Have you ever used a metal lathe? If so, you know how important precision is. When it comes to lathe repair, one of the most critical parts is the tailstock. A misaligned tailstock can ruin your work. But how do you fix it? That’s where a lathe repair kit comes into play.

Imagine trying to create a perfect cylinder but finding it wobbly. Frustrating, right? Many hobbyists face this problem. They don’t realize that a simple adjustment could save their project. Tailstock alignment is vital for smooth, accurate cuts.

Did you know that even small misalignments could lead to big mistakes? With the right tools and knowledge, you can align your tailstock quickly. In this article, we will explore how to use a lathe repair kit to achieve that perfect alignment.

Get ready to dive into the world of lathe repair. Whether you’re a beginner or a seasoned pro, you’ll find helpful tips to improve your skills and take your projects to the next level!

Lathe Repair Kit: Metal Lathe Tailstock Alignment Guide In The World Of Metalworking, Precision Is Paramount, And Having A Well-Aligned Tailstock On Your Lathe Is Essential For Achieving Accurate Results. If Your Lathe Is Experiencing Issues With Tailstock Alignment, A Lathe Repair Kit Can Be Your Best Friend. This Article Will Delve Into What A Lathe Repair Kit Entails, Why Tailstock Alignment Is Crucial, And How You Can Effectively Utilize This Kit For Optimal Results. Understanding Tailstock Alignment The Tailstock Of A Metal Lathe Is Responsible For Holding Tools And Workpieces Securely. An Improper Alignment Can Lead To Various Issues, Including Tapering Of The Workpiece, Uneven Tool Wear, And Overall Reduced Accuracy In Your Machining Projects. Tailstock Alignment Ensures That The Cutting Tools Are Aligned With The Workpiece, Which Is Vital For Smooth Operation And Achieving Desired Dimensions. Components Of A Lathe Repair Kit A Typical Lathe Repair Kit Enhances Your Ability To Maintain Your Lathe And Ensure Proper Tailstock Alignment. It Usually Includes: 1. **Adjustment Tools**: Tools Like Wrenches And Screwdrivers Are Essential For Making Precise Adjustments To The Tailstock. 2. **Alignment Bars**: These Can Be Used To Check The Alignment And Make Necessary Corrections. 3. **Leveling Devices**: To Ensure That Your Lathe Is Set Up Perfectly Horizontal, Which Is Vital For Accurate Tailstock Alignment. 4. **Instruction Manual**: Detailed Guides That Provide Step-By-Step Instructions On How To Carry Out Repairs And Adjustments. Steps For Tailstock Alignment 1. **Set Up The Lathe**: Ensure The Lathe Is Level And Stable Before Beginning Any Alignment Work. 2. **Check Existing Alignment**: Use An Alignment Bar Or Dial Indicator To Investigate Any Discrepancies In The Tailstock’S Current Position. 3. **Adjust The Tailstock**: Making Small Adjustments, Use Your Tools From The Lathe Repair Kit To Realign The Tailstock Based On The Results From Your Alignment Checks. 4. **Test And Refine**: After Making Adjustments, Run A Test Cut To Assess Accuracy. Fine-Tune The Alignment As Needed. Conclusion Using A Lathe Repair Kit For Metal Lathe Tailstock Alignment Can Significantly Improve The Precision And Efficiency Of Your Machining Projects. With Proper Tools And Knowledge, You Can Maintain Your Equipment Effectively, Ensuring Long-Lasting Performance And High-Quality Outputs. Don’T Overlook The Importance Of Tailstock Alignment; It’S A Small Step That Can Make A Big Difference In Your Lathe Operations.

