DIY Lathe Repairs

Analysis of expenses related to professional repairs versus DIY. Longterm savings from using a lathe repair kit.Fixing your lathe yourself can save you a chunk of change. Professional repairs can make your wallet feel lighter, while a repair kit keeps it full! Just think, why pay someone else when you can channel your inner handyman?

| Repair Method | Cost |

|---|---|

| Professional Repair | $150 – $300 |

| DIY with Repair Kit | $30 – $80 |

Long-term savings really add up with DIY repairs. By using a lathe repair kit, you’ll not only fix your gear but also impress your friends—”Look, Mom! I fixed it!” Who needs expensive services when your toolkit can do the job?

Frequently Asked Questions About Lathe Repair Kits

Answers to common queries regarding usage and maintenance. Troubleshooting tips for common repair challenges.Many people wonder how to get the most from their lathe repair kits. First and foremost, using the right tools is vital. Proper usage helps ensure safety and efficiency. Remember to keep your lathe clean. A tidy workspace makes it easier to spot problems. If you struggle with repairs, don’t fret! Check for loose screws or worn-out parts. These common issues may cause headaches, but they are usually fixable! Here’s a helpful table:

| Common Issues | Troubleshooting Tips |

|---|---|

| Noise | Check for loose gears. |

| Power Loss | Inspect the power supply and connections. |

| Inaccurate Cuts | Ensure the lathe is leveled and aligned. |

Confused? Don’t give up! Many people face these issues. You’re not alone! Just keep calm and fix on!

Recommended Lathe Repair Kits on the Market

Review of popular lathe repair kits with pros and cons. User testimonials and experiences with different kits.Finding the right lathe repair kit can feel like searching for the Holy Grail. Many kits are popular, each with strengths and weaknesses. For example, the XYZ kit has strong gears, but some users mention it’s tricky to install. Another favorite, the ABC kit, is praised for its ease but may lack some parts. User experiences vary, like trying to like a pizza topping! Check out the table below for a quick overview.

| Kit Name | Pros | Cons |

|---|---|---|

| XYZ Kit | Strong gears, durable | Complex installation |

| ABC Kit | Easy to use | Missing some parts |

In the world of lathe repair, you can never have too many options (or pizza toppings). Happy repairing!

Preventive Measures to Extend Lathe Lifespan

Tips for maintaining gears and other parts of a metal lathe. Recommended routine checks and services for optimal performance.Keeping your metal lathe in top shape is key to its long life. Regular care helps prevent big repairs later. Here are some easy tips to keep in mind:

- Check gears and oil them monthly.

- Inspect belts for wear every few weeks.

- Clean dust and chips daily to avoid clogging.

- Test electrical connections every six months.

A regular check-up schedule keeps your machine running smoothly. This simple routine helps you catch problems before they start!

What routine checks should I do on my lathe?

You should check gears, belts, and electrical connections regularly. Monthly maintenance is great for keeping everything running well.

Conclusion

In conclusion, a lathe repair kit is essential for fixing your metal lathe gear. It helps keep your machinery running smoothly. Learning to use the kit can save you time and money. You can improve your skills by practicing repairs. For more tips and guides, check out reliable resources or forums. Happy machining!FAQs

What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Gear System?A lathe repair kit for a metal lathe usually includes gears, bearings, and belts. It may also have tools like wrenches and screws. You might find oil and grease in the kit to help the parts move smoothly. Sometimes, there are instructions to help you fix things. With these pieces, you can keep your lathe working well!

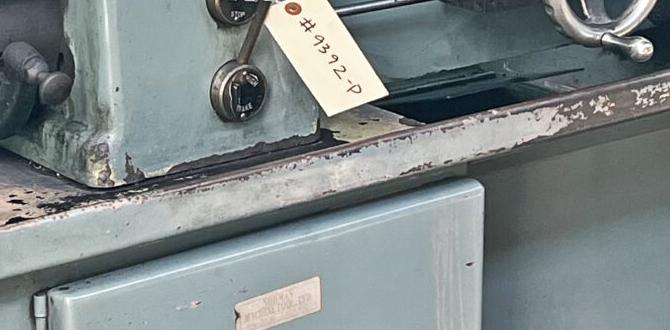

How Do I Determine If My Metal Lathe Gear Needs Repair Or Replacement?To see if your metal lathe gear needs repair or replacement, first look for wear or damage. Check for cracks or breaks in the gear. Listen for strange noises when it runs; this can be a sign of trouble. If it doesn’t turn smoothly or gets stuck, it may need fixing or replacing. Regularly inspect your gear to keep it in good shape.

What Are The Common Signs Of Wear And Tear In Metal Lathe Gears That Might Necessitate A Repair Kit?You can spot wear and tear in metal lathe gears by looking for a few signs. First, listen for strange noises while the lathe runs. If you see rust or damage on the gears, that’s another sign. When the gears fail to fit tightly or feel wobbly, they might need a repair kit. Also, check for any missing teeth on the gears; that means they are worn out.

Can I Use A Universal Lathe Repair Kit For All Types Of Metal Lathes, Or Do I Need A Specific Kit For My Model?You can’t use a universal lathe repair kit for all metal lathes. Each lathe model has different parts and needs. You should find a kit made for your specific lathe. This way, you’ll be sure the kit works properly. Always check your lathe model before buying parts.

What Tools Are Necessary To Properly Install Parts From A Lathe Repair Kit For Metal Lathe Gears?To install parts from a lathe repair kit for metal lathe gears, you need a few tools. First, get a wrench to tighten bolts. You will also need a screwdriver to help fit the parts. Pliers can help hold small pieces tightly. Lastly, a hammer is useful for tapping parts gently into place.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Gear System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for a metal lathe usually includes gears, bearings, and belts. It may also have tools like wrenches and screws. You might find oil and grease in the kit to help the parts move smoothly. Sometimes, there are instructions to help you fix things. With these pieces, you can keep your lathe working well!”}},{“@type”: “Question”,”name”: “How Do I Determine If My Metal Lathe Gear Needs Repair Or Replacement? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To see if your metal lathe gear needs repair or replacement, first look for wear or damage. Check for cracks or breaks in the gear. Listen for strange noises when it runs; this can be a sign of trouble. If it doesn’t turn smoothly or gets stuck, it may need fixing or replacing. Regularly inspect your gear to keep it in good shape.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear And Tear In Metal Lathe Gears That Might Necessitate A Repair Kit? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot wear and tear in metal lathe gears by looking for a few signs. First, listen for strange noises while the lathe runs. If you see rust or damage on the gears, that’s another sign. When the gears fail to fit tightly or feel wobbly, they might need a repair kit. Also, check for any missing teeth on the gears; that means they are worn out.”}},{“@type”: “Question”,”name”: “Can I Use A Universal Lathe Repair Kit For All Types Of Metal Lathes, Or Do I Need A Specific Kit For My Model? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can’t use a universal lathe repair kit for all metal lathes. Each lathe model has different parts and needs. You should find a kit made for your specific lathe. This way, you’ll be sure the kit works properly. Always check your lathe model before buying parts.”}},{“@type”: “Question”,”name”: “What Tools Are Necessary To Properly Install Parts From A Lathe Repair Kit For Metal Lathe Gears? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install parts from a lathe repair kit for metal lathe gears, you need a few tools. First, get a wrench to tighten bolts. You will also need a screwdriver to help fit the parts. Pliers can help hold small pieces tightly. Lastly, a hammer is useful for tapping parts gently into place.”}}]}