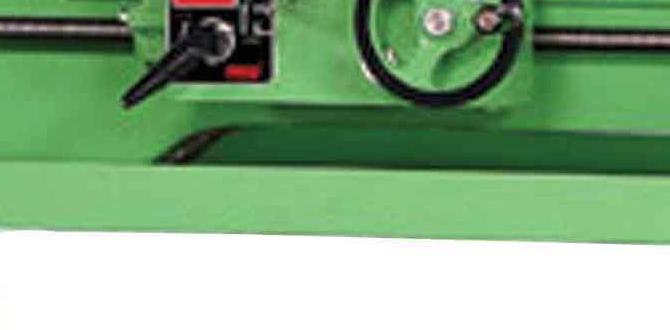

Have you ever wondered how a small machine can create such precise shapes? A metal lathe is a fantastic tool for this. But like any machine, it needs care and repairs. That’s where a lathe repair kit comes in handy. It can help fix common problems and keep your lathe running smoothly.

Imagine wanting to turn a piece of metal into a beautiful vase. You begin the process, but your tool isn’t sharp enough. This is where understanding taper turning becomes vital. It allows you to create that perfect shape with ease. Knowing how to maintain your lathe can make this task so much simpler.

In this article, we will explore lathe repair kits and dive into taper turning. We’ll share tips to ensure your metal lathe works like new. Get ready to discover how easy it is to fix problems and enjoy the craft of metalworking!

Essential Lathe Repair Kit For Metal Lathe Taper Turning

Lathe Repair Kit for Metal Lathe Taper Turning

A lathe repair kit is essential for anyone using a metal lathe for taper turning. It includes various tools and parts that help fix common issues. Have you ever struggled with uneven cuts? This kit can help ensure precision in your projects. You’ll learn how to maintain your lathe and extend its lifespan. Imagine creating perfect tapers every time! With a little knowledge and the right tools, your turning skills can shine.Components of a Lathe Repair Kit

Breakdown of essential tools and parts included in a lathe repair kit.. Importance of each component in maintaining a metal lathe..A lathe repair kit is like a superhero’s toolbox, packed with all the right gadgets! You’ll find essential tools like wrenches, bearings, and tool post screws. Each piece plays a starring role. For example, wrenches help tighten loose parts, while bearings ensure smooth spindle movement. Without them, your metal lathe might feel like a bicycle with square wheels! A well-equipped kit makes maintenance easy and keeps your lathe turning like a pro.

| Component | Importance |

|---|---|

| Wrenches | Tighten loose parts |

| Bearings | Ensure smooth movement |

| Tool Post Screws | Secure cutting tools |

Signs Your Metal Lathe Needs Repairs

Common indicators that suggest a lathe is not functioning optimally.. How to assess the performance of your lathe for signs of wear..Feeling like your metal lathe is having a mid-life crisis? Look for some telltale signs! If you’re hearing strange noises or noticing uneven cuts, it’s time to pay attention. A lathe may also struggle with speed or get stuck, resembling a grumpy turtle. Let’s check some common indicators:

| Indicator | What It Means |

|---|---|

| Unusual Sounds | Time to check the bearings! |

| Uneven Surfaces | Tools may need sharpening or replacing. |

| Stalling | Your lathe needs a little TLC. |

Regular checks can help. Look for wear and tear, and keep an eye on your lathe’s performance. Remember, a happy lathe makes happy projects!

Step-by-Step Guide to Using a Lathe Repair Kit

Detailed instructions for utilizing each component in the kit effectively.. Tips for troubleshooting common problems during the repair process..Using a lathe repair kit can be easier than pie (and a lot less messy!). Each tool in the kit has its own job. Start with the wrenches for loosening parts. Next, use files to smooth out rough edges. If you run into issues, check the belt tension; it shouldn’t feel like a tightrope! Remember, patience is key. If something seems off, take a break—repairing isn’t a race!

| Component | Use |

|---|---|

| Wrenches | Loosen and tighten parts |

| Files | Smooth out rough edges |

| Grease | Keep moving parts slick |

Always check the manual if you’re stuck. Remember: even the best mechanics get flustered sometimes! Keep your tools organized so you can find them easily. Happy repairing!