Lathe Repair Kit: Metal Lathe Tailstock Alignment

A well-aligned tailstock is essential for accuracy in metalworking. With a lathe repair kit, you can fix misalignment easily. This prevents wasted materials and ensures smooth operations. Did you know that even minor misalignments can cause significant errors in your projects? By learning to use a repair kit, you can save money and enhance your skills. Proper tailstock alignment helps achieve fine details in your work, making every project a joy to complete.Understanding Metal Lathes

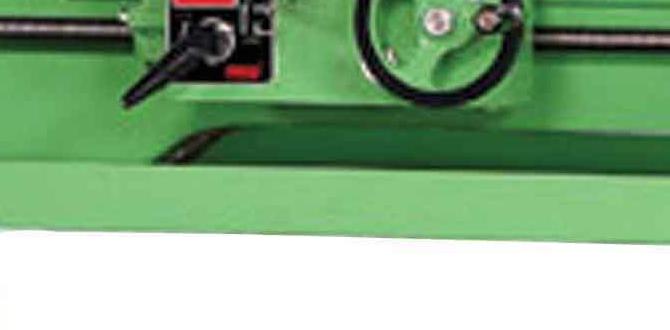

Definition and purpose of metal lathes. Key components of a metal lathe.Metal lathes are machines that shape metal into different parts. They spin metal pieces while cutting tools shape them. This helps create everything from bike parts to engine components. Understanding lathes helps you know how to fix them correctly. A metal lathe has several key parts:

- Headstock: Holds the motor and spinning part.

- Tailstock: Supports the other end of the metal piece.

- Beds: The base where everything sits.

- Carriage: Moves the cutting tool.

Each part plays an important role in the lathe’s function. Proper alignment of these parts, especially the tailstock, is crucial for precise work.

What is a metal lathe used for?

A metal lathe is used for shaping metal into precise pieces, which are important in many engineering and manufacturing tasks.The Importance of Tailstock Alignment

Role of the tailstock in precision machining. Common issues caused by misalignment.The tailstock plays a key role in precision machining. It holds the workpiece steady during cutting. If not aligned properly, problems can arise. Common issues include poor cuts and uneven surfaces. This can lead to wasted materials and extra repairs. Proper alignment saves time and effort.

Why is tailstock alignment important?

Tailstock alignment ensures accuracy in machining. Without it, you risk problems like vibration and wear on tools.Effects of misalignment:

- Poor cut quality

- Increased tool wear

- Time wasted on fixing mistakes

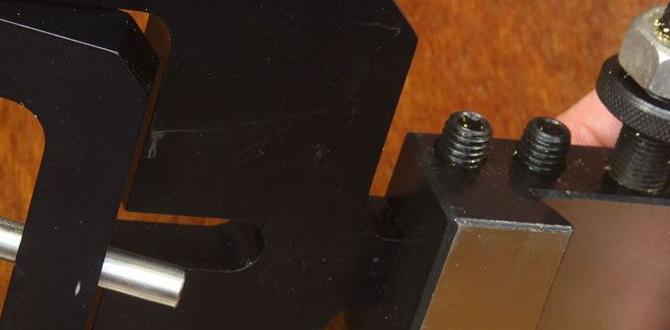

Components of a Lathe Repair Kit

Tools and parts included in a typical repair kit. Specialized items for tailstock alignment.A lathe repair kit is like a first-aid kit for your metal lathe, and it includes some essential tools. You’ll find items such as wrenches, screwdrivers, and a few cool gadgets to fix those pesky problems. For those wanting their tailstock aligned perfectly, specialized tools are included, such as alignment pins and dial indicators. These simple tools can save the day, or at least your workpiece! Our trusty toolkit:

| Components | Description |

|---|---|

| Wrenches | For tightening and loosening bolts. |

| Screwdrivers | To fix those little screws that like to hide! |

| Alignment Pins | Helps get that tailstock just right. |

| Dial Indicators | Measures alignment with precise accuracy. |

With this kit, your lathe will run smoother than a puppy on roller skates. Remember, a well-maintained lathe means happier projects!

