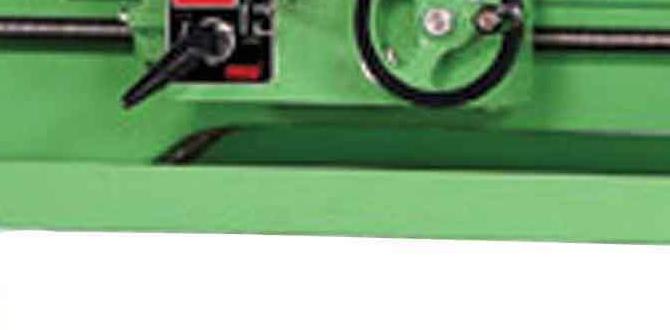

Have you ever wondered how metal lathes work? These machines shape metal into useful parts for many projects. But what happens when they break? That’s where a lathe repair kit comes into play.

Imagine you’re in your workshop, and your trusty lathe suddenly stops working. It can be frustrating! Luckily, a lathe repair kit can help you fix it. With the right tools and instructions, you can get back to your metal lathe operations quickly.

Did you know that even small parts of a lathe can cause big problems? A simple worn-out bearing can make it hard to cut metal accurately. Having a repair kit on hand makes it easier to solve these issues. It’s like having a first aid kit for your machine!

In this article, we’ll explore how to use a lathe repair kit. We’ll also look at essential metal lathe operations every maker should know. Let’s dive into the exciting world of metalworking!

Essential Lathe Repair Kit For Optimal Metal Lathe Operations

Lathe Repair Kit: Metal Lathe Operations

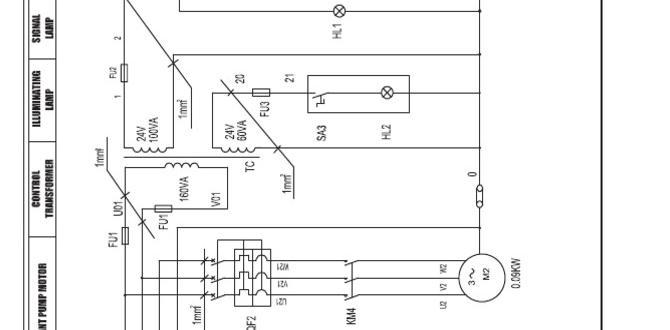

A lathe repair kit is essential for anyone using metal lathe operations. It helps keep your machine in top shape. Regular maintenance ensures precision and extends the lathe’s life. Have you ever faced issues like vibrations or unusual noises? These can signal parts need attention. A good repair kit often includes bearings, belts, and wrenches. Remember, taking care of your lathe leads to better projects and more fun in the workshop! Don’t wait—be proactive in your maintenance!Understanding Metal Lathe Operations

Types of metal lathes and their applications. Basic operations performed on a metal lathe.Metal lathes are like the Swiss Army knives of machines! There are several types, each with its special job. For example, engine lathes are great for general work, while turret lathes can switch tools quickly—like a magician pulling bunnies out of a hat. Basic operations include turning to shape metal, facing to smooth surfaces, and drilling holes that fit perfectly. Just think of it as crafting your favorite pasta, each step is deliciously important!

| Type of Lathe | Application |

|---|---|

| Engine Lathe | General purpose machining |

| Turret Lathe | High-volume production |

| CNC Lathe | Precise and automated tasks |

Importance of Lathe Maintenance

Consequences of neglecting lathe maintenance. Benefits of regular maintenance for longevity and performance.Regular lathe maintenance is crucial for keeping your machine in top shape. Ignoring it can lead to serious problems like breakdowns and costly repairs. A well-maintained lathe operates smoothly, helping you create precise parts. This not only boosts your productivity but also extends the lathe’s life. Here are some benefits:

- Improved Accuracy: Regular checks keep your lathe working perfectly, ensuring tight tolerances.

- Longer Lifespan: Routine maintenance reduces wear and tear.

- Better Safety: A well-maintained machine helps prevent accidents.

- Cost Efficiency: Frequent maintenance saves money over time by avoiding major repairs.

What happens if I ignore lathe maintenance?

Neglecting maintenance can lead to expensive repairs. Your lathe might break down often, costing you time and money. Wear on parts increases, making them less reliable. This can slow your work and affect quality!

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a kit. Comparisons between different manufacturers.Picking a good lathe repair kit is important. You should think about several factors. First, check the quality of parts. Strong materials last longer. Next, compare different brands. Some offer better tools than others. Look for kits that meet your needs. Ask about customer support and warranty. A good warranty can save money later.

- Quality of parts

- Brand reputation

- Warranty terms

- Price and value

What should you consider when selecting a lathe repair kit?