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a repair kit for your lathe.. Recommended brands and kits that are best suited for taper turning..Selecting the right kit for lathe repair is vital for smooth operation and taper turning. Here are key factors to keep in mind:

- Know your lathe model

- Check the parts included in the kit

- Consider the quality of materials

- Look for user reviews and ratings

Some trusted brands for repair kits include:

– Grizzly

– Jet

– PM (Precision Matthews)

Choose high-quality options designed specifically for taper turning.

What should I consider when buying a lathe repair kit?

Look for compatibility, quality, and reviews to make the best choice.

Maintenance Tips for Longevity of Your Metal Lathe

Routine maintenance practices to prevent the need for repairs.. Importance of regular inspections and cleaning procedures..Taking good care of your metal lathe gives it a longer life. Routine maintenance keeps it running well and avoids repairs. Here are some easy tips:

- Check all parts regularly for wear.

- Clean the lathe to avoid dust build-up.

- Oil moving parts to keep them smooth.

- Tighten loose screws to prevent accidents.

Regular checks help you catch problems early. Clean machines work better. Remember, a little maintenance each month can save you big repair costs in the future!

Why are regular inspections important?

Regular inspections catch problems early, saving time and money. They help keep your machine safe and efficient. A well-maintained lathe can last many years longer.

Comparison of DIY Repairs vs. Professional Repair Services

Pros and cons of repairing your lathe yourself versus hiring professionals.. Cost analysis and time considerations for both options..Deciding between DIY repairs or hiring a pro can be hard. Each choice has its ups and downs. DIY repairs can save money, but they need time and skill. On the other hand, pros can finish the job quickly, but it costs more. Here’s a quick look:

- DIY Pros: Low cost, rewarding experience.

- DIY Cons: Time-consuming, requires tools and skills.

- Pro Service Pros: Fast and reliable work.

- Pro Service Cons: Higher costs.

Think about how much time and money you can spend. If you need to fix it fast, calling a pro may be best. But if you have time and want to learn, try fixing it yourself!

Should I fix my lathe or hire a pro?

Consider your skills and time. If you’re handy and enjoy learning, DIY is great. If not, hire someone!

FAQs on Lathe Repair Kits for Taper Turning

Commonly asked questions regarding the use and selection of lathe repair kits.. Expert answers to clarify misconceptions in taper turning and lathe maintenance..Curious about lathe repair kits for taper turning? You’re not alone! Many folks wonder about the best ways to choose these kits. First, look for kits with all the needed parts. Some ask if it’s okay to mix brands. Here’s a tip: Stick to one brand for a smoother operation. And when should you replace parts? If they look like they went through a monster truck rally, it’s time! Understanding these basics will make taper turning a breeze.

| Question | Answer |

|---|---|

| How do I choose a lathe repair kit? | Check for complete parts and user ratings! |

| Can I mix different brands? | Better to stick with one brand! |

| When should I replace my lathe parts? | Replace if they’re damaged or worn out! |

Conclusion

In conclusion, a lathe repair kit is essential for keeping your metal lathe in great shape. Taper turning helps create precise shapes in your projects. With the right tools and knowledge, you can easily make repairs. We encourage you to explore more about lathe maintenance and practice taper turning. This will boost your skills and confidence in metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits, Metal Lathes, And Taper Turning:Sure! A lathe is a machine that shapes metal or wood by spinning it. If it breaks, a lathe repair kit helps fix it. You can also use a metal lathe to make parts for machines. Taper turning means making one end of a piece smaller, like a pencil. These tools help you create cool things!

Got it! Please provide the question you’d like me to answer.