Steps for Tailstock Alignment Using a Repair Kit

Initial assessment of tailstock position. Adjusting the tailstock for optimal alignment.First, check the tailstock’s position. It should sit straight on the bed of your lathe. If it looks like it’s standing on one leg after a long day, it needs help! Use a wrench to loosen the securing bolts. Carefully adjust it until it’s level. Then, snug the bolts back up. Make sure you don’t over-tighten—they’re not the Hulk! This simple adjustment can make a huge difference in your work.

| Step | Description |

|---|---|

| 1 | Check the tailstock position |

| 2 | Loosen the bolts |

| 3 | Adjust for alignment |

| 4 | Tighten bolts securely |

Common Issues and Solutions for Tailstock Misalignment

Identifying signs of misalignment. Troubleshooting tips and techniques.Misalignment of your lathe’s tailstock can cause problems when working on projects. You can spot these issues in a few ways. Look for uneven cuts or difficulty in sliding the tailstock. Here are some troubleshooting tips:

- Check for loose screws.

- Inspect the tailstock for dirt or damage.

- Use a dial indicator to measure alignment.

- Make adjustments slowly and carefully.

By following these steps, you can help restore precision to your lathe.

What are the signs of tailstock misalignment?

Some signs include uneven cuts, difficulty in moving the tailstock, and unusual noises during operation.

How can I troubleshoot tailstock misalignment?

- Examine all parts for wear.

- Clean the tailstock and ways.

- Use alignment tools properly.

Maintenance Tips for Metal Lathes

Regular checkups and adjustments. Best practices for prolonging lathe lifespan.Taking care of your metal lathe is like giving your best friend a good haircut—it keeps them looking sharp! Regular checkups and adjustments are key to keeping your machine in top shape. Check for wear and tear and adjust parts when needed. This simple routine can extend your lathe’s lifespan dramatically. Trust me; a happy lathe makes for smooth projects!

| Maintenance Task | Frequency |

|---|---|

| Lubricate moving parts | Every month |

| Check tailstock alignment | Every few weeks |

| Clean the machine | Weekly |

So, keep your lathe happy, and it’ll turn out beautiful projects for you. Remember, an aligned tailstock is like a straightened bowtie—mandatory for smooth operations!

When to Seek Professional Help

Signs that indicate the need for expert assistance. Benefits of professional lathe services.Noticing strange sounds or wobbly movements from your lathe? Don’t ignore them! Signs like these mean it’s time to call for backup. Professional help can make your lathe run smoothly again. They know the tricks to fix issues quickly. You’ll save time, and let’s be honest, avoiding a mishap with sharp tools is always smart!

| Signs You Need Help | Benefits of Professional Services |

|---|---|

| Unusual noises | Your lathe gets expert care |

| Wobbling parts | Less chance of errors |

| Poor alignment | Faster repairs |

So, don’t hesitate! Calling a pro means you’ll get your lathe back in shape fast. Plus, they often have all the right tools, unlike your toolbox full of questionable gadgets. That’s a relief!

Frequently Asked Questions about Lathe Repair Kits

Common inquiries regarding repair kit contents and usage. Clarifications on tailstock alignment techniques.Many people wonder what a lathe repair kit includes. Most kits contain essential items like wrenches, alignment tools, and oils. These make repairs easier than finding a needle in a haystack! Another common question is about tailstock alignment. Proper alignment is crucial for smooth operation. If it’s off, your pieces might look wonky, like a toddler’s drawing. Remember, a well-aligned tailstock ensures accuracy and reduces wear! Below is a quick table of common questions:

| Question | Answer |

|---|---|

| What’s in a repair kit? | Wrenches, alignment tools, oils, and instructions! |

| How do I align the tailstock? | Use gauges and adjust until it’s straight. |

Conclusion

In conclusion, a lathe repair kit helps you align the tailstock for better performance. Proper alignment improves your projects’ accuracy and quality. You can easily follow guides to learn how to adjust it. We encourage you to explore more about lathe maintenance and discover how simple fixes can make a big difference in your work. Happy repairing!FAQs

What Are The Common Signs That Indicate A Misalignment In The Tailstock Of A Metal Lathe?If the tailstock of your metal lathe is misaligned, you might see some problems. First, your workpiece could be turning unevenly or wobbling. Second, you might notice bad cutting marks on your material. Third, drills may not make straight holes. Finally, your pieces might not fit together as they should. These signs mean it’s time to check the tailstock!