Look for quality parts, check brand reputation, and consider warranty options.These steps can help you find the right kit easily. For example, many users prefer kits known for good support and long-lasting tools.

Step-by-Step Guide to Using a Lathe Repair Kit

Preparing the lathe for repairs. Detailed instructions for specific repairs using the kit.Getting the lathe ready for repairs is like waking up a sleepy giant. First, turn it off and unplug it. Safety comes first. Next, clean the lathe from dust and grime. Grab your lathe repair kit and examine the tools. Each piece has its own special job, just like superheroes!

Now, let’s tackle specific repairs with your kit. If you need to fix the belt, loosen the screws, swap it out, and tighten it back. Follow the instructions closely—they don’t bite! Finally, plug it back in and give it a test spin.

| Step | Action |

|---|---|

| 1 | Turn off and unplug lathe |

| 2 | Clean the lathe |

| 3 | Inspect tools in the kit |

| 4 | Fix the issues carefully |

| 5 | Test the lathe |

Remember, practice makes perfect. Your lathe will feel brand new, and you’ll be its best friend!

Common Issues Addressed by Lathe Repair Kits

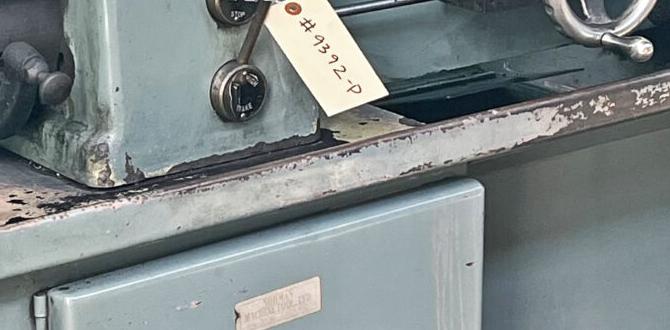

Identifying typical problems faced during metal lathe operations. Solutions provided by lathe repair kits for these issues.Metal lathe operations can sometimes face challenges. Common issues are wear and tear, poor alignment, and noisy parts. These problems can cause mistakes in workpieces. A lathe repair kit can fix these issues easily. Here’s how:

- Wear and Tear: Replacement parts can be included to help restore function.

- Poor Alignment: Adjustment tools can make sure everything is perfectly lined up.

- Noisy Parts: Lubricants are included to quiet down the machine.

Using a lathe repair kit can keep your metal lathe in great shape. It helps prevent bigger issues and improves your work quality!

What are the common problems with metal lathes?

Common problems include misalignment, vibrations, and tool dullness, which can impact performance.

How can a lathe repair kit help?

A lathe repair kit offers tools and parts to fix misalignment, replace dull tools, and minimize vibrations. It helps keep the lathe running smoothly and efficiently.

Safety Precautions When Performing Repairs

Key safety measures to follow during lathe repairs. Importance of personal protective equipment (PPE).Staying safe during lathe repairs is super important. Always wear personal protective equipment (PPE). This includes safety goggles to keep those pesky metal shavings out of your eyes and gloves to protect your hands. Make sure your work area is clean—nobody wants a surprise trip over a stray wrench!

| Safety Gear | Importance |

|---|---|

| Safety Goggles | Protects eyes from shards |

| Gloves | Prevents cuts and scrapes |

| Ear Protection | Prevents hearing damage |

And remember, a clean workstation helps avoid accidents. Let’s keep our fingers and toes where they belong, shall we? Safety first means more time for fun later!

Cost-Effectiveness of Repair Kits vs. Professional Repairs

Analyzing cost benefits of DIY repairs with kits. Situations when professional help is advisable.Using a repair kit can save you cash and time. It’s like turning a broken toy back into a fun one! Some folks can fix things themselves with kits, while others might need a professional. If you are unsure, don’t hesitate to call in the experts. You don’t want your metal lathe to turn into an expensive paperweight!

| Repair Option | Cost | Time | Skill Level |

|---|---|---|---|

| DIY Repair Kit | Low | Short | Beginner |

| Professional Repair | High | Long | Expert |

In general, a DIY kit can save you money, about 50% of the cost of a pro! But remember, if you feel uncertain, it’s best to call for help. Your lathe deserves the best treatment!

Testimonials and Case Studies

Reallife experiences from users of lathe repair kits. Case studies highlighting successful repairs using these kits.Many users have shared their success stories after using lathe repair kits. These kits help fix metal lathe issues quickly and easily. Here are a few highlights:

- Mark’s experience: He repaired his old lathe in less than an hour, saving time and money.

- Lisa’s story: After using the kit, she created perfect parts for her hobby project.