What Are The Essential Components Included In A Lathe Repair Kit For Metal Lathes Used For Taper Turning?A lathe repair kit for metal lathes has some important tools. You will find wrenches to tighten parts. There are also screwdrivers for fixing issues. A measuring tool helps check if everything is straight. Lastly, you might see some extra parts like belts or bearings. These make the lathe work smoothly.

How Do You Determine The Correct Taper Angle When Setting Up A Metal Lathe For Taper Turning?To find the right taper angle, you first need to know how much bigger one end of your metal piece will be than the other. Then, you can use a special tool called a protractor. This tool helps you measure angles. You can also use some math to find the angle using the size difference and the length of the piece. Make sure you set the lathe to this angle before you start turning!

What Common Issues Can Arise During Taper Turning On A Metal Lathe, And How Can A Repair Kit Help Resolve Them?When taper turning on a metal lathe, you might face problems like uneven cuts or tool slipping. These issues can make your piece look bad and not fit right. A repair kit can help by giving you extra tools and parts to fix your lathe. With the kit, you can adjust and tighten the tools, making sure everything works well again. This helps you finish your project correctly and easily.

What Maintenance Tips Can Improve The Longevity And Performance Of A Metal Lathe During Taper Turning Operations?To keep your metal lathe working well during taper turning, make sure to clean it after every use. You should also check all the parts for wear and tear. Lubricate moving parts with oil to help them move smoothly. Tighten any loose screws or bolts to keep everything secure. Finally, always follow the manufacturer’s instructions for care and maintenance.

How Do You Properly Align And Adjust The Tailstock On A Metal Lathe For Accurate Taper Turning?To align and adjust the tailstock on a metal lathe, start by loosening the tailstock screws. Next, slide the tailstock until it lines up with the lathe’s center. You can check this by using a piece of scrap metal or a center drill. Once it’s lined up, tighten the screws back. Finally, make sure everything is secure before you start turning.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits, Metal Lathes, And Taper Turning:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal or wood by spinning it. If it breaks, a lathe repair kit helps fix it. You can also use a metal lathe to make parts for machines. Taper turning means making one end of a piece smaller, like a pencil. These tools help you create cool things!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Got it! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Included In A Lathe Repair Kit For Metal Lathes Used For Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for metal lathes has some important tools. You will find wrenches to tighten parts. There are also screwdrivers for fixing issues. A measuring tool helps check if everything is straight. Lastly, you might see some extra parts like belts or bearings. These make the lathe work smoothly.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Taper Angle When Setting Up A Metal Lathe For Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right taper angle, you first need to know how much bigger one end of your metal piece will be than the other. Then, you can use a special tool called a protractor. This tool helps you measure angles. You can also use some math to find the angle using the size difference and the length of the piece. Make sure you set the lathe to this angle before you start turning!”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise During Taper Turning On A Metal Lathe, And How Can A Repair Kit Help Resolve Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When taper turning on a metal lathe, you might face problems like uneven cuts or tool slipping. These issues can make your piece look bad and not fit right. A repair kit can help by giving you extra tools and parts to fix your lathe. With the kit, you can adjust and tighten the tools, making sure everything works well again. This helps you finish your project correctly and easily.”}},{“@type”: “Question”,”name”: “What Maintenance Tips Can Improve The Longevity And Performance Of A Metal Lathe During Taper Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe working well during taper turning, make sure to clean it after every use. You should also check all the parts for wear and tear. Lubricate moving parts with oil to help them move smoothly. Tighten any loose screws or bolts to keep everything secure. Finally, always follow the manufacturer’s instructions for care and maintenance.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Adjust The Tailstock On A Metal Lathe For Accurate Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and adjust the tailstock on a metal lathe, start by loosening the tailstock screws. Next, slide the tailstock until it lines up with the lathe’s center. You can check this by using a piece of scrap metal or a center drill. Once it’s lined up, tighten the screws back. Finally, make sure everything is secure before you start turning.”}}]}