How Can I Effectively Use A Lathe Repair Kit To Realign The Tailstock On My Metal Lathe?To realign the tailstock on your metal lathe, first, gather your lathe repair kit. Look for the tools that fit your tailstock. Loosen the screws on the tailstock slightly. Then, use your kit to make small adjustments until it lines up correctly. Finally, tighten the screws again to keep it in place.

What Tools And Components Are Typically Included In A Lathe Repair Kit For Tailstock Alignment?A lathe repair kit for tailstock alignment usually includes a few important tools. You’ll find a tailstock alignment bar to check if everything is straight. There are wrenches to tighten loose parts. A set of screws and nuts helps fix any loose pieces. Lastly, a dial indicator measures tiny changes to keep everything precise.

What Are The Systematic Steps To Check And Adjust Tailstock Alignment On A Metal Lathe?To check and adjust the tailstock on a metal lathe, we can follow these steps. First, place a long, straight rod called a dowel through the spindle and tailstock. Next, look at how straight the dowel is. If it’s not straight, adjust the tailstock by loosening its screws and moving it until it lines up. Finally, tighten the screws back when it looks good. This helps the lathe make accurate cuts!

How Frequently Should I Check And Maintain Tailstock Alignment To Ensure Optimal Performance In My Metal Lathe?You should check the tailstock alignment every time you use your metal lathe. It’s also good to check it after moving the machine or changing tools. This way, you can make sure everything is straight and works well. If you notice any trouble when cutting, check the alignment again. Keeping it aligned helps your work be cleaner and easier.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Misalignment In The Tailstock Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock of your metal lathe is misaligned, you might see some problems. First, your workpiece could be turning unevenly or wobbling. Second, you might notice bad cutting marks on your material. Third, drills may not make straight holes. Finally, your pieces might not fit together as they should. These signs mean it’s time to check the tailstock!”}},{“@type”: “Question”,”name”: “How Can I Effectively Use A Lathe Repair Kit To Realign The Tailstock On My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To realign the tailstock on your metal lathe, first, gather your lathe repair kit. Look for the tools that fit your tailstock. Loosen the screws on the tailstock slightly. Then, use your kit to make small adjustments until it lines up correctly. Finally, tighten the screws again to keep it in place.”}},{“@type”: “Question”,”name”: “What Tools And Components Are Typically Included In A Lathe Repair Kit For Tailstock Alignment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for tailstock alignment usually includes a few important tools. You’ll find a tailstock alignment bar to check if everything is straight. There are wrenches to tighten loose parts. A set of screws and nuts helps fix any loose pieces. Lastly, a dial indicator measures tiny changes to keep everything precise.”}},{“@type”: “Question”,”name”: “What Are The Systematic Steps To Check And Adjust Tailstock Alignment On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the tailstock on a metal lathe, we can follow these steps. First, place a long, straight rod called a dowel through the spindle and tailstock. Next, look at how straight the dowel is. If it’s not straight, adjust the tailstock by loosening its screws and moving it until it lines up. Finally, tighten the screws back when it looks good. This helps the lathe make accurate cuts!”}},{“@type”: “Question”,”name”: “How Frequently Should I Check And Maintain Tailstock Alignment To Ensure Optimal Performance In My Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the tailstock alignment every time you use your metal lathe. It’s also good to check it after moving the machine or changing tools. This way, you can make sure everything is straight and works well. If you notice any trouble when cutting, check the alignment again. Keeping it aligned helps your work be cleaner and easier.”}}]}