- Bob’s case: He restored his machine to like-new condition, boosting his workshop productivity.

Testimonials show that with the right tools, anyone can tackle lathe problems. Many report better results than they expected!

What are the benefits of using lathe repair kits?

Lathe repair kits offer users easy solutions to fix small and large issues. They make repairs faster and can often improve machine performance.

Conclusion

In summary, a lathe repair kit is essential for maintaining metal lathe operations. It helps fix problems and keeps your lathe running smoothly. We learned that regular checks can prevent major issues. To get the best results, consider investing in a quality repair kit. You can explore more about lathe maintenance and techniques to improve your skills.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits And Metal Lathe Operations:Lathe repair kits help fix metal lathes when they break. A metal lathe is a machine that shapes metal into different parts. You use tools to cut and smooth the metal. Repair kits have pieces like belts, gears, and tools to help you. Each part in the kit makes the lathe work better again!

Sure! Just ask your question, and I will be happy to help you with a short answer.

What Components Are Typically Included In A Lathe Repair Kit For Metal Lathes?A lathe repair kit for metal lathes usually includes some important parts. You might find tools like wrenches and screwdrivers. There are also spare belts and gears to replace worn-out ones. Sometimes, the kit has special lubricants to keep the lathe running smoothly. These items help fix the lathe and keep it in good working order.

How Can I Identify The Specific Parts That Need Repair Or Replacement On My Metal Lathe?To find parts that need repair on your metal lathe, start by looking for damage. Check the motor for strange noises or vibrations. Look at the tools and belts; they shouldn’t be worn out. You can also check for rust on the parts. If something looks broken or not working right, it might need repair or replacement.

What Maintenance Practices Should Be Followed To Prolong The Lifespan Of A Metal Lathe?To take good care of a metal lathe, you should clean it often. Wipe off dust and metal shavings after each use. Lubricate the moving parts with oil to keep them running smoothly. Check for any loose or damaged pieces regularly. By doing these simple things, you can help your lathe last longer!

Are There Specific Tools Recommended For Performing Repairs On Metal Lathes Using A Repair Kit?Yes, there are specific tools you should use for repairing metal lathes. You will need wrenches, screwdrivers, and pliers. A set of replacement parts from the repair kit is also important. Always use safety glasses to protect your eyes while you work. Lastly, a cleaning cloth helps keep everything neat and tidy.

How Can I Troubleshoot Common Issues With Metal Lathe Operations Before Resorting To Using A Repair Kit?To fix problems with your metal lathe, start by checking the power supply. Make sure the machine is plugged in and turned on. Next, look at the tools you’re using. Are they sharp and clean? Lastly, check if all the parts are tight and in place. If everything looks okay but it still doesn’t work, it might be time for a repair kit.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits And Metal Lathe Operations:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe repair kits help fix metal lathes when they break. A metal lathe is a machine that shapes metal into different parts. You use tools to cut and smooth the metal. Repair kits have pieces like belts, gears, and tools to help you. Each part in the kit makes the lathe work better again!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I will be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Components Are Typically Included In A Lathe Repair Kit For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for metal lathes usually includes some important parts. You might find tools like wrenches and screwdrivers. There are also spare belts and gears to replace worn-out ones. Sometimes, the kit has special lubricants to keep the lathe running smoothly. These items help fix the lathe and keep it in good working order.”}},{“@type”: “Question”,”name”: “How Can I Identify The Specific Parts That Need Repair Or Replacement On My Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find parts that need repair on your metal lathe, start by looking for damage. Check the motor for strange noises or vibrations. Look at the tools and belts; they shouldn’t be worn out. You can also check for rust on the parts. If something looks broken or not working right, it might need repair or replacement.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Prolong The Lifespan Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take good care of a metal lathe, you should clean it often. Wipe off dust and metal shavings after each use. Lubricate the moving parts with oil to keep them running smoothly. Check for any loose or damaged pieces regularly. By doing these simple things, you can help your lathe last longer!”}},{“@type”: “Question”,”name”: “Are There Specific Tools Recommended For Performing Repairs On Metal Lathes Using A Repair Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are specific tools you should use for repairing metal lathes. You will need wrenches, screwdrivers, and pliers. A set of replacement parts from the repair kit is also important. Always use safety glasses to protect your eyes while you work. Lastly, a cleaning cloth helps keep everything neat and tidy.”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Common Issues With Metal Lathe Operations Before Resorting To Using A Repair Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with your metal lathe, start by checking the power supply. Make sure the machine is plugged in and turned on. Next, look at the tools you’re using. Are they sharp and clean? Lastly, check if all the parts are tight and in place. If everything looks okay but it still doesn’t work, it might be time for a repair kit.”}}]}